Custom Connector Corp. elevates RCA color coding in its 4-pin connector manufacturing. The company applies RCA standards with precision, using advanced solder techniques to maintain color integrity. Engineers select solder types that resist fading and support signal clarity. Each connector features distinct RCA color coding, setting it apart from typical M8 connector and Type B connector designs. Custom Connector Corp. uses proprietary solder processes in its connector factory, ensuring every RCA connector meets rigorous standards.

Their approach to solder application and RCA color coding surprises many professionals with its reliability and innovation.

- RCA color coding enhances connector identification.

- Solder quality ensures RCA color coding durability.

RCA Color Coding in 4-Pin Connectors

The Standard Explained

Typical RCA Color Assignments

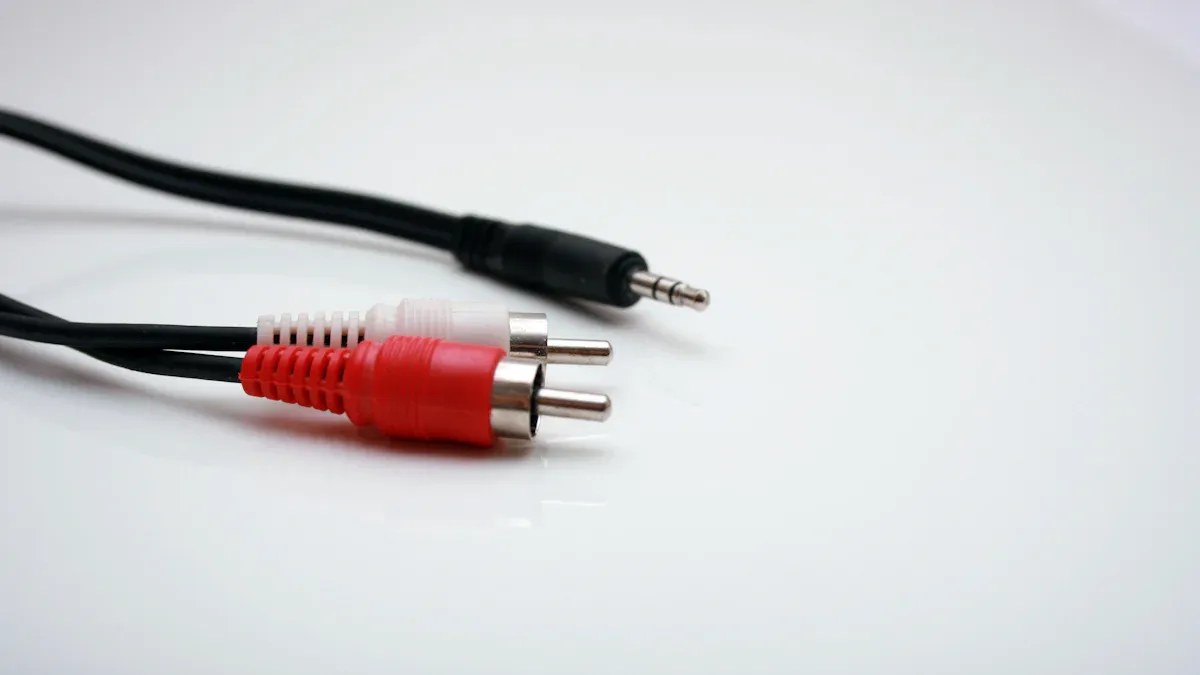

RCA connectors have become a staple in audio and video transmission. Manufacturers assign colors to each connector to indicate its function. The most common assignments include yellow for composite video, white for left audio, and red for right audio. These color-coded jacks simplify the process of matching cables to their respective ports. In coaxial cable systems, color coding helps users distinguish between video and audio signals. This system reduces confusion during installation and maintenance.

| Color | Signal Type | Typical Use |

|---|---|---|

| Yellow | Video | Composite Video |

| White | Audio (Left) | Stereo Audio |

| Red | Audio (Right) | Stereo Audio |

| Black | Audio (Mono) | Mono Audio |

Application to 4-Pin Designs

Custom Connector Corp. adapts RCA color coding for its 4-pin connector designs. Engineers select colors that correspond to each signal path within the connector. The fourth pin often supports additional functions, such as ground or data transmission. Solder plays a critical role in maintaining the integrity of each connection. Technicians use precise solder techniques to ensure each pin receives the correct signal. The application of color coding in these connectors enhances compatibility with various cable types, including coaxial and multi-conductor cables.

