When you compare M5 vs. M8 connectors, you often find the M8 connector offers the best balance for most smart factory environments. Your choice depends on several factors:

- Size and form factor influence how well connectors fit in compact installations.

- Application needs, such as whether you use a Type B connector for sensors or actuators, shape your selection.

- Compatibility with existing connector factory systems ensures smooth integration.

Connection technologies play a crucial role in boosting automation efficiency and reliability. Flexible, innovative options like those from leading manufacturers help you optimize productivity and meet evolving demands.

M5 vs. M8 Connectors: Quick Comparison

Size and Physical Differences

Dimensions and Form Factor

When you compare m5 vs. m8 connectors, you notice clear differences in size and form factor. M5 connectors have a miniature size, making them ideal for applications where every millimeter counts. M8 connectors, while still compact, offer a slightly larger form factor that supports more robust connections. The table below highlights the main physical features:

| Feature | M5 Connectors | M8 Connectors |

|---|---|---|

| Size | Miniature Size | Compact Size |

| Installation | Precision Connectivity | Quick Installation |

| Weight | Lightweight | Not specified |

| Best Applications | Miniature sensors, Medical devices, High-precision instruments, Robotics | Small sensors, Actuators, Industrial lighting, Compact machinery |

Space Requirements in Smart Factories

You often face space constraints in smart factories. M8 connectors occupy about 20 percent less space for adjacent connectors compared to larger series. This compact design allows you to install more connections in high-density environments. You can maximize your panel space and maintain flexibility for future upgrades.

Technical Specifications

Pin Count and Signal Types

M5 vs. m8 connectors differ in their technical capabilities. M5 connectors typically offer 3 or 4 pins, which suit basic sensor connections. M8 connectors provide more options, supporting up to 8 pins. This flexibility lets you handle more complex signals and data transmission needs.

