When you select a female rj45 connector for your ethernet network setups, always match the connector to your cable type and installation environment. You improve network performance by choosing an rj45 female connector with the right category rating, shielding, and PoE support. The following table highlights common network environments where rj45 female connectors, M8 connector, and Type B connector play key roles:

| Network Environment | Description |

|---|---|

| Data Centers | Manage high-speed ethernet transmission for critical network operations. |

| Office and Home Networks | Enable reliable ethernet connections for daily network tasks. |

| Industrial Automation | Support robust ethernet links in manufacturing and robotics. |

| IoT Deployments | Connect smart devices for scalable network growth. |

| Connector factory | Use specialized rj45 female connector solutions for efficient ethernet assembly. |

You ensure long-term reliability by selecting a durable female rj45 connector suited to your network’s demands.

Understanding the Female RJ45 Connector

What Is a Female RJ45 Connector?

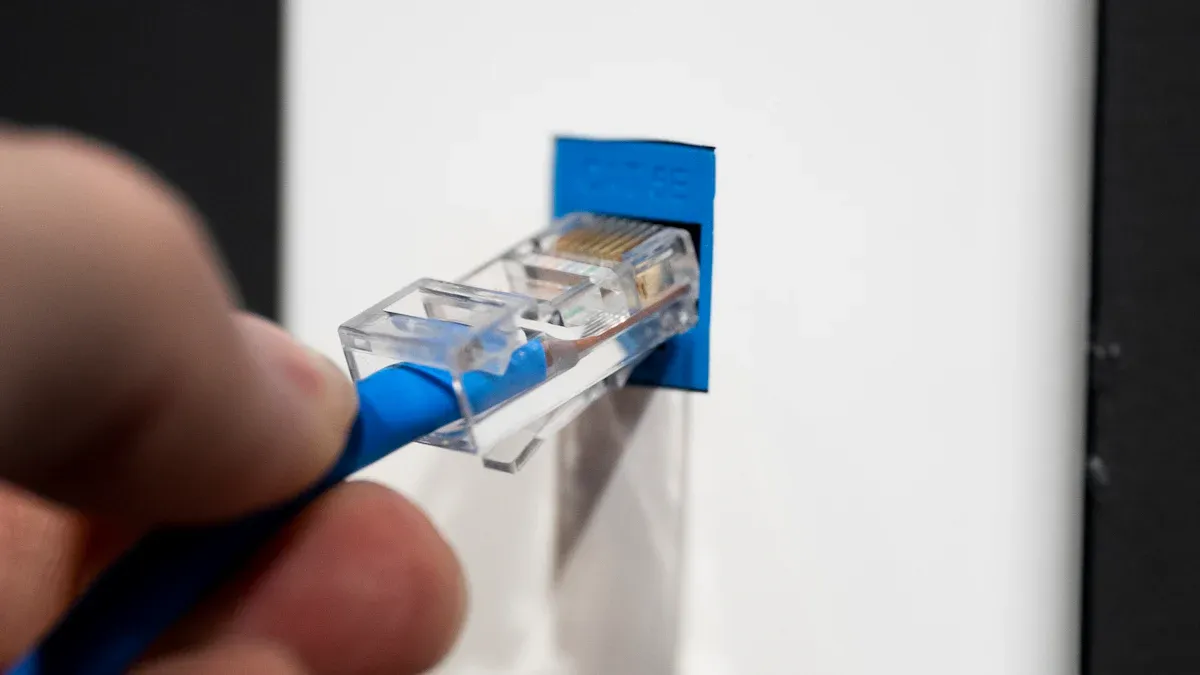

Basic Definition of a Female RJ45 Connector

You encounter the rj45 female connector as a critical component in modern network infrastructure. This connector features an 8P8C modular jack design, which means it has eight positions and eight contacts. Inside the jack, you find metal spring wire contacts angled to ensure a reliable electrical connection with the male plug’s flat metal contacts. The connector includes a clip lock mechanism that secures the mating plug, preventing accidental disconnection. Its shape and size follow strict standards such as ANSI/TIA-1096-A and ISO-8877, ensuring compatibility across devices. Electrically, the rj45 female connector supports eight pins for four twisted wire pairs, enabling high-speed data transmission and power delivery through Power over Ethernet (PoE).

Role of the RJ45 Female Connector in Network Infrastructure

You rely on the rj45 female connector to serve as the receiving end for male rj45 plugs. The springy metal contacts inside the connector touch the gold-plated pins of the male plug, establishing a stable electrical connection. This design supports both data and power transmission, making the rj45 female connector essential for connecting devices such as routers, switches, and computers. The standardized dimensions allow you to integrate these connectors into wall plates, patch panels, and network equipment, ensuring seamless communication across your network.

Common Applications for RJ45 Female Connectors

Home Networking with RJ45 Connectors

In your home, you use rj45 female connectors to create reliable wired Ethernet connections. These connectors appear on devices like PCs, smart TVs, gaming consoles, and routers. By installing rj45 connectors in wall plates or panels, you enable stable and interference-free network connections throughout your living space. This setup supports high-speed internet access and smooth streaming or gaming experiences.

Office and Enterprise Network Use

In office and enterprise environments, you depend on rj45 female connectors for structured cabling systems. These connectors form the backbone of Local Area Networks (LANs), linking computers, printers, VoIP phones, and network switches. You benefit from their ability to provide consistent, high-performance connections that support large volumes of data traffic. The rj45 female connector’s standardized design ensures compatibility with a wide range of network hardware, making it a preferred choice for IT professionals.

Industrial and Outdoor Applications

You find ruggedized rj45 female connectors in industrial and outdoor settings. These connectors withstand harsh conditions, including dust, moisture, vibration, and mechanical stress. In factory automation, robotics, and process control systems, you use rj45 connectors to maintain reliable data transmission. The table below highlights the advantages of using these connectors in industrial networks:

| Advantage | Explanation |

|---|---|

| Reliable Data Transmission | Ensures stable and secure connections essential for efficient Ethernet networks, including industrial setups. |

| Ease of Installation | User-friendly and simple to install, facilitating quick deployment in industrial environments. |

| Cost-Effectiveness | Provides high performance at a lower cost compared to other connectors, beneficial for large-scale industrial use. |

| Wide Compatibility | Compatible with many devices and equipment, supporting versatile industrial network configurations. |

| Support for High-Speed Connections | Supports data transmission speeds up to 10Gbps (Cat 6A), meeting demanding industrial bandwidth needs. |

| Durability | Designed to withstand frequent plugging/unplugging and harsh conditions, ensuring longevity in industrial settings. |

| Ruggedized Features | Includes boots and strain reliefs to survive moisture, dust, vibration, chemicals, and mechanical stress common in industrial environments. |

Tip: When you select an rj45 female connector for industrial or outdoor use, always check for ruggedized features and environmental ratings to ensure long-term reliability.

Key Specifications for Selecting an RJ45 Female Connector

Cable Compatibility and RJ45 Connector Matching

Matching Connector to Ethernet Cable Type and Size

You need to match the rj45 female connector to the correct ethernet cable type and size to ensure reliable network performance. The most compatible ethernet cables for rj45 connectors include Cat5e, Cat6, Cat6a, and Cat7. You find rj45 connectors in both shielded and unshielded variants. Shielded rj45 connectors work best with shielded ethernet cables, providing protection against electromagnetic interference. Unshielded rj45 connectors pair with unshielded ethernet cables, which are suitable for environments with minimal interference.

