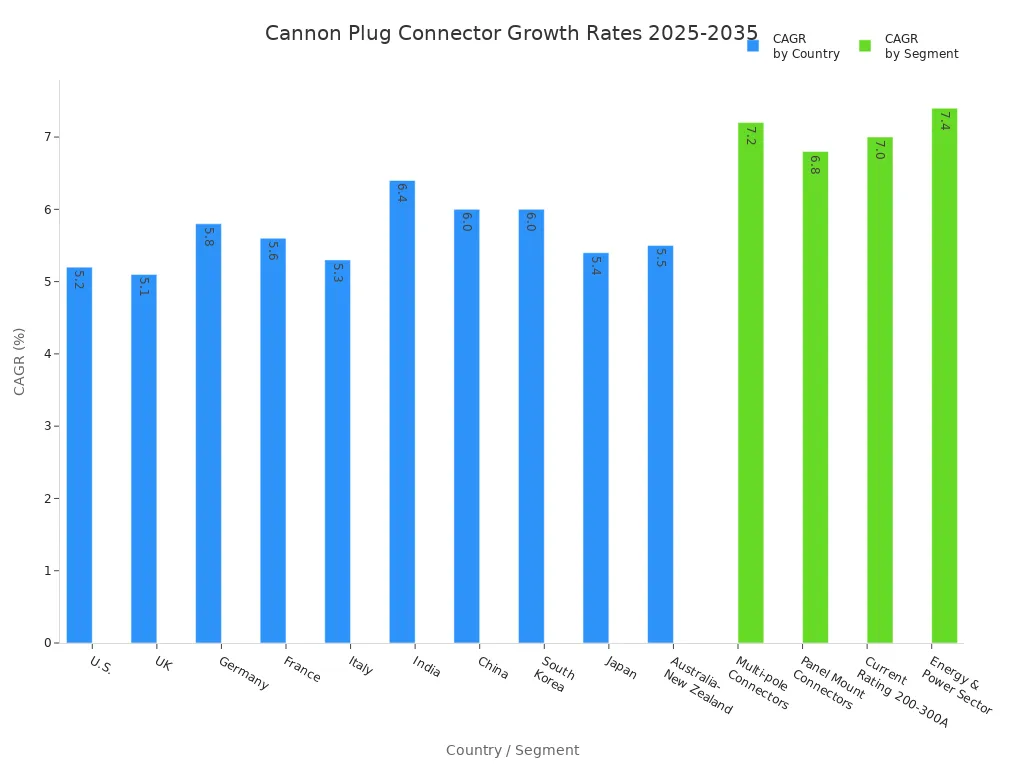

Cannon plug connectors have transformed industrial systems in 2025. The market reached USD 5.47 billion with a 6.1% CAGR projected over the next decade. Advances in cannon technology include silver-plated contacts for conductivity, durable stainless steel, and composite materials that withstand harsh conditions. Miniaturization, like the M8 connector and Type B connector, supports compact equipment. Connector factory innovations deliver eco-friendly designs and smart features. The chart below shows global growth rates for cannon plug connectors:

| Metric / Segment | Data / Projection |

|---|---|

| Overall Market CAGR (2025) | 6.1% CAGR from 2025 to 2035 |

| Market Revenue 2025 | USD 5.47 billion |

| Multi-pole Connectors CAGR | 7.2% CAGR (2025-2035) |

Professionals and decision-makers should recognize these changes to maintain reliability and efficiency in evolving industries.

The Evolution of Cannon Plug Connectors

From Military Origins to Industrial Standard

Early Development and Adoption

Cannon plug connectors trace their roots to the 1930s, when engineers at Cannon developed the first versions for military aircraft. The DC-1 Aircraft project required reliable, rugged connectors that could withstand the harsh conditions of flight. The initial specification, AN9534, appeared in 1939 and quickly gained approval from the US Army, Navy, and Air Force. These connectors set a new standard for durability and performance in extreme environments. The military needed solutions that could handle vibration, moisture, and temperature fluctuations. Cannon responded with robust circular designs that became the backbone of military aviation and ground equipment.

