You depend on shielded RJ45 connectors to maintain stable data transmission and strong network performance in high-EMI environments. These shielded connectors use robust metal housings and grounding to deliver superior protection against interference, which keeps your signal quality high and data loss minimal.

Note: In industrial ethernet cabling, shielded connectors outperform unshielded options, especially in sectors like automation and medical fields.

| Feature | Shielded RJ45 Connectors | Unshielded RJ45 Connectors |

|---|---|---|

| EMI Protection | Excellent | Limited |

| Bandwidth | Consistent under EMI | Degrades under EMI |

Connector factory standards recommend matching shielded RJ45 connectors with shielded cables for best results. Consider advanced solutions like the M8 connector and Type B connector for specialized applications.

Electromagnetic Interference Mitigation in Ethernet Networks

What Is Electromagnetic Interference (EMI)?

Electromagnetic interference, or EMI, refers to unwanted electrical signals that disrupt the normal operation of your Ethernet network. You encounter EMI in many forms, both inside and outside your cabling infrastructure. This interference can travel through cables as conducted EMI or move through the air as radiated EMI. Both types can degrade network performance and cause data errors.

Common Sources of EMI in Networking

You face several sources of EMI in your networking environment. The most common types include:

- Crosstalk: This occurs when EMI from one wire affects another wire within the same cable bundle. Crosstalk often leads to signal distortion and data loss.

- Ambient or stray EMI: Devices such as wireless routers, Bluetooth equipment, cell phones, and other radio frequency sources generate ambient EMI. These sources introduce radio frequency interference (RFI) that can penetrate your network cabling.

- Industrial machinery: Motors, relays, and heavy equipment emit significant electrical noise, especially in factory settings.

- Power lines and fluorescent lighting: These can introduce both conducted and radiated EMI into your network.

Tip: Twisted pair wiring and shielded twisted pair (STP) cables help reduce the impact of EMI, but you must ensure proper installation and grounding for maximum protection.

Effects of EMI on Ethernet Performance

When EMI enters your Ethernet network, you may notice several negative effects:

- Increased transmission errors and packet loss

- Slower data transfer rates

- Intermittent connectivity issues

- False sensor readings in automation systems

These problems often stem from electrical noise and RFI disrupting the signal integrity. Radiated EMI, in particular, can cause hard-to-diagnose failures, especially in high-frequency or high-bandwidth applications. Over time, repeated exposure to EMI can lead to persistent network performance issues and costly downtime.

Why EMI Matters for Industrial Ethernet Cabling

Data Integrity Risks

In industrial environments, electromagnetic interference mitigation becomes critical. EMI introduces unwanted electrical noise that disrupts signal transmission. You may experience intermittent errors, false sensor readings, or even unplanned machine stops. In tightly synchronized automation systems, even a brief data glitch can trigger cascading failures. For example, recent studies show that EMI-related outages in factories can cost millions of dollars per hour. Shielded cables and connectors play a vital role in protecting your data integrity.

- Over half of industrial Ethernet issues result from cable plant problems, including EMI.

- Shielded cables prevent EMI-induced data corruption.

- Certification testing verifies shield integrity, wire mapping, and crosstalk resistance to ensure reliable data transmission.

Network Reliability Challenges

You rely on your network for continuous operation. EMI poses a direct threat to this reliability. Shielding, such as metallic foil around cable pairs, reduces the impact of radiated EMI and RFI. Breaks in shielding or poor cable continuity drastically reduce effectiveness, leading to slowdowns or complete communication failures. Crosstalk between cable pairs can cause intermittent or hard failures, especially at higher frequencies. Environmental factors like temperature and vibration can worsen EMI effects, making proper cable selection and installation essential for long-term network reliability.

Shielded RJ45 Connectors vs. Unshielded Connectors

Shielded RJ45 Connectors Explained

Shielding Materials and Construction

You encounter two main types of RJ45 connectors in network installations: shielded and unshielded. Shielded RJ45 connectors use metal shielding to protect your network from EMI. Manufacturers typically use materials such as nickel-plated or brass-plated metal for the connector housing. This metal shielding forms a physical barrier around the copper wires, reducing the risk of external interference.

Common shielding materials include:

- Aluminum-magnesium wire mesh braiding, which wraps around the signal wires.