| Connector Type | Pin Count | Rated Voltage | Rated Current |

|---|---|---|---|

| M5 | 3 | 60 V | N/A |

| M5 | 4 | 60 V | N/A |

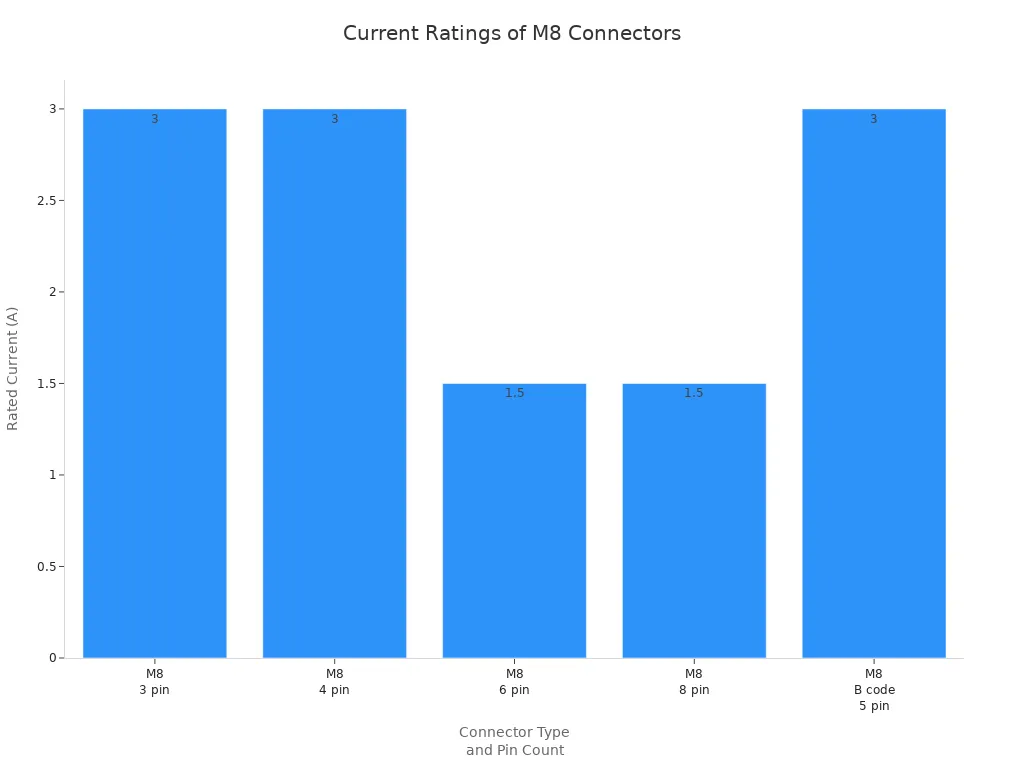

| M8 | 3 | 50 V a.c./ 60 V d.c. | 3 A |

| M8 | 4 | 50 V a.c./ 60 V d.c. | 3 A |

| M8 | 6 | 30 V a.c./ 30 V d.c. | 1.5 A |

| M8 | 8 | 30 V a.c./ 30 V d.c. | 1.5 A |

| M8 (B code) | 5 | 30 V a.c./ 30 V d.c. | 3 A |

Current and Voltage Ratings

You must consider electrical requirements when choosing between m5 vs. m8 connectors. M5 connectors support up to 60 V, but do not specify current ratings. M8 connectors handle up to 3 A and support both AC and DC voltages, making them suitable for a wider range of devices.

Cable Types and Lengths

You can use both connector types with various cable types, but m8 connectors often support longer cable runs and thicker cables. This feature helps you maintain signal integrity in larger installations.

Cost Considerations

Price Differences

You may find that m5 connectors cost less per unit due to their smaller size and simpler design. However, m8 connectors offer more features, which can justify a higher price in complex applications.

Total Cost of Ownership

You should look beyond the initial price when evaluating m5 vs. m8 connectors. The table below outlines key cost factors:

| Cost Factor | Description |

|---|---|

| Assembly Time | Ease of soldering impacts overall labor costs. |

| Rework Rates | Higher rework rates can significantly increase total costs. |

| Connector Lifespan | Longer lifespan reduces the frequency of replacements, lowering costs. |

| MOQ Requirements | Minimum order quantities can affect bulk pricing and overall project costs. |

| Installation Complexity | Simpler designs can reduce installation time and associated costs. |

Tip: You can reduce your total cost of ownership by selecting connectors that offer easy installation and long service life.

Typical Applications in Industrial Automation

M5 Connector Use Cases

Miniature Sensors and Devices

You often encounter m5 connectors in applications that demand compact solutions. These connectors work well with miniature sensors, vehicle control systems, and robotic arms. Their small size allows you to integrate them into automation cameras and other devices where space is at a premium. In many industrial applications, you need reliable sensor connections that do not add bulk to your equipment. M5 connectors deliver this advantage by supporting precise and stable connections in tight layouts.

- Miniature sensors

- Vehicle control systems

- Robotic arms

- Automation cameras

Tight-Space Installations

When you design systems for limited spaces, m5 connectors provide a practical solution. Their miniature form factor lets you fit more connections into dense control panels or compact machinery. You can streamline your automation setup and reduce clutter, which helps with maintenance and troubleshooting. These connectors also minimize the risk of accidental disconnection in environments with frequent movement or vibration.

M8 Connector Use Cases

Standard Sensors and Actuators

M8 connectors serve as a standard choice for connecting sensors in automation systems. You can use them for actuators in tight spaces, which is a common requirement in smart factories. Their robust design ensures reliable performance, even in demanding conditions. Many small devices in industrial settings rely on m8 connectors for consistent power and data transmission.

- Sensors in automation systems

- Actuators in compact installations

- Small devices in industrial environments

Robotics and Motion Control

You often select m8 connectors for robotics and motion control tasks. Their sturdy construction withstands the stress of moving parts and repeated cycles. In automated machinery, these connectors help maintain stable connections, reducing downtime and improving productivity. You benefit from their ability to handle both signal and power lines in a single, compact interface.

Application Overlap and Flexibility

When Either Connector Can Be Used

In some scenarios, you can choose either m5 or m8 connectors. For example, both types support miniature devices and sensor connections in automation projects. If your application does not require high current or voltage, you may select the connector that best fits your space and installation preferences.

Tip: Evaluate your system’s electrical and physical requirements before deciding which connector to use. This approach ensures optimal performance and future scalability.

