Industrial connectors play a vital role in modern manufacturing, automation, and transportation. You encounter a wide range, from circular designs like the M8 connector to specialized solutions such as the Type B connector. The right connector guarantees reliable performance and safety, especially when facing harsh environments or high data volumes.

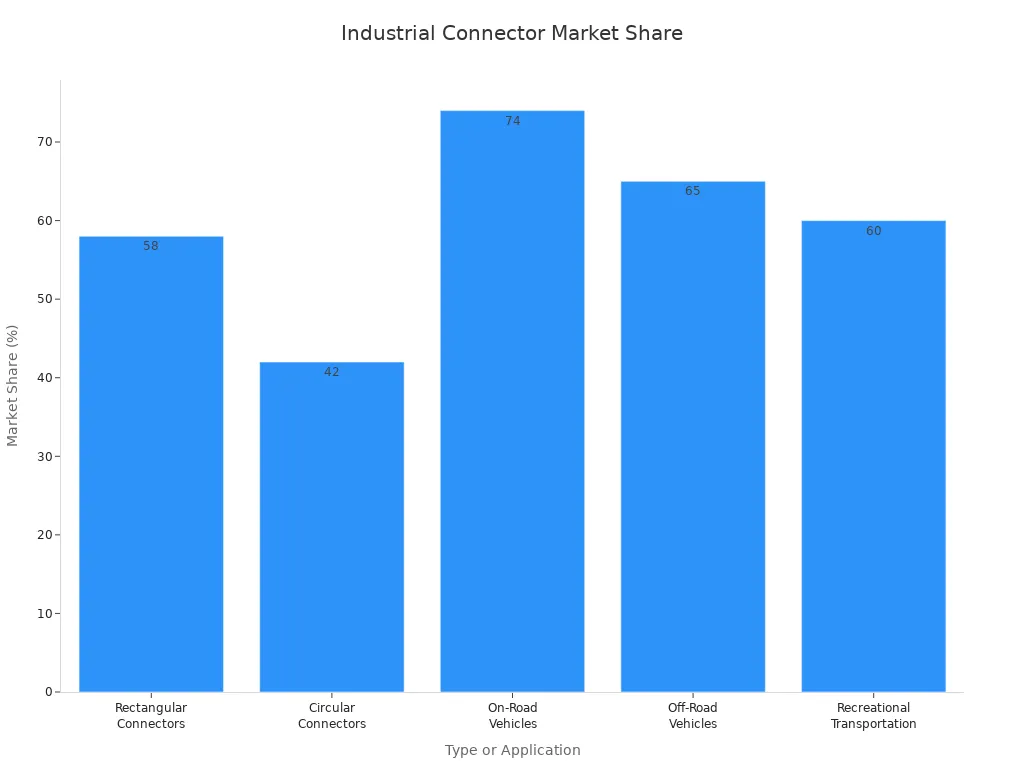

| Type/Application | Market Share/Increase | Key Insights |

|---|---|---|

| Rectangular Connectors | 58% | Widely used in automation and manufacturing; 70% increase due to smart factories. |

| Circular Connectors | 42% | Demand increased by 62% for weatherproof connectors; 66% increase for 5G network support. |

| On-Road Vehicles | 74% | Driven by electric vehicles; 77% increase in high-voltage EV connectors. |

| Off-Road Vehicles | 65% | High-durability connectors needed for extreme conditions; 66% increase due to automated farming. |

| Recreational Transportation | 60% | Growth in advanced electrical connectors; 68% rise in demand for fast-charging connectors. |

Connector factory standards require features like ingress protection, vibration resistance, and electromagnetic shielding to ensure system integrity. When you select industrial connectors, you protect your equipment against dust, moisture, and mechanical stress, securing long-term reliability.

Classification of Industrial Connectors

Definition and Core Functions of Industrial Connectors

You rely on industrial connectors to create secure electrical and mechanical connections in complex systems. The classification of industrial connectors helps you identify the right solution for each application. You see four main categories in industry standards:

| Category | Description |

|---|---|

| Function | Divided into six layers of interconnection based on the function of electronic devices. |

| Structure | Includes board-to-board, board-to-wire, and wire-to-wire connectors. |

| Power | Categorized into power connectors, signal connectors, and high-frequency connectors. |

| Shape | Comprises circular connectors (used in military) and rectangular connectors (widely used). |

Industrial connectors serve several core functions in automation systems. You use them to establish reliable electrical circuits, power equipment, and enable communication between devices. These connectors ensure smooth operation of machinery and help you maintain system integrity in demanding environments.

Importance of Connectors in Industrial Applications

You cannot underestimate the importance of connectors in industrial applications. The classification of industrial connectors guides your selection process, ensuring compatibility and reliability. You must evaluate voltage and current specifications to match your system requirements. You also consider environmental factors such as temperature and humidity to guarantee durability. Size and shape requirements influence user-friendly operation and maintenance.

Circular connectors play a vital role in modern electrical systems. You find them in automation and aerospace industries because they offer reliability and versatility. When you choose the right connector, you protect your equipment from failure and downtime.

Tip: Always match the connector type to the specific needs of your application. This approach reduces the risk of malfunction and extends the lifespan of your equipment.

Key Features and Benefits of Industrial Connectors

You benefit from several key features when you select industrial connectors for your projects. Engineers and end-users value these attributes:

| Feature/Benefit | Description |

|---|---|

| Durability | Connectors made from composite materials wear out 40% less over time, lowering maintenance costs. |

| Modular Design | Facilitates faster assembly and customization, reducing lead times and costs. |

| Smart Technology Integration | Smart connectors with sensors enhance system monitoring and predictive maintenance. |

| Cost-Effectiveness | The demand for cost-effective solutions is rising, driving market growth. |

You gain durability, which means less frequent replacement and lower maintenance costs. Modular design allows you to customize and assemble systems quickly. Smart technology integration gives you real-time monitoring and predictive maintenance capabilities. Cost-effectiveness ensures you stay within budget while meeting performance standards.

The classification of industrial connectors provides a framework for selecting the right connector. You improve efficiency, safety, and reliability in every industrial application.

Main Types of Industrial Connectors

Industrial connectors come in many forms, each designed for specific environments and technical requirements. You encounter a wide range of connector types in manufacturing, automation, and control systems. Understanding the structure, design, and applications of each type helps you select the right connector for your project.

Circular Connectors

Structure and Design

Circular connectors feature a round housing that provides robust mechanical strength and excellent resistance to environmental hazards. You often see these connectors with threaded or bayonet locking mechanisms, which ensure secure mating even in high-vibration settings. The compact, cylindrical shape allows for easy alignment and connection, reducing installation time.

Circular connectors are engineered to withstand:

- Heat

- Cold

- Moisture

- Dust

- Vibration

You benefit from their versatility and durability. Manufacturers offer a variety of sizes and pin configurations, making these connectors suitable for both power and signal transmission. Some popular circular connector types include VULCON™, M12, Micro-D, and MIL-DTL-5015. Each offers unique features, such as waterproofing or high-density pin arrangements.

| Connector Type | Characteristics | Typical Use Cases |

|---|---|---|

| VULCON™ | Waterproof, robust, compact | Manufacturing plants, cable-to-panel connections |

| M12 | Dust and waterproof, durable | Industrial automation, robotics control systems |

| Micro-D | Flexible, reliable | Robotics and industrial applications |

| MIL-DTL-5015 | High durability, various sizes | Military and aerospace applications |

Note: When you select a circular connector, always consider the size, durability, and space limitations in your equipment.

