7/8 connectors play a vital role in ensuring reliable power supply in industrial settings. Their design allows these connectors to withstand harsh environments and maintain optimal electrical performance. Many engineers select 7/8 connectors over an M8 connector or Type B connector for high current and voltage applications. Connector factory processes guarantee strict adherence to safety and compatibility standards. Reliable power delivery in demanding environments depends on robust connector solutions.

Key Applications of 7/8 Connectors

Industrial Automation Applications

Factory Equipment

Manufacturers rely on 7/8 connectors to power and control factory equipment. These connectors offer robust construction, making them suitable for harsh industrial environments. Their high current capacity supports motors, lighting, and sensor-actuator boxes. Many factories choose these connectors for their environmental protection features, such as IP67 and IP68 ratings. These ratings ensure resistance to dust, moisture, chemicals, and vibration. The standardized mating interface allows compatibility across different manufacturers, simplifying integration into existing systems. Panel-mount flange connectors provide easy installation in equipment housings. The flexibility in pin counts and termination options supports a wide range of automation needs.

Robotics and Motion Control

Robotics and motion control systems demand reliable power and signal transmission. 7/8 connectors deliver consistent performance in these automation applications. Their rugged design withstands constant movement and vibration. Many robotics systems use these connectors to connect servo motors, sensors, and controllers. The availability of straight, angled, and stainless steel variants ensures compatibility with diverse robotic architectures. Gold-plated contacts enhance conductivity and reduce maintenance needs. DeviceNet support enables efficient wiring and device powering, which is essential for modern automation networks.

Transportation Systems Applications

Rail and Mass Transit

Rail and mass transit systems require durable connectors for power and communication. 7/8 connectors provide reliable connections in environments exposed to vibration, temperature changes, and contaminants. These connectors support signaling, lighting, and control systems on trains and in stations. Their corrosion-resistant materials extend service life, reducing downtime for maintenance. The standardized interface ensures interchangeability across brands, which simplifies procurement and replacement.

Electric Vehicles and Charging Infrastructure

Electric vehicles and charging stations benefit from the high current handling of 7/8 connectors. These connectors enable safe and efficient power delivery between charging units and vehicles. Their environmental sealing protects against dust and water ingress, which is critical for outdoor installations. The flexibility in design allows integration into both vehicle and infrastructure components. Many charging networks select these connectors for their proven reliability in demanding transportation applications.

Renewable Energy Applications

Solar Power Systems

Solar power systems depend on reliable connectors to transfer energy from panels to inverters and storage units. 7/8 connectors offer low contact resistance and high voltage tolerance, ensuring minimal energy loss. Their weatherproof construction withstands exposure to sunlight, rain, and temperature extremes. Installers appreciate the ease of assembly and secure locking mechanisms, which help maintain system uptime.

Wind Turbines

Wind turbines operate in remote and challenging environments. 7/8 connectors provide the durability needed for these applications. Their corrosion-resistant materials and vibration resistance ensure long-term performance. Technicians use these connectors to link sensors, control units, and power distribution systems within the turbine. The modular design supports quick replacement and maintenance, reducing downtime and improving energy output.

Note: 7/8 connectors also play a significant role in telecommunications, broadcast, and maritime communications, supporting high-speed data and signal integrity in critical infrastructure.

Outdoor and Harsh Environment Applications

Agricultural Machinery

Agricultural machinery operates in fields where dust, mud, and moisture are common. Equipment such as tractors, harvesters, and irrigation systems require reliable electrical connections to function efficiently. 7/8 connectors provide robust sealing against water and dirt. Their rugged housings resist impacts from stones and debris. Farmers and technicians benefit from quick-connect features, which reduce downtime during maintenance. These connectors also support high current loads, making them suitable for powering motors and control units in large machines.

Tip: Regular inspection of connectors in agricultural machinery helps prevent unexpected failures during peak seasons.

