You rely on the mil-dtl-38999 connector to maintain performance in demanding military and aerospace missions. When you choose connectors, you face challenges such as extreme temperatures, moisture, vibration, and installation difficulties. These problems often lead to failures:

- Connector malfunctions account for 40-50% of military component failures.

- About 70% of aerospace quality defects stem from mil spec electrical connector issues.

| Challenge | Description |

|---|---|

| Extreme Temperature Variations | Connectors are subjected to severe heat and extreme cold, leading to material degradation and failure. |

| Moisture and Humidity | Exposure to moisture can cause corrosion, affecting electrical connections and requiring sealed designs. |

| Vibration and Shock | Excessive vibrations can lead to mechanical failures, necessitating advanced designs for stability. |

| Installation Difficulties | Proper installation requires understanding of mechanical properties, with misalignments leading to failures. |

| Material Selection Issues | Choosing appropriate materials is critical due to exposure to extreme conditions and chemical agents. |

You demand environmental resistance, proven durability, and EMI shielding whether you work with an M8 connector, Type B connector, or source from a connector factory.

Overview of the MIL-DTL-38999 Connector Family

Purpose and Applications of mil-dtl-38999 connector

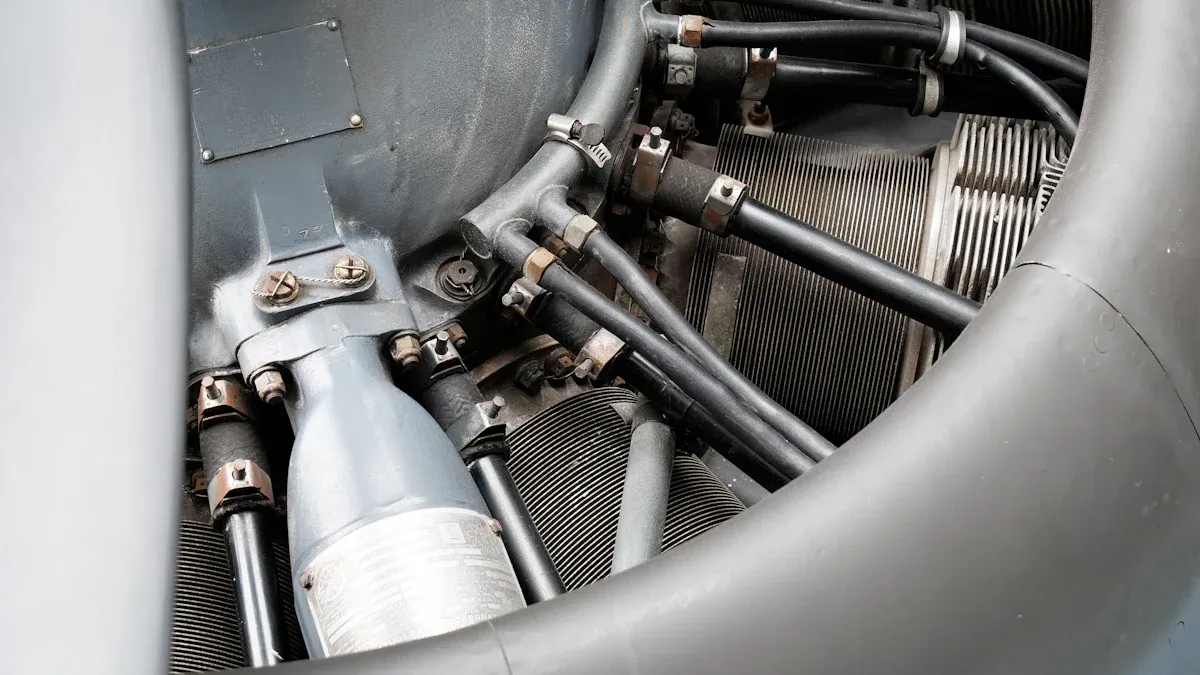

You encounter mil-dtl-38999 connectors in some of the world’s most demanding environments. These connectors serve as the backbone for mission-critical systems in military, aerospace, and other harsh settings. When you work with advanced avionics or electronic systems in military vehicles and aircraft, you rely on these connectors for secure and stable connections. In aerospace, you see them deployed in flight control, navigation, and communication systems because they withstand vibration, shock, and extreme temperatures.