Importance of Color Coding

Signal Identification

Color coding in RCA connectors provides immediate visual cues for signal identification. Technicians can quickly match cables to the correct connector, reducing the risk of miswiring. In multi-pin connectors, such as those found in Ethernet and coaxial cable assemblies, color coding enables easy identification of individual wires. This practice ensures correct wiring and proper pairing, which minimizes crosstalk and noise interference. Technical standards dictate wire placement and color coding to separate signals with sharp edges from those sensitive to noise. Twisted pair and balanced line cabling techniques, supported by color coding, help mitigate electrical disturbances.

- Color coding distinguishes wiring standards and supports signal integrity.

- Proper identification reduces errors and improves connection reliability.

Error Prevention

Manufacturers rely on color coding to prevent errors during connector assembly. Crimping tools use color-coded dies that match the wire insulation, ensuring the correct wire gauge and secure connection. Solder selection further impacts the durability of color coding. High-quality solder resists fading and maintains the clarity of each color-coded connection. Proper soldering techniques protect the color-coded insulation from heat damage, preserving the visibility of each signal path. This attention to detail reduces connection errors and improves the reliability of RCA connectors in both professional and consumer applications.

Tip: Always verify color coding before soldering to maintain signal integrity and prevent connection mistakes.

Custom Connector Corp.’s Implementation Process

Materials and Manufacturing Techniques

Color-Coded Insulation Materials

Custom Connector Corp. selects advanced materials for insulation in its 4-pin connector designs. The company often uses PA GF, or Polyamide with Glass Fiber, for the connector housing. This material offers high durability and supports a wide range of color options. Engineers choose PA GF because it resists wear and maintains color vibrancy over time. The color-coded housing allows for easy circuit identification, which is essential in complex cable assemblies. By using robust materials, Custom Connector Corp. ensures that each connector withstands repeated soldering and assembly processes without losing its color clarity.

The insulation materials must also tolerate the heat generated during soldering. Technicians apply solder to each pin, and the insulation must not degrade or discolor. The choice of PA GF helps maintain the integrity of the RCA color coding, even after multiple soldering cycles. This approach supports both the mechanical strength and the visual clarity of each connector.

Precision Molding and Printing

Precision molding plays a critical role in the manufacturing of Custom Connector Corp.’s 4-pin connectors. The company uses high-precision molds to shape the connector housing and ensure consistent dimensions. This process guarantees that each connector fits securely with its corresponding cable and device. During molding, the color is integrated directly into the housing material, which prevents fading and chipping.

After molding, technicians use advanced printing techniques to add any necessary symbols or markings. These markings complement the RCA color coding and provide additional identification for each connector. The printing process uses inks that resist heat and chemicals, which is vital during soldering and assembly. The combination of precision molding and durable printing ensures that each connector maintains its appearance and function throughout its service life.

Proprietary Methods

Unique Color Application Process for 4-Pin Connectors

Custom Connector Corp. has developed a proprietary process for applying color to its 4-pin connectors. The process begins with the selection of high-quality base materials that accept color evenly. Engineers then use a multi-stage coloring technique that embeds the RCA color coding into the connector housing. This method ensures that the color remains vibrant and visible, even after repeated soldering and handling.

The unique color application process also allows for custom color combinations. This flexibility supports specialized cable assemblies that require non-standard RCA color coding. The process minimizes the risk of color transfer or fading during soldering, which is essential for maintaining signal identification in demanding environments.

Quality Control Procedures for RCA Color Coding

Quality control stands at the core of Custom Connector Corp.’s manufacturing philosophy. The company implements rigorous inspection protocols at every stage of connector production. Technicians examine each connector for color accuracy, clarity, and consistency. They also test the connector’s resistance to heat and chemicals, simulating the conditions experienced during soldering and assembly.

A dedicated team monitors the soldering process to ensure that the color-coded insulation remains intact. They verify that each solder joint meets strict quality standards and that the RCA color coding is not compromised. The company uses automated vision systems to detect any defects in color application or printing. These systems help maintain high levels of quality and reliability in every connector produced.