Transition to Civilian and Industrial Use

After World War II, the demand for high-performance connectors expanded beyond the military. Industrial sectors recognized the value of these rugged components. Power generators, off-road vehicles, and earth-moving machinery began to use cannon plug connectors for their proven reliability. The MIL-C-5015 connector, later renamed MIL-DTL-5015 and eventually SAE-AS5015, became a staple in heavy-duty circular connectors for both military and civilian applications. Over time, these connectors evolved to meet the needs of diverse industries, including energy, transportation, and manufacturing. The transition from exclusive military use to industrial standard marked a significant shift in the connector landscape.

Key Milestones in Connector Technology

Standardization and Global Expansion

The evolution of connector technology saw several pivotal moments. In 1952, Cannon engineers introduced the D-Subminiature connector, or d-sub, to address the need for smaller, high-performance connectors in commercial and military aircraft radio systems. The d-sub connector, patented in 1957, broke away from traditional forms and offered a compact, versatile solution. This innovation led to the widespread adoption of multi-contact electrical connectors across various industries. The d-sub and its variants found their way into consumer electronics, medical devices, and industrial automation. The global expansion of these connectors established new benchmarks for reliability and adaptability.

Major Design Improvements Over Decades

Cannon consistently improved its connector designs to address evolving industry requirements. The table below highlights key design advancements across major series:

| Series | Coupling Mechanism | Key Design Improvements | Effectiveness Evidence |

|---|---|---|---|

| Series I | Bayonet coupling with three-point locking | Quick connect/disconnect, good environmental protection, high contact density | Widely used in military and aerospace applications, reliable in harsh environments |

| Series II | Bayonet coupling with enhanced features | Improved vibration resistance, better environmental sealing, five-key/keyway system to prevent misalignment, smaller form factor | Enhanced performance in vibration and sealing, preventing misalignment reduces connection errors |

| Series III | Threaded coupling | Secure connection with superior vibration resistance, highest contact density, superior environmental sealing against moisture, dust, contaminants | Preferred for critical applications requiring maximum reliability and environmental protection, adopted extensively in military and aerospace sectors |

Cannon’s innovations in coupling mechanisms, environmental sealing, and contact density set new standards for heavy-duty circular connectors. The m-1 and cannon dbm-25p connector series further expanded the range of options for specialized applications. These improvements ensured that cannon plug connectors remained at the forefront of reliability and performance, even as industries demanded more compact and customizable solutions.

Note: The evolution of cannon plug connectors demonstrates how military-driven innovation can shape industrial standards. Today, these connectors serve as critical components in sectors that require robust, high-performance connectivity.

Technological Advancements Shaping 2025

Materials and Durability Innovations

High-Performance Alloys and Composites

Manufacturers have introduced advanced materials to meet the demands of modern industrial environments. Corrosion-resistant alloys and reinforced thermoplastics now form the backbone of many cannon plug connectors. These materials provide lightweight yet durable solutions, supporting the trend toward miniaturization without sacrificing strength. The heavy-duty connector market in 2025 reflects a strong preference for alloys that withstand high temperatures and chemical exposure. Companies such as Molex and Amphenol have developed rugged circular connectors for aerospace, military, and outdoor applications, ensuring reliable interconnect performance in the harshest conditions.

| Technological Advancement | Description |

|---|---|

| New Materials | Corrosion-resistant alloys and reinforced thermoplastics improve durability and performance. |

| High Ingress Protection (IP69K) | Over 35% of new connectors achieve IP69K rating, resisting dust, water, and high-pressure cleaning. |

| Modular and Hybrid Designs | Modular connectors combine power and data, reducing installation time by up to 25%. |

Enhanced Environmental Resistance

Cannon plug connectors now offer superior resistance to dust, moisture, and extreme temperatures. More than one-third of new models feature IP69K ingress protection, making them suitable for high-pressure cleaning and outdoor use. These advancements address the needs of industries such as automotive, renewable energy, and industrial automation, where connectors must perform reliably under constant stress. The integration of high-performance alloys and advanced sealing techniques ensures that circular interconnect solutions remain operational in challenging environments.

