You rely on RJ45 network ports every time you establish connections for ethernet networking, whether at home or in a professional environment. RJ45 connectors feature a standardized eight-pin design, setting them apart from alternatives like an M8 connector or a Type B connector. When you use low-quality materials from a Connector factory, you risk failures caused by degraded plastics, loose terminal clips, or improper wiring. These problems can disrupt network performance and lead to unstable connections. Regular care and testing of RJ45 help prevent issues such as packet loss, signal reflection, or intermittent disconnections, ensuring your network remains robust.

Identifying RJ45 Network Ports

RJ45 Connector Physical Design

Shape and Size of RJ45 Ports

You can recognize an RJ45 connector by its rectangular shape and compact size. The port fits a standard 8P8C (eight position, eight contact) configuration, which sets it apart from other connectors. RJ45 network ports feature a unique orientation tab that prevents incorrect insertion. The retaining latch locks the connector securely in place, yet allows easy removal when needed. Most RJ45 connectors use polycarbonate housing, often transparent, but you may see different colors depending on the manufacturer. Shielded versions include metal housing with nickel or gold plating, which helps reduce electromagnetic interference in demanding environments.

Tip: Always check for the elastic retaining latch on your RJ45 connector. This feature ensures durability and repeated use without breaking.

Pin Configuration and Layout

Inside every RJ45 connector, you find eight gold-plated contacts separated by insulating plastic channels. These pins support four twisted wire pairs, which are essential for ethernet networking. Manufacturers use bronze or phosphor bronze for the contact pins, then apply gold plating to prevent corrosion and maintain stable data transmission. You may encounter two-prong or three-prong pin designs, with three-prong offering greater stability. The precise alignment of these pins ensures reliable data flow and minimizes signal loss.

RJ45 Network Ports Compatibility

Supported Ethernet and Networking Standards

RJ45 network ports must comply with ethernet standards set by the IEEE. These standards define the physical and electrical characteristics of ethernet connections, ensuring interoperability across devices from different manufacturers. You can use RJ45 connectors for various transmission speeds, including 10/100 Mbps, 1 Gbps, and 10 Gbps. This compatibility guarantees that your ethernet networking setup remains flexible and future-proof.

Devices Commonly Using RJ45 Ports

You encounter RJ45 network ports on a wide range of devices in modern networking environments. Common examples include:

- Computers

- Gaming consoles

- Smart TVs

- Routers

- Modems

- Servers

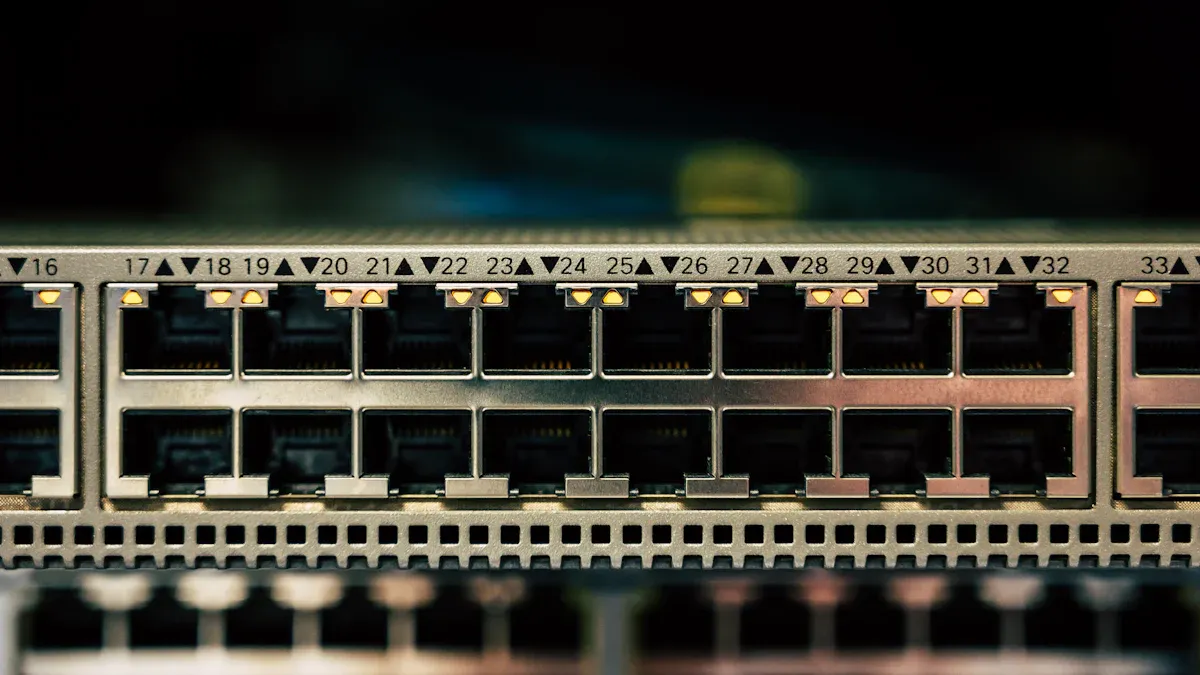

- Switches

- Networked peripherals

These devices rely on RJ45 connectors to establish stable ethernet connections and support high-speed data transfer.

Typical Use Cases for RJ45 Network Ports

Home Networking Applications

In residential settings, you use RJ45 connectors to link computers, gaming consoles, and smart TVs to routers or modems. This setup enables fast and reliable ethernet networking for streaming, gaming, and everyday internet access. RJ45 network ports also support Power over Ethernet (PoE), allowing you to power devices such as IP cameras directly through the cable.

Business and Enterprise Networking

In offices and enterprise environments, RJ45 connectors play a critical role in connecting workstations, printers, VoIP phones, and servers. You depend on these connectors for secure data transmission and efficient network management. Data centers utilize RJ45 network ports to support large-scale server infrastructure and high-speed networking between storage devices. Industrial automation and security systems also rely on RJ45 connectors for robust and consistent performance.

| Environment | Typical Devices Connected via RJ45 | Common Applications |

|---|---|---|

| Home | Computers, Smart TVs, Consoles | Streaming, Gaming, Internet |

| Office/Business | Workstations, Printers, VoIP Phones | Data Transfer, Communication |

| Data Center | Servers, Switches, Storage | High-Speed Networking |

| Industrial | Automation Equipment, IP Cameras | Control, Surveillance |

Unique Features of RJ45 Network Ports

Electrical and Mechanical Properties of RJ45

Eight-Pin Configuration Explained

You benefit from the eight-pin configuration in every rj45 connector. This design supports four twisted pairs of wires, which are essential for reliable ethernet data transmission. Each pin in the rj45 connector corresponds to a specific wire in the cable, ensuring accurate data flow and minimizing signal loss. The gold-plated or nickel-plated copper pins inside the connector provide excellent electrical conductivity and resist corrosion. This setup guarantees stable, low-resistance contacts, which are critical for high-speed data transmission and consistent network performance.

The rj45 connector follows strict wiring standards, such as T568A and T568B. These standards ensure compatibility across different devices and maintain the integrity of your ethernet network. The locking mechanism in the connector secures the cable, preventing accidental disconnections and maintaining uninterrupted data transmission.

Shielding, Durability, and Build Quality

You can trust the shielding in rj45 cables to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). Shielded cables use braided, foil, or combined shields to maintain signal integrity, especially in environments with high interference. Proper grounding and cable management further enhance the effectiveness of shielding.

Manufacturers use impact-resistant ABS or polycarbonate plastic for the housing of rj45 connectors. This material resists environmental damage and mechanical stress. The gold-plated contacts inside the connector ensure long-lasting connections and resist corrosion, which is vital for installations that require durability. The retaining latch on the rj45 connector provides strong pull-out resistance, securing the connection physically and contributing to overall reliability.

Note: Regular testing and maintenance of your rj45 connectors help sustain their performance and extend their service life.

You also find strain relief boots and dust covers on many rj45 connectors. These features protect the cable from physical stress, dust, and moisture, further enhancing the connector’s longevity.