When you select an rj45 female connector, consider the mounting method. You can choose panel mount, board mount, through-hole, or surface mount options based on your installation needs. Wiring standards such as T568A and T568B define the arrangement of the eight wires inside the connector. Consistent use of these standards ensures compatibility and signal quality across your network.

Tip: Always use shielded rj45 connectors with shielded ethernet cables in environments with high electromagnetic interference. For home or office networks, unshielded rj45 connectors and cables provide adequate performance.

- RJ45 connectors come in shielded and unshielded types.

- Cat5e, Cat6, and Cat6a ethernet cables are standard for rj45 connectivity.

- Shielded connectors require shielded cables for proper grounding and interference protection.

- T568A and T568B wiring standards apply to both male and female rj45 connectors.

- Proper mounting and termination methods improve network reliability.

Solid vs. Stranded Wire Support in RJ45 Female Connectors

You must consider whether your ethernet cable uses solid or stranded wire when selecting an rj45 female connector. Solid wire consists of a single conductor, while stranded wire contains multiple smaller strands twisted together. The choice affects both performance and durability.

| Aspect | Solid Wire | Stranded Wire |

|---|---|---|

| Conductor Structure | Single solid conductor | Multiple smaller strands twisted together |

| Electrical Performance | Lower attenuation, lower DC resistance, better for long distances and stable connections | Higher attenuation, higher DC resistance, less ideal for long distances |

| Flexibility | Less flexible, prone to damage if bent repeatedly | More flexible, durable under frequent movement or bending |

| Typical Use | Permanent installations (walls, ceilings), punch-down blocks, IDC terminations | Patch cables, short runs, frequently moved or flexed cables |

| Impact on RJ45 Connectors | Provides more stable, reliable connections over long distances | Suitable for flexible connections but may reduce signal integrity over distance |

| Cost | Generally less expensive | More expensive due to manufacturing complexity |

You use solid wire for permanent installations, such as wall plates and patch panels, where stable connections matter most. Stranded wire suits patch cables and areas where cables move frequently. The rj45 female connector must support the wire type to maintain signal integrity and reduce connection issues.

Category Ratings and RJ45 Specifications

Cat5e, Cat6, Cat6a, Cat7, and Cat8 Explained

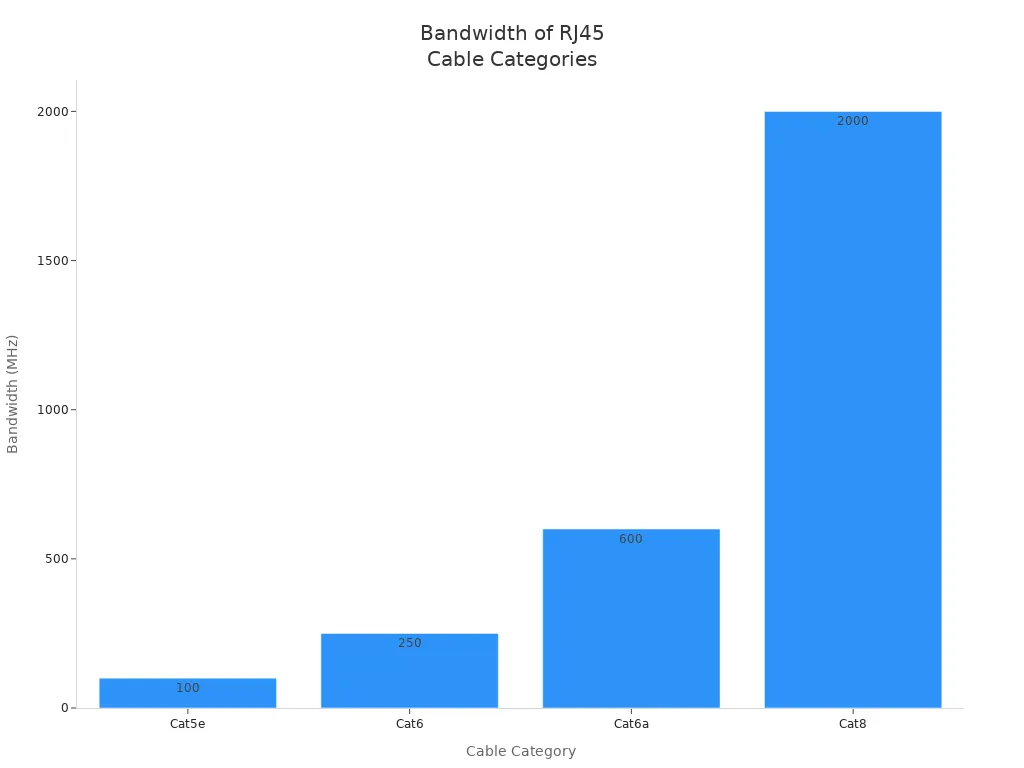

You encounter several ethernet cable categories when choosing an rj45 female connector. Each category supports different data transmission rates and bandwidths. Cat5e and Cat6 cables use standard rj45 connectors, while Cat6a and Cat8 cables require connectors rated for higher speeds and frequencies. Cat7 cables use a proprietary connector, not the standard rj45.

| Cable Category | Transmission Speed | Bandwidth | Connector Type (Female RJ45) |

|---|---|---|---|

| Cat5e | Up to 1 Gbps | 100 MHz | RJ45 |

| Cat6 | Up to 10 Gbps (up to 55m) | 250 MHz | RJ45 |

| Cat6a | Up to 10 Gbps (up to 90-100m) | 500-600 MHz | RJ45 |

| Cat7 | Up to 10 Gbps | 600 MHz | Proprietary (not RJ45) |

| Cat8 | Up to 40 Gbps | 2000 MHz | RJ45 |

You select the rj45 female connector based on the cable category to achieve the desired network performance. Cat6 rj45 connectors support higher speeds and bandwidth than Cat5e. Cat6a connectors double the bandwidth of Cat6 and maintain 10 Gbps over longer distances. Cat8 rj45 connectors deliver the highest data transmission rates for high-speed data applications.