Construction Equipment

Construction sites present harsh conditions, including vibration, temperature swings, and exposure to chemicals. Heavy equipment like excavators, cranes, and concrete mixers rely on durable connectors for power and control signals. 7/8 connectors withstand constant movement and mechanical stress. Their corrosion-resistant materials extend service life, even when exposed to rain or dust. Quick-locking mechanisms allow for fast installation and replacement, which keeps projects on schedule. The standardized design ensures compatibility with a wide range of construction equipment.

Specialized Applications of 7/8 Connectors

Food and Beverage Processing Equipment

Food and beverage processing environments demand strict hygiene and reliable operation. Equipment in these facilities often undergoes frequent washdowns with high-pressure water and cleaning agents. 7/8 connectors feature smooth surfaces and sealing gaskets that prevent liquid ingress. Stainless steel variants resist corrosion and support sanitary requirements. These connectors maintain electrical integrity, even after repeated cleaning cycles. Their secure locking systems help prevent accidental disconnections during production.

Marine and Offshore Platforms

Marine and offshore platforms face saltwater, humidity, and extreme weather. Electrical systems on ships, oil rigs, and wind farms require connectors that can endure these challenges. 7/8 connectors use materials that resist salt corrosion and UV exposure. Their watertight seals protect internal contacts from moisture. Technicians can install these connectors quickly, even in confined spaces. The reliability of these connectors supports safety and continuous operation in critical marine applications.

CNC Machines and Metal Cutting Industries

CNC machines and metal cutting tools operate in environments with metal shavings, lubricants, and vibration. These machines need connectors that deliver stable power and signal transmission. 7/8 connectors offer low contact resistance and strong mechanical retention. Their compact size fits into tight control panels. Operators can replace or service connectors without special tools, reducing machine downtime. The robust design ensures consistent performance, even in demanding industrial settings.