RJ45 Performance Capabilities

Data Transfer Speeds and Bandwidth

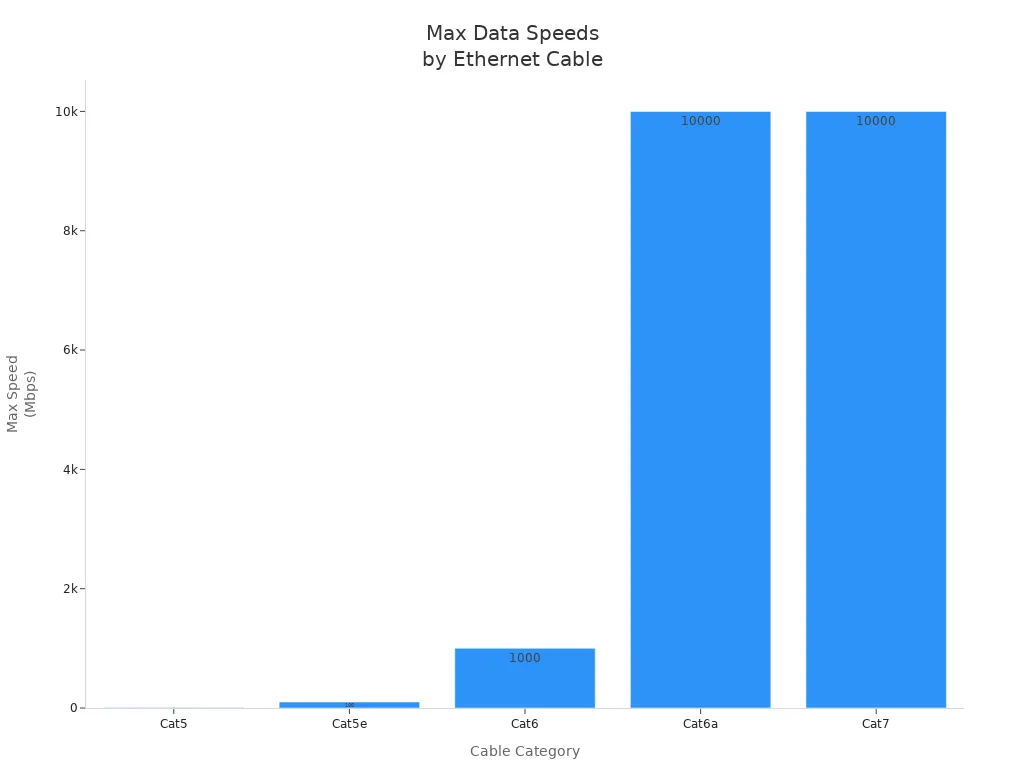

You rely on rj45 connectors to deliver high-speed ethernet data transmission. The maximum speed and bandwidth depend on the cable category you choose. The table below summarizes the capabilities of different cable types:

| Cable Category | Introduction Year | Max Speed Supported | Bandwidth | Notes |

|---|---|---|---|---|

| Cat5 | ~1995-2001 | 10 Mbps | 100 MHz | Oldest type with 4 twisted pairs |

| Cat5e | 2001 | 100 Mbps | 100 MHz | Improved version of Cat5 |

| Cat6 | ~2002 | 1 Gbps | 250 MHz | Has divider to reduce crosstalk |

| Cat6a | Later than Cat6 | 10 Gbps | 600 MHz | More durable, reduced noise |

| Cat7 | N/A | 10 Gbps or higher | N/A | Supports up to 100 Gbps in some cases |

You can see that rj45 connectors support a wide range of ethernet standards, from Fast Ethernet (100 Mbps) to 10 Gigabit Ethernet (10 Gbps) and beyond. This flexibility allows you to upgrade your network without changing the connector type.

The bandwidth capacity of rj45 connectors also varies by cable type. For example, Cat6a cables support up to 500 MHz, while Cat7a cables reach 1,000 MHz. This high bandwidth ensures fast and reliable data transmission, which is essential for modern applications and data center performance.

Cable Type Support and Flexibility

You can use rj45 connectors with a variety of cable categories, including Cat5, Cat5e, Cat6, Cat6a, Cat7, and Cat7a. All these cables use four twisted pairs and eight pins, making them fully compatible with the rj45 connector. Shielded and ruggedized versions of the connector exist to improve performance and durability in harsh environments, such as industrial settings or areas with high EMI.

| Cable Category | Max Speed (Mbps) | Max Bandwidth (MHz) |

|---|---|---|

| Cat5 | 100 | 100 |

| Cat5e | 1000 | 100 |

| Cat6 | 1000 | 250 |

| Cat6a | 10000 | 500 |

| Cat7 | 10000 | 600 |

| Cat7a | 10000 | 1000 |

RJ45 connectors also support Power over Ethernet (PoE), allowing you to power devices like IP cameras and phones directly through the ethernet cable. This feature increases installation flexibility and reduces the need for additional power sources.