Note: Consistent quality control during soldering and assembly helps prevent signal loss and ensures long-term performance for every RCA connector.

Custom Connector Corp.’s commitment to quality extends to the final stages of production. Each connector undergoes a final inspection before packaging. This step guarantees that the RCA color coding, solder joints, and overall assembly meet the company’s high standards. The result is a connector that delivers reliable performance and easy identification in any cable system.

Surprising Elements in Custom Connector’s Approach

Non-Standard Color Assignments

Rationale for Deviations from RCA Norms

Custom Connector Corp. often chooses to move beyond traditional RCA color assignments in its 4-pin connector designs. The engineering team studies the requirements of each application before selecting a color scheme. They recognize that standard RCA color coding does not always fit the needs of modern connection systems. For example, some industrial environments require additional signal paths or unique functions that standard RCA colors do not represent. The team evaluates the signal type, the environment, and the expected use case before finalizing the color assignment for each connector.

This approach allows the company to optimize each connection for clarity and efficiency. The engineers consider how soldering and assembly processes might affect color visibility. They also account for the possibility of future upgrades or changes in the connection layout. By deviating from RCA norms, Custom Connector Corp. ensures that each connector supports the specific needs of its users.

Benefits of Custom Color Choices

Custom color choices provide several advantages in connector manufacturing. First, they help users identify each connection quickly, even in complex assemblies. The use of unique colors reduces the risk of confusion during soldering and installation. Technicians can match each wire to its corresponding pin without second-guessing the RCA standard.

Second, custom color coding improves the reliability of each connection. When the color scheme matches the function of each pin, users can avoid mistakes that might damage the connector or compromise signal quality. The solder used in each connection maintains the integrity of the color coding, even after repeated use. This attention to detail supports long-term performance and reduces maintenance needs.

Note: Custom color assignments can also support specialized applications, such as medical devices or high-frequency data transmission, where standard RCA colors may not provide enough differentiation.

Enhanced Visibility Features

High-Contrast Color Schemes for Easy Identification

Custom Connector Corp. prioritizes visibility in every connector design. The company selects high-contrast color schemes that stand out against the background of the connector housing. This strategy makes it easier for technicians to identify each RCA-coded pin during soldering and assembly. High-contrast colors also help users spot the correct connection point in low-light or high-traffic environments.

The use of high-contrast colors supports faster troubleshooting. When a connection fails, technicians can quickly locate the affected pin and inspect the solder joint. This reduces downtime and improves the overall reliability of the RCA connector system. The company tests each color scheme for visibility under different lighting conditions to ensure consistent performance.

User-Centric Design Adjustments for Accessibility

Accessibility remains a key focus for Custom Connector Corp. The design team incorporates user feedback to improve the accessibility of each connector. They adjust the size and placement of color-coded areas to make them easier to see and touch. For example, the company may use raised markings or textured surfaces near each RCA-coded pin. These features help users with limited vision or dexterity make accurate connections.

The team also considers the impact of soldering on accessibility. They select solder types that do not obscure the color coding during assembly. This ensures that each connection remains visible and easy to identify, even after multiple soldering cycles. The result is a connector that supports a wide range of users in both professional and consumer settings.

Innovative Labeling Techniques

Dual-Mode Identification: Color and Symbol

Custom Connector Corp. enhances each connector with dual-mode identification. In addition to RCA color coding, the company adds symbols or numbers to each pin location. This approach provides a backup method for identifying each connection, especially in environments where color coding might fade or become obscured by solder.

The dual-mode system supports technicians during soldering and maintenance. If the color coding becomes less visible, the symbol or number still guides the user to the correct connection point. This redundancy reduces the risk of errors and supports long-term reliability. The company uses durable printing techniques to ensure that both the color and symbol remain clear throughout the life of the connector.

Accessibility Enhancements for All Users

Custom Connector Corp. believes that every user should have access to reliable connection systems. The company integrates accessibility features into every RCA connector design. These enhancements include larger color-coded areas, tactile markings, and clear symbols. The team tests each connector with users who have different needs to ensure that the design supports everyone.