Typical Applications

You find circular connectors in a variety of demanding environments. Their rugged design makes them ideal for:

- Manufacturing plants

- Robotics and automation systems

- Military and aerospace equipment

- Cable-to-panel connections

- Ruggedized networking

You rely on these connectors for reliable performance in harsh conditions. Their ability to resist dust, moisture, and vibration ensures long-term system integrity.

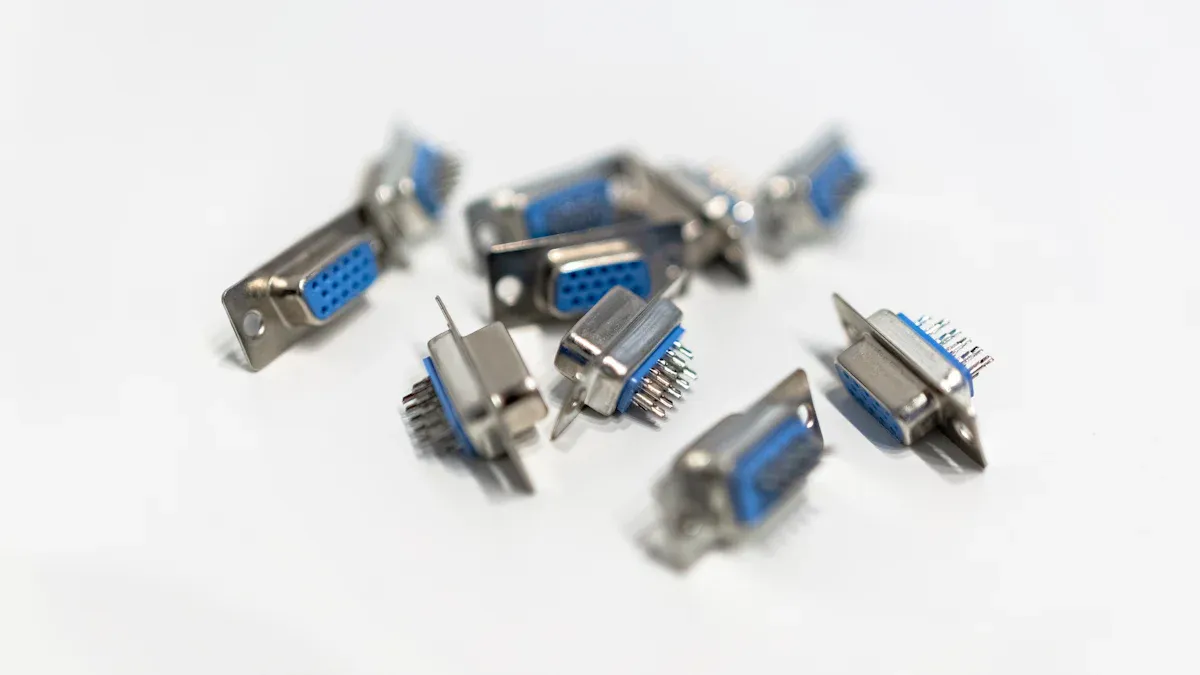

Rectangular Connectors

Structure and Design

Rectangular connectors use a flat, grid-like arrangement of contacts within a rectangular housing. This design maximizes space efficiency and allows for high-density pin configurations. You often choose these connectors when you need to optimize PCB space or require multiple signal paths in a compact footprint.

Key characteristics include:

- Compact and space-saving design

- High-density pin arrangements

- Versatile configurations and pin counts

Rectangular connectors excel at supporting high-speed signals and efficient heat dissipation. However, you may encounter challenges with sealing at the edges, and long-term mechanical strength can be lower compared to circular connectors. Additional shielding may be necessary to prevent high-frequency interference.

| Characteristic | Advantage |

|---|---|

| Space Optimization | Right-angle design maximizes PCB space utilization |

| Signal Density | Supports high-density pin arrangement |

| Transmission Rate | Optimized design for high-speed signals |

| Heat Dissipation | Planar contact facilitates heat conduction |

| Sealing Limitations | Difficult to seal at edges |

| Mechanical Strength | Long-term mating may cause structural fatigue |

| High-Frequency Interference | Requires additional shielding |

Tip: Use rectangular connectors when you need to save space and manage multiple connections efficiently.

Typical Applications

You see rectangular connectors widely used in:

- Industrial automation and control panels

- Data centers and telecommunications equipment

- Power distribution units

- Consumer electronics

- Automotive systems

Their flat profile and grid arrangement make them ideal for applications where size and weight matter. You also benefit from their versatility in supporting various pin counts and configurations.

Terminal Blocks

Structure and Design

Terminal blocks provide a modular, easy-to-use solution for connecting wires within control panels and distribution boards. You connect wires by inserting them into individual terminals and securing them with screws or spring clamps. This design ensures a safe, reliable connection with no exposed wires.

You appreciate terminal blocks for their:

- Secure, organized wiring

- Modular design for easy expansion

- Quick connection and disconnection without soldering

Terminal blocks help you manage complex wiring systems by keeping connections neat and accessible. Their design supports both power and signal wiring, making them a staple in industrial connectors.

Typical Applications

Terminal blocks serve as the backbone of many industrial control systems. You use them for:

- Circuit management and expansion in infrastructure

- Central junctions for control circuits (sensors, switches, actuators)

- Streamlined maintenance and troubleshooting

- Power management in solar and wind energy setups

- Organized connections in data centers and telecom facilities

- HVAC system integration for climate control panels

You benefit from their cost-effectiveness and ease of use. Terminal blocks simplify maintenance and reduce the risk of electrical shorts, making them a reliable choice for many industrial applications.

Callout: Terminal blocks ensure safety and organization in your wiring systems, supporting both automation and power management needs.

Heavy-Duty Connectors

Structure and Design

You encounter heavy-duty connectors when you need maximum reliability in harsh industrial environments. These connectors use robust materials such as stainless steel, copper alloys, and high-performance polymers. The shells and hoods resist impact and provide strong protection for internal contacts. You often see heavy-duty connectors with advanced sealing systems that achieve high ingress protection (IP) ratings, such as IP67 or IP68. This level of sealing keeps out water, dust, and contaminants, even in extreme conditions.

Heavy-duty connectors must operate in a wide temperature range, from -55°C to +70°C. Manufacturers use corrosion-resistant materials and heavy gold plating to ensure long-term performance. You benefit from flexible contact systems that support power, data, and signal transmission within a single connector. The design also allows for high-density connectivity, which saves space in compact installations.

| Key Feature | Description |

|---|---|

| Construction | Heavy-duty materials and rugged design with reliable contacts and durable shells. |

| Sealing Capabilities | Must achieve high IP ratings (IP67, IP68) for protection against water, dust, and contaminants. |

| Operating Temperature | Connectors must operate in extreme temperatures from -55°C to +70°C. |

| Environmental Resistance | Must withstand shock, vibration, moisture, and dust. |

| Material Quality | Use of corrosion-resistant materials like copper alloys and stainless steel for durability. |

| Plating Requirements | Heavy gold plating for corrosion resistance and low contact resistance over time. |

| Impact Resistance | Hoods and housing must be impact-resistant and robust. |

| Compliance with Standards | Must meet industrial standards for ingress protection and performance criteria. |

Note: You should always select heavy-duty connectors with high-quality electrical contacts and robust materials. This ensures reliability in the most demanding environments.

Typical Applications

You rely on heavy-duty connectors in industries where equipment faces constant exposure to vibration, moisture, chemicals, and dust. These connectors are essential in:

- Manufacturing plants with automated machinery

- Railway and transportation systems

- Renewable energy installations, including wind and solar farms

- Oil and gas exploration sites

- Construction equipment and mining operations

You also find heavy-duty connectors in control cabinets, robotics, and outdoor installations. Their ability to withstand harsh conditions makes them a top choice for critical connections in industrial connectors. When you need a connector that will not fail under stress, heavy-duty options deliver unmatched durability.