The table below highlights where you most often find mil-dtl-38999 connectors:

| Industry/Application | Description |

|---|---|

| Military | Used in advanced avionics and electronic systems in military vehicles and aircraft. |

| Aerospace | Deployed in various aerospace applications due to reliability and performance in harsh environments. |

| Harsh Environments | Proven reliability and durability make them suitable for extreme conditions in both military and aerospace sectors. |

You choose these connectors when you need performance that does not falter under pressure. Their design supports critical applications where failure is not an option.

Key Features Across the mil-dtl-38999 Family

Every mil-dtl-38999 connector series shares a set of technical features that set them apart from standard connectors. You benefit from these features whether you select Series I, II, III, or IV. Here are the key attributes you can expect:

- Triple-start mating thread prevents galling and cross-threading, making installation smoother.

- Quick disconnect mechanism with single-turn action ensures self-locking and grounded coupling.

- Accessory threads and environmental sealing allow for secure backshell attachment.

- Scoop-proof shell design protects crimp-removable contacts from accidental damage.

- Integrated grounding provides reliable plug-to-receptacle and shell-to-shell bottoming.

- Minimum shielding of 65dB at 10 GHz delivers strong EMI protection.

- Wide variety of contact sizes and wire arrangements, all compliant with MIL-STD-1560.

You also need to understand the differences between the series. The table below summarizes the main design distinctions and intended uses:

| Series | Key Features |

|---|---|

| Series I | Scoop-proof, bayonet-locking system for quick, secure connections in rugged environments. |

| Series II | Non-scoop-proof, low-profile bayonet-locking system for space-constrained applications. |

| Series III | Scoop-proof, triple-start threaded coupling system with self-locking action that improves alignment and resists vibration. |

| Series IV | Scoop-proof, breech-lock coupling system for high shock and vibration. |

When you select a mil-dtl-38999 connector, you gain access to a family of connectors engineered for reliability, environmental resistance, and superior EMI shielding. These features ensure your systems perform consistently, even in the harshest conditions.

Series Comparison: Pressure Performance and Reliability in Military Applications

Series I: General Characteristics of mil-dtl-38999

Pressure Resistance

You can rely on Series I mil-dtl-38999 connectors when your application demands high-pressure and low-leakage performance. These connectors feature a fast, 1/3 turn bayonet coupling that allows you to achieve secure connections quickly. The scoop-proof design protects the contacts from accidental damage during mating and unmating. You will find that Series I connectors meet strict mil-spec sealing requirements through a glass-to-metal seal. This construction makes them ideal for use in air, sea, and space environments where pressure resistance is critical.

- Fast, 1/3 turn bayonet coupling for quick, secure connections

- Scoop-proof design for contact protection

- Glass-to-metal seal for superior pressure resistance

- Suitable for high-pressure, low-leakage applications

Durability and Sealing

You benefit from robust durability with Series I connectors. The rugged shell construction and advanced sealing technology ensure long-term reliability in harsh military environments. You can trust these connectors to maintain their integrity under repeated mating cycles and exposure to contaminants. The environmental sealing keeps moisture and dust out, which helps prevent corrosion and electrical failures.

EMI Shielding

You gain strong EMI and RFI shielding with Series I connectors. The integrated grounding and shell-to-shell bottoming provide a continuous conductive path, which helps block electromagnetic interference. This shielding is essential for high-speed applications and high-speed transmission support, where signal integrity matters most. You can use Series I connectors in systems that require high contact density and reliable EMI/RFI shielding.

Series II: Low-Profile Design for Compact Military Systems

Pressure Resistance

You will appreciate the low-profile design of Series II mil-dtl-38999 connectors if you work with compact military systems. The reduced size and weight make these connectors a smart choice for applications where space and mass are at a premium. This design directly contributes to improved pressure performance by minimizing the connector’s footprint while maintaining reliability. You can install Series II connectors in tight spaces without sacrificing performance under pressure.

Durability and Sealing

You get dependable durability with Series II connectors. The bayonet coupling mechanism ensures a secure connection, even in environments with vibration and shock. The environmental sealing protects the contacts from moisture and dust, which extends the connector’s service life. You can count on Series II connectors to deliver consistent performance in high-speed and high-speed applications that demand high contact density.

