You need to focus on specific features when choosing pin female connectors for your electrical applications. The right female connector helps you achieve performance and reliability, especially in environments that demand consistent operation. Selecting connectors with proper contact material and secure mating systems reduces risks and improves safety. You should consider options like the M8 connector or Type B connector for specialized needs. A trusted connector factory delivers quality pin connectors and female connectors that meet your requirements.

Understanding Pin Female Connectors

Definition and Function of Pin Female Connectors

What Are Pin Female Connectors?

You encounter pin female connectors in many modern electrical systems. These connectors belong to the family of pin and socket connectors, which represent one of the most common types of electrical connectors. A pin female connector features a series of sockets or receptacles designed to receive the pins from a corresponding male connector. This design allows you to create a secure and stable electrical connection. You often see these connectors in power and data transmission, where reliability and safety matter most.

How Do Pin Female Connectors Work in Electrical Systems?

Pin female connectors work by providing a secure interface for the pins of male connectors. When you insert the pins into the female connector, the sockets grip the pins tightly. This ensures efficient current flow and reduces the risk of short circuits or accidental disconnections. The female connector’s design supports a wide range of connector applications, from consumer electronics to industrial automation. You benefit from their ability to maintain stable connections even in environments with vibration or movement.

Role of Female Connectors in Connection Reliability

Importance of Pin Female Connectors in Signal Integrity

You rely on female connectors to maintain signal integrity in your systems. Their precise socket design minimizes resistance and signal loss, which is critical for sensitive applications. For example, in semiconductor testing, pin connectors must deliver low resistance and minimal signal degradation. You also find these connectors in consumer electronics, such as charging contacts for wearables like smartwatches and wireless earbuds. The stable connection provided by female connectors ensures your devices operate without interruption.

Impact of Female Connectors on System Safety

Female connectors play a vital role in system safety. Their secure mating mechanism prevents accidental disconnections and protects against short circuits. In medical devices, you depend on these connectors to deliver stable performance, even under vibration or movement. Industrial automation systems also use pin connectors in robotic docking stations and modular assembly lines, where quick and reliable electrical interfacing is essential. By choosing the right female connector, you enhance both the safety and reliability of your electrical systems.

Tip: Always match your connector choice to your specific application needs. Consider factors like vibration, signal integrity, and environmental exposure to ensure long-term reliability.

Types of Pin Female Connectors

When you select pin connectors, you encounter a wide range of types designed for different needs. Understanding the main categories helps you choose the right connector for your application.

Pin Female Connectors by Mounting Style

Through-Hole Pin Female Connectors

Through-hole pin connectors use leads that pass through holes in a printed circuit board (PCB). You solder these leads on the opposite side, which creates a strong mechanical bond. This mounting style works well in environments where you expect mechanical stress or vibration. You often find through-hole connectors in industrial equipment and automotive systems, where durability matters most.

Surface-Mount Pin Female Connectors

Surface-mount pin connectors attach directly to the surface of a PCB. You benefit from this style when you need compact designs and automated assembly. Surface-mount connectors suit consumer electronics, such as smartphones and tablets, where space is limited. You achieve reliable electrical connections while saving valuable board space.

Pin Female Connectors by Application

Pin connector types vary based on the demands of different industries. The table below highlights the most widely used female connector types and their typical applications:

| Connector Type | Applications |

|---|---|

| Power Connectors | AC power receptacles, DC power jacks, IEC C13/C15 connectors for specific voltage and current. |

| Data/Communication Connectors | USB connectors, RJ45 Ethernet jacks, serial interface receptacles for signal integrity. |

| Audio/Video Connectors | 2.5 mm headphone jacks, XLR sockets, HDMI ports for specific signal transmission. |

| Industrial/Specialized Connectors | Ruggedized designs with environmental sealing for harsh conditions, often meeting military specs. |

You see power connectors in equipment that requires stable voltage and current delivery. Data and communication connectors maintain signal integrity in networking and computing devices. Audio/video connectors support clear signal transmission in entertainment systems. Industrial connectors withstand harsh environments, making them ideal for factory automation and specialized machinery.

Industrial Pin Female Connectors

You rely on industrial connectors for ruggedness and environmental resistance. These connectors often feature sealing and reinforced housings. They perform well in manufacturing plants and outdoor installations.

Consumer Electronics Pin Female Connectors

Consumer electronics demand compact and easy-to-use connectors. You find these pin connectors in devices like laptops, headphones, and gaming consoles. They offer reliable connections in small spaces.