Digital Integration and Smart Features

Embedded Sensors and Diagnostics

The rise of Industry 4.0 has driven the adoption of smart connectors with embedded sensors. These sensors enable real-time condition monitoring and predictive maintenance, reducing unexpected downtime. At least 15 manufacturers now offer connectors with built-in diagnostics, supporting the shift toward intelligent interconnect systems. This innovation allows operators to detect wear, temperature changes, and electrical faults before they impact system performance.

Data Transmission Capabilities

Modern cannon connectors support high-speed data transmission alongside traditional power delivery. Hybrid designs combine power and data lines in a single interconnect, streamlining installation and improving efficiency. TE Connectivity, for example, has launched connectors capable of handling up to 300 A for electric vehicle charging and renewable energy systems. These advancements meet the growing need for reliable, high-bandwidth connections in smart manufacturing and transportation.

Miniaturization and Customization

Compact Designs for Modern Equipment

The demand for smaller, high-density connectors continues to grow. Miniaturized cannon plug connectors now serve critical roles in robotics, medical devices, and telecommunications. Lightweight metal alloys and high-temperature polymers enable compact designs that fit into tight spaces without compromising durability. Board-to-board and wire-to-board interconnect solutions support higher integration and reliability in modern equipment.

Industry-Specific Adaptations

Customization has become a key differentiator in the connector market. Manufacturers tailor connector designs, materials, and connection techniques to meet the unique requirements of sectors such as aerospace, pharmaceuticals, and industrial automation. Specialized treatments, including antioxidant and waterproof coatings, enhance durability. Compliance with regulations like RoHS and REACH drives innovation in eco-friendly materials and sustainable manufacturing. Leading companies invest in R&D to ensure their circular interconnect products meet evolving industry standards and support real-time monitoring, predictive maintenance, and operational efficiency.

Impact of Cannon Plug Connectors on Industrial Systems

Reliability and Safety Enhancements

Fail-Safe Mechanisms

Cannon plug connectors play a critical role in ensuring the reliability of industrial systems. Engineers design these interconnect solutions with robust fail-safe mechanisms that prevent accidental disconnection and signal loss. Circular connector designs often feature bayonet or threaded coupling systems, which maintain secure connections even under intense vibration or shock. These mechanical features help prevent system failures in demanding environments such as railways, aerospace, and heavy manufacturing.

Manufacturers use advanced contact retention systems, often rated for thousands of mating cycles. Gold or silver plating on contacts minimizes corrosion and maintains low resistance, supporting consistent electrical performance. Many connectors include safety interlocks and arc suppression features, which protect both equipment and personnel during operation. These enhancements reduce the risk of electrical faults and contribute to the overall safety of industrial applications.

Note: EMI shielding is essential in environments with high electrical noise, such as those with traction drives or overhead cables. This shielding preserves signal integrity and prevents data loss, further supporting system reliability.

Compliance with Modern Standards

Modern cannon plug connectors must meet strict industry standards to guarantee safety and performance. These standards address mechanical, environmental, and electrical requirements. Key standards include:

- EN 50155 and EN 45545-2 for rail applications, ensuring resistance to shock, vibration, fire, and temperature extremes.

- MIL-DTL-5015 and VG 95234 for military and defense, covering durability and environmental resilience.

- RoHS and REACH compliance, which restrict hazardous substances and promote eco-friendly manufacturing.

- IEC 61373 for shock and vibration, especially in high-voltage and high-current interconnect systems.

- AS9100 and SAE Aerospace Standards for aerospace quality management.

Connectors that comply with these standards offer enhanced safety, reliability, and longevity. Manufacturers also emphasize rigorous testing and documentation to meet certification requirements. These practices ensure that each connector performs reliably in harsh conditions, whether in rail, aerospace, or industrial automation.

Efficiency and Maintenance Benefits

Quick-Connect/Disconnect Features

Cannon plug connectors improve efficiency in industrial settings through user-friendly quick-connect and disconnect features. Bayonet coupling mechanisms allow technicians to install or remove connectors with a simple push and twist motion. This process requires only a one-third turn of the coupling ring, making it fast and convenient for frequent mating and unmating.