Features of 7/8 Connectors Ensuring Reliable Power Delivery

Environmental Protection Features

IP Ratings and Water Resistance

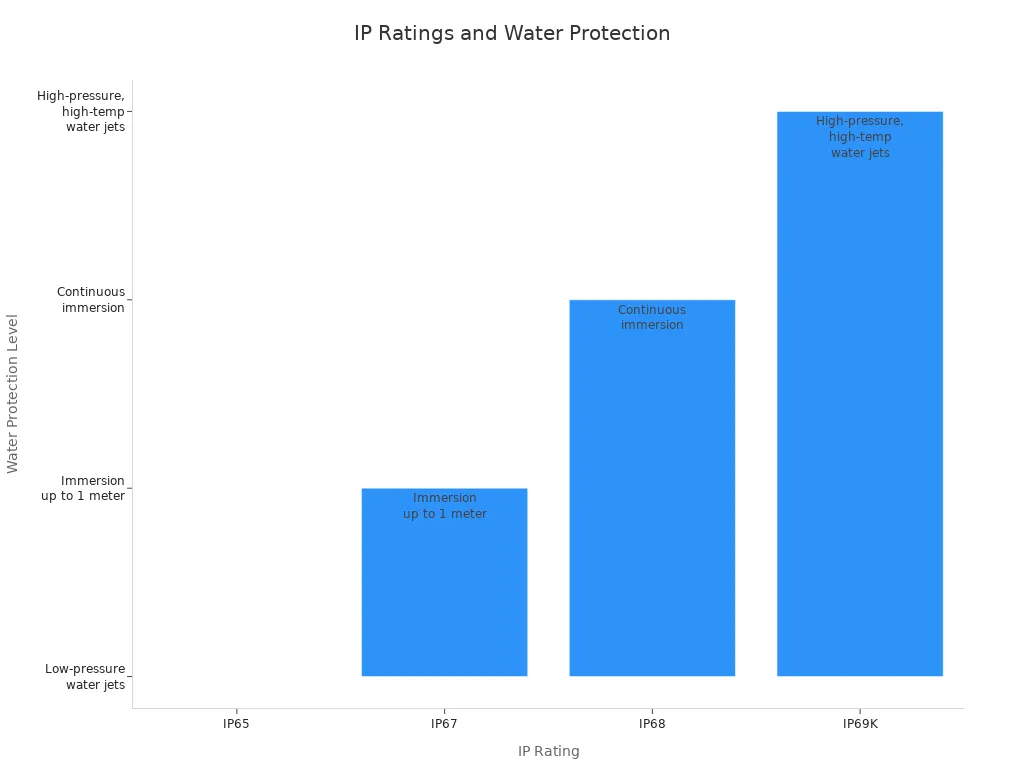

Manufacturers design 7/8 connectors to operate in environments where exposure to dust and water is common. The Ingress Protection (IP) rating system provides a clear standard for evaluating how well these connectors resist environmental hazards. The most common IP ratings for these connectors include IP65, IP67, IP68, and IP69K. Each rating offers a different level of protection, making it easier to select the right connector for a specific application.

| IP Rating | Dust Protection Level | Water Protection Level | Typical Use Case |

|---|---|---|---|

| IP65 | Dust-tight | Protection against low-pressure water jets | Automation, conveyors |

| IP67 | Dust-tight | Protection against immersion up to 1 meter | Outdoor devices, robotics |

| IP68 | Dust-tight | Protection against continuous immersion | Submersible sensors, irrigation systems, outdoor installations |

| IP69K | Dust-tight | Protection against high-pressure, high-temperature water jets | Food & beverage, pharmaceutical machinery, sanitary washdown areas |

The first digit in the IP code indicates protection against solids, ranging from 0 (no protection) to 6 (dust-tight). The second digit refers to liquid protection, ranging from 0 (no protection) to 9K (protection against high-pressure, high-temperature water jets). For example, IP67 connectors are completely dust-tight and can withstand immersion in water up to 1 meter.

Dust and Particle Sealing

Dust and particle ingress can compromise electrical connections and lead to system failures. 7/8 connectors feature advanced sealing technologies that prevent dust and other contaminants from entering the connector housing. These seals maintain the integrity of the power supply, even in environments with high levels of airborne particles. The robust construction ensures that sensitive contacts remain protected, supporting reliable operation in factories, outdoor installations, and agricultural equipment.

Mechanical Durability of Connectors

Vibration and Shock Resistance

Industrial environments often expose connectors to vibration and mechanical shock. Engineers test the mechanical durability of 7/8 connectors by subjecting them to cycling, thermal shock, and vibration tests according to EIA-364 specifications. During these tests, the contact interface is secured to prevent relative motion, which helps avoid fretting corrosion. Low Level Contact Resistance (LLCR) is measured before and after testing to ensure stability. Results show that vibration can cause minor fluctuations in contact resistance, but the LLCR remains stable within acceptable limits. Products do not pass if the LLCR changes by more than 15 milliohms, ensuring only reliable connectors reach the market.

Research highlights that vibration can increase surface wear and cause resistance fluctuations. The amplitude of these fluctuations depends on the vibration frequency. Excessive insertion and withdrawal forces, combined with vibration, accelerate contact wear and can degrade performance. Vibration resistance testing includes both sinusoidal and random vibration modes, providing a comprehensive assessment of connector reliability under real-world conditions.

Corrosion-Resistant Materials

Corrosive environments, such as those found in marine, food processing, or outdoor applications, demand connectors built from materials that resist rust and chemical attack. 7/8 connectors often use stainless steel, nickel-plated brass, or specialized polymers to prevent corrosion. These materials extend the service life of the connector and maintain a stable power supply, even when exposed to moisture, cleaning agents, or salt spray. The use of corrosion-resistant materials ensures that connectors continue to perform reliably, reducing maintenance needs and minimizing downtime.