Tip: Choose shielded rj45 connectors and cables for environments with high electromagnetic interference to maintain optimal network performance.

RJ45 vs. Other Network Connectors

RJ45 vs. RJ11: Key Differences

You may encounter both rj45 and RJ11 connectors, but they serve different purposes. The table below highlights the main differences:

| Feature | RJ45 Connector | RJ11 Connector |

|---|---|---|

| Pin Count | 8 pins (8P8C) | Commonly 4 pins (6P4C), sometimes 6 |

| Size | Larger, rectangular | Smaller, compact square |

| Typical Use | High-speed Ethernet networking | Analog telephone lines, DSL services |

| Cable Types | Twisted pair cables (Cat5, Cat6, etc.) | Telephone cables (flat, stranded wire) |

| Bandwidth Support | High bandwidth for data transmission | Low bandwidth, optimized for voice |

| Applications | LAN devices, PoE devices | Telephones, fax machines, DSL lines |

You use rj45 connectors for ethernet networking, supporting high-speed data transmission and complex wiring schemes. RJ11 connectors, on the other hand, are optimized for voice communication and lower-speed data transmission.

RJ45 vs. USB and Fiber Ports

You might also compare rj45 connectors with USB and fiber ports. RJ45 connectors, when used with copper cables, support speeds from 100 Mbps up to 10 Gbps, depending on the cable category. This makes them suitable for short-distance, cost-effective applications such as home and small office networks.

Fiber ports, often using SFP modules, support much higher bandwidths, ranging from 1 Gbps to 25 Gbps or more. Fiber excels in long-distance, high-performance environments like data centers, where you need stable, high-speed transmission and resistance to electromagnetic interference.

- RJ45 connectors support Power over Ethernet (PoE), enabling you to power devices like IP phones and cameras.

- SFP and fiber ports do not support PoE but offer superior data center performance for long-distance connections.

- USB connectors are common for peripheral devices but do not match the speed and bandwidth of rj45 or fiber for network data transmission.

Note: For most home and office networks, rj45 connectors provide the best balance of speed, flexibility, and cost. In data centers or environments requiring the highest network performance, fiber ports become the preferred choice.

RJ45 Connectors Maintenance Essentials

Routine Inspection of RJ45 Network Ports

Visual Checks for Wear or Damage

You should prioritize regular inspection of every rj45 connector in your network. Visual checks help you spot early signs of wear or damage that can impact data transmission and network performance. Examine each connector for bent pins, broken retaining clips, or cracks in the housing. Look for frayed cable jackets and discoloration, which may indicate overheating or corrosion. In high-traffic environments, inspect rj45 connectors every six months to detect issues before they disrupt your network.

Tip: Label each cable after inspection and testing. This practice helps you track the condition of your connectors and cables over time, making future maintenance more efficient.

Testing Connectivity and Signal Quality

After visual inspection, you need to test the connectivity and signal quality of your rj45 connectors. Use a cable tester to verify continuity, check for shorts, and confirm correct pinouts. This step ensures that each rj45 connector maintains a reliable connection and supports optimal data flow. If you notice intermittent connections or reduced speeds, use a time-domain reflectometer (TDR) to locate impedance mismatches or discontinuities in the cable. Regular inspection and testing help you predict and prevent problems, reducing unexpected downtime and costly repairs.

Cleaning RJ45 Network Ports

Safe Cleaning Methods for RJ45 Connectors

Proper cleaning is essential for rj45 connectors maintenance. Always power down and disconnect cables before cleaning. Start by removing surface dust with a microfiber cloth or compressed air. For stubborn debris, use isopropyl alcohol on a lint-free cloth or cotton swab to gently clean the contacts and housing. Avoid using excessive force, which can damage the delicate pins inside the connector. After cleaning, allow the connector and port to dry completely before reconnecting.

Note: Establish a regular cleaning schedule to prevent dust and moisture buildup. Clean connectors and ports at least twice a year, or more often in dusty or humid environments.

Recommended Tools and Materials

Industry experts recommend using the following tools and materials for rj45 connector upkeep:

- High-quality rj45 connectors such as Mr. Tronic Cat5e and Cat6 modular plugs for reliable data transmission.