EMI Shielding

You benefit from effective EMI and RFI shielding with Series II connectors. The shell design and grounding features help reduce electromagnetic interference, which is crucial for sensitive military electronics. You can use these connectors in systems that require high-speed transmission support and robust EMI/RFI shielding. The compact form factor does not compromise the shielding effectiveness, so you maintain signal integrity in demanding environments.

Series III: Enhanced Environmental Protection in mil-dtl-38999 series iii

Pressure Resistance

You choose Series III mil-dtl-38999 connectors when you need the highest level of pressure resistance. The triple-start threaded coupling system with self-locking action ensures a tight, vibration-resistant connection. This design excels in environments where you face extreme pressure changes, such as high-altitude aerospace or deep-sea military operations. The advanced sealing technology provides unmatched environmental resistance, making Series III the top performer under pressure.

Durability and Sealing

You experience superior durability with Series III connectors. The rugged shell construction and enhanced sealing features protect against moisture, dust, and chemical exposure. You can rely on these connectors for long-term reliability in the harshest military and aerospace environments. The scoop-proof design and high contact density support high-speed and high-speed applications, ensuring your systems remain operational even under stress.

EMI Shielding

You achieve the highest level of EMI and RFI shielding with Series III connectors. The integrated grounding and shell-to-shell bottoming deliver exceptional EMI/RFI shielding effectiveness. This capability is vital for high-speed transmission support and high-speed applications where signal integrity is non-negotiable. You can deploy Series III connectors in mission-critical systems that demand maximum shielding and environmental resistance.

Tip: When you select a mil-dtl-38999 connector for your military or aerospace project, always match the series features to your specific pressure, durability, and EMI requirements. Series III offers the best all-around performance, but Series I and II provide unique advantages for specialized applications.

Series IV: Hermetic Sealing for Specialized Military Environments

Pressure Resistance

You encounter MIL-DTL-38999 Series IV connectors in military environments where pressure changes rapidly and reliability is essential. These connectors use hermetic sealing to create an airtight barrier, which keeps moisture, gases, and contaminants out. You benefit from this technology in high-altitude aircraft, submarines, and missile systems. Hermetic sealing ensures that the connector remains operational even when exposed to vacuum or positive pressure. You see Series IV connectors perform well in extreme temperature fluctuations and aggressive media, such as chemicals or fuel vapors. The breech-lock mechanism allows you to engage the connector securely with a simple 90-degree rotation, which helps maintain leak-proof performance under pressure.

| Feature | Description |

|---|---|

| Breech-Lock mechanism | Facilitates easy connection with a 90-degree rotation, ensuring secure engagement. |

| Leak-proof design | Prevents ingress of moisture and gases, essential for hermetic sealing in military applications. |

| Robust sealing technologies | Utilizes glass-to-metal, ceramic-to-metal, and epoxy polymer-based sealing for durability. |

You rely on Series IV when you need a mil-dtl-38999 connector that can withstand pressure differentials and maintain integrity in hazardous environments.

Durability and Sealing

You demand connectors that last through repeated cycles and exposure to harsh conditions. Series IV mil-dtl-38999 connectors use advanced sealing technologies, such as glass-to-metal and ceramic-to-metal seals, to deliver long-term durability. These seals protect the connector from water, dust, and aggressive chemicals. You find that Series IV connectors meet or exceed IP67/IP68 sealing standards, which means they resist water ingress even during immersion. The leak-proof design keeps your systems safe from corrosion and electrical failures. You use these connectors in environments where thermal and mechanical shocks are common, and you expect them to endure without loss of performance.

- Creates an airtight seal

- Waterproofs the connector

- Protects against aggressive media in hazardous environments

- Enhances resistance to thermal and mechanical shocks

- Improves endurance in high altitudes

- Enables operation under vacuum or positive pressure

You choose Series IV when you need mil-dtl-38999 connectors that offer maximum protection and reliability in specialized military applications.

EMI Shielding

You recognize the importance of shielding in military electronics. Series IV mil-dtl-38999 connectors provide robust EMI and RFI protection, which helps maintain signal integrity in mission-critical systems. The connector shell and grounding features block electromagnetic interference, so you avoid data loss and system malfunctions. You deploy Series IV connectors in environments with high levels of electrical noise, such as radar installations or electronic warfare systems. The hermetic sealing works together with the shielding to ensure that your connections remain secure and reliable, even under the most demanding conditions.