Technicians benefit from multiple confirmation methods—visual, audible, and tactile—that verify correct alignment and secure mating. Inspection holes on the coupling ring provide a clear view of the locking mechanism, allowing for rapid maintenance checks. These features reduce the likelihood of connection errors and minimize the time needed for routine inspections.

- Quick-connect designs support blind mating, which is valuable in confined or hard-to-reach spaces.

- Rugged construction ensures that connectors withstand shock and vibration, reducing the need for frequent repairs.

Reduced Downtime and Lifecycle Costs

Efficient maintenance directly impacts operational uptime and cost savings. Cannon plug connectors, especially those with modular and hybrid designs, simplify installation and replacement. Modular interconnect solutions combine power and data in a single unit, reducing installation time by up to 25%. This integration streamlines system architecture and minimizes the number of components that require maintenance.

Proper installation and routine cleaning extend the life of each connector. The use of corrosion-resistant materials and advanced sealing techniques further reduces maintenance needs. As a result, industries experience fewer unplanned outages and lower lifecycle costs.

Tip: Regular inspection and cleaning of connectors help maintain optimal performance and extend service life, supporting long-term reliability in industrial systems.

Major Industrial Applications of Cannon Plug Connectors in 2025

Aerospace and Defense

Avionics and Flight Control Systems

Cannon plug connectors serve as vital components in avionics and flight control systems. Engineers rely on these connectors for lightweight, robust, and watertight interconnect solutions. Aircraft systems demand connectors that withstand shock, vibration, and temperature extremes. The shift from stainless steel to aluminum and composite materials reduces weight, which improves fuel efficiency and operational endurance. These connectors support high data rates, enabling reliable transmission of sensor data and imagery. Compliance with strict military and aerospace standards ensures performance in both commercial and military applications.

Military Ground and Naval Equipment

Military ground vehicles and naval equipment require connectors that endure harsh conditions. Cannon plug connectors provide durable connections in environments exposed to saltwater, electromagnetic interference, and mechanical stress. Designers focus on watertight seals and EMI shielding to maintain signal integrity. These connectors play a critical role in soldier modernization, munitions, and control systems. Major companies such as ITT Cannon and Amphenol supply specialized connectors for military and aerospace applications, supporting mission-critical operations.

| Company Name | Market Role and Focus | Approximate Revenue (2025) | Contribution to Cannon Plug Connector Market |

|---|---|---|---|

| TE Connectivity | Extensive product portfolio, advanced tech | ~$14 billion | Leading innovation and growth in aviation and industrial sectors |

| Amphenol | High-performance durable connectors | ~$9 billion | Strong presence in aerospace and industrial applications |

| ITT Cannon | Specialized aerospace and defense connectors | Part of ITT’s $3 billion | Key player in industrial and military connector markets |

| Japan Aviation Electronics | Aerospace and defense focus | >$1 billion | Significant contributor to aviation plug and socket market |

Transportation and Automotive

Electric and Autonomous Vehicles

Cannon plug connectors enable reliable integration of sensors, power, and signal lines in electric and autonomous vehicles. Manufacturers design these connectors to meet IP67/69 standards, ensuring protection against dust and water. High-power and high-voltage variants support electrification and automated driving functions. The connectors comply with ISO 15170 and ISOBUS standards, which guarantee plug-and-play compatibility between vehicle components. Automotive-grade connectors originally developed for transportation now support agricultural and off-road vehicles, including autonomous tractors.

- Enable sensor data transmission and vehicle stabilization

- Support diagnostics, control units, and auxiliary controls

- Facilitate interoperability in complex vehicle systems

Rail and Mass Transit Systems

Rail and mass transit systems depend on cannon plug connectors for signaling and control. These connectors provide secure electrical connections in environments subject to vibration and temperature fluctuations. Their rugged construction ensures reliable operation, which is critical for safety and efficiency in public transportation. Industry 4.0 trends and automation drive increased adoption of these connectors in rail infrastructure.