- Good-quality crimping and testing tools to avoid installation errors.

- Microfiber cloths and compressed air for dust removal.

- Isopropyl alcohol and lint-free swabs for cleaning contacts.

- Strain relief boots and dust covers to protect connectors from physical stress and contamination.

Investing in proper tools and materials ensures your maintenance requirements are met and extends the lifespan of your rj45 connectors.

Preventing Common RJ45 Issues

Avoiding Physical Stress and Strain

Physical damage remains one of the most common threats to rj45 connector performance. Excessive cable movement, improper termination, and rough handling can cause bent pins, broken latches, or misaligned connectors. Use strain relief boots to minimize conductor stress and prevent cable kinks. Train your staff on proper handling and installation techniques to reduce the risk of mechanical damage. Always ensure full conductor insertion and use transparent housings for visual inspection.

| Failure Type | Symptoms | Causes | Prevention & Solutions |

|---|---|---|---|

| Physical Damage & Wear | Bent/broken pins, loose port, intermittent connection | Rough mating/unmating, cable strain, mechanical shock | Use strain relief boots, train staff on proper handling, specify robust jacks with reinforced shrouds |

| Mechanical Issues | Poor strain relief, pin misalignment, damaged latches | Excessive cable movement, improper termination, rough handling | Use proper strain relief, ensure full conductor insertion, visual inspection through transparent housings |

Protection Against Dust and Moisture

Dust and moisture can degrade rj45 connector performance and cause corrosion or intermittent connections. Use connectors and couplers with high ingress protection ratings such as IP67 or IP68 for harsh environments. These connectors feature sealed housings, corrosion-resistant materials, and integrated gaskets to block contaminants. Proper installation, including sealing and strain relief, enhances long-term reliability. For outdoor or industrial applications, select UV-stable and ruggedized rj45 connectors to withstand temperature extremes and chemical exposure.

To maintain a clean environment:

- Power down and disconnect cables before cleaning.

- Remove dust with a microfiber cloth and compressed air.

- Clean contacts with isopropyl alcohol.

- Allow all components to dry before reconnecting.

- Schedule regular cleaning and avoid placing equipment near dust or moisture sources.

Investing in IP68-rated rj45 connectors reduces maintenance costs by preventing environmental damage and extending equipment lifespan.

The Importance of Regular Inspection and Preventive Maintenance

You cannot overstate the importance of regular inspection and preventive maintenance for rj45 connectors. These practices help you detect early warning signs, maintain optimal data transmission, and ensure network performance. By following a structured maintenance schedule, you meet all maintenance requirements and minimize the risk of unexpected failures. The impact of rj45 connector maintenance extends beyond simple upkeep—it safeguards your entire network infrastructure.

Troubleshooting RJ45 Network Ports

Diagnosing Connection and Signal Problems

You often encounter network issues that stem from problems with your rj45 connector or port. Effective troubleshooting starts with a systematic approach. Begin by verifying that all network devices are powered on and display activity lights. These indicators confirm that your devices receive power and operate at a basic level. Next, ensure every cable is properly plugged into the correct rj45 port. Loose or misaligned connectors can disrupt data flow and cause intermittent connectivity.

You should diagram your network setup to confirm logical connections between devices. This step helps you visualize how switches, routers, and endpoints interact. Use basic Ethernet testing tools, such as a blinky tester, to check cable integrity and conductor continuity. These tools quickly identify wiring errors or broken conductors inside the rj45 connector.

Pay attention to the cable bend radius. Excessive bending can damage the internal wires and degrade data transmission. If you complete all physical checks and still experience issues, consult a troubleshooting flowchart or seek advanced network troubleshooting assistance. This structured process ensures you address both simple and complex problems with your rj45 connectors.

Tip: Always start troubleshooting with the simplest checks. Many network issues result from loose connectors or improperly seated cables.

Fixing Bent Pins or Loose RJ45 Connectors

Bent pins inside an rj45 connector can interrupt data transmission and cause network failures. You should inspect the connector visually for any misaligned or damaged pins. If you find a bent pin, use a small, non-conductive tool to gently realign it. Avoid excessive force, as this can break the pin or damage the connector housing.

