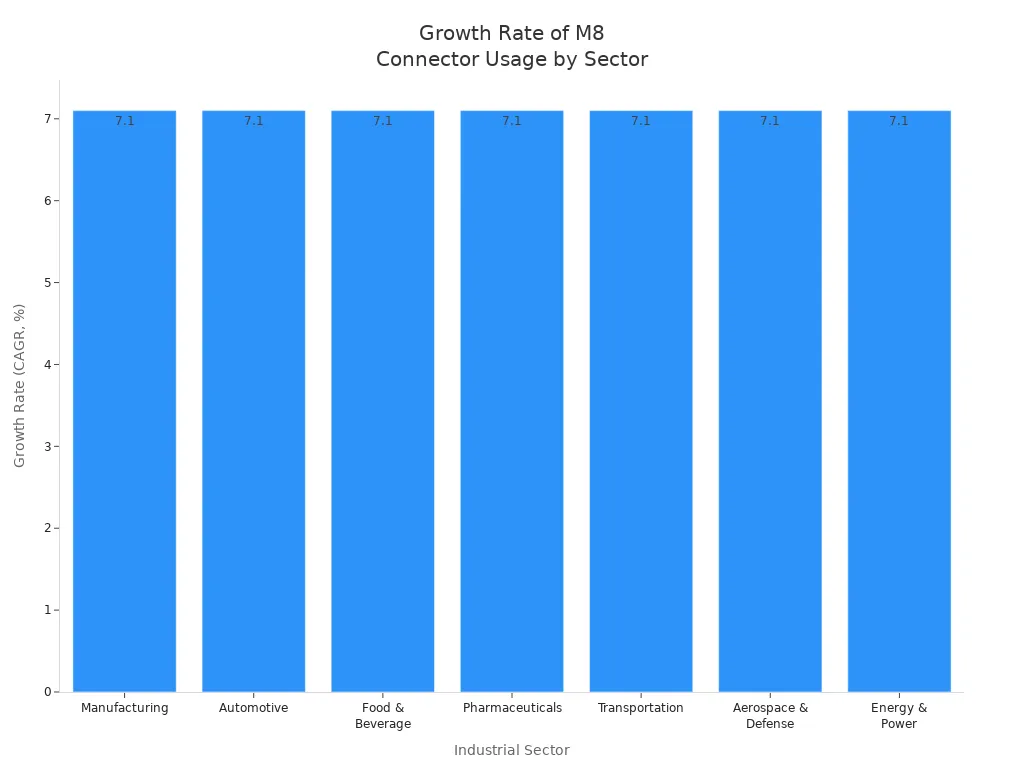

You encounter m8 in industrial connectivity across many sectors due to its compact profile and robust build. The m8 connector delivers consistent performance in harsh environments, supporting both data and power transmission. Many industries, including manufacturing, automotive, and pharmaceuticals, rely on m8 screw connector designs for reliable operation. You see steady adoption of Type B connector technology, especially from a connector factory supplying scalable solutions. The table below highlights the growth rate of m8 connectors in major sectors.