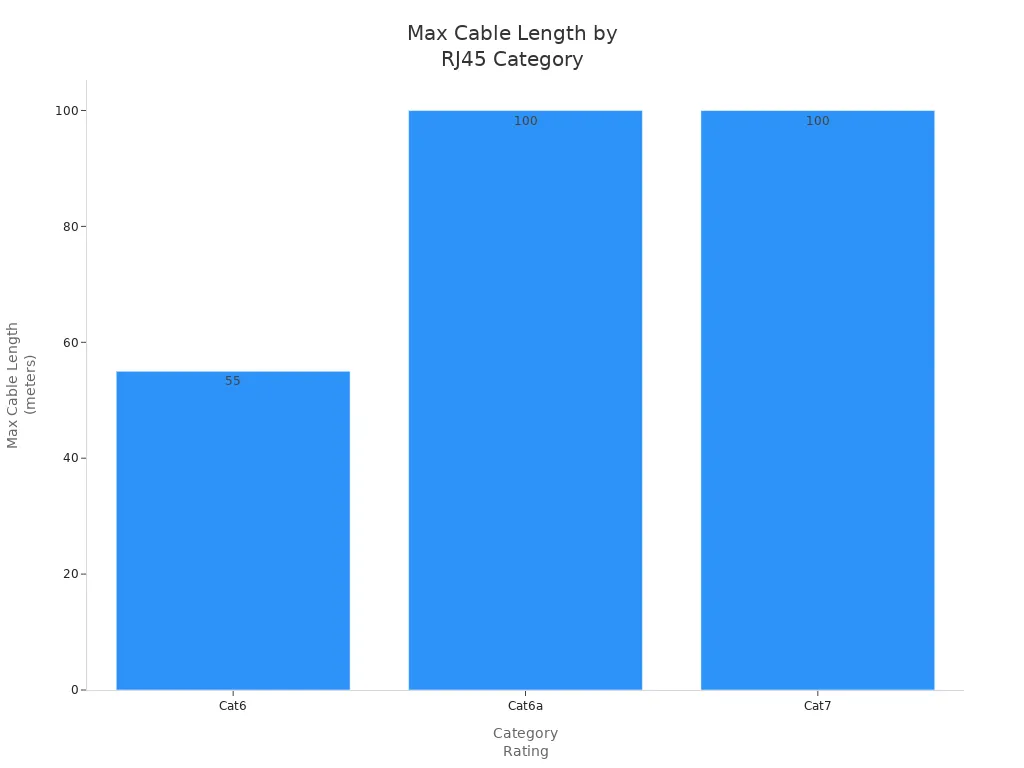

Performance Differences by Category

Category ratings directly affect maximum cable length and data integrity. You must match the rj45 female connector to the cable category to avoid bottlenecks and signal loss.

| Category Rating | Maximum Data Speed | Maximum Cable Length | Frequency Support | Connector/Coupler Requirements | Impact on Data Integrity and Performance |

|---|---|---|---|---|---|

| Cat6 | Up to 10 Gbps | Up to 55 meters | N/A | Use Cat6 rated connectors/couplers | Using lower-rated connectors causes bottlenecks, latency, and signal loss |

| Cat6a | 10 Gbps | Up to 100 meters | 500 MHz | Use Cat6a rated connectors/couplers | Maintains full potential; mismatched connectors degrade performance |

| Cat7 | 10 Gbps | Up to 100 meters | 600 MHz | Use Cat7 rated connectors/couplers | Same as Cat6a; ensures high-frequency signal handling |

| Shielded Cables | N/A | N/A | N/A | Use shielded RJ45 connectors with proper grounding | Preserves shielding effectiveness, prevents EMI, maintains data integrity |

You maintain optimal network performance by using rj45 connectors that match the cable category. Shielded cables require shielded rj45 connectors to prevent electromagnetic interference and preserve data integrity.

Shielding Options for RJ45 Female Connectors

Unshielded vs. Shielded RJ45 Connectors

You choose between shielded and unshielded rj45 connectors based on your installation environment. Shielded rj45 connectors feature a conductive metal casing that protects against electromagnetic interference (EMI) and radio frequency interference (RFI). Unshielded rj45 connectors use plastic housings and do not provide EMI/RFI protection.

| Feature/Aspect | Shielded RJ45 Connectors | Unshielded RJ45 Connectors |

|---|---|---|

| EMI Protection | Conductive metal casing shields against EMI and RFI, critical in high interference environments | No shielding; suitable for low EMI environments like homes or offices |

| Signal Integrity | Improves signal-to-noise ratio, reduces packet loss and transmission errors by up to 90%, prevents crosstalk | Lacks EMI protection, more prone to signal degradation and errors in noisy environments |

| Suitable Environments | Industrial, manufacturing, data centers, areas with heavy machinery or electrical noise | Residential and office environments with minimal electromagnetic interference |

| Network Performance | Essential for high-speed networks (gigabit and 10-gigabit Ethernet), maintains stable and reliable data flow | Adequate for standard networking needs without significant EMI concerns |

| Cable Compatibility | Best used with shielded cables (STP) for full EMI suppression; limited benefit when used with unshielded cables (UTP) | Typically used with unshielded cables (UTP); no EMI shielding |

| Installation Considerations | Requires proper grounding and installation to realize full benefits | Simpler installation, no grounding required |

| Cost | Higher cost justified by improved reliability and performance in EMI-rich environments | More cost-effective for low-interference settings |

You use shielded rj45 connectors in industrial, manufacturing, and data center environments where EMI is a concern. Unshielded rj45 connectors suit home and office networks with minimal interference.

| Configuration | EMI Suppression Effectiveness | Notes |

|---|---|---|

| Shielded Connector + Shielded Cable (STP) | High EMI suppression due to combined shielding of connector and cable | Recommended for environments with high electromagnetic interference |

| Shielded Connector + Unshielded Cable (UTP) | Limited EMI suppression; connector provides some protection but cable lacks shielding | May improve signal quality slightly but does not fully prevent interference; not ideal for high EMI areas |

| Unshielded Connector + Unshielded Cable (UTP) | No EMI protection | Suitable only for low interference environments |

EMI and RFI Protection Specifications

Shielded rj45 connectors include metal shielding, often nickel-plated, to reduce EMI and RFI. You must pair shielded connectors with shielded ethernet cables to achieve effective protection. Unshielded rj45 connectors lack this shielding and do not protect against interference. Standards such as ANSI/TIA 1096-A and IEEE Ethernet/PoE define the physical and mechanical characteristics of rj45 connectors.

Note: Proper shielding improves network performance by enhancing data transfer stability and reliability in environments with high EMI or RFI.

- Shielded rj45 connectors require correct grounding during installation.

- Unshielded rj45 connectors offer simpler installation but less protection.

- Shielded connectors must be used with shielded ethernet cables for full EMI/RFI suppression.

- Using mismatched connectors and cables can negatively impact data transfer and network reliability.

Environmental Ratings for RJ45 Female Connectors

IP67 and IP68 Waterproof Ratings

You encounter environmental ratings such as IP67 and IP68 when selecting an rj45 female connector for outdoor or industrial applications. These ratings, defined by IEC 60529, measure the connector’s ability to resist dust and water. An rj45 connector with an IP67 rating provides complete protection against dust ingress and can withstand immersion in water up to 1 meter for 30 minutes. This makes the rj45 female connector suitable for harsh environments, including outdoor lighting, transportation, and industrial automation. You benefit from secure locking mechanisms, flame-retardant and UV-resistant materials, and rugged construction that prevents corrosion and signal loss.

IP68-rated rj45 female connectors offer even greater water resistance. You can rely on these connectors for deeper and longer immersion, as specified by the manufacturer. The protection applies only when the rj45 connector is fully mated. If you disconnect the connector, you lose the environmental seal unless you use special accessories. You find these rugged rj45 female connectors in outdoor security cameras, WiFi access points, and factory equipment. The combination of the standard rj45 interface and protective housing ensures reliable performance in wet and dusty environments.

Tip: Always verify the IP rating of your rj45 female connector before installation in outdoor or high-vibration locations. This ensures long-term reliability and reduces maintenance needs.