Loose rj45 connectors often result from repeated insertions or physical stress. If the retaining latch on the connector breaks, the cable may not stay securely in the port. Replace any connector with a broken latch to maintain a stable connection. For persistent issues, consider replacing the entire rj45 connector or port. Proper maintenance and careful handling reduce the risk of physical damage and extend the lifespan of your connectors.

Note: Never force a cable into an rj45 port. Forcing can bend pins or crack the connector, leading to costly repairs and downtime.

Upgrading or Replacing RJ45 Network Ports

Recognizing Signs of Wear and Tear

You need to recognize when an rj45 network port or connector requires replacement. Several signs indicate that your connectors no longer support reliable data transmission. The table below summarizes common symptoms and their descriptions:

| Sign | Description |

|---|---|

| No Connection | Device shows no network connection despite a working cable; may be due to bent pins or internal faults. |

| Intermittent Connectivity | Connection drops or fluctuates frequently, possibly caused by dirty or damaged contacts inside the port. |

| Link Light Issues | Link LED is absent, flickering erratically, or unstable, indicating electrical or physical port problems. |

| Slow Speeds | Noticeably reduced network speeds when other factors are ruled out, suggesting internal port damage. |

| Physical Damage | Visible damage such as bent pins, broken casing, or oxidation (e.g., from salty air exposure) impairing contact. |

| Device Recognition Problems | Device Manager shows missing or warning signs; network diagnostics fail, indicating port malfunction. |

You should perform regular maintenance checks to catch these issues early. Addressing them promptly prevents data loss and network downtime.

Selecting New RJ45 Ports or Cables

When you decide to upgrade or replace your rj45 connectors, you must follow specific criteria to ensure optimal performance. Start by matching the rj45 connector to the cable category, such as Cat6, to meet your network’s data requirements. Choose between regular and pass-through connector types based on installation needs and cost considerations. Select connectors from reputable brands to guarantee stable operation and long-term reliability.

Verify that you have the proper crimping tools for your chosen connectors. Assess your project’s requirements, including the number of terminations and the accuracy needed. Perform cable continuity tests to detect breaks or shorts, and conduct wire mapping tests to confirm correct conductor-to-pin connections according to T568A or T568B standards.

You should also measure signal loss (attenuation) to ensure minimal degradation over the cable length. Test for near-end crosstalk (NEXT) to detect interference between wire pairs. Measure return loss to identify signal reflections caused by poor terminations or damage. Evaluate propagation delay and delay skew to ensure data synchronization across your network.

- Inspect cables for physical damage, such as kinks, cuts, or crushing, to avoid signal degradation.

- Use cable testers to verify correct wire termination, continuity, and absence of shorts or miswires.

- Re-crimp connectors if crimps are uneven or shallow to ensure good contact.

- Avoid electromagnetic interference by routing cables away from power lines and fluorescent lights.

- Use high-quality rj45 connectors rated for the cable category to maintain data integrity.

- Select connectors based on cable length needs to preserve signal quality over distance.

- Consider shielding requirements in environments with high electromagnetic interference.

- Choose between integrated or external magnetics depending on design constraints.

- Align connector pinout with wiring standards and system protocols.

- Confirm Power over Ethernet (PoE) capability if you need to deliver power over the cable.

- Evaluate ruggedization for harsh or outdoor environments to protect connectors.

- Plan for EMI and ESD protection in noisy or static-prone environments.

- Match connectors and cables to required data speeds and bandwidth to avoid bottlenecks.

You should also match the keystone jack category to the cable type for proper conductor fit. Choose between 90° or 180° jack designs based on installation space and cable routing preferences. Select shielded keystone jacks in environments with significant electromagnetic interference, or use unshielded jacks in low-EMI environments for cost-effectiveness.

Callout: Investing in the right rj45 connectors and cables during upgrades ensures reliable data transmission and reduces future maintenance needs.

Common RJ45 Maintenance Mistakes to Avoid

Improper RJ45 Cable Insertion

Forcing Cables into Ports

You risk damaging your rj45 connector and port when you force cables into place. The retaining latch and pin alignment in the rj45 connector require gentle handling during installation. If you apply too much pressure, you can bend pins or crack the connector housing. These physical issues lead to intermittent connectivity and signal loss. Poor workmanship during cable termination, such as excessive untwisting of wires, increases crosstalk and insertion loss. This degrades data quality and causes bit errors. Category 6 plugs use management bars to maintain consistent performance, so you must follow proper installation techniques.