| Industrial Sector | Growth Rate (CAGR) |

|---|---|

| Manufacturing | 7.1% |

| Automotive | 7.1% |

| Food & Beverage | 7.1% |

| Pharmaceuticals | 7.1% |

| Transportation | 7.1% |

| Aerospace & Defense | 7.1% |

| Energy & Power | 7.1% |

Unique Features of M8 in Industrial Connectivity

Compact Design of M8 Connector

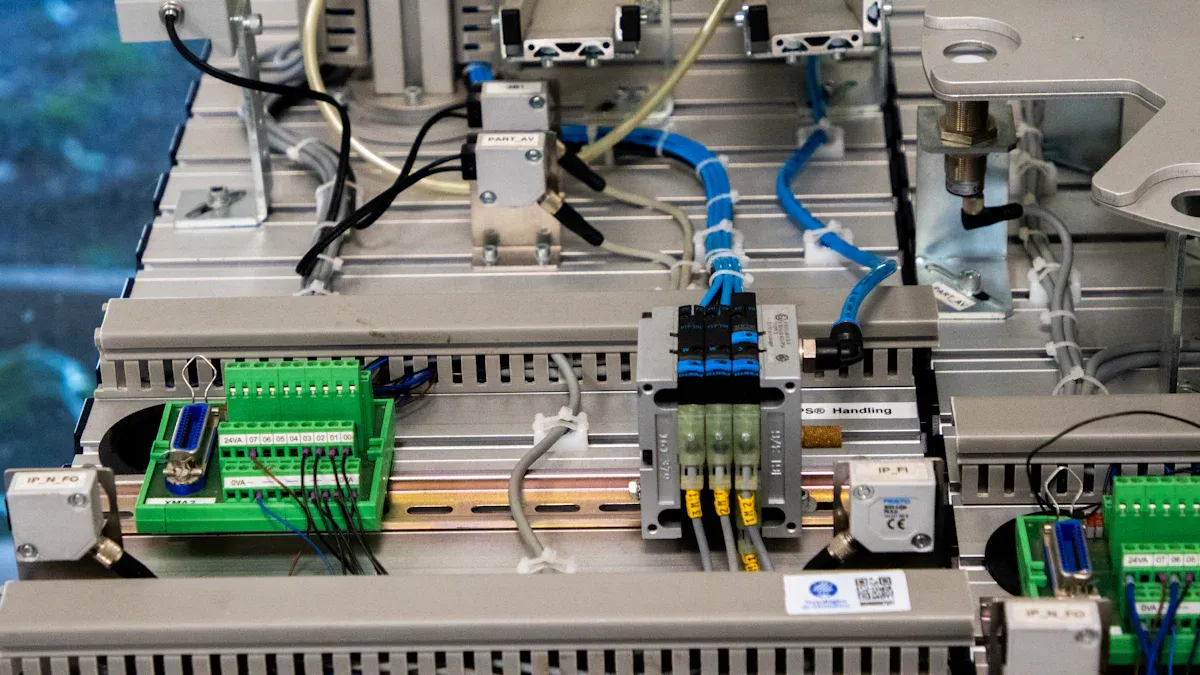

Space-Saving Benefits in Industrial Systems

You often face space constraints when designing industrial systems. M8 connectors offer a compact solution that fits seamlessly into tight control panels and embedded systems. Their small size allows you to maximize available space, making them ideal for small sensors, actuators, industrial lighting, and compact machinery. You benefit from efficient installations and reliable signal transmission, which is crucial for low-power applications in industrial automation.

Tip: Choosing M8 in industrial connectivity helps you optimize layouts and improve system efficiency, especially in environments where every millimeter counts.

Here’s a comparison of design elements that make the M8 connector more compact than other industrial connectors:

| Design Element | M8 Connector | Other Connectors (e.g., M12) |

|---|---|---|

| Thread Diameter | 8mm | Larger than 8mm |

| Coupling Design | Threaded | Varies |

| Overall Size | Compact | Bulkier |

| Application Suitability | Space-constrained environments | General use |

You see that the M8 screw connector stands out for its ability to deliver reliable performance in space-constrained environments.

Integration of M8 in Tight Spaces

You can easily integrate M8 connectors into tight spaces due to their compact size. This feature proves valuable when you work with embedded systems or densely packed control panels. The quick installation process allows you to set up efficient connections without sacrificing reliability. You also gain the advantage of effective power transmission, even in limited spaces.

- Compact Size: Perfect for applications with limited space.

- Quick Installation: Facilitates efficient setups in space-constrained environments.

- Reliable Power: Capable of effective power transmission despite their small size.

Robust Construction of M8 Connector

Resistance to Vibration and Shock

You encounter harsh conditions in many industrial environments. M8 connectors are engineered to withstand vibration and shock, ensuring stable connections even in dynamic settings. You benefit from vibration damping materials and shock absorption techniques that enhance connector stability. Manufacturers use connector fatigue analysis and ruggedized designs to guarantee long-term reliability.

| Key Factors | Description |

|---|---|

| Shock absorption techniques | Techniques to mitigate impacts in dynamic environments. |

| Vibration damping materials | Materials that reduce oscillation, enhancing connector stability. |

| Connector fatigue analysis | Evaluates durability under repeated stress. |

| Ruggedized designs | Designs compliant with environmental testing standards for reliable performance. |

Protection Against Dust and Moisture (IP67 Rating)

You need connectors that resist dust and moisture in demanding industrial settings. M8 connectors meet the IP67 rating, which means they provide excellent waterproofing and dust protection. You can rely on these connectors in environments exposed to oil, acids, alkalis, and welding sparks. Their robust construction ensures consistent performance, even in the most challenging conditions.

| Standard/Certification | Description |

|---|---|

| IEC 61076-2-104 | Specifies dimensions, pin configuration, and environmental resistance for M8 connectors. |

| UL Certification | Focuses on safety criteria such as fire resistance, ensuring the connector meets specific safety standards. |