PCB Connectors

Structure and Design

PCB connectors form the backbone of modern electronics. You use them to connect printed circuit boards (PCBs) to other boards, wires, or external devices. These connectors come in many shapes and sizes, including wire-to-board, board-to-board, and edge connectors. The design focuses on compactness and high-density pin arrangements, which allow you to save space on crowded PCBs.

Manufacturers use high-quality plastics and metals to ensure reliable electrical contact and mechanical stability. You benefit from modular designs that support easy assembly and replacement. Many PCB connectors feature locking mechanisms to prevent accidental disconnection during operation or maintenance.

Tip: Choose PCB connectors with gold-plated contacts for improved conductivity and longer service life.

Typical Applications

You see PCB connectors in almost every sector that uses electronics. Their versatility supports a wide range of applications, including:

- Aviation and aerospace projects

- Railway and industrial automation systems

- Test instruments and shipboard electronics

- Electric vehicles, such as buses, forklifts, and golf carts

- Medical equipment, including suction machines and electric treatment beds

- Power distribution equipment and UPS systems

- Communication power supplies and chargers

- Consumer electronics and appliance applications

You also use PCB connectors in automotive systems and industrial equipment. The AMPMODU interconnect system is a popular choice for automation and appliance applications. Compact, high-quality wire-to-board and board-to-board connectors help you achieve reliable performance in demanding environments.

Fiber Optic Connectors

Structure and Design

Fiber optic connectors enable you to transmit data using light signals through optical fibres. These connectors use precision-engineered ferrules to align and join fibre ends, minimizing signal loss. You find several fibre optic connector types, each designed for specific performance needs and installation environments.

The most common fibre optic connectors include LC, SC, ST, FC, and MU. Each type offers unique features:

| Connector Type | Description | Performance Specifications |

|---|---|---|

| LC | Small form-factor, easy installation | Low insertion loss, ideal for high-density applications |

| SC | Common in fibre optic networks | Larger ferrule for reduced light loss, high pulling strength |

| ST | Bayonet locking mechanism | Reliable but bulkier, lower insertion loss |

| FC | Stable connection for single-mode | Threaded interface for secure connection, suitable for harsh environments |

| MU | Miniature version of SC | Compact size for high-density applications, requires careful handling |

You benefit from connectors with bayonet or threaded locking mechanisms, which ensure secure mating and prevent accidental disconnection. The use of high-quality materials and precise alignment technology guarantees low insertion loss and high signal integrity.

Callout: Always handle fibre optic connectors with care. Even small particles of dust can degrade optical performance.

Typical Applications

You use fibre optic connectors in environments where high-speed, interference-free data transmission is critical. Common applications include:

- Industrial automation and process control systems

- Data centers and telecommunications infrastructure

- Medical imaging and diagnostic equipment

- Railway signaling and transportation networks

- Oil and gas monitoring systems

- Military and aerospace communication systems

You also find fibre optic connectors in smart infrastructure and security systems. Their ability to transmit large volumes of data over long distances without electromagnetic interference makes them essential in modern industrial connectors. When you need reliable, high-bandwidth connections, fibre optic connector types deliver unmatched performance.

RF (Radio Frequency) Connectors

Structure and Design

You use RF connectors when you need to transmit radio frequency signals with minimal loss and high reliability. These connectors feature a coaxial design, which consists of a central conductor, dielectric insulator, outer conductor, and protective shell. This structure shields the signal from electromagnetic interference and maintains signal integrity, even in environments with high electrical noise.

Manufacturers offer a variety of RF connector types, such as SMA, BNC, N-type, and TNC. Each type supports different frequency ranges and mechanical locking mechanisms. You often select connectors with threaded or bayonet couplings to ensure secure connections in vibration-prone settings. The precision of the mating surfaces and the quality of the materials directly impact performance, especially for high-frequency or high-voltage dc connectors.

Using low-loss connectors can reduce insertion loss by up to 0.2 dB, which is crucial for high-speed data transmission and low latency.

Typical Applications

You find RF connectors in many critical industrial connectors applications. Their ability to maintain signal integrity makes them essential for systems that demand reliable, high-frequency communication. Typical use cases include:

- Aerospace and defense: Radar systems and GPS

- Medical: Remote patient monitoring and robotic surgery

- Test and measurement: Quality assurance in manufacturing setups

- Telecommunications: Maintaining signal integrity in LTE and 5G networks

- Industrial: IoT sensors, automated assembly lines, and telemetry systems

- Automotive: Infotainment systems and vehicular communication networks

You rely on these connectors to ensure that data travels quickly and accurately, even in challenging environments. Their robust design and shielding capabilities make them a preferred choice for high-voltage dc connectors in advanced communication systems.

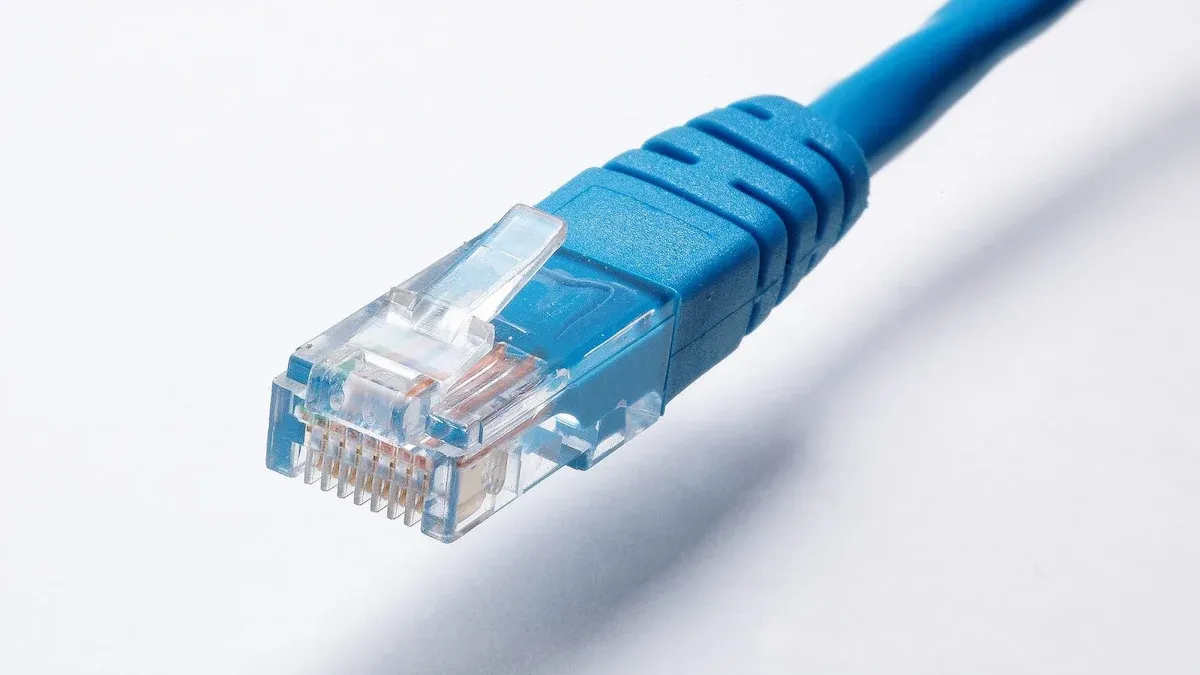

Modular Connectors

Structure and Design

You encounter modular connectors in a wide range of industrial connectors applications, especially where flexibility and scalability matter. These connectors use a standardized, interchangeable design that allows you to mix and match components for different configurations. The most common modular connectors include RJ45, RJ11, and industrial-grade variants designed for harsh environments.