Electrical Performance of 7/8 Connectors

High Current and Voltage Handling

Reliable power delivery depends on a connector’s ability to handle high current and voltage without overheating or failing. 7/8 connectors are engineered for demanding industrial applications, offering impressive electrical ratings:

| Parameter | Value |

|---|---|

| Maximum Rated Current | 12.0 A |

| Rated Voltage | 300 V (600 V UL) |

| Rated Impulse Voltage | 4000 V |

These ratings allow 7/8 connectors to support motors, actuators, and other equipment that require a stable power supply. The high impulse voltage rating provides additional protection against electrical surges, which can occur in industrial and outdoor environments.

Low Contact Resistance

Low contact resistance is essential for efficient power transmission. 7/8 connectors use precision-engineered contacts, often with gold plating, to minimize resistance at the connection point. This design reduces energy loss and heat generation, ensuring that the power supply remains stable and efficient. Consistent low contact resistance also helps prevent voltage drops, which can affect sensitive equipment and lead to operational issues. By maintaining low resistance, these connectors support long-term reliability and optimal performance in critical applications.

Safety and Compliance in Connectors

Secure Locking Mechanisms

Reliable power delivery depends on secure connections. Engineers design connectors with advanced locking mechanisms to prevent accidental disconnection. These mechanisms include threaded couplings, bayonet locks, and snap-in latches. Each type provides a firm hold, even when exposed to vibration or mechanical stress. In industrial environments, equipment often moves or shakes during operation. Secure locking features keep connectors in place, reducing the risk of power loss or signal interruption.

A secure lock also protects against environmental hazards. When a connector remains tightly sealed, dust and moisture cannot enter the contact area. This protection helps maintain electrical integrity and extends the lifespan of both the connector and the equipment it powers. Many manufacturers test locking mechanisms for durability, ensuring they withstand repeated use without failure. The result is a safer, more reliable connection that supports continuous operation in demanding settings.

Tip: Always check that the locking mechanism is fully engaged before starting equipment. This simple step can prevent unexpected downtime and equipment damage.

Overvoltage and Short-Circuit Protection

Electrical faults such as overvoltage and short circuits pose serious risks to equipment and personnel. To address these hazards, designers integrate multiple safety features into connectors. Circuit conditioning components, including overvoltage protectors, surge suppressors, and thermal cutoff devices, work together to shield sensitive electronics. These components maintain signal integrity while protecting against dangerous voltage spikes and current surges.

Semiconductor-based devices such as transient voltage suppressors (TVS), metal oxide varistors (MOVs), and polymeric positive temperature coefficient (PPTC) devices play a critical role. These devices clamp voltage spikes and interrupt fault currents, preventing damage from overvoltage and short circuits. Thyristor surge protectors respond rapidly to transient events by diverting surge currents away from vulnerable components. This action reduces the risk of electrical hazards and ensures the safety of the entire system.

Miniature thermal cutoff devices, sometimes called mini-breakers, provide another layer of protection. When current exceeds safe thresholds, these devices interrupt the flow, stopping electrical faults before they cause harm. This feature proves especially valuable in sensitive electronics, where even brief overcurrent conditions can lead to permanent damage.

Integrated protection solutions, similar to those used for RS-485 ports, combine overvoltage protection, transient voltage suppression, and current limiting. These features help prevent damage from electrical faults and ensure reliable operation of communication and power ports. By incorporating these advanced safety measures, 7/8 connectors deliver dependable performance and protect both equipment and users from electrical hazards.

Note: Regular inspection and maintenance of protective features can further enhance safety and extend the service life of connectors in critical power applications.

Design and Compatibility of 7/8 Connectors

Standardized Interfaces for Connectors

Mating Compatibility

Engineers design 7/8 connectors with a standardized mating interface. The NFPA/T3.5.29 R1-2007 quasi-standard defines this interface, ensuring that connectors from different manufacturers fit together seamlessly. This standardization supports reliable connections in industrial environments, where equipment from multiple brands often operates side by side. The consistent design of the circular connector allows for straightforward integration and reduces the risk of mismatched components.