Material Options for M8 Connector

Metal vs. Plastic Housings

You have several material options when selecting M8 connectors for industrial connectivity. Manufacturers offer plastic, metal, and stainless steel housings. Each material provides distinct advantages. Plastic housings are lightweight and cost-effective. Metal housings deliver enhanced durability and shielding. Stainless steel housings offer superior corrosion resistance for the most demanding environments.

| Material | Properties |

|---|---|

| Copper Alloys | Strong rust and corrosion resistance |

| Insulating Body | High-performance molding for reliable insulation |

- Plastic

- Metal

- Stainless Steel

Corrosion Resistance in Industrial Environments

You need connectors that withstand exposure to harsh chemicals and moisture. M8 connectors use copper alloys and high-performance insulating bodies to resist rust and corrosion. You benefit from excellent waterproofing, oil resistance, and high resistance to acids and alkalis. These features make M8 connectors suitable for machinery, automobiles, and industrial equipment in the petroleum, chemical, and automotive industries.

Note: Proactive maintenance strategies and environmental resistance contribute to the durability and lifespan of M8 connectors, ensuring reliable performance in demanding industrial environments.

Technical Specifications of M8 Connector

Pin Configurations and Versatility

You encounter a wide range of pin configurations when working with m8 connectors. This flexibility allows you to match the connector to your specific application requirements. You can select from 3-pin, 4-pin, 5-pin, 6-pin, or even 8-pin versions. Each configuration supports different signal and power needs, making m8 connectors suitable for diverse industrial tasks.

- 3-pin: Common for simple sensor connections.

- 4-pin: Frequently used for switches and actuators.

- 5-pin: Ideal for more complex devices like PLCs and I/O boxes.

- 6-pin and 8-pin: Support advanced applications with multiple signals or combined data and power.

You often use m8 in industrial connectivity for the following components:

- Sensors

- Switches

- Actuators

- PLCs

- I/O boxes

This versatility extends to many environments. You can rely on m8 connectors in factory automation, industrial robotics, and measurement systems. These connectors ensure reliable data and power transmission, even in demanding conditions.

Tip: When you select the right pin configuration, you streamline installation and reduce wiring complexity in your automation projects.

Current and Voltage Ratings for Industrial Use

You must consider electrical ratings when choosing an m8 screw connector for your system. M8 connectors typically support rated currents from 1A to 4A. You also see voltage ratings ranging from 30V up to 60V. These specifications allow you to use m8 connectors for both signal and low-power applications.

| Pin Configuration | Rated Current (A) | Rated Voltage (V) |

|---|---|---|

| 3-pin | 1-4 | 30-60 |

| 4-pin | 1-4 | 30-60 |

| 5-pin | 1-4 | 30-60 |

| 6-pin | 1-4 | 30-60 |

| 8-pin | 1-4 | 30-60 |

You benefit from these ratings in environments where safety and reliability matter. For example, a 4-pin m8 connector rated at 3A and 60V can handle both power and data lines in a compact form. This capability makes m8 connectors a preferred choice for modern automation systems.

You ensure system stability and protect sensitive equipment by matching the connector’s ratings to your application. You also reduce the risk of overheating or electrical failure.

Note: Always verify the current and voltage requirements of your devices before selecting an m8 connector. Proper selection extends the lifespan of your equipment and minimizes maintenance.

Practical Advantages of M8 in Industrial Automation

Reliability of M8 Connector in Harsh Environments

Consistent Signal Transmission

You demand reliable connectivity in every industrial automation project. M8 connectors deliver consistent signal transmission, even when exposed to extreme conditions. Manufacturers subject these connectors to rigorous environmental and mechanical testing. You see them perform under mechanical shock and random vibration, simulating the stresses found in real-world industrial settings. Temperature cycling tests push the connectors from -65°C to 125°C, ensuring they maintain electrical function in severe environments. Salt spray and corrosion resistance tests confirm their robust performance in corrosive atmospheres. These features make m8 connectors a trusted choice for maintaining stable data and power transmission, which is essential for operational safety in modern factories.

- Connectors maintain low contact resistance after vibration and shock testing.

- You benefit from reliable signal flow, even in environments with high mechanical stress.

- M8 in industrial connectivity supports IIoT systems, providing the backbone for smart automation.

Reduced Downtime and Maintenance

You strive to minimize downtime and maintenance costs in your operations. M8 connectors help you achieve this goal. Their rugged design withstands repeated stress, reducing the risk of connection failures. You experience fewer interruptions because these connectors resist dust, moisture, and corrosion. The extended connector lifespan means you replace components less often, which lowers your overall maintenance expenses. You also avoid costly production delays, as m8 connectors maintain reliable connectivity throughout their lifecycle.

