When choosing the right fastener, you should consider your project demands. You might pick a 4-40 screw for reliable strength in electronics or opt for metric M5 push pins if you need fast assembly. Metric screws provide consistent fit for global standards, while metric push pins work well with modular systems. Strength, ease of use, compatibility, reliability, and cost all play a role in choosing the right fastener. If your application involves an M8 connector, a metric screw ensures proper alignment. For quick changes, a metric push pin suits a Type B connector or a Connector factory setup. Always match the screw or metric fastener to your needs.

Quick Comparison Table for Choosing the Right Fastener

Side-by-Side Summary of 4-40 Screws vs. M5 Push Pins

When you compare 4-40 screws and M5 push pins, you see clear differences in how each fastener fits your project. You need to look at the metric sizing, standard compatibility, and the way each screw or pin works in real-world applications. The table below gives you a quick overview to help you decide which fastener matches your needs.

| Feature | 4-40 Screws (Standard) | M5 Push Pins (Metric) |

|---|---|---|

| Sizing System | Imperial (standard) | Metric (standard) |

| Thread Type | Fine thread (standard) | No thread (metric push fit) |

| Installation | Requires screwdriver | Tool-free, push-in |

| Strength | High (standard applications) | Moderate (metric assemblies) |

| Reusability | Excellent (standard screw) | Good (metric push pin) |

| Speed of Assembly | Slower (standard screw) | Faster (metric push pin) |

| Compatibility | Electronics, enclosures | Modular, metric panels |

| Cost | Low (standard screw) | Low to moderate (metric pin) |

4-40 Screws Overview

You use 4-40 screws when you need a reliable fastener for electronics or small mechanical assemblies. These screws follow the imperial standard, so you see them in many American products. The fine thread on each screw gives you strong holding power. You need a screwdriver to install or remove these screws, which means you get a secure fit. You find 4-40 screws in circuit boards, enclosures, and other standard applications. You can reuse these screws many times without losing strength. You see the standard sizing makes it easy to match replacement screws.

Tip: If you work with American-made electronics, you often need 4-40 screws for standard compatibility.

M5 Push Pins Overview

You choose M5 push pins when you want fast assembly and metric compatibility. These metric fasteners do not use threads. You push each pin into place by hand, so you save time during installation. You see M5 push pins in modular metric panels, rapid prototyping, and connector setups. The metric sizing fits global standards, making these pins ideal for international projects. You can reuse metric push pins, but you may see some wear after many cycles. You do not need tools, so you speed up your workflow.

Note: M5 push pins work best in metric modular systems where you need quick changes and standard fit.

Key Differences at a Glance

- You get higher strength and secure fit with 4-40 screws, especially in standard electronics.

- You achieve faster assembly and metric compatibility with M5 push pins, ideal for modular setups.

- You need tools for screws, but you install push pins by hand.

- You see standard sizing in 4-40 screws for American products, while metric sizing in M5 push pins fits global standards.

- You reuse both fasteners, but screws offer better durability over time.

You should match the fastener to your project’s metric or standard requirements. You need to consider whether you want the strength of a screw or the speed of a metric push pin.

Application Fit—Choosing the Right Fastener for Your Project

Electronics Projects

Circuit Boards

When you work with circuit boards, you need to select the right screw for both safety and performance. Most experts recommend using machine screws with fine threads. These screws provide a secure hold without damaging delicate PCB materials. You often see 4-40 screws in American electronics, while metric screws like M2.5 or M3 are common in global designs. You should match the screw size to the board’s mounting holes and consider the space around components. Corrosion resistance and electrical insulation matter, so stainless steel or coated screws work best. You may also use standoffs with screws to prevent short circuits and maintain proper spacing.

Tip: Always check for proper torque when tightening a screw on a PCB. Over-tightening can crack the board or strip the hole.

Enclosures

For electronics enclosures, you want a fastener that balances strength and ease of access. You often use 4-40 screws for American-standard cases and metric screws like M3 or M4 for metric enclosures. If you need frequent access, metric M5 push pins offer tool-free convenience. These metric fasteners allow you to open and close enclosures quickly during testing or maintenance. You should also consider environmental factors. If your enclosure faces humidity or vibration, choose screws with corrosion resistance and secure threads. For EMI/RFI shielding, select a screw with conductive coatings.