- Improper crimping, such as incorrect wire alignment or insufficient pressure, results in poor network performance.

- Using inferior-quality rj45 connectors causes packet loss and unexpected disconnects.

- Neglecting cable management, like color-coding and labeling, complicates troubleshooting and reduces reliability.

Tip: Always align the rj45 connector with the port before insertion. Never force the cable, and check for a secure click from the retaining latch.

Misalignment and Connection Issues

Misalignment during installation prevents the rj45 connector from seating correctly. You may experience unreliable connections or complete failure if the pins do not make proper contact. Impedance mismatches between connectors and cables cause insertion loss deviation, which introduces noise and reduces data transmission quality. Signal reflections and noise from poor termination practices lower network stability and throughput.

Neglecting RJ45 Connectors Maintenance

Skipping Regular Inspections

You must inspect your rj45 connectors regularly to maintain optimal performance. Skipping inspections allows physical wear and damage to accumulate. Bent pins, cracked bodies, and broken locking tabs often go unnoticed until they cause connectivity problems. Dust and debris build up on connectors, degrading signal quality and slowing data speeds.

| Consequence Category | Description | Impact on Network Performance |

|---|---|---|

| Physical Wear and Damage | Cracked/broken plastic bodies, bent/misaligned pins, damaged locking tabs due to frequent use. | Causes intermittent connectivity, slow speeds, or total loss. |

| Dust and Debris Accumulation | Lack of cleaning leads to dust buildup on connectors. | Degrades signal quality and overall network performance. |

| Poor Crimping and Wiring Faults | Improper crimping, untwisting wire pairs, or wrong connectors used. | Results in packet loss, increased latency, reduced throughput, and higher bit error rates. |

| Signal Loss and Interference | Untwisting pairs too much and poor shielding increase crosstalk and electromagnetic interference. | Destabilizes network, causing cascading failures and downtime. |

| Lack of Regular Inspection | Failure to detect and replace worn connectors early. | Leads to increased downtime and reduced network reliability. |

Note: Regular cleaning and inspection of rj45 connectors prevent signal degradation and network instability.

Ignoring Early Warning Signs

You should never ignore warning signs such as intermittent connectivity, slow data speeds, or flickering link lights. These symptoms often indicate underlying problems with your rj45 connector or port. Early detection and prompt maintenance help you avoid costly downtime and data loss.

Using Incompatible RJ45 Equipment

Mismatched Cables and Connectors

Using incompatible rj45 connectors and cables creates physical and electrical problems. Plugs that do not fit properly into jacks cause unreliable connections. Differences in connector dimensions or retention mechanisms prevent a secure fit, leading to intermittent or failed connectivity. Cheap or counterfeit connectors often fail to meet standards, wasting time and money during installation.

- Faulty or damaged rj45 connectors and improper crimping cause connectivity failures.

- Using the wrong type of connector or cable, such as stranded versus solid or shielded versus unshielded, degrades network performance.

- Physical cable damage, including sharp bends or knots, results in slow speeds and packet loss.

Unsupported Devices and Standards

Non-standard or indexed modular connectors exist to prevent interchangeability. Mixing these with standard rj45 connectors causes compatibility problems. Electromagnetic interference from nearby power lines or devices disrupts signal quality. Network disruptions, slow speeds, and continuity problems often stem from hardware incompatibilities or damage.

Callout: Always verify that your rj45 connector, cable, and device support the same standards before installation. This practice ensures reliable data transmission and reduces troubleshooting time.

Practical RJ45 Maintenance Advice for Home and Office

Setting Up Reliable RJ45 Connections

Choosing High-Quality Ethernet Cables

You set the foundation for stable network performance by selecting the right ethernet cable and connectors. Solid copper cables outperform Copper-Clad Aluminum (CCA) cables in durability, data speed, and resistance to electromagnetic interference. When you use solid copper, you reduce latency and support demanding tasks like video conferencing and large file transfers. For longer cable runs, solid copper maintains signal integrity better than CCA. Always match your cable category—such as Cat6 or Cat7—with your connector to ensure compatibility and future-proof your network. High-quality connectors, like those found on Mr. Tronic Cat 6 ethernet cables, provide secure, reliable connections and minimize signal loss.

Tip: Choose high-quality connectors and cables rated for your network speed to avoid frequent maintenance and costly replacements.