Limitations and Trade-Offs

You should consider the limitations of each connector type. M5 connectors excel in miniature and low-power applications but may not support higher current needs. M8 connectors offer more versatility but occupy slightly more space. Balancing these trade-offs helps you achieve the best results in your automation setup.

Application Suitability for Smart Factories

Sensors and Data Acquisition

High-Density Sensor Networks

You often need to connect many sensors in a smart factory. When you work with high-density sensor networks, space becomes a critical factor. Connectors with a compact size allow you to fit more connections into tight spaces. This helps you increase the number of sensors without making your control panels crowded. You can achieve precise data collection and maintain organized wiring, which is essential for troubleshooting and future upgrades.

Environmental Monitoring

Environmental monitoring systems require reliable and efficient connections. You want to ensure that your sensors work well in limited spaces and harsh conditions. The table below highlights the main strengths of using these connectors in environmental monitoring:

| Strengths | Description |

|---|---|

| Compact Size | Ideal for applications with limited space. |

| Quick Installation | Efficient in space-constrained environments. |

| Reliable Power | Handles power transmission effectively despite small size. |

You benefit from quick installation and dependable power delivery, even when you install sensors in challenging locations.

Actuators and Control Systems

Compact Actuator Integration

You often need to integrate actuators into small control panels or machinery. The table below compares features for actuator and control system integration:

| Feature | M5 Connectors | M8 Connectors |

|---|---|---|

| Size | Smallest in M series, suitable for miniature devices | Robust and compact, suitable for various applications |

| Applications | Low-power applications, tight control panels | Factory automation, automotive, robotics |

| Protection Rating | N/A | IP67 rating for dust and water protection |

| Data Rate | N/A | Supports high data rates |

| Environment Suitability | Limited to low-power, less harsh environments | Reliable performance in harsh environments |

You can use these connectors to save space and maintain a clean layout. M8 connectors offer extra protection and support higher data rates, which is important for advanced automation systems.

Power Delivery Needs

When you select connectors for actuators, you must consider power delivery. The table below outlines the limitations:

| Connector | Characteristics | Power Delivery Limitations |

|---|---|---|

| M5 | Compact, sealed, robust interface for small sensors | Limited to low-current applications, not suitable for high power delivery |

| M8 | Flexible, supports signal, data, and low-current power | More suitable for mobile systems, but still limited compared to M12 for high power applications |

You should choose the right connector based on your actuator’s power needs. M8 connectors handle more power than M5, but you may need larger connectors for high-power devices.