Temperature and Humidity Tolerance Specifications

You must consider temperature and humidity tolerance when choosing an rj45 female connector for outdoor installations. Manufacturers design these connectors with waterproof ratings like IP67 and IP68 to protect against dust and water, directly addressing humidity and moisture exposure. Durable housing materials such as ABS, nylon, polycarbonate, and fire-retardant plastics resist impact, UV exposure, and temperature fluctuations. Gold-plated contact pins prevent corrosion caused by moisture and maintain stable electrical conductivity, which is critical for reliable signal transmission.

- Silicon rubber grommets and secure locking mechanisms maintain environmental seals, preventing water and dust ingress even during temperature changes.

- Ruggedized rj45 connector designs with shielding layers protect against electromagnetic interference and physical stresses.

- The combination of these materials and design features ensures long-term reliability and durability of the rj45 female connector in outdoor installations.

You should select an rj45 connector with these features to manage environmental stresses and maintain consistent network performance.

PoE Support in Female RJ45 Connectors

Power over Ethernet Compatibility and Safety

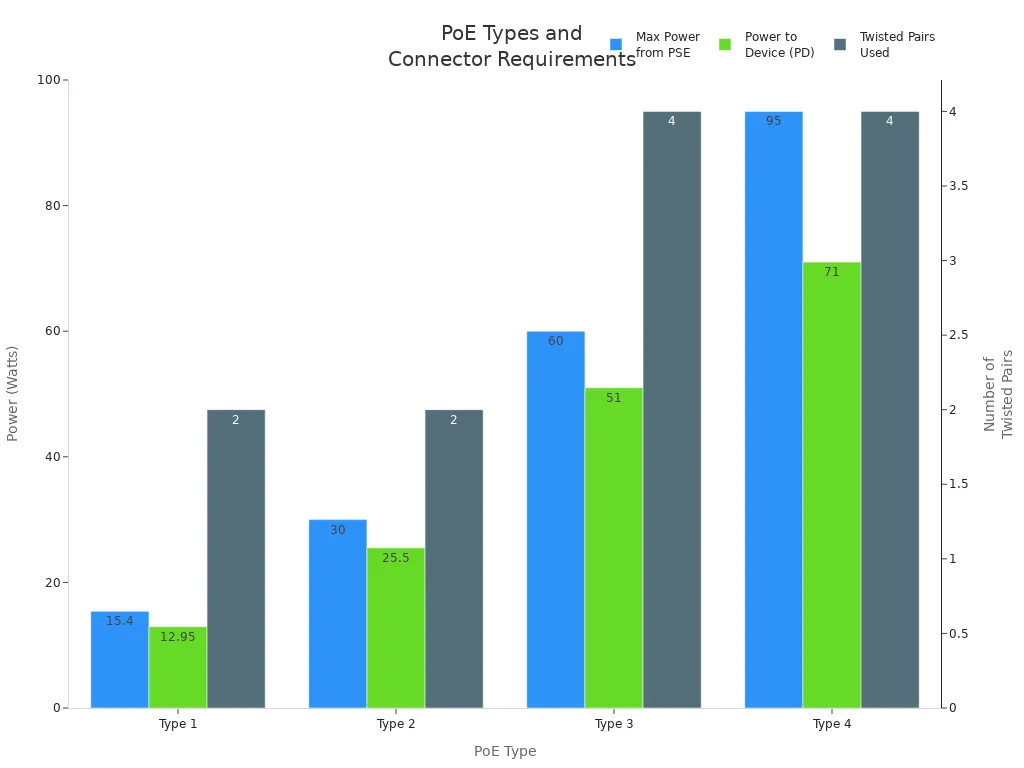

You rely on Power over Ethernet (PoE) technology to transmit both data and electrical power through a single ethernet cable. The rj45 female connector must safely handle DC power alongside data signals. You need connectors that provide electrical isolation, maintain signal integrity, and reduce electromagnetic interference. RJ45 connectors with integrated magnetics help reduce EMI and improve signal quality when power is transmitted.

The primary safety standard for PoE support in rj45 female connectors is IEC 60512-99-001. This standard ensures that the rj45 connector can handle increased power loads without damage, corrosion, or performance degradation. Manufacturers test connectors under real-life PoE Plus loads and aging processes, including exposure to corrosive gases. Gold plating on contacts maintains integrity under load and prevents contact damage caused by electrical arcing during disconnection. Third-party laboratories certify connectors compliant with IEC 60512-99-001, ensuring reliability and safety.

You must also consider the PoE standard supported by your rj45 female connector. The main PoE standards and their characteristics are:

| PoE Type | Standard | Max Power from PSE | Power to Device (PD) | Twisted Pairs Used |

|---|---|---|---|---|

| Type 1 | IEEE 802.3af | 15.4 W | 12.95 W | 2 |

| Type 2 | IEEE 802.3at | 30 W | 25.5 W | 2 |

| Type 3 | IEEE 802.3bt | 60 W | 51 W | 4 |

| Type 4 | IEEE 802.3bt | 90-100 W | 71 W | 4 |

You find rj45 female connectors for Cat 6 cables with a maximum voltage rating of 150 Vac and a current rating of 1.5 A. These connectors offer contact resistance around 20 milliohms, insulation resistance of 500 megaohms, and dielectric strength of 1000 Vac. Manufacturers design rj45 connectors for durability, supporting up to 1500 connection cycles. Zinc alloy housings and gold-plated contacts ensure reliable electrical performance under PoE loads. These specifications contribute to safe operation and limit electrical risks.

Note: Always select an rj45 female connector that meets the required PoE standard and safety certifications for your network devices. This prevents contact damage and reduces maintenance costs.

Housing Material and Durability

Plastic vs. Metal RJ45 Female Connector Construction

You choose between plastic and metal housings when selecting an rj45 female connector. Plastic housings, often made from ABS, polycarbonate, or nylon, provide lightweight protection and resist impact and chemical exposure. Metal housings, typically zinc alloy or stainless steel, offer enhanced durability and shielded protection against electromagnetic interference.

- Shielded metal housings reduce EMI, improving performance in electrically noisy environments.

- High-quality materials prevent physical damage and maintain stable connections over time.

- Poor-quality housings may crack or fail under heavy strain, increasing maintenance needs and risking network issues.

- Unshielded plastic housings can be fragile in industrial or outdoor settings, leading to performance degradation.

You should select a metal shielded rj45 connector for environments with high EMI or physical stress. For home or office use, unshielded plastic rj45 connectors may provide adequate performance.

Durability and Longevity Considerations

You must evaluate durability and longevity when choosing an rj45 female connector. High-quality housing materials enhance resistance to heat, impact, and chemical exposure. Frequent use can wear down contact pins, but durable housing helps mitigate physical damage. Shielded rj45 connectors maintain performance in challenging environments, while unshielded connectors may require more frequent replacement.

- Ruggedized rj45 connector designs with reinforced housings and gold-plated contacts extend service life.

- Shielded connectors reduce maintenance needs by preventing EMI-related issues.

- Unshielded connectors may be suitable for low-stress environments but can degrade quickly under harsh conditions.