Interchangeability Across Brands

Manufacturers follow strict guidelines to guarantee that their connectors remain interchangeable. The table below highlights key aspects that enable this interoperability:

| Aspect | Description |

|---|---|

| Threaded Interface | 7/8″-16UNF threading used by major brands |

| Pin Arrangements | Standardized pin counts (2, 3, 4, or 5 pins) |

| Electrical Parameters | Uniform voltage and current ratings |

| Connection Form | Identical connection mechanisms |

| Environmental Protection | IP67 or higher for dust and water resistance |

| Interoperability Outcome | Connectors from different brands connect and function reliably in the same system |

This approach ensures that users can replace or upgrade components without compatibility concerns.

Connector Configurations and Options

Pin Counts and Arrangements

7/8 connectors offer a wide range of pin configurations, supporting both simple and complex applications. Common options include 2, 3, 4, and 5 pins, but some lines extend up to 19 pins. This flexibility allows engineers to select the right configuration for power, signal, or mixed-use requirements. Gold over nickel-plated contacts and molded key indicators further enhance durability and alignment.

Cable and Panel Mount Options

Manufacturers provide several mounting styles to suit different installation needs. Options include panel mount, bulkhead, field wireable, and overmolded plugs. Both male and female versions are available, supporting cable-to-cable and cable-to-panel connections. These choices enable quick installation and secure connections in diverse environments, from factory floors to outdoor sites.

Tip: Selecting the correct mounting style improves installation efficiency and long-term reliability.

Customization and Modularity in 7/8 Connectors

Field-Installable Variants

Field-installable variants give technicians the ability to assemble connectors on-site. This feature proves valuable when custom cable lengths or rapid repairs are necessary. The modular design reduces downtime and supports flexible system layouts.

Modular System Integration

Modularity benefits both system integrators and end users. Customizable configurations allow for tailored solutions that fit specific application needs. Modular connectors simplify complex setups, reduce clutter, and enable rapid assembly. These features improve scalability and adaptability, making it easier to expand or modify systems as requirements change.

Technical Specifications of 7/8 Connectors

Electrical Ratings of Connectors

Voltage Ranges

7/8 connectors support a wide range of voltage requirements in industrial and automotive settings. Their robust design allows them to handle higher voltages than smaller connectors. Most models feature a rated voltage of 300 V, with some versions certified for up to 600 V under UL standards. This capability makes them suitable for high-voltage applications, including power distribution and heavy machinery.

| Parameter | Value |

|---|---|

| Rated voltage | 300 V (600 V UL) |

| Rated impulse voltage | 2500 V |

| Pollution degree | 3 |

| Overvoltage category | II |

The high impulse voltage rating ensures protection against transient surges, which often occur in industrial environments.

Current Carrying Capacity

Engineers select 7/8 connectors for their ability to carry significant current loads. These connectors typically support up to 13.0 A, making them ideal for powering motors, actuators, and other high-demand devices. The combination of high current and voltage ratings enables reliable operation in demanding applications where stable power delivery is critical.

The 7/8 connector’s waterproof construction and multiple pin options further enhance its suitability for high-current, high-voltage tasks.

Mechanical Specifications of 7/8 Connectors

Size and Form Factor

Manufacturers design 7/8 connectors with a circular form factor, which provides secure and vibration-resistant mating. The connectors come in various sizes to accommodate different equipment and installation needs. Most models use robust materials such as aluminum or stainless steel, ensuring durability and corrosion resistance. Threaded and bayonet coupling mechanisms allow for secure locking and easy handling, even in challenging environments.

- Circular design supports secure connections.

- Robust housings resist impacts and corrosion.

- Threaded and bayonet couplings prevent accidental disconnection.

- IP67 or higher sealing protects against dust and water ingress.

Mating Cycles and Lifespan

Durability stands out as a key feature of 7/8 connectors. Most models guarantee a minimum of 500 mating cycles, which means users can connect and disconnect them many times without performance loss. The coupling mechanism, typically threaded, ensures a tight fit. Engagement and disengagement forces remain within ergonomic limits, with a maximum of 100 N. The minimum working mating torque is 25 N-m, balancing ease of use with retention strength.