Automotive Pin Female Connectors

Automotive systems require connectors that handle vibration, temperature changes, and exposure to moisture. You use these connectors in vehicle wiring harnesses, control modules, and sensor interfaces.

Pin Female Connectors by Contact Arrangement

Single Row vs. Double Row Pin Connectors

Single row pin connectors arrange contacts in a straight line. You use them for simple connections or when space is tight. Double row connectors provide more contacts in the same footprint, which allows you to connect multiple circuits efficiently.

Circular vs. Rectangular Pin Female Connectors

The arrangement of contacts in pin connectors affects both electrical and mechanical performance. Circular connectors use a concentric pin layout, which gives you durability and easy mating. These connectors distribute mechanical stress evenly, making them suitable for demanding environments. Rectangular connectors, with their grid layout, offer higher pin density. You choose these when you need to connect many channels or support high-speed data. However, rectangular connectors may need extra reinforcement to maintain structural integrity under stress.

Tip: Match the connector style and arrangement to your application’s electrical, mechanical, and environmental requirements. This ensures long-term reliability and performance.

Key Features for Reliable Pin Female Connectors

Contact Material and Plating in Female Connectors

Common Materials: Copper, Brass, Phosphor Bronze

When you select female connector types, you need to consider the contact material. The material directly affects conductivity, durability, and cost. The table below compares the most common materials used in pin connectors and electrical pin terminals:

| Material | Electrical Properties | Cost Comparison |

|---|---|---|

| Beryllium Copper | Excellent mechanical and electrical performance, good for high cycle applications. | More expensive than other copper-based materials. |

| Silver | Very high thermal and electrical conductivity, but low mechanical strength. | Expensive compared to copper or bronze. |

| Stainless Steel | Good resistance to oxidation, but not primarily chosen for electrical properties. | Varies based on alloy composition. |

| Nickel | Fair conductor, resistant to corrosion, often used in alloys. | Generally less expensive than copper. |

| Phosphor Bronze | Higher tensile strength than brass, good for harsh environments. | More expensive than brass, less than BeCu. |

You often see copper and its alloys, such as brass and phosphor bronze, in 5-pin and other pin connector types. Copper provides the best conductivity, which allows for greater current-carrying capacity. Phosphor bronze offers higher tensile strength, making it suitable for harsh environments and high mating cycles. Brass is cost-effective and works well in many consumer applications. Stronger metals with higher tensile strength and current capacities usually come at a higher price.

- Higher quality materials provide better spring contacts, which are essential for reliability in high mating cycles.

- Copper content directly impacts current-carrying capabilities.

- Cost increases with stronger metals and higher performance.

Plating Options: Gold, Tin, Nickel

The plating on female connectors plays a critical role in both lifespan and conductivity. You need to match the plating to your application’s requirements. Gold plating stands out for its exceptional corrosion resistance and conductivity. You often choose gold for high-reliability environments, such as medical or aerospace applications. Tin plating is more cost-effective and offers good solderability, but it may require more maintenance due to the risk of fretting corrosion. Nickel plating adds durability and wear resistance, which extends the life of your connectors.

- Gold plating: Delivers outstanding corrosion resistance and conductivity, ideal for demanding applications.

- Tin plating: Offers good solderability and affordability, but may need periodic maintenance.

- Nickel plating: Enhances durability and wear resistance, supporting long-term connector performance.

Tip: For 5-pin connectors in critical systems, gold plating ensures maximum performance and reliability.

Design for Secure Mating in Pin Connectors

Pin Retention Mechanisms in Female Connectors

A secure mating design prevents accidental disconnection and maintains stable electrical contact. You find several retention mechanisms across female connector types. The table below highlights key features in different connector types:

| Connector Type | Key Features | Applications |

|---|---|---|

| Threaded Couplers | Significant mating force, lockwire holes, triple-start threads, ratcheting coupling | Communication equipment, military aircraft, missiles |

| Bayonet Connectors | Push and twist mating, visual/audible/tactile confirmation, inspection holes | Rugged industrial environments, power generators |

| Push-Pull Connectors | Self-latching mechanism, axial force for connection/disconnection | Medical, instrumentation, military vehicles |

Threaded couplers provide strong retention for high-vibration environments. Bayonet connectors offer quick and secure mating with clear feedback. Push-pull connectors use a self-latching mechanism, making them easy to connect and disconnect while maintaining a reliable hold.