Medical Electronics

Diagnostic and Imaging Equipment

Medical electronics require connectors that combine miniaturization, durability, and reliability. Cannon plug connectors, such as ITT Cannon’s QLC Solderless plug, support portable ultrasonic, diagnostic, and imaging equipment. The zero-insertion-force design simplifies assembly and reduces costs. These connectors operate reliably across a wide temperature range and support over 20,000 mating cycles. Micro-D connectors enable high-density signal transmission in ultrasound, MRI, and CT machines, maintaining signal integrity and supporting accurate diagnostics.

Surgical and Patient Monitoring Devices

Surgical and patient monitoring devices rely on ruggedized connectors for stable power supply and data transmission. Features such as hermetic sealing, biocompatibility, and EMI/RFI protection ensure safety and reliability. Gold-plated contacts and precise impedance matching reduce signal loss. The connectors’ mechanical durability supports long-term clinical use, even in mobile and wearable medical devices.

| Industrial Sector/Application | Role of Cannon Plug Connectors | Supporting Data / Market Insight |

|---|---|---|

| Industrial Machinery & Automation | Provide reliable electrical connections for automation, robotics, and control systems | Driven by Industry 4.0, smart manufacturing, and sensor integration trends |

| Aerospace | Enable safe power and data transfer in aircraft systems | Fastest-growing segment; driven by aircraft technology advancements and air travel demand |

| Military and Defense | Ensure durable connections in harsh conditions | Specialized aerospace and defense applications by major players |

| Rail Transportation | Facilitate connections in signaling and control systems | Critical for reliable operation in rail systems |

| Medical Equipment | Secure power supply and data transmission | Used in sensitive medical devices requiring reliability |

Cannon plug connectors continue to expand their role in industrial machinery, automation, and electronics. The ongoing investments in automation and smart manufacturing confirm their significance in 2025.

Energy and Power Systems

Renewable Energy Installations

Cannon plug connectors have become essential in renewable energy installations. Engineers select these connectors for solar farms, wind turbines, and battery storage systems. The connectors provide reliable power transmission and signal integrity in harsh outdoor environments. Manufacturers design them to resist corrosion, UV exposure, and temperature extremes. These features ensure long-term performance in remote locations.

Operators value the modularity of cannon plug connectors. They can quickly replace faulty units without disrupting the entire system. This approach reduces maintenance time and improves uptime. Many renewable energy projects use connectors with high ingress protection ratings, such as IP68 and IP69K. These ratings guarantee protection against dust, water, and high-pressure cleaning.

Tip: Regular inspection of connectors in solar and wind installations helps prevent unexpected failures and supports continuous energy production.

The table below highlights key requirements for connectors in renewable energy:

| Requirement | Description |

|---|---|

| Corrosion Resistance | Withstands moisture and chemicals |

| UV Protection | Maintains integrity under sunlight |

| High Current Capacity | Supports large-scale power transmission |

| Modular Design | Enables fast replacement and upgrades |

Industrial Automation and Control

Industrial automation relies on cannon plug connectors for robust connectivity. Factories use these connectors in robotics, conveyor systems, and control panels. The connectors support high-speed data transmission and power delivery. Engineers choose them for their durability and ease of installation.

Cannon plug connectors offer quick-connect features. Technicians can install or remove them with minimal effort. This capability reduces downtime during maintenance. Many connectors include locking mechanisms that prevent accidental disconnection. These features enhance safety in automated environments.

Manufacturers customize connectors for specific industrial applications. They select materials and designs that match the demands of each system. For example, connectors in food processing plants require waterproof and chemical-resistant properties. In automotive assembly lines, connectors must withstand vibration and repeated use.

Note: Smart connectors with embedded sensors enable predictive maintenance. Operators can monitor system health and schedule repairs before failures occur.

Cannon plug connectors continue to support the growth of industrial automation. Their reliability and adaptability make them a preferred choice for engineers in diverse sectors.