- Minimum 500 mating cycles for long-term reliability.

- Threaded coupling mechanism for secure engagement.

- Optimized torque and force for user safety and convenience.

Environmental Ratings for Connectors

Operating Temperature Range

7/8 connectors operate reliably across a broad temperature range, making them suitable for both indoor and outdoor installations. Their construction allows them to withstand temperature extremes commonly found in industrial, marine, and transportation environments.

Chemical and UV Resistance

Manufacturers often use stainless steel, coated brass, or specialized polymers to enhance resistance to chemicals and UV exposure. Stainless steel variants, in particular, offer superior corrosion resistance. These connectors perform well in environments exposed to ammonia, petroleum products, household chemicals, and high-sulfur gases. The risk of failure remains low, even under harsh conditions such as lightning or chemical exposure.

- Stainless steel construction ensures low failure probability.

- Protective coatings improve operational reliability.

- Suitable for outdoor use and environments with vibration or corrosive agents.

Choosing connectors with high corrosion resistance and protective coatings increases system reliability and reduces maintenance needs in challenging environments.

Cable and Termination Options for 7/8 Connectors

Pre-Molded vs. Field-Wireable

Engineers can select between pre-molded and field-wireable cable options for 7/8 connectors. Pre-molded cables arrive with factory-attached connectors, ensuring consistent quality and rapid deployment. These cables reduce the risk of wiring errors and provide reliable environmental sealing. Pre-molded assemblies suit applications where speed and repeatability matter most.

Field-wireable connectors offer flexibility for custom cable lengths or on-site repairs. Technicians can assemble these connectors during installation, which proves valuable in complex or evolving systems. Field-wireable options support several termination methods, each with unique benefits for installation and maintenance.

| Termination Option | Description | Influence on Installation and Maintenance |

|---|---|---|

| Crimp Termination | Uses a crimping tool to compress a metal sleeve around wire and contact pin. | Provides secure, reliable connections; good for vibration-prone environments; requires crimping tools. |

| Solder Termination | Melts filler metal to join wire to contact pin. | Offers strong, permanent connections; requires soldering skills and equipment; less easy to rework. |

| Screw Termination | Uses screws to clamp wire onto contact pin. | Allows easy connection/disconnection; suitable for frequent adjustments; simpler maintenance. |

| Lug Termination | Connects large-gauge wires using lug terminals. | Provides secure connections for high-power applications; may require specialized tools. |

| Wire Wrap Termination | Wraps wire around a post on the contact pin. | Low-cost, reliable; suitable for specific applications; may be less common in modern use. |

Accessories such as backshells, cable clamps, and sealing gaskets further enhance cable assemblies. These components protect against mechanical stress and environmental hazards, improving durability and simplifying maintenance tasks.

Tip: Field-wireable connectors allow quick adaptation to unexpected changes in cable routing or length requirements during installation.

Shielded and Unshielded Variants

7/8 connectors support both shielded and unshielded cable types. Shielded variants use metal housings and conductive backshells to terminate the cable shield, providing 360° electromagnetic interference (EMI) protection. Proper connection of the cable’s braided shield to the connector housing ensures effective EMI suppression. This shielding depends on secure galvanic contact between plug and receptacle, as well as between the panel-mounted connector and the metal panel.

Shielded connectors prove essential in environments with high electrical noise, such as industrial automation or transportation systems. They help maintain signal integrity and reduce the risk of data errors or equipment malfunction. Unshielded variants suit less demanding environments, where EMI is not a significant concern.

Technicians must assemble shielded connectors carefully to maintain shielding integrity. This attention to detail during installation ensures long-term system reliability and minimizes EMI-related issues.

Industry Standards and Certifications for 7/8 Connectors

International Standards for Connectors

IEC and UL Compliance

Manufacturers design 7/8 connectors to meet strict international standards. These standards ensure safety, reliability, and compatibility in global markets. Key standards include:

- IEC 60807: Specifies requirements for rectangular connectors used at frequencies below 3 MHz.