During soldering, technicians follow strict guidelines to preserve the accessibility features. The solder must not cover or damage the color coding or symbols. This careful approach ensures that each connection remains easy to identify and use, regardless of the user’s abilities. The company’s commitment to accessibility sets a new standard in the connector industry.

Tip: When working with RCA connectors, always check both the color coding and the symbol before making a connection. This practice helps prevent mistakes and supports long-term reliability.

Impact on Usability and Identification

User Experience Improvements

Faster Setup and Troubleshooting with RCA Color Coding

Custom Connector Corp. designs each connector with clear RCA color coding, which streamlines the setup process. Technicians identify each signal path at a glance, reducing the time needed to match each connection. The company’s approach to soldering ensures that every solder joint remains visible and does not obscure the RCA color. This visibility allows users to confirm each signal assignment quickly. When troubleshooting, engineers locate the correct connector and signal path without confusion. The color coding, combined with precise soldering, helps users avoid mistakes during assembly. Each connector supports efficient signal routing, which speeds up both installation and maintenance. The solder used in every connection resists fading, so the RCA color coding stays clear even after repeated soldering cycles. This reliability means users spend less time searching for the right signal path or correcting errors caused by unclear connections.

Reduced Connection Errors in 4-Pin Connectors

The use of RCA color coding in 4-pin connectors significantly reduces connection errors. Each connector features distinct colors for every signal, making it easy to identify the correct pin during soldering. The soldering process at Custom Connector Corp. maintains the clarity of each RCA color, so technicians do not lose track of signal assignments. When assembling a connector, the color coding guides the placement of each signal wire. This guidance minimizes the risk of crossing signals or creating faulty connections. The solder used in each connection also protects the color coding from heat damage, which preserves the integrity of the signal identification. As a result, users experience fewer connection errors and enjoy more reliable signal transmission.

Field and Lab Applications

Professional Use Cases in Audio/Video and Industrial Settings

Professionals in audio, video, and industrial environments rely on connectors that deliver consistent signal performance. Custom Connector Corp. manufactures each connector with RCA color coding that stands up to frequent soldering and handling. The solder used in every connection ensures that the RCA color remains vibrant, even in demanding field conditions. Engineers working in labs or on-site installations benefit from the clear signal identification provided by each connector. The soldering process supports robust connections that maintain signal integrity over time. In industrial settings, technicians often face complex wiring layouts. The RCA color coding and precise soldering help them trace each signal path and verify every connection quickly. This efficiency reduces downtime and supports high-quality signal transmission in every application.

Consumer Benefits of Clear Color Coding

Consumers also gain advantages from clear RCA color coding in connectors. When setting up a cable system at home, users can easily identify each signal and make the correct connection. The soldering techniques used by Custom Connector Corp. keep the RCA color coding intact, so users do not struggle with faded or unclear markings. Each connector provides a straightforward guide for signal placement, which simplifies the process for non-experts. The solder in every connection protects the color coding from wear, ensuring that the signal identification remains reliable over time. This attention to detail means consumers experience fewer issues with signal loss or connection errors. The result is a smoother setup and a more enjoyable user experience.

Quality and Reliability Outcomes

Durability of Color Coding

Resistance to Wear and Fading in Connectors

Custom Connector Corp. focuses on the durability of color coding in every connector. Engineers select insulation materials that resist abrasion and maintain color vibrancy. The company uses PA GF for the housing, which protects the color from frequent handling and environmental exposure. Soldering plays a critical role in preserving the color coding. Technicians apply solder with precision, ensuring that heat does not degrade the color or cause fading. Each connector undergoes repeated soldering cycles during assembly and testing. The color-coded areas remain clear and visible, even after extensive use in coaxial cable systems.

A connector must withstand physical stress in both field and lab environments. Custom Connector Corp. tests each connector for resistance to chemicals and UV light. The soldering process supports this durability by preventing discoloration at the pin interface. The company’s approach ensures that the color coding remains reliable for the lifetime of the connector.

Long-Term Signal Integrity Supported by Solder Quality

Signal integrity depends on the quality of soldering and the materials used in each connector. Custom Connector Corp. selects solder that resists oxidation and maintains a strong bond between the pin and wire. This choice prevents signal loss and supports consistent performance in coaxial assemblies. Technicians monitor the soldering temperature to avoid damaging the insulation or color coding. Each connector receives a controlled amount of solder, which protects the signal path from interference.