- Aluminum foil layers, providing an extra level of EMI protection.

- Metal shells on the modular plug, aligning with the shielded cables for continuous coverage.

You must pair shielded RJ45 connectors with shielded cables to maintain effective EMI protection. The metal shielding in both the connector and cable must connect and ground properly. This ensures that the entire link resists external noise and maintains signal integrity.

Note: Shielded connectors require careful installation and grounding. Without proper grounding, the metal shielding cannot block EMI effectively.

Types of Shielded Connectors (FTP, STP, S/FTP)

You will find several types of shielded RJ45 connectors, each designed for specific cable constructions:

- FTP (Foiled Twisted Pair): Each cable contains twisted pairs wrapped in a single foil shield. The RJ45 connector includes a metal shell that connects to the cable’s foil.

- STP (Shielded Twisted Pair): Each pair of wires has its own shield, and the connector provides a metal enclosure for each pair.

- S/FTP (Shielded/Foiled Twisted Pair): This type combines an overall braided shield with individual foil shields for each pair. The RJ45 connector features robust metal shielding to match the cable’s construction.

These connector types support higher category shielded cables, such as Cat 6A and above, where EMI protection becomes critical.

| Feature | Shielded RJ45 Connector | Unshielded RJ45 Connector |

|---|---|---|

| Housing Material | Metal shield (nickel or brass-plated) | Plastic housing (usually transparent) |

| Purpose | Protects against EMI and RFI, reduces crosstalk | Designed for environments with minimal interference |

| Internal Protection | Metal shield acts as a physical barrier for copper wires | No metal shielding, relies on cable only |

| Grounding Requirement | Requires proper grounding, includes ground collar | No grounding required |

| Cable Compatibility | Paired with shielded cables | Used with unshielded cables |

| Installation Complexity | More complex, requires careful termination steps | Simpler installation |

| Cost | More expensive due to materials and manufacturing complexity | Less expensive |

How Shielded Connectors Mitigate EMI

Blocking External Interference

You rely on shielded RJ45 connectors to block external EMI. The metal shielding in these connectors acts as a barrier, preventing electromagnetic waves from reaching the copper conductors inside. When you install shielded cables and connectors together, the shielding forms a continuous path that diverts unwanted signals away from your data lines. Proper grounding of the connector shielding is essential. This process allows the shield to safely discharge interference, keeping your network stable even in environments with heavy electrical noise.

Reducing Crosstalk and Noise

Shielded connectors also reduce crosstalk and internal noise. Crosstalk occurs when signals from one pair of wires interfere with another pair. The metal shielding in shielded RJ45 connectors, combined with foil or braided shields in shielded cables, isolates each pair and minimizes signal bleed. You benefit from cleaner data transmission and fewer errors, especially in dense cable installations or high-frequency applications. Controlled tests show that shielded connectors and shielded cables maintain signal quality and data rates, even when exposed to strong EMI sources.

Tip: Always use shielded connectors with shielded cables for maximum EMI protection. Proper termination and grounding are critical for effective shielding.

Unshielded Connectors in Low-EMI Environments

Appropriate Use Cases

You can use unshielded RJ45 connectors in environments with minimal EMI. These connectors feature plastic housings and lack metal shielding. They work well in residential networks, administrative offices, and guest rooms where electrical noise is low. Unshielded connectors offer a cost-effective and simple installation process. You do not need to worry about grounding or complex termination steps.

Limitations in High-EMI Settings

Unshielded connectors have clear limitations in high-EMI environments. Without metal shielding, these connectors cannot block external interference. You risk data loss, slower speeds, and frequent network errors if you use unshielded connectors with unshielded cables near industrial machinery or power lines. Industry guidelines recommend shielded RJ45 connectors and shielded cables for any setting with significant EMI. You should avoid unshielded connectors in factories, data centers, or areas with dense cabling and high-frequency signals.

Benefits of Shielded RJ45 Connectors for Electromagnetic Interference Mitigation

Enhanced Signal Integrity

Stable Data Transmission

You need stable data transmission in environments with high EMI. Shielded RJ45 connectors deliver this stability by combining robust shielding with advanced internal components. Many shielded connectors now feature integrated magnetics, such as transformers and chokes, which isolate signals and suppress unwanted interference. This design maintains signal integrity by reducing insertion loss and increasing the common-mode rejection ratio. You benefit from reliable communication, even when electrical noise surrounds your network. The shielding also prevents data loss and corruption, ensuring your network operates at peak performance. When you install shielded connectors with proper grounding, you create a continuous barrier that keeps your signal quality high and your network secure.