You benefit from features such as solderless assembly, which enables quick installation and easy maintenance. Many modular connectors offer keying to prevent incorrect connections and integrated magnetics for improved EMI shielding. Ruggedized versions withstand vibration, moisture, and temperature extremes, making them suitable for demanding industrial settings. Some modular connectors support Power over Ethernet (PoE), allowing you to transmit both data and power through a single cable—ideal for IoT devices and smart infrastructure.

| Feature/Application | Description |

|---|---|

| Low Cost | Modular connectors are affordable, making them suitable for various applications. |

| Off-the-shelf Availability | Easily accessible for manufacturers and repair services. |

| Solderless Assembly | Facilitates quick and easy installation without soldering. |

| Easy Customization | Allows for tailored solutions to meet specific needs. |

| Ruggedized Versions | Designed for durability in industrial environments. |

| Power over Ethernet (PoE) | Enables power transfer alongside data, enhancing device portability. |

| Shielding | Protects against EMI/RFI interference, crucial for industrial settings. |

| Keying | Prevents incorrect connections, ensuring reliability. |

| Integrated Magnetics | Improves connection reliability and EMI shielding in Ethernet applications. |

| Hi-Reliability Products | Suitable for critical applications in military and aerospace sectors. |

Tip: Choose modular connectors with shielding and ruggedized features for the best performance in industrial environments.

Typical Applications

You use modular connectors in many types of connectors systems, especially where you need quick changes or upgrades. Common applications include:

- Industrial networking and automation systems

- Data centers and server rooms

- Telecommunications infrastructure

- Smart building controls and IoT devices

- Security and surveillance systems

- High-voltage dc connectors for PoE-enabled devices

You appreciate modular connectors for their ease of use and adaptability. Their standardized design simplifies installation and maintenance, reducing downtime and costs. In industrial connectors applications, modular connectors help you build scalable, future-proof networks.

Specialty and Custom Connectors

Structure and Design

You turn to specialty and custom connectors when standard solutions do not meet your unique requirements. These connectors address specific challenges, such as extreme environments, space constraints, or specialized electrical needs. Manufacturers design specialty connectors with features like integrated rear housings to reduce weight and increase conductivity. Some use cylindrical shapes with PC tail contacts for direct mounting on printed circuit boards, offering advantages in size and electrical performance.

You may also encounter double flange connectors, which allow direct mounting to PC boards and ensure compatibility with military specification plugs. Filter connectors integrate EMI and RFI filtering components, protecting sensitive equipment from interference. Sealed connectors provide moisture and gas protection, and you can customize them for particular environmental conditions.

Typical Applications

You rely on specialty and custom connectors in niche industrial connectors applications where off-the-shelf options fall short. Common examples include:

- Connectors with integrated rear housing for lightweight, high-conductivity needs

- Cylindrical connectors with PC tail contacts for direct PCB mounting in compact devices

- Double flange connectors for secure, mil-spec board connections

- Filter connectors for EMI and RFI protection in sensitive electronics

- Sealed connectors for moisture and gas protection in harsh or hazardous environments

You often see these connectors in aerospace, defense, medical equipment, and advanced manufacturing. Specialty and custom connectors ensure that your systems operate reliably, even under the most demanding conditions. When you face unique challenges, these connectors provide tailored solutions that standard types of connectors cannot match.

Board-to-Board Connectors

Structure and Design

You encounter board-to-board connectors when you need to link two printed circuit boards (PCBs) directly. This type of connector enables you to create compact, multi-board systems without the need for external wiring. Manufacturers design these connectors in several configurations, such as mezzanine, coplanar, and right-angle setups. You often see very small pitch sizes, which allow for high-density connections in limited spaces.

Board-to-board connectors feature:

- Direct PCB-to-PCB connection for streamlined layouts

- Multiple stacking heights and orientations for flexible design

- High signal integrity due to short transmission paths

- Secure mechanical locking for vibration resistance

You benefit from their ability to reduce signal loss and improve reliability in electronic assemblies. The compact design supports advanced devices, including smartphones and industrial controllers, where space is at a premium.

Tip: Select board-to-board connectors with robust locking mechanisms if your equipment operates in high-vibration environments.

Typical Applications

You use board-to-board connectors in applications that demand compactness and high performance. These connectors excel in:

- Multi-board systems for smartphones and tablets

- Industrial controllers and automation modules

- Medical devices with layered PCB architecture

- Communication equipment requiring high-density interconnects

- Embedded computing platforms

You rely on board-to-board connectors to maintain signal integrity and mechanical stability in tight spaces. Their direct connection between PCBs makes them a preferred choice for advanced industrial connectors in modern electronics.

- Board-to-board connectors are ideal for compact designs, directly linking two PCBs.

- You use them in tight spaces to connect PCBs directly.

- They suit multi-board systems like smartphones and industrial controllers.

- You find various configurations, such as mezzanine and coplanar setups, with very small pitch sizes for high-density applications.

Cable-to-Cable Connectors

Structure and Design

You select cable-to-cable connectors when you need to join two separate cables securely. This connector type provides a reliable interface for transmitting power, signals, or data between different parts of your system. Manufacturers offer a range of designs, including inline, circular, and rectangular housings. You often see locking features such as latches, screws, or bayonet mechanisms, which prevent accidental disconnection.

Cable-to-cable connectors offer:

- Flexible cable routing for complex installations

- Ruggedized shells for protection against environmental hazards

- Multiple contact arrangements for power and signal transmission

- Easy mating and unmating for quick maintenance

You appreciate their versatility in connecting equipment across long distances or between moving parts. The robust construction ensures durability in harsh industrial environments.

Note: Always verify the compatibility of cable-to-cable connectors with your cable type and system voltage to avoid connection failures.

Typical Applications

You use cable-to-cable connectors in scenarios where modularity and flexibility are essential. Common applications include:

- Industrial automation systems with distributed sensors and actuators

- Power distribution networks in manufacturing plants

- Robotics and machinery with moving components

- Outdoor installations requiring weatherproof connections

- Temporary setups for events or field operations

You rely on cable-to-cable connectors to simplify system expansion and maintenance. Their adaptability makes them a vital part of industrial connectors, especially when you need to reconfigure or extend your network quickly.

- Board-to-board connectors are ideal for compact designs, directly linking two PCBs.

- In contrast, wire-to-board connectors facilitate the connection of external wires to a PCB, serving different purposes in electronic systems.

Wire-to-Board Connectors

Structure and Design

You use wire-to-board connectors to link external wires directly to a PCB. This connector type allows you to integrate sensors, switches, and other devices into your electronic system. Manufacturers design wire-to-board connectors with features such as crimp contacts, insulation displacement, and locking tabs. You benefit from options that support both single and multi-pin configurations, which provide flexibility for various wiring needs.

Wire-to-board connectors include:

- Secure mating interfaces for stable electrical contact

- Polarized housings to prevent incorrect connections

- Options for tool-less or quick-connect assembly

- Support for different wire gauges and insulation types

You value their ability to simplify wiring and enhance system reliability. The design ensures that connections remain stable, even in environments with vibration or movement.

Callout: Use polarized wire-to-board connectors to reduce the risk of wiring errors during installation.