Anti-Vibration Features for Reliable Connections

Vibration can compromise the integrity of pin connectors, especially in industrial and automotive applications. Manufacturers implement several anti-vibration features to ensure reliable connections. The table below shows examples of anti-vibration solutions in leading products:

| Product | Anti-Vibration Features |

|---|---|

| Weidmuller OMNIMATE Signal PCB Plug-In Connectors | Tool-free self-actuating lock-and-release mechanism, visual cues for secure connection, reduces mechanical stress on solder joint |

| Smiths Interconnect C9394 High-Density Line Receptacle Module | High resistance to shock and vibration, eliminates fretting, reduces wear rates |

| Omnetics Micro 360® Circular Connectors | Metal housing for high shock and vibration resistance, sealed to IP68, qualified to MIL-DTL-83513 specifications |

| Aero-Electric MIL-DTL-83723 Series III Connectors | Bayonet and threaded coupling, rear-release contact retention system, designed to withstand random vibration levels per MIL-STD-1344 |

You should look for features like self-actuating locks, metal housings, and rear-release contact retention systems. These features help your 5-pin and other pin terminal connectors withstand harsh conditions and maintain stable connections.

Note: Anti-vibration features are essential for wire connector pins in automotive, aerospace, and industrial environments.

Electrical Ratings of Pin Female Connectors

Current Carrying Capacity of Female Connectors

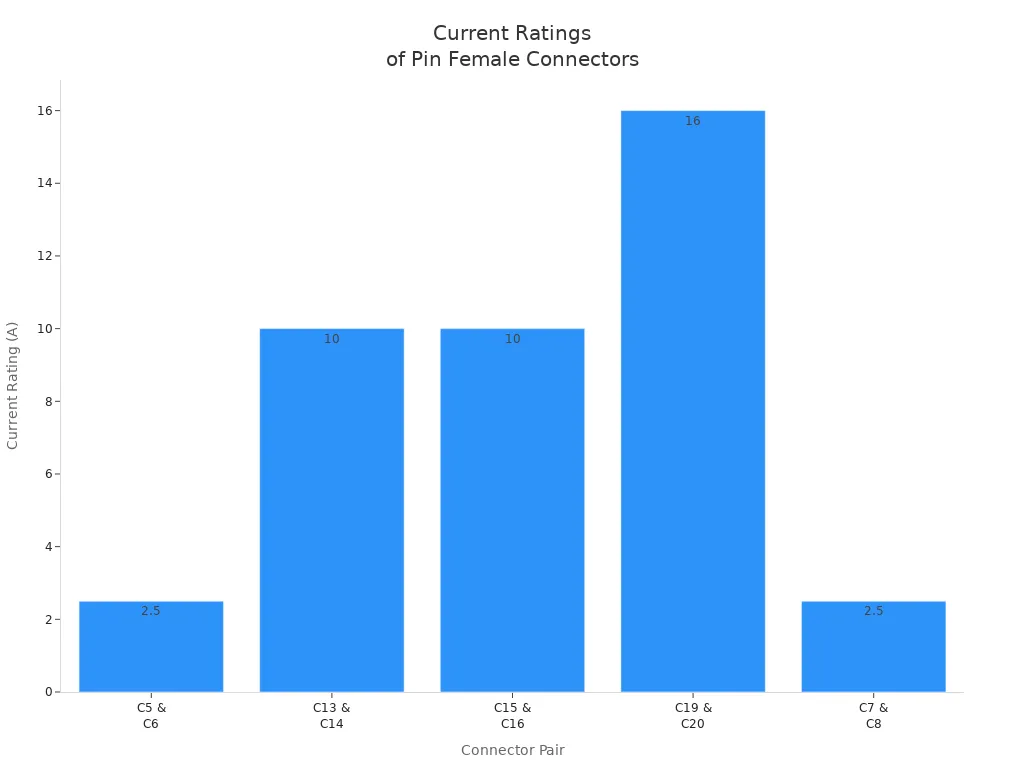

You must select female connectors that match your application’s current requirements. The current-carrying capacity depends on the contact material, plating, and design. For example, copper-based contacts in 5-pin connectors allow for higher current flow. The chart below compares current ratings for standard pin connector pairs:

Voltage Ratings for Pin Connectors

Voltage ratings indicate the maximum voltage a connector can safely handle. You need to check these ratings for your specific application. The table below summarizes voltage and current ratings for common female connector types:

| Connector Pair | Voltage Rating | Current Rating | Number of Conductors | Typical Use |

|---|---|---|---|---|

| C5 & C6 | Up to 250 V | 2.5 A | 3 | Laptops, smaller devices |

| C13 & C14 | Up to 250 V | 10 A | 3 | PCs, monitors, peripherals |

| C15 & C16 | Up to 250 V | 10 A | 3 | Higher-temp (kettles, etc.) |

| C19 & C20 | Up to 250 V | 16 A | 3 | Servers, heavy machinery |

| C7 & C8 | Up to 250 V | 2.5 A | 2 | TVs, Blu-ray players, etc. |

You should always verify that your pin female connectors meet or exceed the voltage and current demands of your system. This ensures safe operation and prevents overheating or failure.