The company’s soldering standards ensure that every connector delivers stable signal transmission. Engineers evaluate the solder joints for strength and conductivity. The soldering process also prevents micro-cracks that could compromise signal quality over time. By maintaining strict control over soldering, Custom Connector Corp. supports long-term reliability in every connector.

Tip: Proper soldering technique is essential for preserving both color coding and signal integrity in coaxial connectors.

Compliance and Testing

Industry Standards Met for RCA Color Coding

Custom Connector Corp. adheres to industry standards for RCA color coding in every connector. The company references guidelines from organizations such as IEC and ANSI to ensure compatibility with coaxial and multi-pin systems. Soldering procedures align with these standards, guaranteeing that each connector meets the required specifications for signal identification. Engineers verify that the color coding matches the intended signal type and function.

A connector must pass visual and functional inspections before leaving the factory. The company uses automated testing equipment to check the accuracy of color coding and solder placement. This process confirms that each connector supports reliable signal transmission in coaxial cable assemblies.

Custom Connector’s Quality Assurance in Manufacturing

Quality assurance forms the foundation of Custom Connector Corp.’s manufacturing process. The company implements multiple checkpoints during connector production. Technicians inspect each solder joint for consistency and strength. Soldering specialists receive training to maintain high standards in every connector. The quality team reviews the color coding for clarity and durability after soldering.

Custom Connector Corp. uses environmental testing to simulate real-world conditions. Each connector undergoes thermal cycling, vibration, and exposure to moisture. The soldering process ensures that the connector maintains signal integrity and color coding throughout these tests. The company’s commitment to quality results in connectors that perform reliably in coaxial, audio, and industrial applications.

| Test Type | Purpose | Outcome |

|---|---|---|

| Thermal Cycling | Assess solder durability | Stable solder joints |

| Vibration | Evaluate connector strength | No signal loss |

| Moisture Exposure | Check color coding resilience | No fading or wear |

Note: Consistent soldering and rigorous testing guarantee the quality of every connector produced by Custom Connector Corp.

Solder and How to Solder in 4-Pin Connector Manufacturing

Role of Solder in Signal Reliability

Solder Selection for RCA Color Coded Connectors

Soldering plays a vital role in the performance of every 4-pin connector. Engineers select solder that creates a secure bond between wires and pins, which directly impacts audio quality and connection longevity. The right solder prevents loose connections, which can cause intermittent signals or complete signal loss. In RCA color coded connectors, the soldering process must support both electrical and mechanical stability. Technicians often insulate soldered joints with heat shrink tubing or electrical tape. This step protects the connection from moisture and physical damage, maintaining signal integrity over time.

Tip: Always choose solder with high conductivity and strong bonding properties for reliable connector assembly.

Impact of Soldering on Color Coding Durability

The soldering process affects the durability of RCA color coding. Excessive heat or improper soldering can damage the insulation or cause color fading. Technicians use precise soldering techniques to avoid these issues. By applying just enough solder, they preserve the clarity of each color-coded area. Insulating the soldered joint further shields the color coding from environmental stress. This careful approach ensures that the connector remains easy to identify, even after repeated use.