Tip: Always match the housing material and shielding level of your rj45 female connector to your installation environment. This ensures long-term reliability and reduces the risk of network failures.

Types of Female RJ45 Connectors and Use Cases

Standard RJ45 Female Connectors

Typical Applications for Standard RJ45 Connectors

You often use a standard rj45 connector for everyday Ethernet terminations. This type of connector appears most frequently at the ends of patch cables or directly on network devices. You find these connectors in home networks, office setups, and data centers where the environment remains controlled and free from excessive interference or moisture.

A standard rj45 connector works best for connecting computers, printers, and switches in structured cabling systems. You benefit from their ease of installation and compatibility with most Ethernet cables, especially when you do not require extra protection from electromagnetic interference or harsh conditions. When you use an unshielded rj45 connector, you simplify installation and reduce costs, making it ideal for low-interference environments.

Note: You should avoid using a standard rj45 connector in areas exposed to high EMI, moisture, or physical stress.

| Connector Type | Main Use Case / Environment | Key Characteristics / Advantages |

|---|---|---|

| Standard RJ45 Connector | Commonly used for Ethernet terminations, especially on patch cables or device ends | Typical plug for Ethernet, less ideal for solid copper cables; used mainly at device ends or PoE runs |

Shielded RJ45 Female Connectors

When to Use Shielded RJ45 Connectors

You select shielded rj45 connectors when your network operates in environments with significant electromagnetic interference (EMI) or radio frequency interference (RFI). These connectors feature a metal shield, often nickel-plated, that protects your data signals from external noise. You must pair a shielded rj45 connector with shielded cables to maintain the effectiveness of the shielding.

Shielded rj45 connectors are essential in industrial settings, manufacturing plants, and data centers where heavy machinery or dense electronic equipment generates interference. You also use them in broadcast studios and hospitals to ensure stable, high-speed data transmission. Unlike unshielded rj45 connectors, shielded rj45 connectors prevent crosstalk and signal degradation, which helps you maintain network reliability.

- You should use shielded rj45 connectors in:

- Data centers with high-speed networking

- Industrial automation environments

- Areas with dense electrical equipment

Tip: Always match shielded rj45 connectors with shielded cables for maximum EMI protection.

| Connector Type | Main Use Case / Environment | Key Characteristics / Advantages |

|---|---|---|

| Shielded RJ45 Connector | Used with shielded cables to maintain EMI protection | Prevents electromagnetic interference, critical in noisy environments |

Waterproof RJ45 Female Connectors

Outdoor and Industrial Use Cases

You rely on waterproof rj45 connectors when your network must withstand exposure to moisture, dust, or harsh weather. These connectors feature ruggedized housings and sealing mechanisms, often rated IP67 or higher, to protect your connections from water and debris. You find waterproof rj45 connectors in outdoor surveillance systems, industrial automation, marine applications, and public networking installations.

Common scenarios include outdoor security cameras, factory equipment, and networking in parks or stadiums. You use these connectors to ensure reliable Ethernet connections even in challenging environments. Unlike standard or unshielded rj45 connectors, waterproof rj45 connectors prevent corrosion and signal loss caused by moisture.

- Key advantages of waterproof rj45 connectors:

- Sealed against water and dust ingress

- Durable under vibration and physical stress

- Suitable for cable-to-cable and panel-mount installations

| Scenario | Environmental Challenge | Reason for Waterproof Female RJ45 Connector Preference |

|---|---|---|

| Outdoor Surveillance | Exposure to moisture, dust, harsh weather | Maintains network integrity and reliable Ethernet connection in adverse weather |

| Industrial Automation and IoT | High moisture, vibration, dust | Provides rugged durability and stable data transmission in harsh factory environments |

| Marine Environments | High humidity, salt exposure, constant water presence | Ensures sealed, corrosion-resistant connections on ships, docks, offshore platforms |

| Outdoor Networking | Exposure to weather, dust, and physical stress | Delivers durable, IP-rated protection for public spaces like parks and stadiums |

Alert: Always verify the IP rating of your waterproof rj45 connector before deploying it in outdoor or industrial environments.

Toolless RJ45 Female Connectors

Quick Installation Scenarios for Toolless RJ45 Connectors

You often face tight deadlines and need to complete network installations quickly. Toolless RJ45 female connectors help you save time and reduce errors during setup. These connectors do not require crimping tools or punch-down blocks. You simply insert the wires into the connector and snap it shut. This design streamlines your workflow and minimizes the risk of miswiring.

You use toolless connectors in temporary setups, quick repairs, and environments where you need to make frequent changes. For example, you might install them in classrooms, conference rooms, or event spaces. You benefit from their compatibility with modular connectors, which allow you to swap out components without rewiring the entire system. Toolless connectors also support both solid and stranded wire, making them versatile for different cable types.

Tip: Choose toolless RJ45 connectors when you need a fast, reliable solution for modular connectors in dynamic environments.

- You avoid the need for specialized tools.

- You reduce installation time.

- You minimize wiring mistakes.

| Scenario | Benefit of Toolless RJ45 Connector |

|---|---|

| Temporary Installations | Quick setup and removal |

| Classroom Networks | Easy upgrades and repairs |

| Event Spaces | Fast deployment for modular connectors |

You also find pass-through rj45 connector options in toolless designs. These connectors let you verify wire order before termination, which further reduces errors.

Keystone Jack RJ45 Female Connectors

Modular Panel Integration with Keystone Jacks

You rely on keystone jack RJ45 female connectors for structured cabling in offices and data centers. These connectors fit into modular connectors panels, wall plates, and surface mount boxes. You snap the keystone jack into a panel, creating a clean and organized network interface. This modular approach allows you to customize your network layout and expand as needed.

Keystone jacks support various cable categories, including Cat5e, Cat6, and Cat6a. You benefit from their compatibility with modular connectors, which makes upgrades and maintenance straightforward. You can easily replace a single keystone jack without disturbing other connections. This flexibility is essential for environments where you need to adapt to changing network requirements.

Note: Use keystone jack RJ45 connectors to simplify cable management and support modular connectors in scalable network installations.

- You achieve a professional finish for wall plates and patch panels.

- You maintain easy access for troubleshooting and upgrades.

- You support high-density installations with modular connectors.

| Feature | Advantage for Modular Connectors Panels |

|---|---|

| Snap-in Design | Quick installation and removal |

| Category Compatibility | Supports Cat5e, Cat6, Cat6a |

| Modular Expansion | Easy to add or replace connectors |

You also find pass-through rj45 connector keystone jacks, which help you confirm wire alignment before securing the connection.

Panel Mount RJ45 Female Connectors

Equipment and Enclosure Use for Panel Mount Connectors

You use panel mount RJ45 female connectors to provide secure Ethernet access on equipment enclosures, control panels, and rack-mounted devices. These connectors install directly into a panel cutout, giving you a fixed network port that resists movement and vibration. You benefit from their robust construction, which protects the connection in industrial and commercial environments.

Panel mount connectors work well with modular connectors, allowing you to integrate multiple network ports into a single enclosure. You can select shielded or unshielded versions based on your EMI protection needs. You also find waterproof panel mount RJ45 connectors for outdoor or harsh environments.

Alert: Always verify the panel cutout dimensions and mounting hardware compatibility before installing modular connectors in equipment enclosures.