Industry Trends and Future Directions for Cannon Plug Connectors

Sustainability and Eco-Friendly Design

Recyclable Materials and Green Manufacturing

Manufacturers now prioritize sustainability in the design and production of cannon plug connectors. They select recyclable metals and polymers to reduce environmental impact. Many companies invest in green manufacturing processes that use less energy and generate fewer emissions. These efforts help industries meet global environmental standards and appeal to customers who value eco-friendly solutions.

Energy Efficiency in Connector Design

Energy efficiency shapes the next generation of connectors. Engineers focus on reducing contact resistance and improving conductivity. These improvements lower power loss during operation. Some designs use advanced plating techniques to enhance electrical performance while minimizing material waste. Energy-efficient connectors support the growing demand for sustainable industrial systems.

Integration with IoT and Industry 4.0

Real-Time Monitoring and Predictive Maintenance

The rise of IoT and Industry 4.0 transforms how industries use connectors. Modern connectors feature embedded sensors that monitor temperature, vibration, and electrical load. These sensors provide real-time data, allowing operators to predict maintenance needs before failures occur. Predictive maintenance reduces downtime and extends equipment life. Factories benefit from increased productivity and lower repair costs.

Secure Data Connectivity

Secure data transmission remains a top priority in connected industrial environments. Engineers design connectors with shielding and encryption features to protect sensitive information. These measures prevent data breaches and ensure reliable communication between machines. As factories adopt more automated systems, secure connectors become essential for safe and efficient operations.

Global Supply Chain and Standardization

International Compliance and Certification

Global markets require strict compliance with international regulations. Cannon plug connectors must meet export control laws such as ITAR in the United States and ECO in the United Kingdom. These regulations demand export licenses for controlled products. Non-compliance can lead to severe penalties, both financial and legal. Adhering to these standards ensures responsible distribution and protects sensitive technologies.

Addressing Supply Chain Challenges

Supply chain resilience has become a major focus for manufacturers. Companies diversify suppliers and invest in local production to reduce risks from global disruptions. Standardized connector designs help streamline sourcing and replacement, making it easier to maintain consistent quality. By addressing these challenges, industries ensure reliable access to critical components and maintain operational stability.

Tip: Companies that stay ahead of regulatory changes and invest in sustainable practices position themselves for long-term success in the evolving connector market.

The Role of MIL-DTL-5015 Connectors in Modern Industry

Historical Significance and Evolution

Military Specifications and Adoption

MIL-DTL-5015 connectors have shaped the foundation of rugged connectivity since their inception in the 1930s. Engineers at Douglas Aircraft Company developed the first versions to meet the demands of DC aircraft platforms. The AN9534 standard emerged in 1939, setting the stage for the MIL-DTL-5015 specification introduced in 1949. Over the decades, these connectors underwent several revisions, reflecting the evolving requirements of military operations. Each update, from 1958 through the 2000s, enhanced durability, reliability, and adaptability. The transition to SAE-AS50151 in 2009 marked a significant milestone, aligning the standard with modern industry needs.

- MIL-DTL-5015 connectors established benchmarks for vibration resistance and mechanical shock.

- Their ease of field handling made them indispensable in military and commercial applications.

- The connector family expanded to include multiple series and classes, each tailored for specific operational environments.

These features set the standard for rugged circular connectors, influencing the design of modern interconnect solutions across industries.

Transition to Broader Industrial Use

After World War II, industries outside the military recognized the value of MIL-DTL-5015 connectors. Heavy machinery, transportation, and oil and gas sectors adopted these connectors for their proven mechanical strength. Early designs prioritized robustness over miniaturization, meeting the needs of demanding environments. As digital technology advanced from the 1980s onward, the market demanded smaller connectors with higher data transmission capabilities. Manufacturers responded by refining MIL-DTL-5015 connectors, integrating smart features and improving environmental resilience. Commercial equivalents, such as Amphenol Industrial 97 Series, demonstrate the connector’s impact beyond military specifications, supporting robotics and industrial automation.

The legacy of MIL-DTL-5015 connectors remains evident in today’s standards, which emphasize ruggedness, reliability, and backward compatibility.