- IEC 60828: Defines pin allocations for microprocessor systems.

- IEC 60309: Covers plugs, socket-outlets, and couplers for industrial purposes.

- IEC 60947, IEC 62271, IEC 60204: Address low-voltage switchgear, high-voltage equipment, and safety of machinery.

- UL certification: Recognized for safety and reliability in North America. Many 7/8 connectors, such as the UTGX series, carry both UL and IEC certifications, confirming their long lifespan and high safety standards.

These certifications help users trust that connectors will perform as expected in demanding environments.

ISO Certifications

ISO certifications further support quality and consistency. Manufacturers often follow ISO 9001 for quality management systems. This certification ensures that every step, from design to production, meets rigorous standards. ISO 14001 addresses environmental management, helping companies reduce their environmental impact. These certifications show a commitment to continuous improvement and global best practices.

Application-Specific Standards for 7/8 Connectors

Automation and Control Standards

The automation industry requires connectors that meet unique demands. Engineers select 7/8 connectors with coding, pin counts, and locking features tailored for automation systems. Coding prevents mismating and supports fast maintenance, even in dusty or wet environments. Different codings support various signal and power needs, such as A-coded for sensors or S-coded for AC power. Secure coupling systems, like threaded or bayonet types, provide vibration resistance and ease of use.

Transportation and Energy Sector Requirements

Transportation and energy sectors demand rugged connectors. 7/8 connectors must resist dust, fluids, vibration, and temperature changes. Metal housings provide effective EMI shielding. Environmental protection ratings, such as IP67 to IP69K, guarantee reliable operation in harsh conditions. Compact designs support miniaturization trends, especially in modern vehicles and energy systems. These features ensure connectors meet sector-specific requirements for durability and performance.

Ensuring Compatibility and Performance in Connectors

Third-Party Testing and Validation

Independent laboratories conduct rigorous testing on 7/8 connectors. They use devices like the multi-terminal fretter to simulate real-world vibration and wear. Tests follow standards such as ASTM D4170, which evaluates fretting wear protection. Statistical models, including Weibull analysis, estimate failure rates and life expectancy. Results show that dielectric lubricants can increase connector lifespan by up to 24 times under high-frequency conditions. These tests confirm that connectors meet safety and performance requirements.

Markings and Documentation

Manufacturers provide clear markings on connectors to indicate compliance with standards. Documentation includes test reports, certificates, and installation guides. These materials help users verify compatibility and ensure proper installation. Proper labeling and documentation support traceability and simplify maintenance.

Tip: Always check for certification markings and review documentation before installing connectors in critical systems.

Selecting the Right 7/8 Connector for Your Applications

Assessing Application Requirements for Connectors

Environmental Considerations

Selecting the right 7/8 connector starts with a careful evaluation of the operating environment. Connectors must withstand shock, vibration, and accidental disconnection, especially in industrial and automation settings. High ingress protection ratings, such as IP67 or IP69K, ensure resistance to dust, moisture, and contaminants. Materials like stainless steel, aluminum, and high-performance polymers provide strength and corrosion resistance. Some environments require connectors that resist chemicals or extreme temperatures, ranging from -40°C to 100°C. In classified hazardous locations, such as areas with flammable gases, connectors must comply with strict safety standards. These features guarantee long-term reliability and consistent performance, even under continuous use in harsh conditions.

Electrical Load Needs

Electrical requirements play a crucial role in connector selection. Connectors should offer low contact resistance to maintain signal integrity and support both power and data signals. Compatibility with analog signaling standards, such as 0-10V or 4-20mA, is essential for many automation systems. The connector must handle the required current and voltage without overheating or degrading. Mechanical integrity, achieved through locking mechanisms like locking rings or bayonet connections, prevents accidental disconnection during operation. Using connectors from the same series can simplify assembly, repair, and inventory management, while features like 360° shielding improve electromagnetic compatibility.