Callout: Always match the electrical ratings of your pin connector types to your application’s requirements for optimal performance and reliability.

Environmental Resistance in Female Connectors

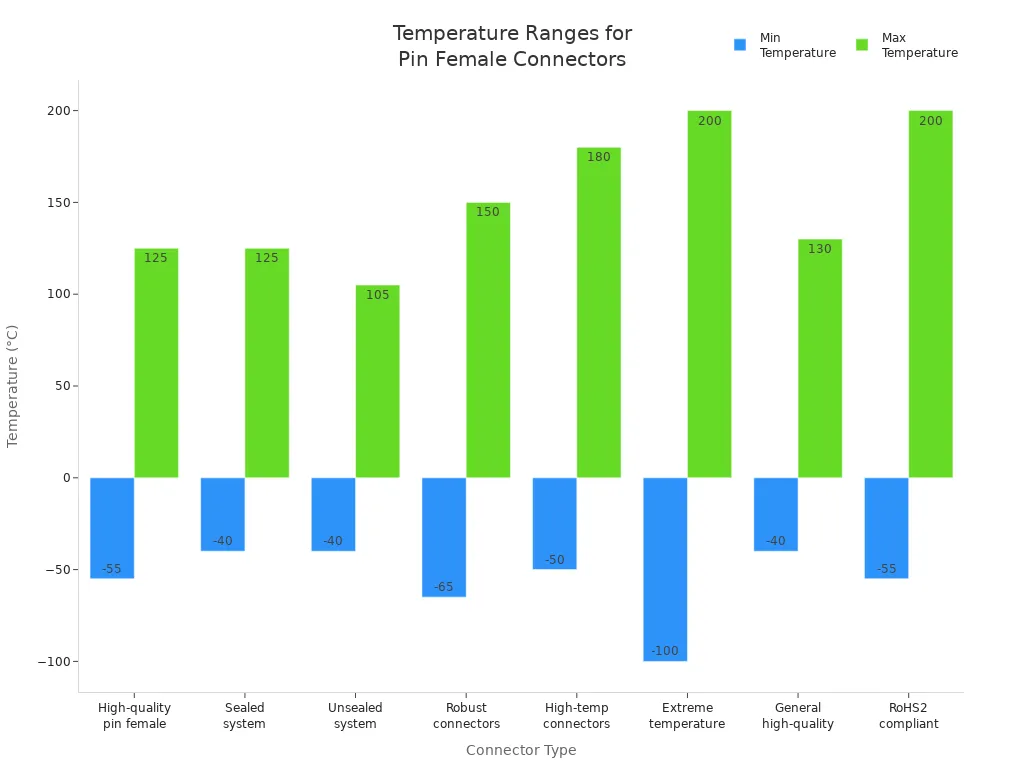

Temperature Tolerance of Pin Female Connectors

You need to consider temperature tolerance when selecting female connector types for demanding environments. Extreme heat or cold can damage connectors, leading to system failures. High-quality pin connectors are engineered to withstand a wide range of temperatures, ensuring consistent performance and reliability in critical applications. The following table shows typical temperature ranges for various female connectors:

| Temperature Range (°C) | Description |

|---|---|

| -55 to +125 | High-quality pin female connectors |

| -40 to +125 | Sealed system connectors |

| -40 to +105 | Unsealed system connectors |

| -65 to +150 | Robust connectors with high resistance |

| -50 to +180 | Additional high-temperature connectors |

| -100 to +200 | Extreme temperature connectors |

| -40 to +130 | General high-quality connectors |

| -55 to +200 | Compliant with RoHS2 directive |

You should always verify the temperature rating of your 5-pin connectors before installation. This step helps you avoid unexpected failures in harsh environments.

Moisture and Corrosion Protection in Connectors

Moisture poses a significant threat to female connectors, especially in outdoor or industrial settings. Humidity, rain, and salt spray can corrode terminals and degrade electrical performance. Rugged pin connectors feature seals and corrosion-resistant materials to protect against water ingress. You benefit from these features in marine, automotive, and factory applications where moisture exposure is common.