- Fewer replacements required due to robust construction.

- Lower maintenance costs thanks to corrosion-resistant materials.

- Stable operations with reduced risk of accidental disconnections.

Ease of Installation and Maintenance with M8

Quick-Connect Mechanisms and Push-Lock Features

You need fast and error-proof installation in industrial environments. M8 connectors offer guided key designs that prevent mismating, saving you from bent or broken pins. You can easily mate connectors in tight spaces, even without direct visibility, which speeds up assembly. Push-lock features and lockable mating mechanisms ensure secure connections, preventing accidental disconnects during operation. These features streamline your setup process and reduce installation time.

| Feature | Benefit |

|---|---|

| Guided Key Design | Prevents mismating, reducing the risk of bent or broken pins, which saves downtime. |

| Ease of Blind Mating | Allows for faster, error-proof assembly in tight spaces, enhancing installation efficiency. |

| Extended Connector Lifespan | Minimizes wear and damage, leading to lower maintenance costs and longer-lasting connectors. |

| Backward Compatibility with Standard M8 | Ensures integration into existing systems without redesign, maintaining the benefits of M8 systems. |

| Feature | Impact on Installation Time and Maintenance Costs |

|---|---|

| Simplified installation process | Reduces time spent on setup and configuration. |

| Enhanced compatibility | Minimizes the risk of incompatibility issues, leading to fewer delays. |

| Quick replacements | Facilitates faster maintenance, reducing downtime. |

| Standardization | Allows for easy sourcing of components, streamlining repairs. |

| Lockable mating | Prevents accidental disconnections, ensuring stable operations. |

| IP67 rating | Increases durability, lowering maintenance costs due to fewer replacements. |

Tip: You can reduce installation errors and speed up maintenance by choosing connectors with quick-connect and push-lock features.

Simplified Troubleshooting and Replacement

You often face tight deadlines and need to resolve issues quickly. M8 connectors simplify troubleshooting and replacement. Their standardized design allows you to swap out faulty units without redesigning your system. You benefit from easy sourcing of replacement parts, which streamlines repairs. The robust construction minimizes wear, so you spend less time on maintenance. You keep your automation systems running smoothly with minimal effort.

- Standardized connectors enable quick identification and replacement.

- You avoid extended downtime due to easy access to compatible parts.

- Maintenance teams appreciate the straightforward troubleshooting process.

Signal Integrity and Performance of M8 Connector

Shielding Against Electromagnetic Interference

You require high signal integrity in environments filled with electrical noise. M8 connectors feature EMI-resistant architecture, which prevents data corruption from electrical interference. Their fully shielded metal shells endure shock and vibration, making them ideal for applications such as data loggers and marine electronics. Compliance with IEC 61076-2-104 guarantees mechanical compatibility and signal reliability according to global standards. You maintain stable data transmission, even in the presence of strong electromagnetic fields.

| Specification | Benefit |

|---|---|

| Compact Design | Ideal for miniature sensors and compact modules, ensuring efficient space usage. |

| EMI-Resistant Architecture | Prevents data corruption from electrical interference, crucial in industrial settings. |

| Compliance with IEC 61076-2-104 | Guarantees mechanical compatibility and signal reliability according to global standards. |

| PCB-Friendly Designs | Facilitates surface-mount capabilities, optimizing space on high-density PCBs. |

| Rugged and Sealed Options | Provides protection in harsh environments, maintaining signal integrity under adverse conditions. |

| Flexible Cable Terminations | Offers various configurations for system integration, enhancing versatility in installations. |

Note: Shielded m8 connectors outperform many other connector types in maintaining signal integrity under environmental stress.

Support for Mixed Data and Power Applications

You often need to transmit both data and power through a single connector. M8 connectors support mixed data and power applications, making them essential for compact installations. You use them for Ethernet applications, where secure and precise data transmission is critical. M8-D connectors handle high-speed data communication, supporting rates up to 100 Mbit/s. Their IP67 protection ensures reliability in industrial environments. You can choose from straight cable connectors, flange connectors, and distribution boxes to centralize cable management and enhance system efficiency. Integration with M12 connectors further secures reliable data and power transmission.

- M8 connectors enable robust data transmission in limited spaces.

- Shielded designs support high-speed communication and protect against environmental hazards.

- Distribution boxes streamline installation and improve overall system efficiency.

Callout: You achieve efficient and reliable connectivity for both data and power lines by selecting m8 connectors for your automation projects.