Tip: When you select a connector for environments with extreme pressure and aggressive media, consider Series IV for its unmatched sealing and EMI performance.

Comparison Table: mil-dtl-38999 Series I vs II vs III vs IV

Performance Under Pressure

You need connectors that perform reliably when exposed to high pressure. Each series in the mil-dtl-38999 family offers unique strengths. Series I and III excel in environments with rapid pressure changes. Series III stands out with its triple-start threaded coupling, which resists vibration and maintains a secure connection. Series IV uses hermetic sealing, making it ideal for vacuum and positive pressure scenarios. Series II provides a low-profile option for compact systems, but it may not match the pressure resistance of Series III or IV.

| Series | Pressure Performance | Coupling Mechanism | Best Use Case |

|---|---|---|---|

| I | High | Bayonet | General military, aerospace |

| II | Moderate | Bayonet (low-profile) | Space-constrained military systems |

| III | Superior | Triple-start threaded | Extreme pressure, vibration, shock |

| IV | Exceptional | Breech-lock, hermetic | Vacuum, high-altitude, hazardous |

Tip: Choose Series III or IV mil-dtl-38999 connectors for the most demanding pressure environments.

Environmental Sealing Capabilities

You want connectors that keep moisture, dust, and contaminants out. The mil-dtl-38999 connectors use advanced sealing mechanisms. Series III and IV provide the highest level of environmental protection. Series IV uses hermetic sealing, which creates an airtight barrier. Series III relies on enhanced gaskets and threaded coupling for superior sealing. Series I and II offer reliable protection, but Series III and IV set the standard for harsh environments.

The following table compares key sealing features:

| Feature | Series I | Series II | Series III | Series IV |

|---|---|---|---|---|

| Sealing Mechanism | Flat gasket | Flat gasket | O-ring radial interface | Hermetic (glass-to-metal, ceramic-to-metal) |

| Altitude Immersion Testing | Not specified | Not specified | 75,000 ft | 75,000 ft |

| Voltage Rating | Standard | Standard | Higher due to Top Hat insulator | Higher due to Top Hat insulator |

| Independent Lab Verification | Yes | Yes | Yes | Yes |

| Resistance to Vibration-Induced Decoupling | Standard | Standard | Improved with re-engineered ratchet mechanism | Improved with breech-lock |

Note: Series III and IV mil-dtl-38999 connectors deliver the best sealing for altitude, moisture, and vibration.

EMI Shielding Effectiveness

You require connectors that block unwanted electrical noise. All mil-dtl-38999 connectors provide strong EMI protection. Series III and IV offer the highest shielding effectiveness, with a minimum of 65dB at 10 GHz. This level of EMI shielding ensures your systems maintain signal integrity in environments with high electromagnetic interference. Series I and II also deliver reliable EMI performance, but Series III and IV are preferred for mission-critical applications.

- Series I: 65dB minimum at 10 GHz

- Series II: 65dB minimum at 10 GHz

- Series III: 65dB minimum at 10 GHz

- Series IV: 65dB minimum at 10 GHz

🛡️ You can trust Series III and IV mil-dtl-38999 connectors to protect your equipment from EMI in the most challenging conditions.

Durability and Long-Term Reliability

You expect MIL-DTL-38999 connectors to deliver consistent performance in the harshest environments. These connectors use rugged shells, advanced sealing, and high-quality materials to resist corrosion, vibration, and thermal shock. You benefit from their robust construction, which helps prevent physical fatigue and electrical failure during repeated use.

When you deploy these connectors in military or aerospace systems, you rely on their ability to withstand thousands of mating cycles. The scoop-proof design protects contacts from accidental damage. The self-locking coupling mechanisms, such as bayonet or threaded systems, maintain secure connections even when exposed to vibration or shock. You see these features extend the service life of your equipment and reduce downtime.