- You ensure a stable connection for mission-critical devices.

- You simplify maintenance by providing accessible network ports.

- You support modular connectors for flexible equipment layouts.

| Application | Benefit of Panel Mount RJ45 Connector |

|---|---|

| Control Panels | Secure, vibration-resistant connection |

| Rack-Mounted Devices | Organized, accessible network ports |

| Outdoor Enclosures | Waterproof options for harsh settings |

You often combine panel mount connectors with pass-through rj45 connector designs to simplify cable routing inside enclosures.

Best Practices for RJ45 Female Connector Installation

Preparation and Tools for RJ45 Connector Installation

Essential Tools for Installing RJ45 Female Connectors

You need the right tools to install an RJ45 female connector correctly. Using industry-standard equipment ensures a secure and reliable connection for your ethernet cable. Follow these steps for a professional installation:

- Use wire cutters to trim the ethernet cable to the desired length.

- Strip about two inches of the cable’s outer insulation with wire strippers, exposing the twisted pairs without damaging them.

- Untwist and align the individual wires according to the T568A or T568B wiring standard.

- Trim the wires to the correct length so they fit inside the RJ45 female connector.

- Insert the wires fully into the connector, making sure they reach the end but do not overlap.

- Use a crimping tool to attach the connector securely to the cable.

- Test the terminated cable with a network cable tester or multimeter to verify continuity and correct wiring.

The essential tools for this process include a wire cutter and a crimping tool. These tools help you achieve a stable and industry-standard termination for your RJ45 connector.

Workspace Setup for RJ45 Connector Termination

A well-organized workspace helps you avoid errors during RJ45 female connector installation. Gather all necessary tools, such as wire cutters, wire strippers, a crimping tool, and an ethernet tester. Measure and cut the ethernet cable to the required length. Strip about an inch of the outer insulation without damaging the internal wires. Untwist and separate the wires, then arrange them according to your chosen wiring standard. Double-check the wire order before crimping to prevent miswiring. Always confirm that the cable jacket is held by the connector for strain relief. Attach wall plates securely at outlet points, and test the cable with an ethernet tester to ensure proper network performance.

Tip: Select RJ45 connectors rated for the environmental conditions of your installation. Features like sealing, corrosion resistance, and strain relief improve durability and reduce termination errors.

Wiring Standards for RJ45 Female Connectors

T568A vs. T568B Wiring Standards

You must choose between T568A and T568B wiring standards when terminating an RJ45 female connector. The main difference is the swapping of the orange and green wire pairs. T568A assigns the green pair to pins 1 and 2 and the orange pair to pins 3 and 6. T568B reverses this assignment. Both standards comply with ANSI/TIA-568.2-D and support the same ethernet protocols, including Gigabit Ethernet. T568A is often used for residential and government installations, while T568B is common in commercial settings. Consistency is critical—use the same standard on both ends of the ethernet cable to avoid communication issues.

| Pin Number | T568A Color | T568B Color |

|---|---|---|

| 1 | Green/White | Orange/White |

| 2 | Green | Orange |

| 3 | Orange/White | Green/White |

| 4 | Blue | Blue |

| 5 | Blue/White | Blue/White |

| 6 | Orange | Green |

| 7 | Brown/White | Brown/White |

| 8 | Brown | Brown |

Color Coding and Pinouts for RJ45 Connectors

Accurate color coding and pinout alignment are essential for RJ45 female connector performance. Following the T568A or T568B standard ensures reliable data transfer and prevents network failures. Incorrect wiring or mixing standards can cause signal loss and complicate troubleshooting. Always use a high-quality crimping tool and verify that each pin contacts the correct wire. Most network issues with RJ45 connectors result from poor crimping or incorrect wiring, so pay close attention to color coding and pinout accuracy.

Step-by-Step RJ45 Female Connector Installation Guide

Cable Stripping and Termination for RJ45 Connectors

Begin by cutting the ethernet cable to the required length. Strip about two inches of the outer insulation, taking care not to nick the internal wires. Untwist and arrange the wires according to your selected wiring standard. Trim the wires evenly, then insert them into the RJ45 female connector, ensuring each wire reaches the end. Use a crimping tool to secure the connector, pushing the metal pins into each wire for a solid electrical connection. Confirm that the cable jacket is held by the connector for strain relief.

Testing RJ45 Female Connector Connections

After termination, always test the RJ45 female connector with a network cable tester or multimeter. This step verifies correct wiring and ensures reliable data transfer. Testing helps you identify and fix wiring mistakes before deploying the ethernet cable in your network. Reliable testing reduces troubleshooting time and supports stable ethernet performance.

Common Installation Mistakes with RJ45 Female Connectors

Poor Cable Management Issues

You often overlook cable management during installation, but this mistake can undermine the reliability of your network. When you fail to secure cables properly, you expose RJ45 female connectors to unnecessary strain. Poor strain relief allows cables to move, which stresses the conductor connections at the termination point. This movement can break conductors or cause intermittent connections that disrupt your network.

Mechanical stress from inadequate strain relief concentrates force on individual conductors. Instead of distributing pressure evenly, you compromise the integrity of each connection. Inadequate crimping creates high-resistance points, which generate heat and accelerate oxidation. Over time, contact degradation becomes inevitable. Environmental factors such as temperature changes and humidity worsen these problems. Connections loosen, and oxidation increases, leading to physical damage and higher electrical resistance.

Tip: Always use cable ties, strain relief boots, and proper routing techniques to protect your RJ45 connectors from mechanical stress and environmental hazards.

Key impacts of poor cable management:

- Cable movement stresses conductor connections, causing breakage or intermittent signals.

- Mechanical stress compromises connection integrity.

- High-resistance connections generate heat, accelerating contact degradation.

- Environmental changes loosen connections and promote oxidation.

- Reduced reliability and lifespan of RJ45 female connectors.

Incorrect Pinouts in RJ45 Connectors

You must pay close attention to wiring standards when terminating RJ45 female connectors. Incorrect pinouts remain one of the most frequent mistakes. If you mix up the wire order or use different standards (T568A vs. T568B) on each end, you risk creating a non-functional or unreliable network link. Devices may fail to communicate, or you may experience intermittent connectivity issues that are difficult to diagnose.

Always verify the color coding and pinout before crimping. Use a cable tester to confirm that each wire matches the correct pin. Consistency in wiring standards ensures stable data transmission and simplifies future troubleshooting.

Note: Double-check your wiring against the chosen standard before finalizing any termination.

Over-tightening or Damaging RJ45 Female Connectors

You may think that tightening connectors ensures a secure fit, but over-tightening can damage the RJ45 female connector housing or internal contacts. Excessive force cracks plastic housings or bends metal shields, reducing the connector’s ability to maintain a stable connection. Damaged contacts lead to poor electrical performance and increase the risk of signal loss.

You should also avoid pulling or twisting cables during installation. These actions can dislodge wires or deform the connector, resulting in unreliable connections. Gentle handling and proper mounting techniques preserve the integrity of your RJ45 connectors.

Alert: Apply only moderate force when securing connectors. Inspect each connector for physical damage before and after installation.

By avoiding these common mistakes, you protect your network from unnecessary downtime and extend the lifespan of your RJ45 female connectors.