Mechanical Assemblies

Structural Components

In mechanical assemblies, you need a screw that can handle load and stress. Bolts and high-strength screws are preferred for structural parts. You often see metric bolts like M6 or M8 in global machinery. These metric screws provide strong tensile and shear strength. For lighter structures, you can use metric M5 screws or even M5 push pins if the load is low. Always select a screw material that resists corrosion, such as stainless steel, especially for outdoor or industrial use.

- Bolts and metric screws handle high loads.

- Stainless steel screws resist weather and chemicals.

- Fine-thread metric screws offer better vibration resistance.

Moving Parts

When you assemble moving parts, you need a screw that stays secure under vibration. Metric screws with fine threads lock tightly and resist loosening. You may use locking washers or thread-locking compounds with your screw for extra security. For quick changes, metric M5 push pins work in low-load, non-critical moving assemblies. However, you should avoid push pins where high strength is needed.

Rapid Prototyping

Temporary Fixtures

During prototyping, you want a fastener that allows fast assembly and removal. Metric M5 push pins excel here. You can insert and remove these metric pins by hand, which speeds up your workflow. If you need a more secure hold, use metric screws like M3 or M4. These screws provide better strength for repeated cycles.

Iterative Design

In iterative design, you often change parts and layouts. Metric screws give you flexibility and durability. You can reuse a metric screw many times without losing holding power. For very quick changes, metric push pins save time. You should match the screw or pin to the fixture’s strength and frequency of change.

Note: Collaboration between designers and engineers helps you choose the best metric screw or push pin for each stage of prototyping.

DIY Projects and Home Repairs

Furniture Assembly

When you assemble furniture, you often rely on screws for both strength and stability. You find that a screw provides a secure hold for wood, particleboard, and composite materials. Most flat-pack furniture kits include Phillips or hex-head screws, which you can drive easily with a manual or powered screwdriver. You should always check the length and diameter of each screw to match the pre-drilled holes. Using the wrong size can split the wood or leave joints loose.

If you need to disassemble and reassemble furniture frequently, choose screws with coarse threads. These screws grip soft materials better and resist stripping. For quick assembly, some modular furniture systems use push pins or cam locks, but a screw remains the most reliable option for long-term durability.

Tip: Tighten each screw gradually and alternate between screws to ensure even pressure and prevent warping.

Small Appliance Fixes

You encounter a variety of screws when repairing small appliances. Manufacturers often use Phillips, Torx, or even security screws to secure panels and internal components. You should use the correct screwdriver tip to avoid damaging the screw head. A stripped screw can make future repairs difficult.

For plastic housings, select screws with a wide thread and blunt tip. These screws reduce the risk of cracking the material. If you replace a lost screw, match the thread type and length to maintain the appliance’s safety and function. Push pins rarely appear in small appliances, as a screw offers better vibration resistance and a more secure fit.

Automotive and Industrial Uses

Interior Panels

You see a wide range of fasteners in automotive interiors. A screw secures trim panels, dashboards, and consoles. Manufacturers often use Phillips or hex-head screws for easy installation and removal. In non-load-bearing areas, you may find plastic push pins or clips. These fasteners allow for quick assembly and reduce weight, but a screw provides a tighter fit and better longevity.

You should consider the operating environment. Interior fasteners must withstand temperature changes, vibration, and occasional moisture. Steel screws with corrosion-resistant coatings work well in these conditions. For visible areas, choose screws with matching finishes to maintain a clean appearance.

Light-Duty Mounting

When you handle light-duty mounting in automotive or industrial settings, you select from a variety of fasteners. Common choices include screws, bolts, rivets, and pins. You use a screw for mounting brackets, securing wire harnesses, or attaching small components. The right screw must meet strength requirements and resist loosening from vibration.

You should evaluate the material and environment. Steel screws offer strength and cost-effectiveness, while stainless steel screws provide superior corrosion resistance. In some cases, plastic screws or push pins work for non-structural parts, especially where weight savings matter. Always follow industry standards to ensure safety and reliability.

- Common fastener types in these settings:

- Hex-head bolts

- Phillips and flat-head screws

- Studs and rivets

- Washers and pins

- Threaded inserts

Note: Select a screw or fastener based on mechanical strength, corrosion resistance, and compatibility with the surrounding materials. This approach ensures durability and performance in demanding environments.