Proper Placement of RJ45 Network Ports

You improve network reliability by planning the placement of each rj45 connector and port. Panel mount rj45 connectors offer a fixed, accessible point for connections, reducing wear from frequent plugging and unplugging. Position ethernet ports away from sources of electromagnetic interference, such as power lines or large appliances. Use cable organizers or Velcro straps to prevent excessive bending or coiling, which can damage the cable and connector. Adhering to wiring standards like T568A or T568B during installation ensures proper alignment and contact between cables and devices.

Long-Term RJ45 Maintenance Strategies

Scheduled Maintenance and Inspections

You extend the lifespan of your rj45 connectors and cables by following a regular maintenance schedule. In business environments, inspect and clean ethernet ports monthly due to heavy network traffic. For home networks, quarterly maintenance usually suffices unless you notice issues. Industrial settings require inspections every two weeks because harsh conditions increase failure rates.

| Environment | Maintenance Frequency Recommendation | Supporting Reason/Notes |

|---|---|---|

| Commercial/Business | Monthly | Heavy network traffic requires frequent checks |

| Home Networks | Quarterly | Generally sufficient unless issues arise |

| Industrial Settings | Every 2 weeks | Harsh conditions increase failure rates without frequent maintenance |

During each maintenance session, clean rj45 ports with compressed air and isopropyl alcohol. Use cable testers to verify signal continuity and check for faults. Inspect for loose connections, damaged cables, and ensure proper cable management.

Environmental Considerations for RJ45 Ports

You protect your rj45 connectors and cables by managing environmental risks. Avoid exposing ethernet cables to heat, moisture, or direct sunlight, as these factors degrade performance and shorten lifespan. Use shielded cables and connectors in areas with high electromagnetic interference. Select cable jackets based on the environment: plenum-rated for fire resistance in air spaces, outdoor-rated for UV and weather protection. Employ cable trays and conduits to guard against physical damage and rodents. Maintain good airflow around network equipment to prevent overheating and dust buildup.

Note: Regular inspection and proper installation practices help you catch early signs of wear, ensuring your rj45 connectors and cables deliver reliable connections for years.

You gain a distinct advantage when you maintain rj45 network ports with regular inspections and cleaning. Network professionals recognize that proper care of rj45 connectors reduces failures, preserves data transmission quality, and extends connector lifespan. You improve performance by upgrading connectors and using high-quality materials.

- Routine visual checks help you spot physical damage and prevent costly downtime.

- Organized cable management and adherence to wiring standards support stable performance.

Applying these strategies ensures your rj45 connectors deliver reliable, long-lasting network connections and empowers you to troubleshoot issues efficiently.

FAQ

What is the main difference between RJ45 and RJ11 connectors?

RJ45 connectors use eight pins for Ethernet networking. RJ11 connectors use fewer pins and support telephone lines. You should use RJ45 for data networks and RJ11 for voice communication.

How often should you inspect RJ45 network ports?

You should inspect RJ45 ports every three to six months in home environments. In offices or industrial settings, monthly inspections help prevent unexpected failures and maintain reliable connections.

Can you clean RJ45 connectors with water?

Never use water to clean RJ45 connectors. You should use isopropyl alcohol and a lint-free cloth. Water can cause corrosion and damage the electrical contacts.

What signs indicate a failing RJ45 port?

You may notice slow speeds, intermittent connections, or missing link lights. Physical damage, such as bent pins or broken latches, also signals a failing port. Replace damaged connectors promptly.

Do shielded RJ45 cables improve network performance?

Shielded RJ45 cables reduce electromagnetic interference. You should use them in environments with high electrical noise. Shielding helps maintain signal quality and supports stable data transmission.

Can you use Cat6 cables with older RJ45 ports?

You can use Cat6 cables with older RJ45 ports. The connector design remains compatible. However, your network speed depends on the lowest-rated component in the connection.

What is Power over Ethernet (PoE) and how does it work with RJ45?

Power over Ethernet (PoE) lets you deliver electrical power and data through a single RJ45 cable. You can power devices like IP cameras and phones without separate power supplies.

How do you prevent physical damage to RJ45 connectors?

You should avoid bending cables sharply and never force connectors into ports. Use strain relief boots and organize cables to reduce stress. Proper handling extends connector lifespan.