Tip: Choose connectors with IP67 or higher ratings for maximum moisture protection in challenging environments.

The table below highlights how environmental factors impact connector durability:

| Environmental Factor | Description |

|---|---|

| Temperature | Extreme hot and cold temperatures can damage connectors. |

| Moisture | Humidity and salt spray can corrode connectors. |

| Dust | Dust and dirt can harm electrical systems, leading to failures. |

You should select female connector types with robust sealing and corrosion-resistant plating, such as nickel or gold, to ensure long-term reliability.

Dust and Debris Sealing for Pin Connectors

Dust and debris can infiltrate connectors, causing shorts and reducing system life. You need pin connectors with effective sealing to block contaminants. Industrial and outdoor applications often require connectors with gaskets or overmolded housings. These features keep dust and dirt away from sensitive terminals, maintaining stable connections.

- Protects against water, including rain and humidity.

- Shields from dust and dirt in industrial and outdoor settings.

- Designed to withstand extreme temperatures.

You should inspect the sealing features of your 5-pin connectors before deployment. This practice helps you maintain performance and reliability in harsh conditions.

Safety Mechanisms in Pin Female Connectors

Locking Systems for Secure Female Connections

Locking systems play a crucial role in the safety and reliability of female connectors. You rely on these mechanisms to prevent accidental disconnections and maintain secure mating, especially in vibration-prone environments. Popular locking systems include threaded couplers, bayonet locks, and push-pull latches. These systems provide strong retention and tactile feedback, ensuring your 5-pin connectors stay connected under stress.

The following table summarizes key safety features:

| Feature | Benefit |

|---|---|

| Four points of contact | Enhances reliability by ensuring a secure connection. |

| Alternative mounting methods | Reduces movement in vibration applications, increasing safety. |

| Optional terminal position assurance (TPA) | Ensures proper assembly and higher retention force. |

You should choose female connector types with locking systems that match your application’s mechanical demands.

Polarization Features in Pin Connectors

Polarization features prevent mis-mating and ensure correct connections. You find these features in many pin connectors, including 5-pin designs. Polarization keys, asymmetric housings, and guide pins help you align connectors properly, reducing the risk of electrical faults.

| Feature | Benefit |

|---|---|

| Polarization | Prevents mis-mating, ensuring correct connections. |

| Positive locking | Provides a secure connection that enhances reliability. |

| Rear cavity identification | Facilitates error-resistant assembly, improving safety. |

You should always verify the polarization features of your female connectors before installation. This step helps you avoid costly mistakes and system downtime.

Insulation and Overmold Protection in Female Connectors

Insulation and overmold protection safeguard your connectors from electrical hazards and mechanical damage. Insulated housings prevent short circuits and protect users from accidental contact with live terminals. Overmolded designs add an extra layer of defense against moisture, dust, and vibration.

Note: Insulation and overmold protection are essential for maintaining safety and reliability in high-voltage or high-current applications.

You should select female connector types with robust insulation and overmold features for demanding environments. These features help you achieve optimal performance and reliability across all connector types.

Selection Criteria for Pin Female Connectors

Evaluating Application Requirements for Female Connectors

Electrical Needs for Pin Connectors

You must assess the electrical requirements of your application before selecting pin connectors. Consider the voltage and current ratings to ensure the connector can handle the electrical load. High-power applications require connectors with larger contacts and robust insulation. Always check that the female connector meets or exceeds your system’s voltage and current needs. This step helps you avoid overheating and electrical failures.

Mechanical Stress Factors in Female Connector Selection

Mechanical stress plays a significant role in connector selection. You should evaluate factors such as vibration, shock, and repeated use. Connectors designed for high mechanical robustness maintain performance under stress and frequent mating cycles. Assess contact pressure to minimize resistance and wear. Choosing the right connector ensures reliable operation in demanding environments.

Environmental Conditions for Reliable Pin Connectors

Environmental factors can impact the durability and reliability of female connectors. You need to select connectors with suitable IP ratings if your application involves exposure to humidity, dust, or extreme temperatures. Flame retardant and self-extinguishing materials help prevent fire risks. Matching connectors to your application environment ensures long-term performance.

Tip: Always verify the environmental ratings of your connectors to prevent unexpected failures in harsh conditions.

Practical Tips for Selecting Pin Female Connectors

Compatibility with Male and Female Pin Connectors

You should confirm that your female connectors are fully compatible with the corresponding male and female pin connectors. Mismatched connectors can lead to poor connections or system malfunctions. Review the manufacturer’s specifications to ensure proper fit and function.