Robotics and Automated Machinery

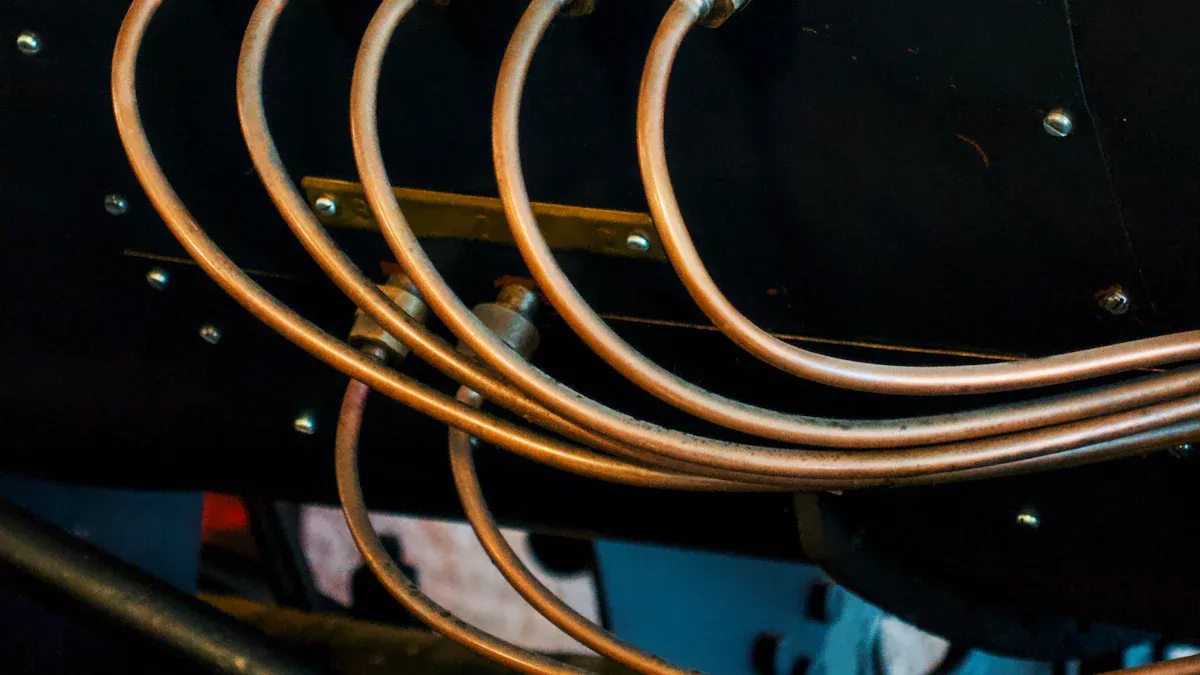

Cable Management in Moving Parts

You face unique challenges when managing cables in robotics and automated machinery. M8 connectors help you organize wiring efficiently because of their compact size. You can route cables through tight spaces and moving joints without adding bulk. This improves the overall design and reduces the risk of cable damage.

- M8 connectors withstand harsh environments, ensuring stable electrical connections.

- You can select from various customization options, such as housing material and termination style.

- Their design supports efficient cable management in complex robotic systems.

Reliability Under Vibration and Motion

You need connectors that maintain stable connections during constant movement and vibration. Both M5 and M8 connectors use high-quality materials, such as metals and high-temperature plastics. These materials help them resist dust, water, and corrosion. You can rely on these connectors to deliver consistent performance, even in demanding production lines. Their durability ensures that your automated systems run smoothly with minimal downtime.

Industrial Cameras and Vision Systems

Space-Saving Connections for Imaging Devices

You face unique challenges when integrating industrial cameras into smart factory environments. Space constraints often limit your options for connectors. M5 and M8 connectors offer compact solutions that help you maximize available space without sacrificing reliability. Their small form factors allow you to fit more connections into tight control panels or camera housings. This advantage proves essential when you work with modular imaging devices or robotic arms, where every millimeter counts.

Consider the following comparison table to understand how these connectors support space-saving requirements:

| Connector Type | Size | Current Rating | IP Rating | Compliance |

|---|---|---|---|---|

| M5 | 5 mm | 1 A | IP67 | IEC61156-12 |

| M8 | 8 mm | Higher current | IP67 | IEC61156-12 |

You benefit from the lightweight design of both connector types. This feature reduces the overall bulk of your installations and supports devices where payload weight is critical. You can deploy more cameras in high-density layouts, improving coverage and data collection across your factory floor.

Tip: Choose connectors with IP67 ratings to ensure protection against dust and water, especially in environments where imaging devices operate near production lines.

Signal Integrity for High-Speed Data

Maintaining signal integrity is crucial for high-speed data transmission in industrial vision systems. You rely on connectors that support robust data rates and minimize interference. M5 and M8 connectors utilize a single twisted pair of wires, which helps you achieve high data rates while reducing signal loss. This design ensures that your imaging devices deliver clear, accurate visuals for quality control and process monitoring.

You should look for connectors that comply with IEC61156-12 standards. Compliance guarantees interoperability and consistent performance across different devices. When you select M5 or M8 connectors, you gain confidence that your system will maintain reliable data flow, even in environments with electrical noise or vibration.

- Compact design reduces bulk in installations.

- Utilizes a single twisted pair of wires for high data rates.

- Compliant with standards ensuring signal integrity and interoperability.

You find these connectors particularly beneficial in applications where space is limited, such as sensors and modular I/O nodes. Their small size and lightweight construction make them ideal for use in robots and automated machinery, where stable connections and minimal weight are essential.

Note: Reliable signal transmission helps you avoid costly downtime and ensures your vision systems operate at peak efficiency.