To maximize long-term reliability, you must follow strict maintenance routines. Regular care helps you identify early signs of wear and prevents unexpected failures. The table below outlines essential maintenance practices:

| Maintenance Practice | Description |

|---|---|

| Routine Inspection | Conduct regular visual evaluations to identify signs of physical fatigue, such as cracks or deformation. |

| Cleaning Procedures | Use non-corrosive agents and lint-free cloths to clean connectors, avoiding abrasive tools. |

| Storage Conditions | Store connectors in moisture-proof packaging and maintain a controlled environment to prevent degradation. |

| Understanding Environmental Impact | Recognize how temperature and humidity affect connector performance to implement appropriate safeguards. |

You should clean connectors carefully to avoid damaging sensitive contacts. Follow these steps for effective cleaning:

- Apply a few drops of cleaning fluid to a cleaning stick.

- Gently insert the stick into the connector and rotate it while applying moderate pressure.

- Visually inspect the end face for any remaining dirt or damage.

- Remove excess cleaning fluid with a lint-free cloth and re-inspect before reconnecting.

Tip: You increase connector lifespan by storing them in moisture-proof packaging and controlling temperature and humidity in your facility.

You must recognize how environmental factors impact connector reliability. High humidity, extreme temperatures, and exposure to chemicals accelerate material degradation. You can prevent these issues by choosing the right series for your application and maintaining a strict inspection schedule.

You ensure long-term reliability by combining robust connector design with disciplined maintenance. MIL-DTL-38999 connectors reward your attention to detail with years of dependable service, even in the most demanding conditions.

Real-World Use Cases and Application Scenarios for mil-dtl-38999 connector

Aerospace and Defense Applications

High-Altitude and Extreme Pressure Environments

You encounter some of the harshest conditions in aerospace and defense missions. When you operate at high altitudes, you face rapid pressure changes, extreme cold, and exposure to chemicals like jet fuel. mil-dtl-38999 connectors help you maintain signal and power integrity under these stresses. You benefit from their ability to withstand shock, vibration, and temperature swings. These connectors also resist corrosion and provide secure mating with quick-locking mechanisms.

| Series | Features | Applications |

|---|---|---|

| Series I | Hermetically sealed, maintains electrical continuity during mating | Military and commercial aerospace applications |

| Series II | Low silhouette for minimum size and weight | Aerospace applications requiring compact connectors |

| Series III | Glass-to-metal sealed, withstands severe environments | High temperature, humidity, vibration, and shock applications |

You rely on these connectors because they meet military-grade standards and perform reliably in high-altitude and extreme pressure environments.

Vibration and Shock Resistance in Military Aircraft

You demand robust connectors in military aircraft. mil-dtl-38999 connectors deliver consistent performance when exposed to constant vibration and mechanical shock. You see these connectors used in avionics, flight control, and communication systems. Their rugged design ensures that you avoid unexpected failures during critical missions. You also benefit from their EMI protection, which keeps your systems free from interference.

Tip: Choose Series III for maximum vibration and shock resistance in military and aerospace applications.

Industrial and Transportation Sectors

Harsh Environmental Conditions in Rail and Marine

You face unique challenges in rail and marine environments. You must protect your systems from temperature extremes, moisture, dust, and salt fog. mil-dtl-38999 connectors provide environmental sealing that prevents ingress of contaminants. You also benefit from their resistance to vibration, shock, and corrosion.

| Factor Type | Specific Factors / Tests | Description / Impact on Connectors |

|---|---|---|

| Environmental | Temperature extremes | Reliable operation across wide temperature ranges |

| Environmental sealing | Prevents moisture and dust ingress | |

| Vibration and shock | Withstands mechanical stresses | |

| Salt fog | Resists corrosion in marine environments | |

| Operational | EMI/RFI interference resistance | Shields against electrical noise |

| Maintenance practices | Regular inspection and cleaning recommended |

You ensure long-term system reliability by selecting connectors that pass rigorous environmental and operational tests.

Long-Term Reliability in Heavy Equipment

You require connectors that last in heavy equipment. mil-dtl-38999 connectors use corrosion-resistant materials and robust sealing. You minimize downtime and maintenance costs by choosing connectors that withstand repeated use and harsh conditions.

Energy, Space, and Medical Mission-Critical Applications

Unique Environmental Challenges in Oil & Gas and Spacecraft

You work in environments with intense pressures, constant vibrations, and extreme temperatures. mil-dtl-38999 connectors help you maintain stable data transmission in oil and gas drilling tools and spacecraft. Their rugged construction ensures reliable performance, even when you monitor geological information in real time or operate in the vacuum of space.