Ease of Installation and Maintenance of Female Connectors

Choose connectors that simplify installation and maintenance. Features such as tool-free locking mechanisms and clear markings reduce errors during assembly. Easy installation and maintenance save time and lower the risk of damage during servicing.

Cost vs. Performance Considerations for Pin Connectors

Balancing cost and performance is essential in connector selection. While high-performance connectors offer greater durability and reliability, they may come at a higher price. Evaluate your application’s needs and select connectors that provide the best value without compromising safety or performance.

Selection Checklist for Pin Female Connectors

Feature Checklist for Reliable Female Connectors

Use the following checklist to guide your selection process:

| Criteria | Description |

|---|---|

| Power Requirements | Evaluate voltage and current needs; high-power applications need larger contacts and robust insulation. |

| Environmental Factors | Select connectors with suitable IP ratings for humidity, dust, or extreme temperatures. |

| Space Constraints | Consider miniature connectors for compact devices; larger equipment can use bigger connectors. |

| Durability | Assess lifespan and usage frequency; frequent connections need connectors designed for multiple cycles. |

| Mechanical Parameters | Consider contact pressure, mechanical life, and electrical continuity under specified conditions. |

Questions to Ask Suppliers About Pin Connectors

- What are the voltage and current ratings for these female connectors?

- Are the connectors tested for resistance to vibration, shock, and temperature extremes?

- Do the connectors meet the required IP ratings for my application?

- How many mating cycles can the connectors withstand?

- Are the materials flame retardant and self-extinguishing?

Note: Asking these questions helps you make informed decisions and ensures your connector applications remain safe and reliable.

Common Mistakes and How to Avoid Them with Pin Female Connectors

Overlooking Key Features in Female Connector Selection

Ignoring Environmental Ratings for Pin Connectors

You might overlook environmental ratings when choosing female connectors. This mistake can lead to failures in harsh conditions. If you use pin connectors without proper sealing or temperature tolerance, moisture or dust can enter and cause corrosion. Corroded connectors lose conductivity, which results in signal loss or even total failure. Always check the IP rating and temperature range before installing female connectors in demanding environments.

Neglecting Safety Mechanisms in Female Connectors

Safety mechanisms in female connectors protect your system from accidental disconnects and misalignment. If you ignore features like locking systems or polarization, you risk bent pins and unreliable connections. The table below highlights common mistakes and their consequences:

| Mistake | Consequence |

|---|---|

| Pin Configuration and Misalignment | Pins can become bent, preventing proper mating and leading to connection failures. |

| Connector Corrosion | Decreased conductivity can result in signal inconsistencies or total cable failure. |

| Overmolding Damage | Damage can lead to intermittent or open connections due to external factors exceeding material limits. |

| Mating Cycle Issues | Mating cycles that do not match application demands can lead to mechanical failure of the connection. |

Tip: Always verify that your female connectors include robust safety features to prevent these issues.

Misjudging Application Needs for Pin Connectors

Underestimating Electrical Loads in Female Connectors

You must match the electrical load of your application to the rating of your female connectors. If you underestimate the current or voltage, the connector may overheat or fail. This can cause system downtime or even safety hazards. Always review the specifications for pin connectors and select those that meet or exceed your requirements.

Choosing Incompatible Pin Connector Designs

Selecting the wrong design for your pin connectors can create compatibility problems. If you choose a connector with the wrong pin configuration or mounting style, you may face installation delays or unreliable performance. You need to ensure that your female connectors match the male connectors and the system layout.

Actionable Advice for Reliable Pin Female Connector Selection

Steps to Ensure Reliable Pin Female Connector Selection

You can avoid most mistakes by following a clear selection process:

- Identify your application’s requirements, such as signal type and power rating.

- Choose the correct coding and pin configuration for your needs.

- Select the number of pins to support your system.

- Assess environmental factors and pick connectors with proper IP ratings.

- Match cable type and length.

- Decide on mounting style.

- Choose connectors from trusted manufacturers.

Best Practices for Installing Pin Female Connectors

When installing female connectors, focus on these best practices:

- Inspect contact base material and plating for quality.

- Check allowable mating force and use contact lubricant if needed.

- Review surface finish and geometry of contact surfaces.

- Ensure closed entry of contacts and proper insertion depth.

- Use connectors with anti-overstress design and mechanical support for contact beams.

- Follow the recommended contact mating sequence and check for contact bifurcation.

Note: Careful selection and installation of female connectors help you achieve reliable performance in all applications.