Support for High Bandwidth

You demand high-speed signals and large data volumes in modern industrial and data center networks. Shielded RJ45 connectors support these requirements by enabling higher bandwidth and faster data rates. For example:

- Shielded Cat6a cables with shielded connectors support up to 500 MHz bandwidth and 10 Gbps speeds over 100 meters.

- Unshielded Cat6 cables typically reach only 250 MHz and may limit 10 Gbps operation to 50 meters.

- Shielded connectors minimize crosstalk and external interference, which is critical for maintaining high-speed data transmission in dense or noisy environments.

You achieve consistent performance and future-proof your network for demanding applications by choosing shielded connectors.

Reduced Crosstalk and Noise

Performance in Dense Installations

Dense network installations, such as data centers and industrial control rooms, present unique challenges. You often run multiple cables in close proximity, which increases the risk of crosstalk and signal degradation. Shielded RJ45 connectors, when paired with shielded cabling, drastically reduce these risks. The shielding acts as a physical barrier, blocking both internal and external sources of noise. You maintain clear, reliable data transmission, even when cables are bundled tightly together. This noise suppression ensures your network remains robust and efficient.

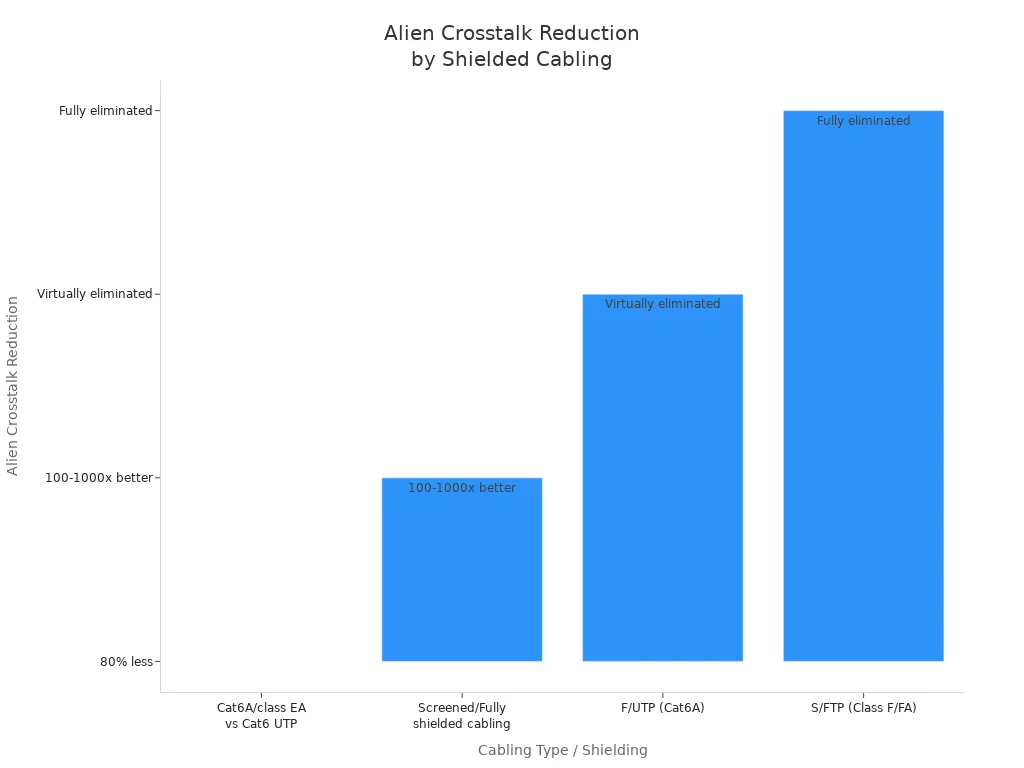

Alien Crosstalk Protection

Alien crosstalk occurs when signals from adjacent cables interfere with each other, leading to errors and reduced throughput. Shielded connectors provide exceptional protection against this phenomenon. The following table highlights the quantified reduction in alien crosstalk when you use shielded cabling systems:

| Aspect | Quantified Reduction / Description |

|---|---|

| Cat6A/class EA cabling vs Cat6 UTP | 80% less alien crosstalk voltage |

| Screened/Fully shielded cabling immunity | 100 to 1000 times better protection from electric field disturbances compared to UTP |

| Alien crosstalk with F/UTP (Cat6A) | Virtually eliminated |

| Alien crosstalk with S/FTP (Class F/FA) | Fully eliminated |

| Shield continuity and grounding | Essential to maintain low impedance path and achieve reductions |

| Effect of shielded RJ45 connectors | Included as part of shielded cabling system, contributing to near zero alien crosstalk |

You see that shielded RJ45 connectors, as part of a properly grounded shielded system, can reduce alien crosstalk by up to 80% compared to unshielded Cat6 and provide up to 1000 times better immunity to electric field interference. This level of protection is essential for maintaining high network performance in environments with dense cabling.

Compliance with EMC Standards

Regulatory Requirements

You must comply with strict electromagnetic compatibility (EMC) standards in industrial Ethernet cabling. These standards, set by organizations such as CISPR, IEC, EN, and FCC, define emission limits and immunity requirements for electrical devices. Shielded RJ45 connectors help you meet these requirements by using multi-layer metal shields and integrated magnetics to reduce EMI and noise. EMC compliance testing involves emission, susceptibility, immunity, and coupling tests. You ensure your network devices emit below specified limits and withstand external EMI by selecting shielded connectors that pass these rigorous tests.

- IEC 61000-4-2 specifies test methods for electrostatic discharge (ESD) immunity.

- ANSI/TIA-1005-A and ISO/IEC 11801-3 address industrial Ethernet cabling, using the MICE classification to guide component selection based on environmental severity.

- CISPR 11, CISPR 22/32, and EN 55032 cover emissions for industrial and multimedia equipment.

You protect your network from regulatory penalties and operational disruptions by ensuring compliance with these standards.

Avoiding Network Failures

Network failures can result from poor EMI protection or inadequate ESD protection. Shielded connectors, when installed with continuous shielding and proper grounding, provide a robust defense against both EMI and ESD. You reduce the risk of electrostatic discharge events that can damage sensitive electronics and disrupt data transmission. The latest IEC 61000-4-2 standard introduces enhanced calibration and measurement procedures, ensuring that shielded RJ45 connectors meet the highest levels of ESD protection. You maintain network uptime and reliability by choosing connectors that pass these updated tests.

Tip: Always verify that your shielded connectors and cabling meet the latest EMC and ESD standards for your region and application.

Choosing Shielded Connectors for Industrial Ethernet Cabling

Assessing Environmental EMI Levels

Identifying EMI Sources

You must identify the sources of electromagnetic interference before selecting shielded connectors for your industrial ethernet cabling. Common EMI sources include heavy machinery, power lines, radio transmitters, and even fluorescent lighting. These elements can disrupt data transmission in shielded cables and ethernet cables. You should walk through your facility and note areas with high electrical activity or dense equipment clusters. This assessment helps you determine where shielded RJ45 connectors are necessary to maintain network reliability.

Evaluating Network Demands

You need to evaluate your network’s demands based on the type of data transmitted and the required bandwidth. Industrial ethernet cabling often supports automation systems, sensors, and high-speed data links. If your network handles large data volumes or operates in harsh conditions, you should prioritize shielded connectors and shielded cables. High-frequency applications and critical control systems demand robust EMI protection to prevent downtime and data loss.

Cable Compatibility and Connector Selection

Matching Shielded Connectors to Shielded Cables

Cable compatibility plays a crucial role in selecting shielded RJ45 connectors. You must match shielded connectors to shielded cables to preserve the shielding effectiveness. The metal connector acts as an extension of the shielded cable, providing grounding and continuous EMI protection. Using shielded connectors on unshielded cables leads to improper fitment and poor performance. Unshielded connectors on shielded cables break the shielding continuity, leaving your network vulnerable to interference. You should check the cable’s outside diameter, conductor insulation, copper gauge, and conductor type to ensure the connector fits and functions correctly. This compatibility guarantees reliable data transmission in environments with high EMI.