Comparison of M8 Connector with Alternative Connector Types

M8 vs. M12 Connectors in Industrial Connectivity

Size and Application Differences

You often choose between m8 and M12 connectors based on the size and requirements of your automation project. M8 connectors feature an 8mm diameter, making them ideal for compact devices and tight installations. M12 connectors, with a 12mm diameter, suit larger equipment and more demanding environments. You see m8 connectors in small sensors and lighting, while M12 connectors power robotics and industrial sensors. The table below highlights key differences:

| Feature | M8 Connectors | M12 Connectors |

|---|---|---|

| Size | 8mm diameter | 12mm diameter |

| Pin Options | 3, 4, 5, 6, 8 pins | 2, 3, 4, 5, 6, 8, 12, 17 pins |

| Protection Level | IP67 | IP65/IP67 |

| Transmission Bandwidth | < 5 Mbps | > 1 Gbps |

| Current Transmission | Up to 4A | Up to 10A or more |

| Transmission Distance | Up to 30 meters | Up to 100 meters |

| Application | Small devices (e.g., automotive, lighting) | Large automation equipment (e.g., robotics, sensors) |

Cost and Performance Considerations

You benefit from the lower cost of m8 connectors when working with compact devices or low-power systems. M12 connectors offer higher current and bandwidth, but you pay more for these capabilities. If your project involves factory automation applications with small sensors, m8 connectors provide reliable performance at a lower price point. For high-power robotics or long-distance data transmission, you may prefer M12 connectors despite the higher cost.

M8 vs. Rectangular Connectors in Automation

Flexibility and Modularity

You gain flexibility with rectangular connectors due to their modular design. These connectors allow you to customize pin layouts and stack modules for complex wiring needs. M8 connectors offer a fixed layout once you select the shell and pin count, which limits flexibility. If you need interchangeable inserts or stackable modules, rectangular connectors provide more options. You find m8 connectors ideal for low-power tasks, while rectangular connectors handle combined power, signal, and data in larger systems.

- Rectangular connectors support greater modularity with interchangeable inserts.

- M8 connectors suit compact, low-power applications but offer less customization.

- Rectangular connectors provide more flexibility for configuration and expansion.

Environmental Protection and Durability

You rely on m8 connectors for moderate protection in harsh environments. Rectangular connectors often deliver higher durability and better environmental sealing, especially in heavy-duty factory automation applications. If your system faces exposure to dust, moisture, or chemicals, rectangular connectors may offer superior protection. M8 connectors still perform well in many industrial settings, but you should assess the specific demands of your application.

M8 vs. Other Common Industrial Connectors

Strengths and Weaknesses of Circular vs. Rectangular Designs

You notice that circular m8 connectors excel in durability and reliability. They withstand harsh conditions and maintain stable connections for power, signal, and data. Rectangular connectors offer higher pin density and greater modularity, which benefits complex wiring setups. The table below compares these features:

| Feature | Circular M8 Connectors | Other Connector Types |

|---|---|---|

| Durability | High, designed for harsh environments | Varies, some may not withstand harsh conditions |

| Reliability | Very reliable for power, signal, and data | Varies, some may have lower reliability |

| Versatility | Suitable for various applications | May be limited in application scope |

| Size | Compact, easy to install | Size varies, may be bulkier |

| Pin Density | Limited compared to rectangular connectors | Higher pin density possible |

| Modularity | Less modularity compared to rectangular types | More modular options available |

Suitability for Automation and Sensor Networks

You select m8 connectors for compact devices and lightweight sensors in factory automation applications. M8 distribution boxes work best in small automation setups, offering up to 6A power handling. M12 distribution boxes suit heavy-duty equipment and high-power robotics. If you need compact wiring and moderate protection, m8 connectors deliver efficient solutions. For high-power, long-distance connections, you may choose M12 or rectangular connectors.

| Feature | M8 Distribution Box | M12 Distribution Box |

|---|---|---|

| Best for | Compact devices, lightweight sensors, and small automation setups | Heavy-duty equipment, industrial automation, and high-power robotics |

| Power Handling | Up to 6A | Up to 4A per port |

| Size & Weight | Smaller, lightweight | Larger, more robust |

| Flexibility | Ideal for tight spaces and compact wiring | Better for high-power, long-distance connections |

| Durability | Moderate protection | Higher durability, better for harsh conditions |

Tip: You improve system efficiency and reliability by matching connector type to your automation needs.