Application Scenarios and Recommendations for Pin Female Connectors

Industrial Automation with Pin Female Connectors

Demands for Durability and Safety in Industrial Pin Connectors

You encounter demanding environments in industrial automation. Pin female connectors must deliver consistent performance under stress. You need female connectors that withstand vibration, extreme temperatures, and exposure to dust or chemicals. These connector applications require reliability and durability for long-term use. You benefit from connectors designed for secure electrical connections and easy maintenance. The table below highlights essential requirements for industrial automation:

| Requirement | Description |

|---|---|

| Reliability and Durability | Connectors must withstand harsh conditions like extreme temperatures and vibrations for long-term use. |

| Signal Integrity | Essential to prevent data loss and ensure accurate communication, minimizing electrical interference. |

| Safety | Designed to prevent accidental disconnections, ensuring secure electrical connections. |

| Ease of Maintenance | Simplifies maintenance with quick and secure connections, reducing downtime. |

| Flexibility | Accommodates diverse equipment and systems, enabling modular setups. |

| Mechanical Design | Must provide a secure fit and withstand mechanical stresses while being easy to connect and disconnect. |

| Electrical Specifications | Must handle required electrical loads without overheating, with high-quality materials. |

| Environmental Resistance | Designed to resist dust, moisture, and chemicals, with features like sealing gaskets. |

| Standards and Certifications | Adherence to industry standards ensures reliability and safety, such as IEC, UL, and IEEE. |

You should select pin connectors that meet these criteria to ensure your industrial automation systems operate safely and efficiently. Female connectors with robust mechanical design and environmental resistance help you minimize downtime and maximize productivity.

Tip: Always verify that your connectors comply with relevant standards for industrial automation to guarantee safety and reliability.

Consumer Electronics and Pin Female Connectors

Prioritizing Compactness and Ease of Use in Female Connectors

You demand compact and user-friendly solutions in consumer electronics. Female connectors must fit into small devices without sacrificing performance. You benefit from pin connectors that offer easy installation and reliable mating. These connectors support frequent connections and disconnections, which is common in consumer devices. You should look for female connectors with clear markings and tool-free locking mechanisms. This approach simplifies assembly and maintenance, reducing the risk of damage.

- Choose connectors with low-profile designs for space-constrained applications.

- Select female connectors that provide tactile feedback for secure mating.

- Opt for pin connectors with high mating cycle ratings to ensure longevity.

You improve device reliability and user experience by prioritizing compactness and ease of use in your connector applications.

Automotive Systems Using Pin Female Connectors

Withstanding Vibration and Temperature Extremes in Automotive Pin Connectors

You face unique challenges in automotive systems. Pin female connectors must operate reliably in environments with constant vibration and wide temperature swings. You need connectors that resist thermal degradation and material fatigue. The table below outlines key challenges for automotive pin connectors:

| Challenge | Description |

|---|---|

| Extreme Temperature Ranges | Connectors must operate reliably from -40°C to +150°C or higher, requiring materials that resist thermal degradation. |

| Thermal Cycling | Repeated heating and cooling can cause material fatigue, leading to connection failures. |

| Environmental Protection | Achieving high ingress protection while maintaining temperature resistance increases design complexity. |

| Electromagnetic Interference (EMI) | High-frequency systems generate EMI, necessitating shielded connectors that perform well at high temperatures. |

| Cost Constraints | Balancing temperature resistance, durability, and cost is essential for high-volume production. |

You should select female connectors with high ingress protection ratings and shielded designs for automotive systems. Pin connectors with robust materials and secure locking mechanisms help you maintain reliable connections despite vibration and temperature extremes.

Note: Always match your connector selection to the specific demands of automotive systems to ensure safety and long-term performance.

Specialized Applications for Pin Female Connectors

Medical Devices: Precision and Reliability in Female Connectors

You work in an industry where precision and reliability are non-negotiable. Medical devices demand female connectors that deliver consistent performance in every procedure. You rely on pin connectors that withstand repeated sterilization cycles, including autoclave, Sterrad, EtO, gamma, and chemical sterilization. These processes can degrade ordinary connectors, but high-quality female connectors use materials that resist corrosion and maintain conductivity. You often see gold-plated, high-conductivity copper alloys in medical devices. This combination prevents pin damage from vibration and ensures stable electrical contact.

You need female connectors that support a minimum of 200 mating cycles. This durability allows you to connect and disconnect medical devices without worrying about failure. You also benefit from IP-rated connectors, which protect against dust and moisture. Many medical devices require up to IP68 protection to ensure safe operation in challenging environments. Quick connect and disconnect features help you save time during equipment setup and emergency procedures.