Connector Types and Pinouts

You encounter several types of shielded RJ45 connectors designed for different shielded cables. Each connector type supports specific pinouts and cable constructions. For example, FTP connectors pair with foiled twisted pair shielded cables, while STP connectors match shielded twisted pair cables. You must verify the pinout configuration to ensure proper signal mapping and grounding. Always consult manufacturer specifications for shielded ethernet cable and connector compatibility.

Tip: Use a checklist to confirm cable and connector compatibility before installation. This step prevents costly errors and network failures.

Cost and Value Considerations

Balancing Performance and Budget

You face a choice between shielded and unshielded RJ45 connectors based on your budget and performance needs. Shielded connectors cost more due to their metal housing and grounding features, but they deliver superior EMI protection and signal integrity. Unshielded connectors offer a lower price and suit environments with minimal interference. The table below compares key features:

| Feature | Shielded RJ45 Connectors | Unshielded RJ45 Connectors |

|---|---|---|

| EMI/RFI Protection | High (due to metal shielding and grounding) | Low (plastic, no shielding) |

| External Housing | Metal shielded | Full plastic |

| Signal Integrity in Harsh Environments | Excellent | Basic |

| Cost | Higher (premium price justified by enhanced performance) | Lower (more cost-effective) |

| Grounding Required | Yes | No |

| Typical Use Cases | Industrial applications, PoE switches, medical, telecom | Consumer electronics, home gateways |

Market analysis shows that shielded connectors command a premium price, justified by their enhanced performance in industrial settings. You should weigh the long-term benefits against initial costs when planning your network.

Long-Term Reliability

You gain long-term reliability by investing in shielded connectors and shielded cables for industrial ethernet cabling. Shielded systems resist EMI and maintain stable data transmission over time. You reduce maintenance costs and avoid unexpected downtime. This reliability supports critical operations and future-proofs your network against evolving EMI challenges.

Installation and Grounding of Shielded RJ45 Connectors

Best Practices for Installation

Ensuring Shield Continuity

You achieve maximum EMI mitigation by maintaining shield continuity throughout your installation. Start by using the right tools, such as a cable stripper, crimper, and scissors. Strip 1-2 inches of the cable jacket with care, making sure you do not damage the shielded wires underneath. Untwist and straighten the wires according to T568A or T568B standards. Trim the wires evenly so they fit the RJ45 connector. Insert the wires fully into the connector, keeping the clip facing down. Crimp the connector firmly to ensure reliable contact. Always fold back the cable shield so it touches the connector’s metal body, creating a low-impedance path for EMI to ground.

Avoiding Common Installation Errors

You must avoid several common mistakes that compromise shielded protection. Improper grounding and shield termination, such as failing to connect drain wires to the connector shell, can cause ground loops and increase noise. Excessive untwisting of cable pairs increases crosstalk and noise. Poor strain relief allows cable movement, risking breaks or intermittent faults. Connector pin misalignment and improper crimping pressure result in high-resistance connections, which degrade EMI performance. Always check that the cable shield mates fully and circumferentially with the connector shell. Avoid pigtail connections, as they can turn the shield into an antenna and reduce effectiveness.

Tip: Use high-quality shielded connectors and verify that all mating surfaces provide full conductive contact for optimal EMI and ESD protection.

Grounding for Maximum Electromagnetic Interference Mitigation

Importance of Proper Grounding

You need proper grounding to maximize EMI and ESD protection. The shielded enclosure of the RJ45 connector should connect directly to chassis or earth ground, not just system ground. This connection allows the shield to direct electrostatic discharge pulses safely away from sensitive electronics. Any break or disruption in the grounding path increases impedance and reduces shielding effectiveness.

Step-by-Step Grounding Guide

Follow these steps for effective grounding:

- Connect the RJ45 connector shield on the main control board to DC ground.

- Link the main control board to earth ground to prevent floating shields.

- Ground the metal shielded cans around RJ45 connectors on the controller board side.

- Use shielded Ethernet cables for consistent EMI mitigation.

- Shorten DC power cords and add shielding, connecting this shielding to earth ground.

- Install ferrite cores on each lead of the DC power cord near the main board.

These steps prevent the shield from acting as an antenna and improve ESD protection by directing pulses to earth ground.