Maintenance and Troubleshooting for RJ45 Female Connectors

Routine Inspection of RJ45 Female Connectors

Visual Checks for RJ45 Connectors

You should inspect your rj45 connectors regularly to maintain a reliable network. In high-traffic environments, perform visual checks every six months. Look for bent pins, broken clips, or loose wires. These issues can cause poor connections or even complete network failure. Schedule routine inspections at least once a year, especially if your network is large or complex. Trained technicians should examine cables and connectors for wear, damage, or improper installation. If you find any damaged rj45 connectors, replace them right away to prevent disruptions.

Connection Testing Procedures

Testing your rj45 connectors helps you catch problems before they affect your network. Use a cable tester to check for continuity, correct wiring, and signal integrity. Network analyzers can help you assess data transmission quality. Always ensure connectors are fully seated and listen for the latch click. This step prevents loose connections that can cause intermittent issues. Maintain proper cable management and labeling to make future troubleshooting easier.

Cleaning and Care for RJ45 Female Connectors

Dust and Debris Removal from RJ45 Connectors

Dust and debris can build up inside rj45 connectors, leading to poor connections. Use isopropyl alcohol as a mild solvent to clean the contacts. Dip a soft-bristled brush or cotton swab in alcohol and gently scrub the connector. For small crevices, a cotton swab works best. After cleaning, dry the connector with a lint-free cloth. You can also use compressed air to blow out loose dust, but always hold the can upright to avoid moisture. Avoid abrasive materials and harsh chemicals, as these can damage the rj45 connector.

Corrosion Prevention in RJ45 Female Connectors

Corrosion can interrupt your network by breaking the electrical path inside the rj45 connector. To prevent this, store devices in dry environments and perform regular cleaning. For heavy corrosion, use specialized cleaners like DeoxIT, which leave a protective coating. Applying a silicone-based lubricant can also help protect contacts. Always dry connectors thoroughly after cleaning to prevent moisture-related corrosion.

Troubleshooting Common RJ45 Female Connector Issues

Intermittent Connections in RJ45 Connectors

Intermittent connections can disrupt your network and are often tricky to diagnose. Start by ensuring the rj45 connector is fully seated in the port. Listen for the latch click. Check both ends of the cable to confirm they follow the same wiring standard, such as T568A or T568B. Inspect the cable for kinks, cuts, or crushed areas. Use a cable tester to check for continuity, open wires, or miswires. If you suspect a bad crimp, cut off the connector, re-strip the cable, and crimp again with even pressure. Clean oxidized or dirty contacts with isopropyl alcohol. Handle connectors gently to avoid bending pins or breaking latches.

Signal Loss or Degradation in RJ45 Female Connectors

Signal loss or degradation can slow down your network or cause dropped connections. Keep ethernet cables away from power lines and fluorescent lights to avoid electromagnetic interference. Use a network cable tester to confirm proper termination and signal quality. If you find damaged cables or connectors, replace them immediately. Proper cable management and regular maintenance help you prevent these issues and keep your rj45 connectors performing at their best.

Top Female RJ45 Connector Products and Recommendations

Recommended Standard RJ45 Female Connectors

Features and Benefits of Leading Standard RJ45 Connectors

When you look for a reliable standard RJ45 female connector, you want a product that delivers consistent performance and easy installation. Many leading manufacturers design connectors with gold-plated contacts, which help maintain strong signal integrity and reduce corrosion over time. For example, WAGO’s front-panel-mount RJ45 connector offers a compact 22.5mm size, a PA/PBT housing, and supports up to 10Gb/s data rates. You benefit from its UL94 V-0 flame rating and a long lifespan of over 750 mating cycles. These features make it suitable for automation and control systems where reliability matters.

You also find the GREENCONN series, which provides compact, shielded metal housings and supports both tab-up and tab-down orientations. These connectors meet IEEE802.3 standards and work well in telecom and test equipment. When you choose a standard RJ45 connector with these features, you ensure your network runs smoothly in office, home, or light industrial environments.

Tip: Select connectors with gold-plated contacts and high mating cycle ratings for the best long-term value.

Best Shielded RJ45 Female Connectors

Features and Benefits of Top Shielded RJ45 Connectors

Shielded RJ45 female connectors give you extra protection against electromagnetic interference. You should consider products like the METZ CONNECT AJT34L, which features a fully shielded, side-entry design and high-temperature nylon housing. This connector includes LED indicators for quick diagnostics and can withstand soldering temperatures up to 260°C. It fits well in telecom, data centers, and building automation projects.

The Lumberg Group’s Series 25 P-136 stands out with its nickel-plated housing and piercing IDC contacts. You get a connector that supports 1.5A at 125V and endures up to 1,000 mating cycles. For industrial Ethernet and robotics, HARTING’s RJ Industrial MultiFeature connector offers a robust metal housing, tool-free IDC termination, and 360° shielding. These shielded connectors help you maintain high-speed data transmission and reduce signal loss in demanding environments.

| Manufacturer | Product/Series | Key Features & Distinguishing Attributes | Application Areas |

|---|---|---|---|

| METZ CONNECT | AJT34L RJ45 connectors | Shielded, side-entry, 8P8C jacks, high-temp nylon housing, LED indicators, RoHS compliant, withstands 260°C soldering | Telecom, data centers, building automation |

| Lumberg Group | Series 25 P-136 RJ45 connectors | Fully shielded, nickel-plated housing, gold-plated contacts, 1.5A/125V, 1000 mating cycles, piercing IDC contacts | Datacom, infotainment, industrial |

| HARTING | RJ Industrial MultiFeature (MF) | Robust metal housing, tool-free IDC termination, 360° shielding, supports CAT5 to CAT6a, 750 mating cycles | Industrial Ethernet, automation, robotics |

Note: Always match shielded connectors with shielded cables to maximize EMI protection and network stability.

Leading Waterproof RJ45 Female Connectors

Features and Benefits of Waterproof RJ45 Connectors

You need waterproof RJ45 connectors for outdoor, marine, or harsh industrial settings. The Amphenol Pcd RJF TV6A CAT6a 10Gb/s connector offers IP68 sealing, which keeps out dust and water. Its patented RJStop system protects against shock and vibration, and you can assemble it tool-free in under 30 seconds. This connector supports 10Gb/s speeds and operates in extreme temperatures from -40°C to +85°C, making it ideal for military, marine, and railway applications.

Neutrik’s etherCON TOP Series provides IP65 environmental sealing, a lockable zinc shell, and a UV-resistant boot. You benefit from its UL 50E certification and over 1,000 mating cycles, which ensures long-term durability for outdoor entertainment and signage. CONEC’s RJ45-IP67 Industrial Ethernet connector features bayonet coupling and gold-plated contacts, giving you a rugged solution for CNC and transportation systems.

Alert: Always check the IP rating and temperature range before choosing a waterproof RJ45 connector for your application.

When you select the best rj45 connector for your environment, you protect your network from moisture, dust, and physical stress. This choice ensures reliable performance in even the toughest conditions.