Current Applications and Performance

Reliability in Harsh Environments

MIL-DTL-5015 connectors deliver exceptional performance in extreme conditions. Military ground vehicles, aircraft, and naval vessels rely on these connectors for secure power and signal transmission. Industrial heavy machinery and oil and gas installations also benefit from their rugged construction. Engineers select these connectors for their ability to withstand vibration, mechanical shock, and environmental extremes. Corrosion-resistant designs and high ingress protection ratings, such as IP67, ensure reliable operation in marine and outdoor settings.

| Aspect | Details |

|---|---|

| Applications | Military ground vehicles, aircraft, naval vessels, communication systems; Industrial heavy machinery, transportation, oil and gas |

| Shell Sizes | 19 shell sizes (size 08 to 40) with ~160 insert arrangements, contacts from 1 to 85 |

| Voltage Rating | 500V at normal temperature; 250V at high temperature |

| Current Rating | 16 AWG: 13A; 12 AWG: 23A; 8 AWG: 46A; 4 AWG: 80A; 0 AWG: 150A |

| Contact Resistance | Maximum 10 milliohms |

| Insulation Resistance | 5000 megohms or higher |

| Durability | Designed for 500 mating cycles |

| Coupling Mechanism | Threaded (MS Series) and bayonet (CA Series) |

| Operating Temperature | -55°C to 125°C |

| Ingress Protection | IP67 rating |

| Shell Material | Aluminum alloy with cadmium plating and olive drab chromate coating |

| Contact Material | High-conductivity copper alloys plated with gold or silver |

| Insulator Material | Durable synthetic rubber |

Compatibility with Modern Systems

Manufacturers continue to refine MIL-DTL-5015 connectors to meet the demands of modern systems. Precision manufacturing and the use of high-temperature polymers enhance performance. Engineers integrate smart features, such as built-in sensors for real-time monitoring, to support predictive maintenance. The wide range of shell sizes and insert arrangements allows for customization in compact devices, including UAVs and portable equipment. These connectors maintain compatibility with legacy systems while supporting new technologies, ensuring seamless integration across military and industrial platforms.

MIL-DTL-5015 connectors remain a trusted choice for engineers who require reliability, adaptability, and proven performance in harsh environments.

Challenges and Opportunities Ahead for Cannon Plug Connectors

Addressing Evolving Industry Demands

Adapting to New Regulatory Requirements

Manufacturers face a complex regulatory landscape as they develop cannon plug connectors for modern applications. New cybersecurity standards, such as those mandated by DFARS and CMMC, require robust encryption and tamper-proof designs. Companies must ensure supply chain transparency and integrate hardware-based security features. Environmental regulations, including RoHS and REACH, push manufacturers to use eco-friendly materials and reduce hazardous substances. Defense applications demand military-grade material compliance and advanced EMI shielding. Major players like Amphenol and TE Connectivity invest in ruggedized, lightweight composite connectors and smart connectors with IoT-enabled diagnostics. To address supply chain risks, firms diversify suppliers, adopt local manufacturing, and implement AI-driven supply chain management tools.

Note: Adapting to these regulations increases operational costs due to extensive testing, certification, and documentation. Noncompliance can result in contract loss and project delays.

Meeting Higher Performance Expectations

Industry demands continue to rise for connectors that deliver superior reliability, durability, and data transmission capabilities. Rapid technological advancements force manufacturers to invest heavily in research and development. Connectors must adapt quickly to new standards, risking obsolescence of older models. The need for advanced materials and specialized engineering drives up development expenses, creating financial barriers for smaller companies. Supply chain disruptions caused by natural disasters, trade restrictions, and geopolitical tensions can delay production and increase costs, impacting availability.

- Companies must balance innovation with cost control.

- High-performance connectors require rigorous testing to ensure reliability in harsh environments.

- The market expects connectors to support smart features, predictive maintenance, and seamless integration with digital systems.