Compatibility and Integration Considerations

Environmental Resistance

IP Ratings and Protection

You need to ensure that your factory equipment can withstand dust, water, and other harsh elements. Both M5 and M8 connectors deliver strong protection with IP67 and IP68 ratings. These ratings mean you can use them in environments where water immersion or heavy dust is common. The table below shows how these connectors perform in tough conditions:

| Connector Type | IP Rating | Applications in Harsh Environments |

|---|---|---|

| M5 | IP67/IP68 | Transportation, control systems, automated doors, sensor connectivity |

| M8 | IP67/IP68 | Ruggedized data loggers, sensors, electronic gauges, avionics, marine electronics |

You can rely on these connectors to keep your systems running, even when exposed to challenging industrial settings.

Chemical and Temperature Resistance

You often face chemical exposure and extreme temperatures in smart factories. Manufacturers design M8 connectors for sensor systems and harsh environments. They use advanced materials to resist corrosion and chemical damage. Some brands offer nickel-aluminium bronze or stainless steel options, which hold up well in aggressive conditions. You benefit from reliable connectivity, even when your equipment operates in areas with high humidity or chemical splashes.

- M8 connectors withstand extreme temperatures and chemical exposure.

- Manufacturers use corrosion-resistant materials like nickel-aluminium bronze and stainless steel.

- These connectors provide IP67/IP68 protection, making them suitable for environments with high humidity and chemicals.

System Integration and Future-Proofing

Backward and Forward Compatibility

You want your automation systems to work with both current and future devices. M5 and M8 connectors follow industry standards, so you can integrate them with a wide range of equipment. This compatibility helps you avoid costly upgrades when you add new machines or sensors. You can also replace older components without changing your entire setup.

Scalability for Expanding Systems

Smart factories grow and change over time. You need connectors that support easy expansion. Both M5 and M8 options allow you to add more sensors or devices as your needs evolve. Their compact size lets you fit more connections into limited spaces, which is essential for scaling up your operations. You can plan for future growth without worrying about space or compatibility issues.

Installation and Maintenance

Ease of Assembly and Replacement

You save time and reduce errors when you use connectors designed for quick assembly. M5 and M8 connectors feature user-friendly designs that simplify installation. You can connect or disconnect them without special tools. This ease of use helps you minimize downtime during maintenance or upgrades.

Common Installation Challenges

You may encounter tight spaces or awkward angles during installation. Compact connectors help you overcome these challenges. However, you should always check for proper alignment and secure fastening to prevent accidental disconnections. Regular inspections ensure long-term reliability and reduce the risk of unexpected failures.

Tip: Choose connectors with clear markings and robust locking mechanisms to make installation and maintenance even easier.

Making the Right Choice: M5 or M8?

Decision Criteria Checklist

Selecting the right connector for your smart factory requires a systematic approach. You need to evaluate several factors to ensure reliable performance and future scalability.

Space Constraints

You often face limited space in control panels and machinery. If you work with miniature sensors or devices where every millimeter matters, m5 connectors provide a significant advantage. Their small footprint allows you to maximize the number of connections in dense layouts. In contrast, m8 connectors, while still compact, require slightly more room but offer greater versatility for most industrial applications.

Electrical Requirements

You must match the connector to your system’s electrical needs. M5 connectors suit low-current, low-voltage applications, such as basic sensor signals. If your devices demand higher current or more complex signal transmission, m8 connectors deliver better performance. Always check the rated voltage and current to prevent overheating or electrical failures. Adhering to industry standards and safety protocols protects your equipment and personnel.

Application Demands

You should consider the specific demands of your application. For high-density sensor networks, m5 connectors excel in saving space. If you need robust connections for actuators, robotics, or moving machinery, m8 connectors withstand vibration and mechanical stress. Evaluate the environment, mechanical forces, and frequency of connection cycles to make the best choice.

Tip: Regular inspections and maintenance help you maintain connector reliability in demanding industrial environments.

Common Smart Factory Scenarios

You encounter a variety of scenarios in smart factories. Each situation calls for a different connector strategy.

Best Choice for Sensor Networks

Sensor networks often require compact, high-density connections. M5 connectors shine in these setups, letting you install more sensors in limited space. Their design supports efficient wiring and easy integration into modern industrial systems. When you need to monitor multiple parameters across your facility, m5 connectors help you keep your control panels organized and scalable.