M8 in Industrial Connectivity for Modern Environments

Adaptability of M8 Connector to Automation Trends

Support for Sensor and Actuator Networks

You see rapid changes in industrial automation, especially with the rise of sensor and actuator networks. M8 connectors help you keep pace with these trends. Their compact size fits into tight spaces on modern equipment, allowing you to connect more devices without crowding your control panels. You benefit from high-speed connectivity, which is essential for transmitting real-time data between sensors, actuators, and controllers. The robust construction of these connectors ensures reliable performance, even when you operate in environments filled with dust, oil, or extreme temperatures.

- M8 connectors provide high-speed connectivity essential for IIoT applications.

- You can rely on their robust design in harsh industrial settings.

- Their compact form factor meets the space constraints of modern automation technologies.

Compatibility with IIoT and Smart Factory Systems

You need connectors that support the growing demands of IIoT and smart factory systems. As you add more electronic devices to your factory floor, you require reliable connections that withstand challenging conditions. M8 connectors meet this need by resisting dust, oil, and temperature extremes. Enhanced communication capabilities allow you to integrate robots and automation systems seamlessly. This compatibility ensures that your factory remains efficient and connected as you adopt new technologies.

- The expansion of IIoT increases the number of electronic devices in factories, necessitating reliable connectors.

- M8 connectors withstand exposure to dust, oil, and temperature extremes, which is critical for factory environments.

- Enhanced communication capabilities are vital for the integration of robots and automation systems in smart factories.

Scalability of M8 in Expanding Operations

Modular System Integration with M8 Connector

You often face the challenge of scaling your operations as your business grows. M8 connectors support modular system integration, making it easy for you to expand or reconfigure your automation setup. Their versatility allows you to use them in a wide range of applications, from sensors to control units. You can add new modules or devices without redesigning your entire system, which saves you time and resources.

| Feature | Benefit for Scalability |

|---|---|

| Compact Design | Allows for efficient use of space in expanding operations. |

| Robust Construction | Ensures durability in harsh industrial environments. |

| Versatility | Suitable for various applications, enhancing adaptability. |

| Efficient Transmission | Facilitates power and data flow, crucial for system performance. |

| Waterproof Design | Protects against dust and moisture, ensuring reliability. |

| Wide Temperature Range | Operates effectively in extreme conditions, supporting diverse environments. |

| Ease of Installation | Reduces downtime, increasing overall production efficiency. |

Future-Proofing Industrial Connectivity

You want your investments in automation to last. M8 connectors help you future-proof your industrial connectivity. Their ability to operate in a wide temperature range and resist harsh conditions means you can rely on them as your systems evolve. The ease of installation and maintenance reduces downtime, keeping your production lines running smoothly. As automation technologies advance, you can trust that m8 connectors will continue to meet your needs for reliable, scalable, and efficient connectivity.

Tip: Choosing connectors that adapt to new technologies ensures your automation systems remain competitive and resilient.

Real-World Applications of M8 Connector in Industrial Automation

Factory Automation with M8

Sensor and Actuator Connections

You encounter m8 connectors in many factory automation setups. Their compact size and lightweight design make them ideal for connecting sensors and actuators within factory networks. You rely on m8 cable connectors to link proximity sensors, I/O modules, and encoders to control systems. These connections support precise data transmission and power delivery, which helps you maintain efficient operations. You see the versatility of m8 in industrial automation, as it adapts to various devices and layouts.

- Connect sensors and actuators to control systems with minimal space requirements.

- Use m8 connectors for reliable signal and power transmission in factory networks.

- Integrate m8 into proximity sensors, I/O modules, and encoders for seamless automation.