Specialized Performance Requirements in Medical Devices

You need connectors that meet strict standards in medical devices. mil-dtl-38999 connectors provide secure, contamination-resistant connections. You trust these connectors to deliver consistent performance in mission-critical medical applications, where failure is not an option.

Practical Selection Guide: Choosing the Right mil-dtl-38999 Series

Assessing Application Requirements for Military and Industrial Use

Environmental Factors and Exposure

You must evaluate the environment where your connector will operate. Consider exposure to moisture, dust, chemicals, and temperature extremes. In military and industrial settings, connectors often face vibration, shock, and electromagnetic interference. You should check for IP ratings and chemical resistance to ensure reliable performance. The following table highlights the most important factors to consider when selecting a connector for demanding environments:

| Factor | Description |

|---|---|

| Application demands | Consider vibration, EMI, and exposure conditions. |

| Coupling mechanism | Choose between threaded, bayonet, or push-pull styles based on connection security and efficiency. |

| Environmental sealing | Look for IP ratings and chemical resistance to protect against dust and moisture. |

| Temperature and material limits | Ensure the connector can withstand extreme temperatures and select appropriate materials. |

| Compliance with MIL-SPEC standards | Verify that the connector meets relevant military specifications for quality and interoperability. |

| Future maintenance | Consider ease of maintenance and replacement for long-term use. |

Tip: Always verify that your connector meets the required military specification before deployment.

Pressure and Sealing Needs

You must match the connector’s sealing capabilities to your pressure requirements. High-altitude, underwater, and hazardous environments demand connectors with advanced sealing technologies. Series III and IV offer superior sealing for extreme pressure and immersion. You should assess whether your application requires hermetic sealing or enhanced gasket protection.

Matching Series Features to Application Needs

Series I Selection Criteria

You select Series I when you need a rugged connector for general military and aerospace use. The bayonet coupling provides quick mating, and the scoop-proof design protects contacts. Choose Series I for moderate pressure environments and reliable EMI shielding.

Series II Selection Criteria

You choose Series II for compact systems where space and weight matter. The low-profile bayonet coupling suits applications with limited installation space. Series II works well in environments with moderate vibration and pressure.

Series III Selection Criteria

You rely on Series III for the highest pressure resistance and environmental sealing. The triple-start threaded coupling ensures secure connections in high-vibration and shock-prone environments. Series III excels in mission-critical military applications that demand maximum durability and EMI protection.

Series IV Selection Criteria

You select Series IV for specialized environments requiring hermetic sealing. The breech-lock mechanism and glass-to-metal seals provide airtight protection against moisture, gases, and chemicals. Series IV is ideal for vacuum, high-altitude, and hazardous applications.

Common Mistakes and How to Avoid Them When Selecting mil-dtl-38999 connector

You may overlook cost factors when planning large-scale projects. Consider economies of scale, component weight, and certification costs. The table below outlines key cost considerations:

| Cost Factor | Description |

|---|---|

| Economies of Scale | Mass production techniques can significantly lower the per unit cost when manufacturing large quantities of connectors. |

| Component Weight | Lighter components reduce launch costs, maximizing payload capacity for large-scale projects. |

| Testing and Certification | Flexible processes can lead to reduced overall costs, important for budget management in large projects. |

You should avoid mismatching connector series to your application’s requirements. Always confirm environmental ratings, pressure resistance, and compliance with military specification. You improve reliability and reduce costs by selecting the right series and planning for future maintenance.

Note: Consult with connector specialists if you have unique requirements or face challenging environments.

Future Trends and Innovations in mil-dtl-38999 Connectors

Advancements in Materials and Sealing Technologies

You see rapid progress in the design and construction of mil-dtl-38999 connectors. Manufacturers now use advanced materials to improve durability and performance. You benefit from composite shells that support fiber optic applications and tight-tolerance designs for high-speed data transmission. These connectors protect your systems against moisture and dust with true hermetic seals. You also gain enhanced survival rates for electrical cable assemblies exposed to shock and vibration.

Recent innovations include:

- Power, signal, networking, and fiber optic compatibility.