Evaluating Supplier and Product Quality of 7/8 Connectors

Manufacturer Reputation

Supplier reputation directly impacts the long-term reliability of 7/8 connectors. Established manufacturers, especially those with a history of engineering support and customization, deliver consistent quality. Companies that adhere to rigorous standards, such as DIN and VDE, ensure their products meet demanding industrial requirements. Family-owned firms and specialized manufacturers often maintain long-term customer relationships, developing solutions tailored to specific applications. Their commitment to quality and innovation enhances connector durability and performance in challenging environments.

Warranty and Support

Warranty and after-sales support are critical when choosing connectors for automation or industrial use. Reliable suppliers provide clear warranty terms and responsive technical support. This commitment ensures users can resolve issues quickly and maintain system uptime. High-quality connectors often come with documentation and certifications, confirming compliance with industry standards. Selecting products from reputable manufacturers reduces the risk of failure and supports long-term system reliability.

Installation and Maintenance Factors for Connectors

Ease of Assembly

Ease of assembly simplifies the installation process and reduces downtime. Connectors designed for quick assembly require minimal special tools and provide clear instructions. Field-installable options allow technicians to adapt cable lengths and configurations on-site. Gold-plated contacts and corrosion-resistant housings further streamline assembly and ensure lasting connection integrity.

Serviceability and Replacement

Serviceability remains a key consideration for maintenance teams. Connectors with high mating cycle ratings, ranging from 500 to 10,000 cycles, withstand repeated connections and disconnections. Designs that allow easy inspection and cleaning facilitate routine maintenance. Compatibility with existing systems prevents integration issues and supports future network expansion. Choosing connectors with robust weatherproofing and durable materials ensures reliable performance and simplifies replacement in demanding environments.

Tip: Regular inspection and cleaning of connectors help maintain optimal performance and extend service life in critical automation systems.

7/8 connectors deliver reliable power in industrial, transportation, and outdoor environments. Their corrosion-resistant metals and IP67 sealing withstand extreme temperatures, vibration, and moisture.

- These connectors provide consistent electrical connections in harsh conditions, supporting stable production and reducing downtime.

- Proper selection with the right IP rating protects against dust and moisture, ensuring long-term durability.

- Consulting trusted suppliers and reviewing application needs helps maximize operational efficiency and safety.

Choosing the right 7/8 connector supports continuous operation and simplifies future maintenance or upgrades.

FAQ

What is a 7/8 connector?

A 7/8 connector is a circular industrial connector. It provides secure electrical connections for power and signals in harsh environments. Engineers use it in automation, transportation, and outdoor equipment.

How does a 7/8 connector differ from M8 or M12 connectors?

A 7/8 connector handles higher current and voltage than M8 or M12 connectors. It suits power delivery, while M8 and M12 connectors often serve signal or low-power applications.

Which IP ratings are available for 7/8 connectors?

Most 7/8 connectors offer IP67, IP68, or IP69K ratings. These ratings indicate strong protection against dust and water. Users can select the right rating based on environmental needs.

Can 7/8 connectors be used outdoors?

Yes. Manufacturers design 7/8 connectors for outdoor use. Their robust housings and sealing features protect against moisture, dust, and temperature extremes.

Are 7/8 connectors compatible across different brands?

Most 7/8 connectors follow industry standards for threading, pin layout, and size. This standardization allows users to mix and match connectors from different brands in the same system.

What termination options exist for 7/8 connectors?

Engineers can choose from crimp, solder, screw, or pre-molded terminations. Each option offers unique benefits for installation speed, reliability, and maintenance.

How should users maintain 7/8 connectors?

Regular inspection and cleaning help prevent failures. Users should check for secure locking, clean contacts, and replace damaged seals to ensure long-term reliability.

Where are 7/8 connectors most commonly used?

7/8 connectors appear in factory automation, robotics, transportation, renewable energy, and outdoor machinery. Their durability and electrical performance make them ideal for demanding applications.