Popular Toolless RJ45 Female Connectors

Features and Benefits of Toolless RJ45 Connectors

You often face tight deadlines and need to complete network installations quickly. Toolless RJ45 female connectors help you streamline your workflow. These connectors eliminate the need for crimping tools or punch-down blocks. You simply insert the wires into the connector and snap it shut. This design reduces installation time and minimizes wiring errors.

Toolless connectors support both solid and stranded wire. You gain flexibility when working with different cable types. You also benefit from clear wire guides and color-coded slots. These features make it easy to align wires according to T568A or T568B standards. You avoid miswiring and ensure reliable data transmission.

Manufacturers design toolless RJ45 connectors for modular panels, wall plates, and surface mount boxes. You can use them in classrooms, conference rooms, and event spaces. You find them especially useful in temporary setups or environments where you need to make frequent changes.

Tip: Choose toolless RJ45 connectors when you want to reduce installation time and avoid specialized tools.

Key features of toolless RJ45 female connectors:

- Snap-in termination for quick setup

- Support for both solid and stranded wire

- Clear wire guides for easy alignment

- Compatibility with modular panels and wall plates

- No need for crimping or punch-down tools

| Feature | Benefit |

|---|---|

| Toolless Design | Fast installation, no special tools |

| Wire Compatibility | Works with solid and stranded cables |

| Color-Coded Guides | Reduces wiring mistakes |

| Modular Integration | Fits panels, wall plates, surface boxes |

You improve efficiency and reduce errors by selecting toolless RJ45 connectors for dynamic environments.

Best Keystone Jack RJ45 Female Connectors

Features and Benefits of Keystone Jack RJ45 Connectors

You rely on keystone jack RJ45 female connectors for structured cabling in offices and data centers. These connectors fit into modular panels, wall plates, and surface mount boxes. You snap the keystone jack into a panel, creating a clean and organized network interface.

Keystone jacks support various cable categories, including Cat5e, Cat6, and Cat6a. You benefit from their compatibility with modular connectors, which makes upgrades and maintenance straightforward. You can easily replace a single keystone jack without disturbing other connections. This flexibility is essential for environments where you need to adapt to changing network requirements.

Note: Use keystone jack RJ45 connectors to simplify cable management and support modular connectors in scalable network installations.

- You achieve a professional finish for wall plates and patch panels.

- You maintain easy access for troubleshooting and upgrades.

- You support high-density installations with modular connectors.

| Feature | Advantage for Modular Connectors Panels |

|---|---|

| Snap-in Design | Quick installation and removal |

| Category Compatibility | Supports Cat5e, Cat6, Cat6a |

| Modular Expansion | Easy to add or replace connectors |

You also find pass-through RJ45 connector keystone jacks, which help you confirm wire alignment before securing the connection. Selecting keystone jack RJ45 connectors helps you maintain a scalable, organized, and reliable network infrastructure.

Actionable Recommendations for Selecting RJ45 Female Connectors

Quick Selection Checklist for RJ45 Female Connectors

Must-Have Features in an RJ45 Female Connector

You want to make the right choice when selecting an RJ45 female connector for your network. A quick checklist helps you focus on the most important features. Use this list to guide your decision:

- Category Compatibility: Choose a connector that matches your cable category, such as Cat5e, Cat6, or Cat6a. This ensures you achieve the required data speeds and bandwidth.

- Shielding: Select shielded connectors for environments with high electromagnetic interference. Use unshielded connectors in low-interference areas.

- PoE Support: Confirm that the connector supports Power over Ethernet if you plan to power devices like cameras or access points through the cable.

- Environmental Rating: Look for IP67 or IP68 ratings for outdoor or industrial installations. These ratings protect against dust and water.

- Housing Material: Pick metal housings for durability and EMI protection. Use plastic housings for standard office or home use.

- Wire Compatibility: Make sure the connector supports both solid and stranded wire if your installation requires flexibility.

- Ease of Installation: Toolless or keystone jack designs simplify installation and reduce errors.

- Gold-Plated Contacts: Gold plating resists corrosion and maintains signal quality over time.

- Testing and Certification: Choose connectors that meet industry standards, such as ANSI/TIA-1096-A or IEC 60512-99-001.

Tip: Always test your terminated cables with a network tester before deploying them in your network setups.

Future-Proofing Your Network with RJ45 Female Connectors

Planning for Upgrades and Long-Term Network Needs

You should think ahead when building or upgrading your network. Future-proofing saves you time and money as technology evolves. Start by selecting connectors that support higher cable categories, such as Cat6a or Cat8, even if your current equipment uses lower speeds. This approach prepares your network for faster devices and greater bandwidth demands.

Consider shielded connectors and cables if you expect more electronic devices or machinery in the future. Shielding protects your network from interference as your environment changes. Choose modular connector types, like keystone jacks, to make future upgrades and repairs easier. Modular systems let you swap out connectors without rewiring the entire network.

Plan for Power over Ethernet expansion. Select connectors rated for the latest PoE standards, so you can add smart devices or security cameras without replacing your cabling. Always check for certifications and compliance with current industry standards. This ensures your network remains reliable as new technologies emerge.

Note: Investing in high-quality, future-ready connectors now helps you avoid costly replacements and downtime later.

You improve network reliability when you match RJ45 female connector specifications to your cable type and environment. Careful installation and routine maintenance help you prevent downtime and signal loss.

- Use the checklist to guide your selection process.

- Apply best practices to avoid common mistakes.

Remember: Thoughtful planning and regular inspections ensure your network stays robust and ready for future upgrades.

FAQ

What is the difference between a shielded and unshielded RJ45 female connector?

Shielded connectors protect your network from electromagnetic interference. You use them in environments with heavy electrical noise. Unshielded connectors work best in offices or homes with minimal interference. Always match the connector type to your cable and installation environment.

Can you use a Cat6 RJ45 female connector with a Cat5e cable?

Yes, you can use a Cat6 connector with a Cat5e cable. The connection works, but you only achieve Cat5e performance. For best results, match the connector category to your cable type.

How do you know if an RJ45 female connector supports PoE?

Check the product specifications or datasheet. Look for IEEE 802.3af, 802.3at, or 802.3bt compliance. These standards indicate PoE support. You should also verify the connector’s voltage and current ratings.

What tools do you need to install an RJ45 female connector?

You need a wire cutter, wire stripper, and crimping tool. For keystone jacks or toolless connectors, you may only need a punch-down tool or no tools at all. Always use a cable tester to verify your work.

How often should you inspect or clean RJ45 female connectors?

Inspect connectors every six months in high-use areas. Clean them when you notice dust or connection issues. Use isopropyl alcohol and a soft brush for cleaning. Regular maintenance helps prevent signal loss.

Can you reuse an RJ45 female connector after removal?

Most RJ45 female connectors are not designed for reuse. Removing them can damage the contacts. For reliable connections, always use a new connector when re-terminating a cable.

What does an IP67 rating mean for an RJ45 female connector?

An IP67 rating means the connector resists dust and can withstand immersion in water up to 1 meter for 30 minutes. You use IP67 connectors for outdoor or industrial environments where moisture and dust are concerns.

Why do you need gold-plated contacts in RJ45 female connectors?

Gold-plated contacts resist corrosion and maintain strong electrical connections. You get better signal quality and longer connector life. This feature is especially important in high-humidity or industrial environments.