Key Decision Factors When Choosing the Right Fastener

Strength of Screws and Push Pins

Load Capacity

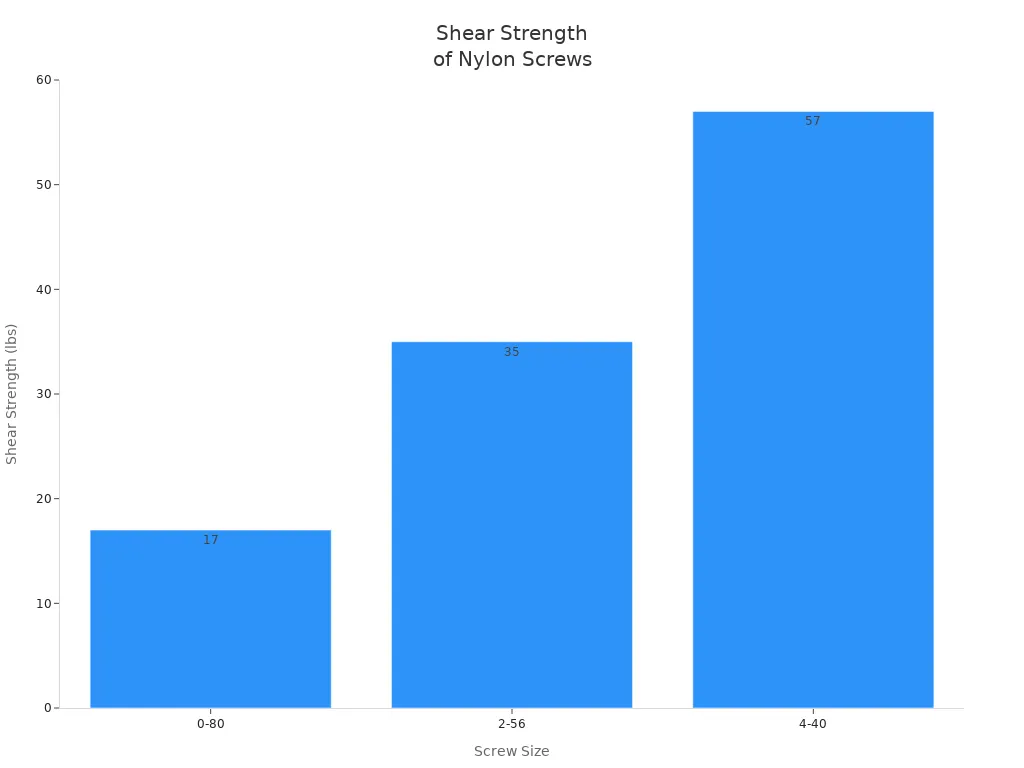

You need to evaluate load capacity when selecting between screws and push pins. The load a screw can handle depends on its material, diameter, and thread design. For example, 4-40 screws made from 6/6 nylon offer a calculated shear strength of 57 lbs, which suits many standard electronics and light mechanical assemblies. M5 push pins, while convenient, typically provide lower load capacity compared to screws with threads. If your application requires high-quality fasteners for structural integrity, you should rely on screws with proven mechanical properties.

| Screw Size | Material | Shear Strength (PSI) | Minor Diameter (inches) | Calculated Shear Strength (lbs) |

|---|---|---|---|---|

| 0-80 | 6/6 Nylon | 10,000 | 0.0465 | 17 |

| 2-56 | 6/6 Nylon | 10,000 | 0.0667 | 35 |

| 4-40 | 6/6 Nylon | 10,000 | 0.0849 | 57 |

You see that as the screw size increases, the load capacity rises. This makes larger standard screws more suitable for demanding applications. Metric push pins, while easy to use, do not match the strength of threaded screws. Always match the fastener to the expected load for optimal performance.

Vibration Resistance

Vibration can loosen fasteners over time. You should choose screws with fine threads for environments with constant movement or vibration. Standard screws, such as 4-40, provide excellent vibration resistance due to their thread engagement. Metric screws with similar thread profiles also perform well in these conditions. Push pins, especially metric types, may not hold as securely under vibration. If you need to secure moving parts or assemblies exposed to shocks, screws remain the best choice. You can also add locking washers or thread-locking compounds to further improve vibration resistance.

Installation and Removal Ease

Tool Requirements

You must consider the tools needed for installation and removal. Standard 4-40 screws require #2 Phillips bits or small nut drivers, such as a 1/4″ nut driver. These tools, especially when equipped with magnetic nut setters or precision bits, make the process smoother and reduce the risk of slippage. Metric M5 push pins often use specialized rivet nut tools or M5-M10 nut driver sets for proper installation. The right tool enhances your experience by making assembly more efficient and reliable.

| Screw/Pin Type | Relevant Tools | Tool Features Impacting User Experience |

|---|---|---|

| 4-40 screws | #2 Phillips bits, small nut drivers (e.g., 1/4″ nut driver) | Precision bits and magnetic nut setters provide secure grip and reduce slippage, facilitating easier installation/removal |

| M5 push pins | M5 wrench-drive rivet nut installation tool, M5-M10 nut driver set | Specialized rivet nut tools ensure proper installation, improving efficiency and reliability |

Tip: Always use the correct tool size for your screw or push pin. This prevents damage and ensures consistent quality during assembly.