Typical Applications

You find wire-to-board connectors in many industrial control panels and automation systems. These connectors play a crucial role in:

- Connecting control devices and sensors in industrial automation

- Facilitating stable communication and power transmission in production lines

- Transmitting control signals and power in intelligent manufacturing systems

- Enhancing communication between robots, sensors, and equipment

- Integrating external components into PCB-based assemblies

You depend on wire-to-board connectors for flexible wiring solutions. Their ability to connect external devices to PCBs makes them indispensable in industrial connectors, especially when you need to expand or modify your system.

- Wire-to-board connectors link cables to boards, providing flexibility in wiring configurations.

- Wire-to-board connectors are used to connect wires to a PCB, allowing for the integration of external components, which is essential for flexible wiring solutions.

- Wire-to-board connectors are used to connect control devices and sensors in industrial automation.

- They facilitate stable communication and power transmission in automated production lines.

- In intelligent manufacturing systems, they transmit control signals and power, enhancing communication between robots, sensors, and other equipment.

Applications of Industrial Connectors Across Industries

Industrial connectors play a pivotal role in a wide range of applications, supporting critical operations in diverse sectors. You encounter different connector types and requirements depending on the industry, each tailored to meet unique operational challenges.

Manufacturing and Automation

You rely on industrial connectors to ensure seamless communication and power transfer in manufacturing and automation environments. These connectors support precise automation, reliable machinery operation, and efficient system integration. The selection process can be complex, as you must consider bandwidth, environmental resistance, and ease of installation. If you choose the wrong connector, you risk system inefficiencies and higher costs.

Tip: Always match connector specifications to your application’s data rate and environmental demands to maximize uptime.

In manufacturing, rectangular connectors are common due to their reliability in machinery and control panels. You also see terminal blocks and heavy-duty connectors in automated production lines, where durability and quick maintenance are essential.

Critical requirements for connectors in manufacturing and automation:

- Bandwidth and data rate must meet your application’s needs.

- Environmental resistance ensures long-term durability.

- Ease of installation improves overall efficiency.

You find that industrial connectors are essential for supporting both discrete and batch manufacturing, helping you maintain productivity and safety.

Energy and Power Generation

In energy and power generation, you face unique challenges that demand robust connector solutions. You often use rectangular connectors for high-continuity connections in electrical control equipment. Card Edge connectors provide easy plug-in options for electrical panels, while D-Sub connectors handle both data feeds and power transfer.

You see these applications in electric vehicles, charging infrastructure, and renewable energy systems like solar and wind farms. Industrial connectors facilitate reliable power transmission and support the integration of automation in power plants.

- Stäubli’s MULTILAM technology offers stable connections with low contact resistance, which is crucial for high-power applications.

- Custom connectors address extreme demands in power transmission and distribution.

- You must consider wear and tear on contacts to prevent failures and maintain reliability.

Solar energy systems present additional challenges. You need connectors that withstand harsh outdoor conditions and support large-scale installations. The environmental impact of manufacturing PV cables and connectors, along with high upfront costs, requires you to select robust designs for long-term performance.

Transportation and Automotive

You encounter a variety of connector applications in transportation and automotive sectors. Circular connectors are widely used for electrical systems, including power distribution and advanced driver-assistance systems (ADAS). These connectors must deliver reliable performance in vehicles exposed to vibration, temperature changes, and moisture.

| Industrial Sector | Common Connector Types |

|---|---|

| Automotive | Circular connectors for electrical systems, including power distribution and ADAS |

| Industrial | Rectangular connectors for reliable connections in machinery and automation |

| Telecommunications | Fiber optic connectors, coaxial connectors, high-performance connectors |

| Consumer Electronics | USB-C, HDMI, Thunderbolt connectors for smartphones and laptops |

| Aerospace and Medical | Specialized connectors meeting regulatory standards for critical applications |

You depend on industrial connectors to support electric vehicles, charging stations, and onboard electronics. These connectors enable safe, efficient power transfer and data communication, ensuring that modern vehicles meet safety and performance standards.

Note: Choosing the right connector type for your automotive application helps you avoid costly downtime and enhances vehicle reliability.

Aerospace and Defense

You face some of the most demanding environments in aerospace and defense. Here, reliability and safety are non-negotiable. Industrial connectors play a critical role in these sectors. You use them in avionics, radar systems, satellite communications, and military vehicles. These applications require connectors that withstand extreme temperatures, vibration, and electromagnetic interference.

You often select circular connectors with locking mechanisms for secure connections. Many aerospace systems use high-density rectangular connectors for compact control modules. You also rely on fiber optic connectors for high-speed data transfer in aircraft and spacecraft. In defense, you need connectors that meet strict military standards for durability and performance.

Tip: Always verify that your connectors meet the required MIL-SPEC or aerospace certifications before installation.

Common aerospace and defense applications:

- Flight control systems

- Navigation and communication equipment

- Missile guidance and launch systems

- Ground support vehicles

You depend on industrial connectors to ensure mission-critical systems operate without failure. The right choice helps you maintain safety and performance in every mission.

Telecommunications

You work in telecommunications, where speed and reliability matter most. Industrial connectors support a wide range of applications, from data centers to cellular base stations. You use them to connect fiber optic cables, coaxial lines, and modular network equipment.

Fiber optic connectors enable you to transmit large volumes of data with minimal loss. You often choose modular connectors, such as RJ45, for Ethernet networks. In outdoor installations, you select weatherproof connectors to protect against moisture and dust.

You must consider signal integrity and bandwidth when choosing connectors for telecommunications applications. High-frequency RF connectors help you maintain clear signals in wireless networks. You also use terminal blocks and PCB connectors in switching equipment and routers.

Key telecommunications applications:

- Internet backbone infrastructure

- 5G and LTE cellular networks

- Data center interconnects

- Broadcast and satellite communication

Note: Proper connector selection reduces downtime and improves network reliability.

Medical Equipment

You support life-saving technology in medical equipment. Industrial connectors ensure that devices function safely and accurately. You use them in diagnostic machines, imaging systems, patient monitors, and surgical robots. These applications demand connectors that resist sterilization chemicals and frequent disconnection.

You often select compact, high-density connectors for portable medical devices. Many systems require shielded connectors to prevent electromagnetic interference with sensitive electronics. You also rely on modular connectors for easy maintenance and quick replacement.

Typical medical equipment applications:

- MRI and CT scanners

- Patient monitoring systems

- Infusion pumps and ventilators

- Laboratory automation devices

You must prioritize safety and reliability in every connection. The right industrial connectors help you deliver consistent performance in critical healthcare environments.

Oil and Gas

You face some of the harshest environments in the oil and gas industry. Equipment must operate reliably in remote locations, often under extreme temperatures, high pressure, and exposure to corrosive substances. Industrial connectors play a crucial role in these settings. You use them to ensure safe and stable connections for both power and data transmission.

You often encounter applications such as drilling rigs, offshore platforms, and pipeline monitoring systems. These require connectors that resist moisture, salt, chemicals, and even explosive atmospheres. Many connectors in this sector feature rugged housings, advanced sealing, and corrosion-resistant materials. You benefit from designs that support quick installation and easy maintenance, which helps reduce downtime in critical operations.

Tip: Always select connectors with the appropriate ingress protection (IP) rating for your oil and gas applications. This ensures long-term reliability and safety.

You also rely on connectors that support high current and voltage, especially for heavy machinery and control systems. Fiber optic connectors have become more common in oil and gas, as you need fast, interference-free data transmission for real-time monitoring and automation. When you choose the right industrial connectors, you help prevent costly failures and maintain operational efficiency in challenging environments.

Data Centers and Smart Infrastructure

You see rapid growth in data centers and smart infrastructure. These environments demand high-speed, reliable connections to support massive data flows and interconnected devices. Industrial connectors form the backbone of these systems, enabling you to build scalable and resilient networks.