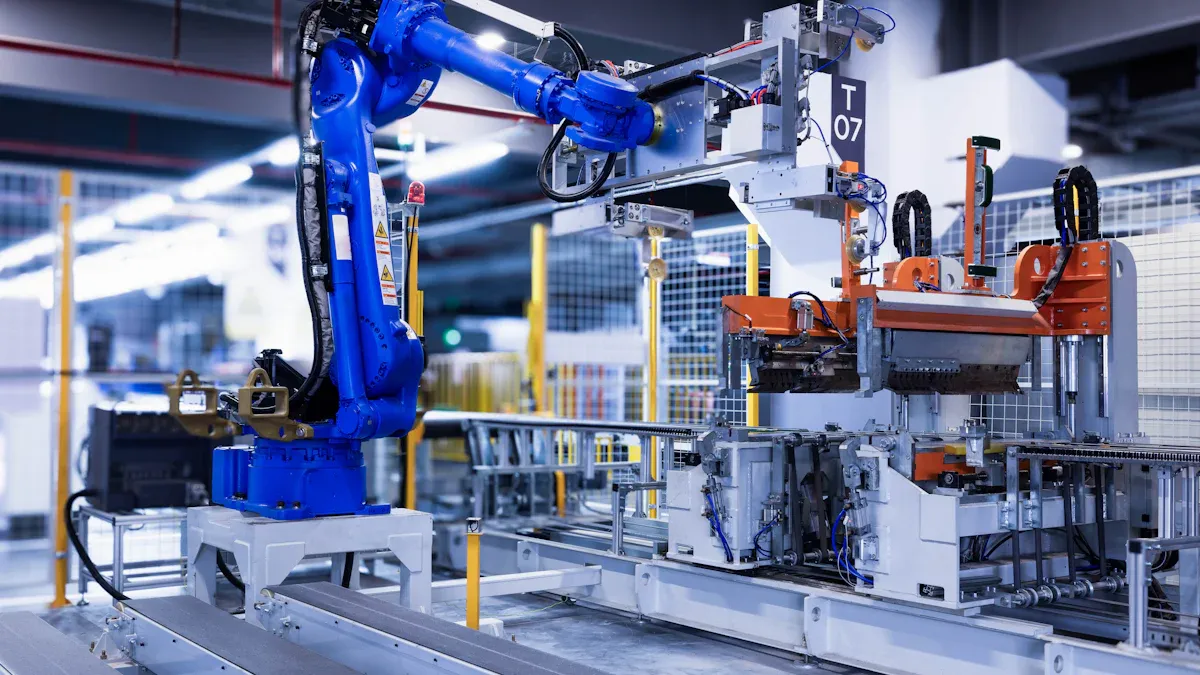

Conveyor and Robotics Systems

You use m8 connectors to support conveyor systems and robotics in manufacturing environments. These connectors provide stable connections for moving parts and automated machinery. You benefit from their robust construction, which resists vibration and shock. This reliability ensures that control systems operate smoothly, even in dynamic settings. You can deploy m8 connectors in robotics for precise movement and feedback, which enhances productivity and safety.

Process Control Using M8 Connector

Monitoring and Feedback Loops

You depend on m8 connectors to link sensors and actuators in process control systems. These connections facilitate communication between devices and control units, enabling real-time monitoring. You optimize workflow by receiving immediate feedback from sensors, which allows you to adjust operations quickly. This capability improves production efficiency and helps you maintain consistent quality.

- Connect sensors and actuators to control systems for real-time data exchange.

- Use m8 connectors to enable feedback loops that enhance process control.

- Monitor production lines and adjust parameters based on sensor input.

Environmental Sensing and Data Collection

You implement m8 connectors in environmental sensing applications. These connectors support data collection from temperature, humidity, and pressure sensors. You transmit this information to control systems, which analyze conditions and trigger necessary adjustments. You maintain safe and efficient operations by integrating m8 into your monitoring infrastructure.

Transportation and Logistics with M8

Automated Warehousing Systems

You apply m8 connectors in automated warehousing systems to connect sensors and controllers in conveyor networks. These connections ensure that control systems manage inventory movement accurately. You achieve reliable communication between devices, which supports efficient sorting and tracking.

Vehicle System Integration and Control

You use m8 connectors to control and monitor transport vehicles. These connectors link sensors to control systems, enabling real-time diagnostics and operational adjustments. You also find m8 in energy sector applications, such as wind power plants, and in medical technology for connecting diagnostic and therapeutic devices.

| Application Area | Role of M8 Connectors |

|---|---|

| Transportation and Logistics Systems | Connect sensors and controllers in conveyor systems |

| Transport Vehicle Monitoring | Control and monitor transport vehicles |

| Energy Sector | Used in wind power plants |

| Medical Technology | Connect devices and sensors in diagnostic and therapeutic systems |

Tip: You improve system reliability and efficiency by choosing m8 connectors for diverse control systems in industrial automation.

Key Considerations for Selecting M8 Connector in Industrial Connectivity

Application Requirements for M8

Environmental Factors and Protection Ratings

You must evaluate the environment where you plan to use M8 connectors. Industrial settings often expose connectors to dust, moisture, chemicals, and temperature extremes. You should select connectors with high protection ratings, such as IP67 or IP68, to ensure reliable operation in harsh conditions. These ratings indicate resistance to water and dust, which helps you maintain system integrity. You also need to consider humidity and exposure to corrosive substances. Choosing connectors with robust sealing and corrosion-resistant materials protects your equipment and reduces the risk of failure.