Testing and Verification

Checking Shield Integrity

You ensure shield integrity by fully inserting each wire into its designated channel in the RJ45 connector. Use a crimping tool to press the contacts into the wires, securing a solid electrical connection. Visually inspect the connector after crimping to confirm all wires are visible at the front and the cable jacket is inside the connector for strain relief.

Troubleshooting EMI Issues

Test the cable using a network cable tester to check for continuity, shorts, opens, and miswires. Connect one end of the cable to the tester’s main unit and the other end to the remote unit or network device. Interpret the results carefully, looking for proper continuity and correct wiring order. If you detect faults, re-terminate or replace the cable. Document your test results for future maintenance. These steps help you maintain effective shielded protection and prevent EMI-related network failures.

When to Use Shielded RJ45 Connectors in Industrial Ethernet Cabling

High-EMI Industrial Environments

Factories and Manufacturing Plants

You operate in factories and manufacturing plants where motors, power systems, and control equipment generate substantial electromagnetic noise. These high-interference environments demand robust protection for your network. Shielded RJ45 connectors play a critical role here. They prevent data corruption and production losses by maintaining signal integrity even when surrounded by heavy machinery. Case studies highlight that industrial automation systems, robotic assembly lines, and process control networks rely on shielded connectors to avoid costly downtime.

- Medical equipment rooms

- Aerospace and defense facilities

- Telecommunications hubs

- Oil and gas processing plants

- Rail and mass transit systems

These settings require shielded RJ45 connectors with 360-degree shield termination to ensure reliable performance.

Medical Facilities and Laboratories

You manage sensitive diagnostic imaging and patient monitoring systems in medical facilities and laboratories. These environments require exceptional EMI shielding to protect patient data and ensure accurate readings. Shielded RJ45 connectors provide the necessary protection, preventing interference from nearby electronic devices and laboratory equipment. You maintain compliance with strict safety standards and reduce the risk of data loss or equipment malfunction.

Dense Network Installations

Data Centers and Server Rooms

You oversee dense network installations in data centers and server rooms. Here, you encounter high cable density and elevated EMI levels. Shielded RJ45 connectors maintain cable shielding and proper grounding, which reduces electromagnetic interference and crosstalk. When you install and ground these connectors correctly, you can reduce EMI-induced bit errors by up to 63%. This improvement is critical for maintaining high-speed data transmission, reducing packet loss, and ensuring low latency.

| Feature | Benefit/Description |

|---|---|

| Shielded RJ45 Construction | Reduces EMI/RFI interference for stable network connections |

| Gold-Plated Contacts | Prevents oxidation, maintains stable contact resistance |

| Industrial-Grade Durability | Withstands rugged environments, suitable for data centers |

You benefit from reliable, secure connections that support demanding applications.

Office Buildings with Extensive Cabling

You manage office buildings with extensive cabling, where network cables run close together in trays and conduits. Shielded RJ45 connectors help you minimize crosstalk and maintain network performance, especially in areas with high device density. You ensure stable connections for VoIP, video conferencing, and high-speed internet access throughout the building.

Outdoor and Harsh Conditions

External Installations

You face unique challenges when deploying networks outdoors or in harsh industrial settings. You must select shielded RJ45 connectors with durable, corrosion-resistant housings made from materials like ABS or nylon. Gold-plated contacts enhance conductivity and reduce signal loss. Waterproofing is essential, so you should look for connectors rated at IP67 or higher to protect against dust and water ingress. Features such as silicon rubber grommets and strain relief improve mechanical robustness and maintain a tight seal.

Areas Prone to Electrical Storms

You install network infrastructure in areas prone to electrical storms or extreme weather. Shielded RJ45 connectors with proper grounding and environmental sealing protect your network from surges, moisture, and temperature fluctuations. You should choose connectors with 360-degree shielding and low-impedance grounding paths to maintain signal integrity. Compliance with standards like MIL-STD-810G and ATEX/IECEx ensures durability and safety in hazardous conditions.

Tip: Always match your connector choice to the specific environmental and operational demands of your installation. This approach ensures long-term reliability and optimal network performance.