How to Solder for Optimal Performance

Step-by-Step Soldering Process in Connector Assembly

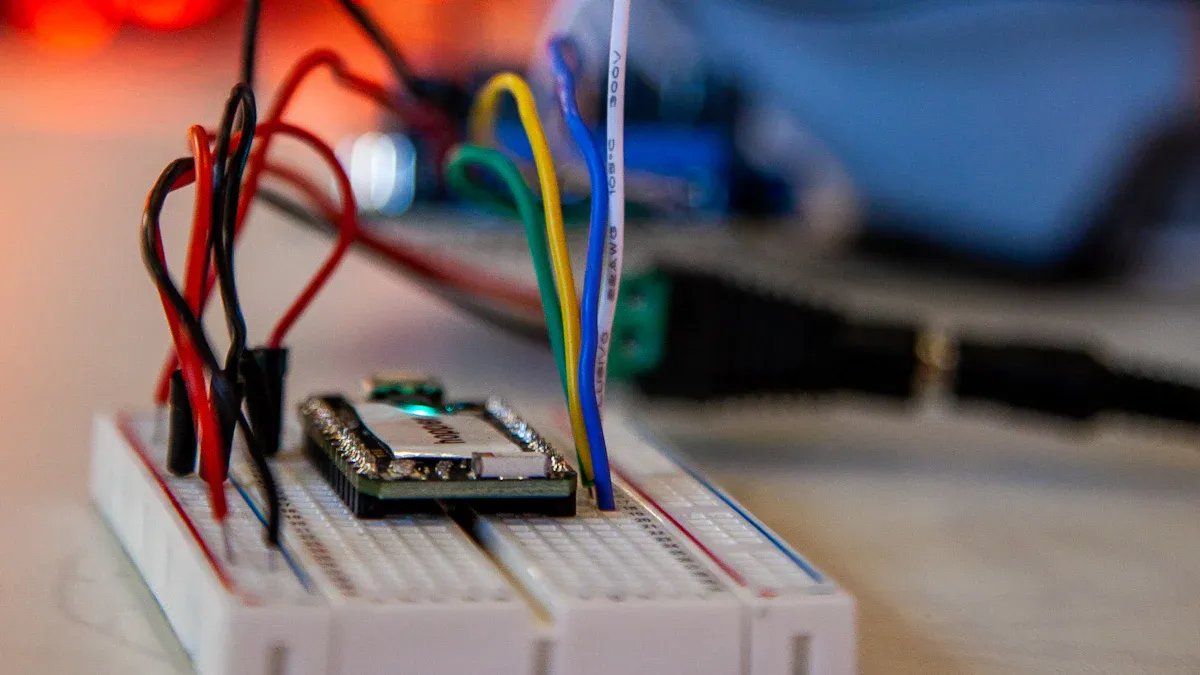

A structured approach to soldering rca plugs in 4-pin connectors ensures optimal results. The following diy guide outlines each step:

- Prepare a soldering iron with at least 25 watts and a narrow conical tip for precision.

- Tin the ends of each conductor wire before insertion.

- Insert the tinned signal conductor into the solder cup aligned with the center pin.

- Place the tinned ground conductor into the hole on the connector’s arm.

- Apply just enough solder to secure the conductors—avoid excess.

- Use a helping hand or table-top vise to stabilize the connector and cable during soldering.

- Organize all components neatly to streamline the assembly process.

- Slide heat shrink tubing over the cable before soldering for added rigidity and identification.

- After soldering, secure the conductors with a cable clamp, pressing it with pliers.

- Shrink the tubing over the clamp with a heat gun for flexibility and durability.

- Reassemble the connector by threading the outer barrel and sleeve together.

- Test the assembled cable for continuity and polarity using a cable tester or multimeter.

- For multiple cables, use different colored tubing for easy identification.

This diy guide applies to both standard and multi-pin RCA connectors, ensuring consistent soldering quality.

Best Practices for Maintaining Color Coding Integrity

Maintaining color coding integrity during soldering requires attention to detail. Technicians avoid overheating the connector, which can cause insulation to melt or colors to fade. They use only the necessary amount of solder, preventing overflow onto color-coded areas. Organizing the workspace and using proper tools, such as a helping hand, reduces the risk of accidental damage. Insulating each soldered joint with heat shrink tubing preserves both the mechanical strength and the visual clarity of the color coding. Following these best practices ensures that every connector remains reliable and easy to identify throughout its service life.

Note: Consistent soldering practices and careful assembly protect both signal reliability and the visibility of RCA color coding.

Customer and Industry Feedback

Testimonials and Case Studies

End-User Experiences with RCA Color Coding

End users often report that Custom Connector Corp.’s rca color coding in 4-pin connectors simplifies their daily work. Many technicians describe how the clear rca color scheme reduces confusion during soldering. They find that each connector provides a straightforward guide for signal placement. Users appreciate that the soldering process does not obscure the rca color, even after repeated use. This clarity helps them avoid mistakes when connecting multiple cables.

Some users highlight the durability of the color coding. They notice that the rca colors remain vibrant after several soldering cycles. The connector design supports easy identification, which speeds up troubleshooting. Users also mention that the solder used in each connector resists heat and prevents color fading. This reliability gives them confidence in both field and lab environments.