In data centers, you use connectors for server racks, power distribution units, and network switches. You often require modular and high-density solutions to maximize space and improve airflow. Fiber optic connectors are essential for high-bandwidth applications, while modular connectors like RJ45 support flexible network configurations.

Smart infrastructure relies on a wide range of applications, from building automation to intelligent transportation systems. You need connectors that withstand frequent mating cycles and provide secure connections for sensors, controllers, and communication devices. Many smart city projects use connectors with integrated shielding to protect against electromagnetic interference.

- Choose connectors that offer tool-less assembly for faster deployment.

- Look for products with clear labeling and color coding to simplify maintenance.

You depend on industrial connectors to ensure uptime and data integrity in these advanced environments. The right choice supports future expansion and helps you adapt to evolving technology needs.

Selection of Industrial Connectors: Key Criteria

Choosing the right industrial connectors is essential for reliable system operation. You must evaluate several factors during the connector selection process to ensure optimal performance, safety, and longevity. This section guides you through the most important criteria.

Electrical Requirements for Connector Selection

Electrical requirements form the foundation of the connector selection process. You need to match the connector’s capabilities to your system’s demands.

Voltage and Current Ratings

You must assess voltage and current ratings before finalizing your connector selection process. These ratings determine whether the connector can safely handle the electrical load without overheating or causing failures. If you select a connector with insufficient ratings, you risk power loss, operational inefficiency, and even equipment damage.

| Criteria | Description |

|---|---|

| Electrical Requirements | Evaluate voltage and current requirements for compatibility with the electrical system. |

| Current Rating | Ensure it matches the connector capacity to minimize power loss. |

| Voltage Drop | Address to maintain operational efficiency and prevent overheating. |

| Contact Resistance | Maintain low contact resistance for maximum electrical reliability. |

| Insulation Resistance | Ensure insulation integrity to prevent leakage and shorts. |

| Surge Current Capacity | Critical for managing voltage spikes and ensuring reliable operation. |

| EMI Shielding Efficiency | Protects against electromagnetic interference, enhancing performance in demanding environments. |

| Thermal Management Strategies | Implement to safeguard against overheating and enhance system reliability. |

You should always verify that the connector’s current rating matches your application. Low contact resistance and high insulation resistance help you maintain safe and efficient operation. Surge current capacity is vital for systems exposed to voltage spikes, such as power connectors in industrial machinery.

Signal Type and Integrity

Signal connectors require careful consideration of signal type and integrity. You must ensure that the connector supports the required bandwidth and minimizes signal loss. For high-speed data or optical transmission, shielding against electromagnetic interference (EMI) is crucial. Poor signal integrity can degrade network performance and cause communication errors.

You need to select connectors with robust EMI shielding and low contact resistance. This approach helps you maintain clear signals in your network, especially in environments with high electrical noise. For optical applications, precise alignment and low insertion loss are essential for reliable data transmission.

Tip: Always match the connector’s signal specifications to your network’s requirements to avoid data loss and ensure consistent performance.

Mechanical Considerations in Connector Selection

Mechanical factors play a significant role in the connector selection process. You must evaluate size, form factor, and durability to ensure compatibility with your equipment and environment.

Size and Form Factor

You need to choose connectors that fit your available space and support your system’s layout. Size and form factor affect installation, maintenance, and overall system design. Compact connectors are ideal for tight spaces, while larger connectors may offer higher pin counts or enhanced durability.

Material selection also impacts mechanical performance. Consider the following table:

| Material | Characteristics | Common Applications |

|---|---|---|

| Stainless Steel | High strength, corrosion-resistant | Marine, industrial, outdoor environments |

| Aluminum | Lightweight, durable | Aerospace, automotive |

| Plastic/Polymer | Electrical insulation, chemical resistance | Automotive, consumer electronics |

| Brass | Good conductivity, corrosion-resistant | Electrical systems, instrumentation |

You should select materials that match your application’s mechanical and environmental demands. Stainless steel suits harsh environments, while plastic offers insulation and chemical resistance.

Mating Cycles and Durability

Durability is a key factor in the connector selection process. You must consider the number of mating cycles the connector will endure. Frequent connection and disconnection can wear out contacts and housings. High-quality materials and robust locking mechanisms extend connector life and reduce maintenance needs.

You should look for connectors rated for high mating cycles if your system requires regular maintenance or reconfiguration. This approach helps you minimize downtime and maintain reliable operation.

Note: Always check the manufacturer’s specifications for mating cycle ratings to ensure long-term durability.

Environmental Factors Affecting Connector Choice

Environmental factors are critical in the connector selection process, especially in harsh or demanding settings. You must evaluate temperature range, ingress protection, and chemical resistance to ensure reliable performance.

Temperature Range

Temperature extremes can cause connector failure. Thermal stress from differences in material expansion may lead to leaks, cracks, or hardening of seals. You need connectors designed to withstand the temperature range of your application. For outdoor or industrial environments, select connectors with proven thermal management strategies.

You should avoid connectors with materials that degrade under thermal cycling. This approach helps you maintain system integrity and prevent unexpected failures.

Ingress Protection (IP) Ratings

Ingress protection (IP) ratings indicate how well a connector resists dust, moisture, and solid debris. You must test both the connector and enclosure to determine the overall IP rating. The lower rating between the two defines the product’s protection level.

- Test the connector and enclosure for IP rating.

- Use the lower rating as the overall product rating.

- Select connectors rated at least IP-65 for water resistance.

You should choose connectors with high IP ratings for outdoor, marine, or industrial environments. This approach protects your network from dust, moisture, and contaminants.

Chemical and Corrosion Resistance

Exposure to noxious chemicals can corrode connector materials and compromise performance. You need connectors made from corrosion-resistant materials, such as stainless steel or brass, for environments with chemical exposure. Chemical resistance is essential in oil and gas, manufacturing, and outdoor installations.

- Exposure to chemicals can degrade connector materials.

- Moisture and humidity may cause corrosion or short circuits.

- Solid debris, such as dust or metal shavings, can interfere with connector mating.

You should select connectors with proven chemical and corrosion resistance to ensure long-term reliability in challenging environments.

Callout: Always consider environmental factors such as temperature, moisture, and chemical exposure during the connector selection process. This approach helps you protect your network and maintain optimal performance.

Compatibility and Industry Standards for Connectors

Industry Standards and Certifications

You must ensure that every connector you select meets recognized industry standards and certifications. These standards guarantee safety, reliability, and interoperability across different systems and manufacturers. When you work with industrial connectors, you encounter a range of global standards that define design, performance, and testing requirements.

| Standard | Description |

|---|---|

| DIN 41612 | Defined by the German Institute for Standardization, specifying board-to-board connectors. |

| MIL-C-83503 | U.S. Department of Defense standard for flat cable connectors, commonly known as MIL connectors. |

| IEC 61076-4-101 | International standard for 2 mm pitch HM connectors. |

| USB | A communication standard that also specifies the connector design. |

| IEC 60309 | Key international standard for industrial plugs, covering design and performance criteria. |

| IEC 62196 | Standard for electric vehicle charging connectors. |

| IEC 60947 | Standard for low-voltage switchgear and controlgear, relevant for industrial applications. |

You see that North America relies on UL and CSA for safety standards, while Europe uses EN and IEC standards for both safety and performance. These certifications help you verify that your industrial connectors will perform as expected in demanding environments. You should always check for compliance before installation, especially when working with optical systems or high-voltage equipment.

