I.Core Value and Design Evolution of Industrial Connector Anti-Misinsertion Technology

In critical sectors such as industrial automation, energy power, and medical equipment, connector misinsertion can lead to system paralysis, equipment damage, or even safety incidents. For example, misinsertion faults on oil drilling platforms once reached 1200 ppm (failures per million operations). Advanced stepped foolproof structures reduce failure rates to below 85 ppm while increasing Mean Time Between Failures (MTBF) to 250,000 hours. Foolproof design has evolved from early mechanical keyway solutions (±1 mm tolerance) to today’s intelligent magnetic guidance systems (±0.05 mm precision). The core goal is to achieve “zero-tolerance” connections in high-density wiring scenarios, ensuring absolute reliability in power and signal transmission.

II. Key Technology Analysis: Six Foolproof Solutions and Performance Comparisons

1. Stepped Foolproof Structure: Precision Geometric Locking

- Principle: Multi-level radial steps (typically ≥2 levels) are designed on mating surfaces. Plug steps increase incrementally (1.5–6.0 mm), while socket steps decrease (0.8–2.5 mm). Physical engagement occurs only when the n-th plug dimension exceeds the (n-1)-th socket dimension.

- Performance:

- Foolproof combinations: 36 types (dual-locating pin design)

- Radial tolerance: ±0.05 mm (ceramic-reinforced nylon guide posts)

- Mating cycles: 5,000 (nickel-plated 2μm + gold-plated 0.2μm contacts)

- Case study: Offshore wind maintenance systems saw misinsertion accidents reduced by 73%.

2. Self-Locking Connectors: Dual Protection in Vibration Environments

- Triple-Safeguard Design:

- Guide mechanism: Aluminum alloy guide plate compensates for ±0.3 mm deviation.

- Alignment correction: Beryllium copper correction bracket limits contact offset to <0.5°.

- Locking mechanism: Spring slider provides 45N retention force; contact resistance fluctuation <0.2mΩ under vibration.

- Validation: Signal error rate in high-speed rail systems dropped from 10⁻⁶ to 10⁻⁹.

3. Magnetic Foolproof Technology: Non-Contact Active Protection

- Magnetic Pole Configuration:ComponentPole ArrangementFunctionPlugLeft N-pole, Right S-poleGenerates directional fieldSocketLeft S-pole, Right N-poleCorrect mating: Attraction >3NErrorSame poles (e.g., N-N)Repulsion >5N blocks insertion

- Hybrid Solution: NdFeB magnets + electromagnetic coils reduce standby power to 0.1W and cut magnetic interference by 50%.

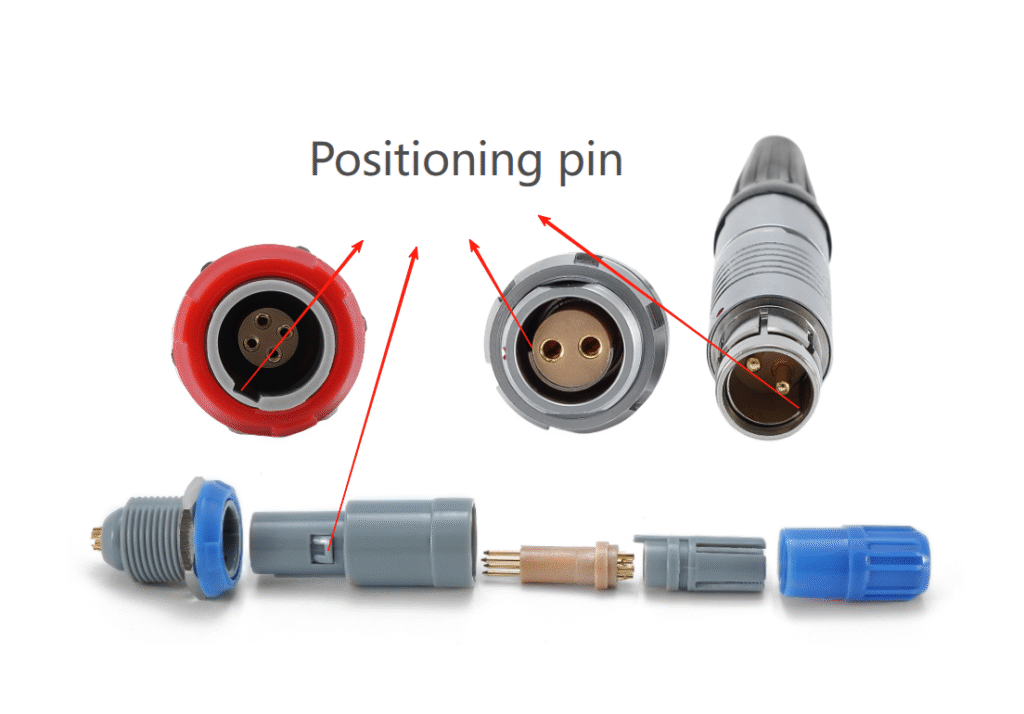

4. Quick-Lock Components: Miniaturization and High-Density Integration

- Micro-Positioning Pin Tech:

- Hexagonal pins (1.2 mm side length) with sleeve fit (±0.01 mm tolerance).

- Countersunk screws + thread adhesive reduce size by 40%.

- Supports 20A current + 56Gbps signal transmission.

5. Spring Pin Contact System: Vibration Resistance and Longevity

- Advantages:

- Multi-point contact: 12 independent springs maintain pathways even if one fails.

- Self-cleaning coating: 0.5μm hard gold layer reduces friction to 0.18.

- Mating cycles: 100,000 (military standard MIL-DTL-38999).

6. Arc Protection Integration: High-Voltage Safety

- Arc-Quenching Design:

- Ceramic gas discharge tube response: 0.3 ms.

- Transient current handling: 50kA@1500V.

- Complies with ISO 6469-3 EV safety standards.

III. Industry Applications and Performance Validation

1. Energy Power Systems

- Challenge: Internal arc temperatures in substation switchgear reach 15,000°C.

- Solution: Stepped foolproof + pressure relief channels withstand arcing >0.5s (GB3906 standard).

2. Rail Transit Equipment

- Challenge: 5–200Hz vibration causes 35% contact resistance fluctuation.

- Solution: Self-locking connectors + silicone damping gel cut vibration transmission to 0.05.

3. Medical Electronics

- Challenge: Surgical robots require 10A current in 2mm spacing.

- Solution: Quick-lock components + silver-copper solder limit interface resistance to ≤0.8μΩ·cm².

IV. Future Trends: Smartization and Material Innovation

- AI Predictive Maintenance: Integrated impedance monitoring chips (0.1mΩ precision) alert to contact wear.

- Nano-Composites: Graphene-enhanced LCP insulators achieve CTI >600V and withstand 230°C.

- Magnetic Adaptive Systems: Electromagnetic coils adjust force (0.5–5N) for multi-model compatibility.

Zhongxiang Electronic Technology: Custom Foolproof Connector Solutions

As an IATF 16949-certified industrial connector customization expert, Zhongxiang Electronic Technology Co., Ltd. offers:

- Rapid Prototyping: 96-hour foolproof structure sample delivery; supports -65°C~200°C materials.

- Harsh-Environment Validation: 20G vibration tables + IP69K test chambers ensure MIL-STD-810H compliance.

- Arc Protection Integration: Built-in ceramic discharge tubes (<0.5ms response) for 800V systems.

- Global Compliance: Meets REACH, RoHS 3.0 & UL1977; monthly capacity: 2 million sets.Request solutions: www.zx-connector.com info@pushpull-connector.com

References

- IEC 60512-27-100:2024 High-Frequency Connector Testing

- GB/T 20234-2023 EV Charging Interface Standards

- MIL-STD-1344 Salt Spray & Shock Testing

- IPC-620D Cable Assembly Specifications

- High-Voltage Switchgear Arcing Protection Whitepaper(State Grid, 2025)

FAQ

Q1: How many step levels are optimal for foolproof structures?

Three-step design recommended:

- Level 1: ±0.1mm (coarse guidance)

- Level 2: ±0.05mm (precision alignment)

- Level 3: ±0.02mm (final lock); enables 72 foolproof combinations.

Q2: Do magnetic designs interfere with signals?

Shielded samarium-cobalt magnets (<5μT leakage) stay below USB 3.0 noise thresholds (100μT).

Q3: Can quick-lock connectors endure high-frequency vibration?

Spring pin systems pass EIA-364-28: Contact resistance fluctuation <5mΩ at 10–2000Hz/15Grms.

Q4: How to validate arc protection?

Per ISO 6469-3: Arc duration <3ms at 50kA transient current; housing temperature rise <70K.

Q5: What cost impact do foolproof designs have?

Stepped structures add ~8% cost but reduce maintenance expenses by 37% (less downtime).