Many users value the combination of precise soldering and robust rca color coding. They believe this approach leads to fewer connection errors and better signal quality.

Industry Expert Opinions on Custom Connector’s Approach

Industry experts recognize the unique approach Custom Connector Corp. takes with rca color coding and soldering. They observe that the connector design stands out due to its attention to detail. Experts note that the soldering process maintains both mechanical strength and visual clarity. They often point out that the rca color coding supports fast signal identification, even in complex assemblies.

Experts also discuss the importance of using high-quality solder. They agree that the right solder prevents signal loss and supports long-term reliability. The connector’s ability to withstand repeated soldering without losing color integrity impresses many professionals. They see this as a key factor in the connector’s success across different industries.

Adoption in Specialized Markets

Broadcast and AV Applications Using 4-Pin Connectors

Broadcast and AV professionals rely on connectors that deliver consistent performance. Custom Connector Corp.’s rca color coding and soldering techniques meet the demands of these environments. Technicians in studios and live events use the connector for quick setups. The rca color coding allows them to identify each signal path instantly. Soldering ensures that every connection remains secure, even after frequent handling.

The connector’s robust design supports repeated soldering without degrading the rca color. This durability proves essential in high-traffic settings. AV teams often choose these connectors for their reliability and ease of use. The combination of clear rca color coding and strong solder joints reduces downtime during events.

Emerging Technology Sectors Benefiting from Enhanced Color Coding

Emerging technology sectors also benefit from Custom Connector Corp.’s innovations. Fields such as medical devices and industrial automation require connectors with precise rca color coding. The soldering process ensures that each connector maintains signal integrity under demanding conditions. Engineers in these sectors value the way the rca color coding simplifies complex wiring tasks.

The connector’s ability to withstand multiple soldering cycles appeals to industries with strict reliability standards. Enhanced rca color coding helps teams avoid costly mistakes during assembly. The use of high-quality solder further supports long-term performance. As technology advances, more sectors adopt these connectors for their proven combination of rca color clarity and soldering excellence.

Custom Connector Corp. sets a new standard in connector manufacturing. Their approach to soldering ensures each solder joint remains strong and reliable. Soldering protects the color coding from damage and fading. Technicians use precise soldering methods to maintain signal clarity. Solder quality supports long-term performance. Soldering also helps prevent errors during assembly. Each soldered connection preserves the rca color scheme. Solder keeps every connector durable and easy to identify.

Reliable soldering and high-quality solder deliver lasting benefits for users and professionals.

FAQ

What makes Custom Connector Corp.’s RCA color coding unique?

Custom Connector Corp. uses proprietary color application methods and high-contrast schemes. Their approach improves visibility and identification. The company also integrates symbols for dual-mode identification, supporting both professional and consumer users.

How does color coding help prevent connection errors?

Color coding provides immediate visual cues for each signal path. Technicians match wires quickly, reducing the risk of miswiring. This system supports faster assembly and troubleshooting in both field and lab environments.

Why does Custom Connector Corp. sometimes use non-standard RCA colors?

Engineers select custom color schemes to meet specific application needs. Non-standard colors help differentiate additional functions or unique signal paths. This flexibility supports specialized industries and complex wiring systems.

What materials ensure the durability of color coding?

The company uses PA GF (Polyamide with Glass Fiber) for connector housings. This material resists wear, heat, and fading. It maintains color vibrancy and structural integrity, even after repeated soldering and handling.

How does soldering impact RCA color coding?

Proper soldering techniques protect color-coded insulation from heat damage. Technicians use precise amounts of solder to avoid covering or fading the color. This process ensures long-term visibility and reliable signal transmission.

Are these connectors suitable for both professionals and consumers?

Custom Connector Corp. designs connectors for a wide range of users. High-contrast colors, tactile markings, and clear symbols support accessibility. Both professionals and consumers benefit from easy identification and reliable performance.

What testing ensures the quality of RCA color coding?

Each connector undergoes visual inspection, automated testing, and environmental simulations. Tests include thermal cycling, vibration, and moisture exposure. These procedures confirm color coding durability and signal integrity.

Can users solder these connectors themselves?

Technicians and skilled hobbyists can solder these connectors by following best practices. The company recommends using proper tools, heat management, and insulation techniques. Clear color coding and symbols guide correct assembly.