Tip: Standards like IEC 60309 and IEC 62196 are essential for electric vehicle charging and industrial power distribution. Always confirm certification marks on your connectors.

Interchangeability

Interchangeability allows you to replace or upgrade connectors without redesigning your entire system. You benefit from standardized dimensions, pin configurations, and performance criteria. This flexibility is crucial when you maintain large installations or need to source replacement parts quickly.

You should select industrial connectors that comply with international standards. This approach ensures that you can swap components from different manufacturers with minimal risk. Interchangeable connectors reduce downtime and simplify maintenance, especially in systems that use optical or data transmission technologies.

- Standardized connectors support easy upgrades.

- Interchangeable designs help you avoid compatibility issues.

- You save time and resources during repairs and expansions.

Note: Interchangeability is vital for future-proofing your infrastructure. Always choose connectors that follow widely accepted standards.

Installation and Maintenance of Industrial Connectors

Ease of Assembly

You need connectors that offer straightforward assembly to minimize installation time and reduce errors. Manufacturers design industrial connectors with features like tool-less locking, color coding, and clear labeling. These enhancements help you achieve reliable connections, even in complex systems.

| Installation Technique | Steps | Safety Tips |

|---|---|---|

| Crimp connectors | 1. Insert stripped wire ends into the metal barrel. 2. Use a crimping tool. 3. Squeeze the tool to compress the barrel. 4. Inspect the crimp. | Always match the connector to the wire gauge. |

| Push-in connectors | 1. Strip wires to recommended length. 2. Insert wire until it clicks. 3. Check for exposed copper. | Verify all wires are secure. |

| Insulation displacement connectors (IDCs) | 1. Insert unstripped wire into IDC slot. 2. Use a punch-down tool. 3. Confirm the wire is seated. | Follow manufacturer instructions. |

| Specialty connectors | Follow manufacturer instructions for specific types. | Use required tools as specified. |

You should always de-energize circuits before installation. Use insulated tools and wear personal protective equipment, such as gloves and safety glasses. Regular retraining on safety protocols helps you maintain a safe work environment.

Callout: Tool-less connectors and push-in designs speed up installation and reduce the risk of wiring mistakes.

Serviceability and Replacement

Serviceability determines how easily you can inspect, maintain, and replace connectors in your system. You should look for connectors with modular designs and accessible locking mechanisms. These features allow you to perform quick repairs and minimize downtime.

Regular inspection is crucial for maintaining safe and reliable electrical systems. You need to check for signs of corrosion, discoloration, and loose connections. Preventive care, such as inspecting connectors every three years and applying antioxidant compounds, extends the life of your industrial connectors.

- Modular connectors simplify replacement.

- Accessible designs support fast troubleshooting.

- Routine inspections prevent unexpected failures.

Tip: Schedule regular maintenance and keep spare connectors on hand to ensure uninterrupted operation.

Cost and Availability in Connector Selection

Budget Considerations

You must balance performance and cost when selecting industrial connectors. High-quality connectors may have a higher upfront price, but they reduce maintenance expenses and extend system life. You should evaluate the total cost of ownership, including installation, service, and replacement.

You can choose from a wide range of connector options to fit your budget. Standardized designs often cost less and offer reliable performance. Custom connectors may increase costs but provide solutions for unique requirements, such as optical data transmission or harsh environments.

- Assess initial purchase price and long-term savings.

- Consider maintenance and replacement costs.

- Choose standardized connectors for cost-effective solutions.

Note: Investing in quality connectors pays off in reduced downtime and lower maintenance costs.

Lead Times and Sourcing

Lead times and sourcing impact your project schedule and operational efficiency. You should work with reputable suppliers who offer reliable delivery and support. Off-the-shelf connectors are usually available quickly, while custom designs may require longer lead times.

You need to plan ahead for critical projects, especially when sourcing connectors for specialized applications like optical networks or electric vehicle charging. Establish relationships with trusted vendors to ensure consistent supply and technical support.

- Off-the-shelf connectors reduce lead times.

- Custom solutions may require advanced planning.

- Reliable sourcing ensures project continuity.

Tip: Always verify availability and lead times before finalizing your connector selection. This step helps you avoid delays and keeps your operations running smoothly.

Real-World Applications and Case Studies of Industrial Connectors

Successful Connector Selection in Manufacturing

You see the impact of choosing the right industrial connectors in manufacturing every day. When you select connectors that match your operational needs, you improve reliability and efficiency across many applications. Consider these examples:

| Case Study | Description |

|---|---|

| Automotive Testing | Connectors designed for harsh test environments, supporting multiple mating cycles and easy assembly. |

| Agricultural Drones | Main connector supports drones with 25 minutes of flight time, covering six acres per charge. |

| Factory Automation | Test and measurement equipment uses connectors to enhance quality, safety, and productivity. |

| Freeze Dryers | Contactless connectors recharge batteries in automated loading systems. |

| Inductive Charging | Contactless connectors power trolleys in pharmaceutical and food industries, eliminating cables. |

You notice that each application benefits from connectors tailored to specific requirements. In automotive testing, you rely on connectors that withstand repeated use and harsh conditions. Agricultural drones depend on lightweight, high-performance connectors to maximize flight time. Factory automation demands connectors that support precise measurement and control. These examples show how careful selection leads to successful outcomes in manufacturing.

Avoiding Common Pitfalls in Harsh Environments

You often face challenges when deploying industrial connectors in harsh environments. Common pitfalls can disrupt operations and reduce system reliability. You can address these issues by focusing on key factors:

- Select connectors rated for the required mating cycles to prevent excessive wear.

- Choose connectors with appropriate IP ratings, such as IP68 or IP69, to protect against dust and moisture.

- Ensure connectors are designed for the expected temperature range to avoid insulation failure and corrosion.

- Use connectors with secure latching mechanisms to prevent accidental disconnections from shock and vibration.

- Consider vibration resistance to prevent wear and electrical interruptions.

- Opt for materials that withstand extreme temperatures and environmental hazards.

- Confirm that connectors meet rigorous testing standards for harsh conditions.

You encounter problems like dust and moisture ingress, which can cause corrosion and unreliable contacts. Thermal shock may degrade connector materials, affecting electrical performance. Vibration can lead to loss of contact force and increased resistance. Humidity and chemical exposure also threaten connector integrity. By addressing these factors, you maintain reliable connections in demanding applications.

Tip: Always review environmental ratings and material specifications before installing connectors in harsh settings.

Upgrading Legacy Systems with Modern Connectors

You improve system performance and extend equipment life when you upgrade legacy systems with modern industrial connectors. Many older applications use outdated connectors that lack features like enhanced sealing, vibration resistance, or high-speed data support. You can replace these with advanced connectors that meet current standards and operational needs.

Modern connectors offer benefits such as:

- Improved ingress protection for dust and moisture.

- Enhanced durability for frequent mating cycles.

- Support for higher data rates and power transmission.

- Easier installation and maintenance.

You find that upgrading connectors in legacy systems enables you to integrate new technologies and meet evolving industry requirements. This process helps you reduce downtime, increase safety, and ensure compatibility with future applications.

Lessons Learned from Field Failures

You often face unexpected challenges when working with industrial connectors in real-world applications. Field failures can disrupt operations, increase costs, and compromise safety. You gain valuable insights by analyzing these failures and applying lessons to future projects.

Many failures occur because you overlook the total applied cost. You must consider not only the price of the connector but also installation and maintenance expenses. Fast connections help you reduce labor time and minimize errors during setup. You improve efficiency by choosing connectors designed for quick assembly.