Electrical Specifications and Compatibility

You need to match the electrical specifications of the M8 connector to your system requirements. Voltage and current ratings determine if the connector can handle your power needs. You should check the number of pins required for your signals and power lines. Compatibility with existing components is essential. You must choose between male and female configurations and decide on straight or right-angle connectors based on your cable routing. Shielding for EMI/RFI protection and waterproofing features are important if your application involves sensitive data transmission or exposure to moisture.

| Requirement Type | Details |

|---|---|

| Electrical Specifications | Understand voltage and current ratings to ensure the connector can handle power needs. |

| Environmental Conditions | Evaluate temperature, humidity, and exposure to dust or chemicals; opt for higher protection ratings like IP67 or IP68 for harsh environments. |

| Connector Type | Choose between male and female configurations for compatibility with existing components. |

| Orientation | Select straight or right-angle connectors based on space constraints and cable routing needs. |

| Contact Configuration | Determine the number of pins (3 to 8) based on signals and power lines required. |

| Special Features | Consider shielding for EMI/RFI protection and waterproofing for moisture exposure. |

| Mechanical Specifications | Ensure cable compatibility and evaluate the locking mechanism for secure connections. |

Tip: You improve system reliability by selecting connectors that match your environmental and electrical requirements.

Installation and Maintenance Needs for M8

Accessibility and Serviceability in Industrial Settings

You must consider how easily you can access and service M8 connectors in your installation. Industrial environments often require quick troubleshooting and minimal downtime. You should plan for connector placement that allows easy reach for maintenance teams. Standardized designs help you swap out faulty connectors without complex procedures. You benefit from connectors with secure locking mechanisms, which prevent accidental disconnections and simplify service tasks.

Long-Term Reliability and Lifecycle Costs

You want to minimize lifecycle costs and maximize reliability. Routine inspections and proper installation practices extend the lifespan of M8 connectors. You should prepare for installation by gathering the right tools, keeping your workspace clean, and reviewing manuals. Strip wires to the correct length, crimp them securely, and test connections with a multimeter. Regular visual checks and functionality tests help you catch issues early. Avoid overloading connectors to prevent premature wear.

- Prepare for installation with the right tools and a clean workspace.

- Strip wires accurately, crimp securely, and test connections.

- Conduct routine visual inspections and regular functionality tests.

- Ensure connectors are not overloaded to maintain long-term reliability.

Note: You reduce maintenance costs and improve uptime by following best practices for installation and routine care.

You gain a clear advantage by choosing M8 connectors for industrial automation. Their compact form, robust build, and versatile performance deliver reliable connectivity in demanding environments. Compared to alternatives, you benefit from:

- A compact design and standardized pin pattern for greater adaptability

- D-coded options that support advanced data transmission and system compatibility

- Seamless integration with M8 and M12 systems, reducing complexity

- IP67-rated protection for consistent operation in harsh conditions

You support scalable, efficient, and resilient automation by selecting M8 connectors for your modern industrial needs.

FAQ

What is the main advantage of using M8 connectors in industrial automation?

You gain a compact, robust solution for connecting sensors and actuators. M8 connectors save space and withstand harsh environments. Their design ensures reliable data and power transmission, making them ideal for modern automation systems.

How do you choose the right M8 connector for your application?

You should check the number of pins, current and voltage ratings, and protection level (such as IP67). Match the connector type—straight or right-angle—to your installation needs. Always confirm compatibility with your devices.

Can M8 connectors handle both data and power transmission?

Yes, you can use M8 connectors for both data and low-power transmission. Many models support mixed applications, allowing you to simplify wiring and reduce installation time.

Are M8 connectors suitable for outdoor or wet environments?

You can use M8 connectors in outdoor or wet environments if you select models with IP67 or higher ratings. These connectors resist dust and water, ensuring reliable operation in challenging conditions.

What maintenance do M8 connectors require?

You should perform regular visual inspections and clean contacts if needed. Check for secure connections and replace damaged units promptly. Routine care extends connector lifespan and maintains system reliability.

How do M8 connectors compare to M12 connectors?

M8 connectors offer a smaller size, making them ideal for tight spaces and compact devices. M12 connectors provide higher current capacity and more pin options. You should choose based on your system’s power and space requirements.

Can you use M8 connectors in high-vibration environments?

Yes, you can rely on M8 connectors in high-vibration settings. Their threaded coupling and rugged construction prevent accidental disconnections and maintain stable signal transmission.

Tip: Always follow manufacturer guidelines for installation and maintenance to ensure optimal connector performance.