- Hermetic sealing that blocks moisture and dust.

- Superior mating durability for Series III connectors.

- Integrated EMI shield banding porch for improved shielding.

- High-durability anti-vibration coupling.

- Sealed PC tail configurations and crimp contact hermetics.

You notice that back-potting techniques now use NASA-certified low outgassing epoxy. This method hermetically seals the back side of the electrical connection and achieves a leak rate of less than 1X10-9 std cc/sec. You rely on these advancements to meet strict environmental & emi shielding considerations in aerospace and defense systems.

| Feature | Benefit |

|---|---|

| Composite shells | Lightweight, supports fiber optics |

| Hermetic sealing | Protects against moisture and dust |

| Anti-vibration coupling | Enhances shock resistance |

| EMI shield banding porch | Improves emi shielding |

| NASA-certified epoxy | Ensures low outgassing and leak rates |

Tip: You should choose connectors with advanced sealing and composite materials for the most demanding environments.

Evolving Military Standards for Mission-Critical Applications

You face new challenges as military standards evolve. The U.S. Department of Defense sets strict Mil-Spec requirements for connector reliability and environmental performance. You see mil-dtl-38999 connectors designed to adapt to commercial aerospace and rugged military environments. Manufacturers now offer connectors in stainless steel and composite shells, moving beyond traditional aluminum. You select from various coupling methods and shell sizes to match your application needs.

Current trends include:

- Meeting strict Mil-Spec requirements for reliability.

- Using stainless steel and composite shells for enhanced durability.

- Offering diverse coupling methods and shell sizes.

You observe that defense modernization programs drive the adoption of mil-dtl-38999 connectors. You need robust, reliable connectors for high-speed data transmission and power management. The market now demands hybrid connectors that combine data and power lines. You see ongoing investments in electronic warfare and advanced systems worldwide. These trends push manufacturers to innovate in construction and functionality, ensuring your systems meet the latest standards for emi protection and environmental resistance.

Note: You should stay informed about evolving standards and select connectors that meet the latest requirements for mission-critical applications.

- You gain unmatched durability, environmental resistance, and EMI shielding with mil-dtl-38999 series iii.

- You see how mil-dtl-38999 connectors deliver superior connector performance and integrity in military and aerospace applications.

- You compare each series to identify strengths and limitations for your specific applications.

Next, evaluate your requirements and consult connector specialists to select the best mil-dtl-38999 connector for your systems.

FAQ

What makes MIL-DTL-38999 Series III the best choice for high-pressure environments?

You benefit from Series III’s triple-start threaded coupling and advanced sealing. This design resists vibration and maintains a secure connection under extreme pressure. You can trust it for mission-critical aerospace and military applications.

How do you select the right MIL-DTL-38999 series for your project?

You should assess your application’s environment, pressure requirements, and space constraints. Series III suits harsh conditions. Series II fits compact spaces. Series IV offers hermetic sealing. Always match connector features to your system’s needs.

Can you use MIL-DTL-38999 connectors in underwater or vacuum environments?

Yes. You can use Series IV connectors with hermetic sealing for underwater or vacuum applications. The airtight seal prevents moisture and gas ingress, ensuring reliable performance in extreme environments.

How do you maintain MIL-DTL-38999 connectors for long-term reliability?

You should inspect connectors regularly, clean contacts with lint-free materials, and store them in moisture-proof packaging. Routine maintenance helps you prevent corrosion and mechanical wear, extending connector lifespan.

What is the difference between bayonet and threaded coupling mechanisms?

You use bayonet couplings for quick, tool-free connections. Threaded couplings, like those in Series III, provide superior vibration resistance and secure mating. Choose the mechanism that matches your installation and performance needs.

Do MIL-DTL-38999 connectors provide EMI shielding?

Yes. You gain strong EMI shielding with all MIL-DTL-38999 series. Series III and IV offer the highest protection, blocking electromagnetic interference and maintaining signal integrity in sensitive electronic systems.

Are MIL-DTL-38999 connectors suitable for high-speed data transmission?

You can use these connectors for high-speed data. The family supports various contact arrangements, including fiber optic and coaxial options. You ensure reliable, high-speed communication in demanding military and aerospace systems.

Tip: Always consult connector specialists if you have unique requirements or face challenging environments.