Environmental factors play a major role in connector reliability. Dirt, moisture, and temperature extremes can damage connectors and lead to system breakdowns. You need to evaluate the operating environment before selecting connectors for your applications. Vibration and mechanical shock also cause failures, especially in transportation and heavy machinery. You should select connectors with vibration-resistant features to ensure long-term performance.

Signal integrity remains critical in many applications. Poor contact materials can result in data loss or electrical faults. You enhance reliability by choosing connectors with high-quality contacts, such as gold plating. This choice helps you maintain clear signals and prevent costly downtime.

Mismating of connectors often leads to field failures. You can prevent this by using keying and color-coding. These design features guide you during installation and reduce the risk of incorrect connections. You also benefit from connectors that offer clear labeling and distinct shapes.

Here are the key lessons you learn from field failures:

- Always assess the total cost, including installation and maintenance, not just the purchase price.

- Evaluate environmental conditions like dirt, moisture, and temperature before selecting connectors.

- Choose vibration-resistant connectors for applications exposed to mechanical shock.

- Prioritize signal integrity by selecting connectors with high-quality contact materials.

- Opt for connectors designed for fast, error-free connections.

- Use keying and color-coding to prevent mismating and installation errors.

Tip: You improve system reliability and reduce downtime by applying these lessons to your connector selection and maintenance strategies.

You strengthen your approach to industrial connectors by learning from past mistakes. These lessons help you build safer, more efficient systems for a wide range of applications.

Best Practices for Industrial Connector Installation and Maintenance

Proper Handling and Storage of Connectors

You protect your investment in industrial connectors by following strict handling and storage guidelines. Always keep connectors in their original packaging until you need them. This practice prevents dust, moisture, and accidental damage. Store connectors in a clean, dry environment with stable temperatures. Avoid stacking heavy objects on top of connector packages. You reduce the risk of bent pins or cracked housings by keeping storage areas organized.

When you handle connectors, wear gloves to prevent oils or dirt from contaminating contact surfaces. Use antistatic bags for sensitive electronic connectors. Label storage bins clearly so you can find the right part quickly. These steps help you maintain the quality and reliability required for demanding applications.

Tip: Never force a connector into place during storage or handling. Gentle handling extends the life of your components.

Correct Mating and Unmating Procedures

You ensure reliable performance in all applications by using proper mating and unmating techniques. Before connecting, inspect both sides for debris or damage. Align connectors carefully, using any keying features to guide you. Apply even pressure when mating. Never twist or bend connectors during this process. For connectors with locking mechanisms, engage the lock fully to secure the connection.

When you need to disconnect, release any locking tabs or screws first. Pull connectors straight apart without excessive force. Avoid yanking on cables, as this can damage internal contacts. If you encounter resistance, check for misalignment or foreign objects. Following these steps reduces wear and prevents costly failures in your applications.

| Step | Action | Why It Matters |

|---|---|---|

| Inspect | Check for dirt or damage | Prevents poor connections |

| Align | Use keying features | Ensures correct mating |

| Engage Lock | Secure locking mechanisms | Maintains connection integrity |

| Unmate Carefully | Release locks, pull straight apart | Avoids contact or housing damage |

Regular Inspection and Maintenance of Connectors

You keep your systems running smoothly by scheduling regular inspections of all connectors. Look for signs of corrosion, discoloration, or loose contacts. Tighten any screws or locking mechanisms that may have loosened over time. Clean contact surfaces with approved solvents if you see buildup or residue.

Set a maintenance schedule based on the environment and frequency of use. In harsh or high-vibration applications, inspect connectors more often. Replace any damaged or worn connectors immediately to prevent downtime. Document your inspections and repairs so you can track trends and address recurring issues.

Callout: Proactive maintenance of industrial connectors reduces unexpected failures and extends the lifespan of your equipment.

Troubleshooting Common Connector Issues

You often encounter challenges when working with industrial connectors in demanding applications. Quick identification and resolution of common issues help you maintain system reliability and prevent costly downtime. Below, you will find practical steps and tips for troubleshooting connector problems.

Common Issues and Solutions

| Issue | Symptoms | Solution |

|---|---|---|

| Loose Connections | Intermittent signals, power loss | Inspect and reseat connector |

| Corrosion | Discoloration, poor conductivity | Clean contacts, replace if necessary |

| Bent Pins | Connection failure, misalignment | Straighten pins carefully or replace |

| Debris/Dust Ingress | Signal degradation | Clean with compressed air or solvent |

| Overheating | Melted housing, burnt smell | Check current rating, replace connector |

You should start by visually inspecting the connector for physical damage. Look for bent pins, cracks, or signs of corrosion. Use a flashlight to check for debris inside the housing. If you see any contamination, clean the contacts with approved solvents or compressed air.

Tip: Always disconnect power before inspecting or cleaning connectors to avoid electrical hazards.

You may notice intermittent signals or power loss in your applications. These symptoms often point to loose connections. Reseat the connector and ensure locking mechanisms engage fully. If the problem persists, check for worn contacts or damaged housings.

Corrosion can occur in harsh environments. You should clean affected contacts with a contact cleaner. If corrosion is severe, replace the connector to restore performance.

Bent pins cause misalignment and connection failure. You can use needle-nose pliers to straighten minor bends. For severe damage, replace the connector to prevent further issues.

Dust and debris often enter connectors in outdoor or industrial applications. Regular cleaning helps you maintain signal integrity. Use compressed air or a lint-free cloth to remove contaminants.

Overheating signals a mismatch between the connector’s rating and the system’s requirements. Verify that the connector matches the current and voltage demands of your applications. Replace any connector that shows signs of melting or burning.

Note: Document all troubleshooting steps and outcomes. This practice helps you track recurring issues and improves future maintenance.

You improve system reliability by addressing these common connector issues promptly. Proper troubleshooting ensures that your industrial connectors continue to support critical applications without interruption.

You have explored the essential types of industrial connectors and their diverse applications across industries. When choosing the right connector, you should evaluate electrical ratings, environmental resistance, and compatibility with your system. You improve reliability by following best practices for installation and maintenance. For complex requirements, you benefit from consulting connector manufacturers or industry experts.

Careful selection ensures your equipment performs safely and efficiently.

FAQ

What is the difference between circular and rectangular connectors?

Circular connectors use a round shape for durability and easy alignment. Rectangular connectors offer space-saving designs and support high-density pin arrangements. You select based on your system’s layout and connection needs.

How do you choose the right connector for harsh environments?

You look for connectors with high ingress protection (IP) ratings, corrosion-resistant materials, and robust locking mechanisms. These features help you maintain reliable connections in extreme conditions.

Why do you need to consider mating cycles when selecting connectors?

Mating cycles indicate how many times you can connect and disconnect a connector before it wears out. You choose connectors with higher ratings for applications that require frequent maintenance or reconfiguration.

Can you use the same connector type across different industries?

You often find standardized connectors that work in multiple industries. However, you must check certifications and compatibility with your specific equipment and safety requirements.

What maintenance steps help extend connector lifespan?

You inspect connectors regularly for corrosion, loose contacts, and debris. You clean contact surfaces and replace damaged parts promptly. Scheduled maintenance helps you prevent unexpected failures.

How do modular connectors benefit industrial applications?

Modular connectors allow you to customize and expand your system easily. You save time during installation and maintenance. Their standardized design supports quick upgrades and repairs.

What are common signs of connector failure?

You notice intermittent signals, overheating, or visible damage like bent pins and discoloration. You troubleshoot by inspecting, cleaning, and reseating connectors to restore performance.

Do fiber optic connectors require special handling?

You handle fiber optic connectors with care to avoid dust and scratches. You use clean tools and protective caps. Proper handling ensures high-speed data transmission and signal integrity.