Tip: Always select female connectors for medical devices that offer EMI and RFI shielding. This feature reduces noise from internal power supplies and other sources, protecting sensitive signals.

Aerospace: High-Performance Pin Connectors for Extreme Environments

You face some of the harshest conditions in aerospace applications. Female connectors in this field must operate reliably at high altitudes, under extreme temperatures, and during constant vibration. You choose pin connectors with robust metal shells that connect to chassis ground. This design helps reduce electromagnetic interference and ensures signal integrity. You also require connectors that function from -40 °C to 105 °C or higher, depending on the mission profile.

Aerospace-grade female connectors must resist corrosion and mechanical wear. You often select gold-plated contacts for their durability and conductivity. Quick connect and disconnect mechanisms allow for rapid maintenance and system upgrades. You also look for IP-rated connectors to prevent dust and moisture ingress, which can compromise safety and performance.

| Feature | Description |

|---|---|

| Durability | Withstands sterilization and harsh aerospace environments. |

| Corrosion Resistance | Gold-plated copper alloy resists corrosion and pin damage. |

| Mating Cycle | Supports at least 200 cycles for repeated use. |

| IP Rating | Up to IP68 for dust and moisture protection. |

| EMI/RFI Performance | Reduces noise from power supplies and external sources. |

| Quick Connect/Disconnect | Enables fast maintenance and upgrades. |

| Operating Temperature Range | Operates from -40 °C to 105 °C or higher. |

Telecommunications: Signal Integrity in Female Pin Connectors

You depend on flawless signal transmission in telecommunications. Female connectors in this sector must maintain high signal integrity, even in environments with significant electromagnetic interference. You select pin connectors with excellent EMI and RFI performance. Metal shells connected to chassis ground further reduce noise and protect data integrity.

You also require connectors that support frequent mating cycles. Telecommunications equipment often undergoes upgrades and maintenance, so you need female connectors that last. IP-rated connectors prevent dust and moisture from disrupting service. Quick connect and disconnect features help you minimize downtime during repairs or installations.

- Choose female connectors with:

- High EMI/RFI shielding

- IP-rated sealing

- Gold-plated contacts for corrosion resistance

- Quick connect/disconnect capability

You ensure reliable performance in all telecommunications applications by prioritizing these features in your pin connectors.

You ensure reliable connections in your applications by selecting pin female connectors with robust safety features, advanced materials, and secure locking mechanisms. Consider the environment and future needs early in your design process to avoid costly changes. Female connectors cover male pins, reducing accidental contact and enhancing protection. Recent innovations include high-performance plastics and embedded diagnostics for improved reliability.

| Innovation Type | Description |

|---|---|

| Advanced Corrosion Resistance | Gold and silver plating improve connector durability in harsh environments. |

| Smart Features | Embedded monitoring tracks connector performance in real time. |

Choose pin connectors that match your application’s demands for long-term safety and performance.

FAQ

What is the main function of a pin female connector?

You use a pin female connector to create a secure electrical connection by receiving male pins. This design helps you maintain stable current flow and prevents accidental disconnections in your system.

How do you choose the right contact material for your application?

You should select contact materials based on conductivity, durability, and cost. Copper offers high conductivity. Brass provides cost-effectiveness. Phosphor bronze delivers strength for harsh environments.

Why is gold plating recommended for critical applications?

Gold plating resists corrosion and maintains excellent conductivity. You benefit from reliable performance in medical, aerospace, and high-frequency systems where signal integrity matters most.

What does an IP rating mean for pin female connectors?

IP ratings indicate protection against dust and moisture. You should choose connectors with higher IP ratings for outdoor or industrial environments to ensure long-term reliability.

How do locking systems improve connector safety?

Locking systems prevent accidental disconnects. You gain secure mating in vibration-prone environments, reducing the risk of system failure and improving overall safety.

Can you use pin female connectors in high-temperature environments?

You can use pin female connectors rated for high temperatures. Always check the manufacturer’s specifications to ensure the connector matches your application’s temperature range.

What are common mistakes when installing pin female connectors?

You might overlook environmental ratings, mismatch connector types, or ignore safety features. Always verify specifications and follow best practices for installation to avoid failures.

How do you maintain pin female connectors for long-term reliability?

You should inspect connectors regularly for corrosion or wear. Clean contacts with approved solutions. Replace damaged connectors promptly to maintain stable performance.