Speed of Assembly

You want to minimize assembly time, especially in high-volume or rapid prototyping environments. Push pins, particularly metric M5 types, allow you to assemble components quickly without tools. You simply push them into place, which saves time and effort. Standard screws, on the other hand, require more steps. You must align the screw, engage the threads, and tighten with a tool. This process takes longer but provides a more secure connection. If speed is your top priority, metric push pins offer a clear advantage. For applications where quality and strength matter most, standard screws remain the preferred option.

Reusability of Fastener Types

Durability Over Multiple Uses

You should assess how well a fastener holds up after repeated use. Screws, especially those with high-quality threads, typically offer good durability. However, repeated engagement and disengagement can cause wear, especially in softer materials like nylon. For example, a user reported that after several days of repeatedly using a 4-40 screw in an Aero Precision lower, the nylon tip began to show signs of wear and loosening. This highlights the importance of considering both the screw material and the application environment.

Metric push pins can also be reused, but their holding power may decrease after many cycles. The absence of threads means less wear on the pin itself, but the fit can become loose over time. You should monitor the fit and replace worn fasteners to maintain assembly quality.

Wear and Tear

Wear and tear affect both screws and push pins, but in different ways. Screws with threads may strip or deform if over-tightened or used in soft materials. Standard screws made from durable metals resist wear better than those made from nylon or plastic. Metric push pins, while less prone to thread stripping, can lose their grip after repeated use. You should inspect fasteners regularly and replace any that show signs of damage or reduced performance.

Note: Choosing the right material and size for your screw or push pin extends the life of your assembly and ensures consistent quality.

Cost Considerations for Screws and Push Pins

Upfront Price

You always need to consider the upfront price when selecting a fastener. The cost of a screw or push pin depends on several factors. Material, size, and manufacturing process all influence the price. Standard fasteners, such as 4-40 screws, often cost less per unit because manufacturers produce them in large quantities. You can find these screws in bulk at most hardware suppliers. Metric screws and metric push pins may cost slightly more, especially if you require specialized metric screw sizes or unique finishes.

When you compare standard and metric options, you see that standard screws usually have a lower upfront price in North America. Metric fasteners may cost more due to import fees or lower local demand. However, if your project follows metric fastener standards, you might save money by avoiding metric to imperial conversion issues or mismatched parts.

Tip: Always check if your supplier offers discounts for bulk purchases. Buying standard fasteners in large quantities can reduce your overall project cost.

Long-Term Value

You should not focus only on the initial price. Long-term value matters just as much. A screw with high durability and corrosion resistance can save you money over time. You avoid frequent replacements and reduce maintenance costs. Standard screws made from stainless steel or coated alloys last longer in harsh environments. Metric push pins, while convenient, may wear out faster if you use them repeatedly in high-stress applications.

You also need to consider the cost of installation and removal. If you use a screw that requires special tools, you may spend more on equipment and labor. Metric push pins offer faster assembly, which can lower labor costs in high-volume production. However, if you need to disassemble and reassemble parts often, a standard screw provides better long-term value due to its reusability and strength.

| Fastener Type | Upfront Price | Installation Cost | Maintenance Cost | Long-Term Value |

|---|---|---|---|---|

| 4-40 Screw | Low | Moderate | Low | High |

| Metric M5 Push Pin | Moderate | Low | Moderate | Moderate |

Note: Weigh both the upfront price and the long-term value when choosing between standard and metric fasteners for your project.

Compatibility with Materials and Designs

Material Suitability

You must match the fastener material to the materials in your project. A screw made from stainless steel works well with metal, wood, and plastic. Standard screws often come in a wide range of materials, including brass, nylon, and alloy steel. Metric screws also offer many material choices, but you need to check compatibility with your specific application.

Metric push pins usually use plastic or nylon. These materials suit lightweight panels, modular assemblies, and electronics enclosures. However, if you need to fasten heavy or load-bearing parts, a standard screw provides better strength and reliability. Always check the fastener standards for your industry to ensure you select the right material.