Best Choice for Robotics and Motion

Robotics and motion control systems demand connectors that handle dynamic forces and frequent movement. M8 connectors offer superior durability and shock resistance, making them ideal for these applications. You benefit from their ability to maintain stable connections under vibration and repetitive motion. In automated machinery, m8 connectors support both signal and low-current power lines, ensuring reliable operation in industrial robotics.

Best Choice for Harsh Environments

Harsh environments present unique challenges, such as exposure to dust, moisture, chemicals, and temperature extremes. Both m5 and m8 connectors provide IP67 or IP68 protection, but m8 connectors often use advanced materials for added chemical and temperature resistance. You should select connectors that have undergone environmental testing and meet durability standards. This approach ensures your connections remain secure and functional, even in the toughest industrial settings.

| Best Practice | Description |

|---|---|

| Environmental Testing | Test connectors for the specific conditions they will face in your facility. |

| Durability | Choose connectors that withstand wear and tear in harsh environments. |

| Electrical Requirements | Match connectors to the necessary electrical specifications for each application. |

| Mechanical Factors | Consider size, shape, and force needed for insertion and extraction. |

| Shock and Vibration Resistance | Ensure connectors can handle dynamic forces without failure. |

| Compliance with Safety Protocols | Follow industry standards to prevent overheating and electrical failures. |

| Regular Inspections and Maintenance | Schedule routine checks to maintain functionality and reliability. |

Mistakes to Avoid

You can avoid costly errors by steering clear of common pitfalls during connector selection.

Over- or Under-Specifying Connectors

You might feel tempted to choose the smallest or most robust connector available. Over-specifying leads to unnecessary costs and wasted space. Under-specifying results in unreliable connections and frequent failures. Always align your connector choice with the actual requirements of your industrial application.

Ignoring Future Expansion

You should plan for growth from the start. If you overlook scalability, you may face expensive retrofits or system redesigns later. Select connectors that allow for easy expansion and integration with new devices. Both m5 and m8 connectors support modularity, but you must ensure your initial design leaves room for additional connections as your smart factory evolves.

Note: Careful planning and adherence to best practices help you build a resilient, future-proof industrial automation system.

You see clear differences between M5 and M8 connectors in size, electrical capacity, and application flexibility. M8 connectors often suit most smart factory setups because you need faster data rates, higher power throughput, and robust reliability.

- Miniaturization supports compact designs for modern automation.

- Contactless connectivity reduces mechanical wear and boosts long-term performance.

You should always assess your factory’s specific needs before choosing a connector. Careful selection helps you future-proof your automation and maintain efficient operations.

FAQ

What is the main difference between M5 and M8 connectors?

You will notice that M5 connectors have a smaller diameter and fewer pins. M8 connectors offer more pin options and higher current ratings. You should choose based on your space and electrical needs.

Can you use M5 and M8 connectors interchangeably?

You can use both in some sensor and device applications. However, you must check pin count, voltage, and current requirements. Always match the connector to your device specifications.

Are M8 connectors better for harsh environments?

You benefit from M8 connectors in harsh environments. They often use advanced materials and provide strong resistance to chemicals, dust, and water. Look for IP67 or IP68 ratings for maximum protection.

How do you ensure proper installation of these connectors?

You should follow manufacturer guidelines. Always check for secure locking and proper alignment. Use connectors with clear markings and robust locking mechanisms to reduce installation errors.

What is the typical lifespan of M5 and M8 connectors?

You can expect a long service life if you install and maintain them correctly. Most industrial-grade connectors last several years, even in demanding environments.

Do M5 and M8 connectors support high-speed data transmission?

You can use both connector types for high-speed data, especially in sensor and vision systems. Choose connectors that comply with IEC standards to ensure signal integrity and reliable performance.

What should you consider when planning for future expansion?

You should select connectors that allow easy addition of new devices. Plan for extra space and choose modular designs. This approach helps you scale your system without major redesigns.

Tip: Always document your connector choices and wiring layouts for easier upgrades and troubleshooting.