Innovation and Competitive Landscape

Emerging Competitors and Alternatives

The competitive landscape for cannon plug connectors continues to evolve. New entrants introduce alternative connector technologies, such as modular and hybrid designs, that offer enhanced flexibility and performance. Market consolidation leads key players to expand their portfolios with smart, eco-friendly connectors. Regional dynamics shape competition, with Asia-Pacific driving volume growth through industrialization and infrastructure investments, while North America and Europe focus on innovation and sustainability.

| Aspect | Evidence Summary |

|---|---|

| Market Size & Growth | Heavy-Duty Connector market projected to grow from USD 5.12 Billion in 2024 to USD 8.37 Billion by 2033 at a CAGR of 6.5%. |

| Innovation Opportunities | Eco-friendly materials, smart/modular designs, connectors for extreme environments (EVs, renewable energy, aerospace, defense). |

| Regulatory Drivers | RoHS, REACH, EPA regulations drive R&D in sustainable and high-performance connectors. |

| Regional Market Dynamics | Asia-Pacific leads volume growth; North America and Europe focus on innovation, quality, sustainability. |

| Competitive Landscape | Key players invest in R&D, partnerships, and expanding portfolios with smart, modular connectors. |

| Growth Drivers | Rising industrialization, infrastructure investments, demand for high-performance connectors, digital transformation. |

| Leading Companies | TE Connectivity, Phoenix Contact, Harting Technology, Weidmuller Interface, Molex, Amphenol Sine Systems, ITT Cannon. |

Opportunities for Collaboration and Growth

Manufacturers recognize significant opportunities for collaboration and growth. Strategic partnerships enable companies to share expertise and accelerate innovation. Investments in digital transformation and sustainability initiatives help firms differentiate their products and capture new markets. Regulatory foresight embedded in product development provides competitive advantages, especially in highly regulated regions. The development of eco-friendly materials and smart connector solutions positions companies to meet future industry demands and regulatory requirements.

Tip: Companies that prioritize innovation, regulatory compliance, and strategic collaboration will lead the market and shape the future of cannon plug connectors.

Cannon plug connectors and MIL-DTL-5015 connectors continue to shape modern industry through ongoing innovation and adaptation.

- ITT Cannon’s MIL-DTL-5015 series now serves military, aerospace, marine, and automotive sectors, offering robust materials and advanced sealing for harsh environments.

- Features like keyed foolproof designs and corrosion-resistant plating ensure reliability and compliance with evolving standards.

Industry professionals benefit by staying informed about these advancements, as future opportunities depend on strategic integration of high-performance connectors in critical systems.

FAQ

What industries use cannon plug connectors most in 2025?

Aerospace, defense, transportation, medical electronics, and renewable energy sectors rely on cannon plug connectors. These industries demand reliable, rugged, and high-performance connectivity for mission-critical systems.

How do cannon plug connectors improve system reliability?

Engineers design cannon plug connectors with robust locking mechanisms and corrosion-resistant materials. These features prevent accidental disconnection and signal loss, ensuring stable operation in harsh environments.

What standards govern cannon plug connectors?

Key standards include MIL-DTL-5015, EN 50155, IEC 61373, and RoHS. These standards ensure safety, environmental resistance, and compatibility across global markets.

Can cannon plug connectors support high-speed data transmission?

Yes. Modern designs integrate hybrid contacts for both power and data. Many connectors now support high-speed protocols, enabling reliable data transfer in industrial and automotive applications.

How often should technicians inspect or maintain these connectors?

Technicians should inspect connectors during scheduled maintenance or when system performance drops. Regular cleaning and visual checks help prevent corrosion and ensure long-term reliability.

What are the main benefits of miniaturized cannon plug connectors?

Miniaturized connectors save space and reduce weight. They fit compact devices such as medical equipment, drones, and robotics, while maintaining durability and performance.

Are eco-friendly options available for cannon plug connectors?

Many manufacturers now offer connectors made from recyclable materials and use green manufacturing processes. These eco-friendly options help companies meet sustainability goals.

How do smart features enhance cannon plug connectors?

Embedded sensors and diagnostics enable real-time monitoring. These smart features support predictive maintenance, reduce downtime, and improve overall system efficiency.