Quick Tips for Selecting and Maintaining Shielded Connectors

Checklist for Choosing Shielded RJ45 Connectors

Key Questions to Ask

When you select shielded RJ45 connectors for your network, you need a clear checklist to guide your decision. Consider these essential questions:

- What type of shielding does your environment require? Assess if you need UTP, STP, FTP, or S/FTP based on the expected electromagnetic interference.

- Are your connectors and cables compatible with your current network equipment? Plan for future upgrades to avoid compatibility issues.

- Does the cable jacket offer enough protection against environmental hazards such as moisture or chemicals?

- Do the connectors and cables meet industry standards and certifications for performance and safety?

- Do the connectors include integrated magnetics for EMI and ESD protection? These features block noise and provide electrical isolation.

- Are you using proper termination and crimping techniques? High-quality connectors with gold-plated contacts help maintain signal integrity.

- Do you regularly inspect and test your cables and connectors for damage or continuity issues?

- Are you choosing solid copper conductors instead of copper-clad aluminum for better conductivity and EMI resistance?

- Have you planned your cable lengths and management to reduce interference and support future network growth?

Tip: Always match your connector and cable choice to the installation environment and proximity to EMI sources.

Common Pitfalls to Avoid

You can prevent many network issues by steering clear of these common mistakes:

- Using unshielded connectors in high-EMI environments

- Failing to verify cable and connector compatibility

- Overlooking the importance of industry certifications

- Choosing copper-clad aluminum cables instead of solid copper

- Skipping regular inspections and maintenance

- Ignoring proper grounding and termination practices

A careful approach at the selection stage saves you from costly troubleshooting later.

Maintenance and Upgrades

Keeping Your Network EMI-Proof

You maintain strong EMI protection by following a few best practices:

- Inspect RJ45 connectors and cables regularly for wear, damage, or loose connections.

- Clean connectors and ports with compressed air or a soft cloth to remove dust and debris.

- Replace cables that show signs of cuts, fraying, or physical damage.

- Use proper cable management, such as trays and labels, to prevent sharp bends and simplify troubleshooting.

- Avoid routing Ethernet cables near electrical wires or known EMI sources. Maintain at least 12 inches of separation.

- Ground shielded cables at both ends to ensure a low-impedance path and prevent the shield from radiating noise.

Note: Proper grounding at both ends is essential for effective EMI mitigation.

When to Reevaluate Your Connector Choice

You should reassess your connector selection when:

- You upgrade network equipment or increase bandwidth requirements

- You notice frequent network errors or unexplained downtime

- Your facility layout changes, introducing new EMI sources

- Industry standards or compliance requirements update

Regular reviews help you keep your network resilient and ready for future demands. By staying proactive, you ensure your shielded RJ45 connectors continue to deliver reliable EMI protection and network performance.

You secure reliable network performance in high-EMI environments when you choose shielded rj45 connectors. Careful selection, correct installation, and regular maintenance help you achieve stable data transmission and minimize downtime.

Investing in shielded rj45 connectors gives your industrial ethernet cabling the resilience it needs to handle future EMI challenges. You protect your network and ensure long-term value.

FAQ

What is the main difference between shielded and unshielded RJ45 connectors?

Shielded RJ45 connectors use a metal shell to block electromagnetic interference. Unshielded connectors use only plastic. You should choose shielded connectors for high-EMI environments to protect your data and maintain network reliability.

When should you use shielded RJ45 connectors?

You should use shielded RJ45 connectors in factories, data centers, medical facilities, or any area with heavy electrical equipment. These environments generate high EMI, which can disrupt your network if you use unshielded connectors.

Do you need to ground shielded RJ45 connectors?

Yes, you must ground shielded RJ45 connectors. Proper grounding ensures the shield diverts unwanted interference away from your data lines. Without grounding, the shield cannot protect your network from EMI.

Can you mix shielded connectors with unshielded cables?

You should not mix shielded connectors with unshielded cables. This combination breaks the shielding path and leaves your network vulnerable to interference. Always match shielded connectors with shielded cables for full EMI protection.

How do you test if your shielded connection works?

You can use a network cable tester to check continuity and shield integrity. Inspect the connector visually for proper termination. If you notice frequent errors or slow speeds, retest and verify your installation.

Are shielded RJ45 connectors more expensive?

Shielded RJ45 connectors cost more than unshielded ones. You pay for the added metal shielding and grounding features. However, you gain long-term reliability and better performance in high-EMI environments.