Callout: Using the wrong material can cause corrosion, wear, or even failure. Always verify compatibility before installation.

Size and Fit

You need to ensure the fastener fits your design perfectly. Standard screws, such as 4-40, follow imperial sizing. Metric screws and push pins use metric measurements. If your project uses metric components, metric screw sizes provide a precise fit. Standard fasteners work best with imperial designs.

You may encounter challenges when mixing metric and standard parts. Metric to imperial conversion can lead to sizing errors, loose fits, or damaged threads. Always use the correct fastener for your design to maintain structural integrity and meet fastener standards.

- For electronics, match the screw size to the mounting holes.

- For mechanical assemblies, use metric screws if your design follows metric standards.

- For modular systems, metric push pins offer quick installation and removal.

Tip: Double-check your drawings and specifications to avoid costly mistakes during assembly. Proper size and fit ensure your fastener performs as intended.

Pros and Cons of Each Fastener

4-40 Screws

Advantages

You gain reliable strength when you choose a 4-40 screw for your project. This screw fits many electronics and mechanical assemblies, especially those built to standard American specifications. You see consistent performance because the screw uses fine threads, which provide a secure grip in metal and plastic. You can reuse a screw multiple times without losing holding power. The standard sizing makes it easy to find replacements or match existing hardware. You benefit from a wide range of materials, including stainless steel and nylon, which allows you to select the right screw for your environment. You also notice that a screw offers excellent vibration resistance, especially when paired with washers or thread-locking compounds. You can achieve high assembly quality by using the correct torque and installation technique.

Tip: You should always check the screw length and diameter to ensure a proper fit in your assembly.

Disadvantages

You may encounter some limitations when using a 4-40 screw. The Allen set or grub screw restricts the amount of torque you can apply, which helps prevent damage to rods but also limits your ability to tighten the screw fully. You need to be gentle during installation to avoid stripping threads, especially in thermoset plastic. Plastic components often take threads poorly, so you may see reduced holding power or thread wear over time. You might consider adding a protective piece under the screw tip to prevent damage. You also spend more time on assembly because a screw requires tools and careful alignment. If you work with metric components, you may face compatibility issues since the screw follows standard sizing.

Note: You should avoid over-tightening a screw in plastic to maintain thread quality and prevent cracking.

M5 Push Pins

Advantages

You achieve rapid assembly when you use metric M5 push pins. You do not need tools, so you save time and effort during installation. The metric sizing ensures compatibility with global modular systems and panels. You can quickly insert or remove a push pin, which makes it ideal for prototyping and temporary fixtures. You see good reusability, especially in low-load applications. You benefit from a lightweight design, which suits electronics enclosures and metric modular assemblies. You can select from various materials, including nylon and plastic, to match your project needs. You also reduce labor costs in high-volume production because the push pin streamlines the assembly process.

Callout: You should use metric push pins for projects that require frequent changes or quick access.

Disadvantages

You may notice lower strength when you use a metric push pin compared to a screw. The absence of threads means the push pin does not provide the same holding power, especially in high-load or vibration-prone environments. You may see wear after repeated use, which can reduce grip and assembly quality. You need to monitor fit and replace worn push pins to maintain reliability. You also face limitations in material compatibility, as metric push pins work best with lightweight panels and may not suit heavy-duty assemblies. If your design requires a secure, long-lasting connection, you should consider using a screw instead.

Tip: You should avoid using metric push pins in structural or high-stress applications to ensure safety and durability.

Decision Guide—Step-by-Step Checklist for Choosing the Right Fastener

Step-by-Step Checklist

Define Your Application

Start by identifying the exact purpose of your project. Ask yourself what you need the fastener to do. Are you assembling electronics, building furniture, or working on automotive panels? Each application demands a different level of strength, durability, and ease of use. Write down the environment where the fastener will operate. Will it face vibration, moisture, or frequent assembly and disassembly? Clear definition of your application sets the foundation for choosing the right fastener.

Tip: Make a quick list of your project’s main requirements before you compare fastener options.

Prioritize Your Needs

Next, decide which factors matter most for your project. Do you need maximum strength, or is speed of assembly more important? Consider the following priorities:

- Strength and Load Capacity: Essential for structural or load-bearing parts.

- Ease of Installation: Important for rapid prototyping or high-volume assembly.

- Reusability: Valuable if you plan to disassemble and reassemble parts often.

- Cost: Critical for large projects or tight budgets.

- Compatibility: Necessary for matching metric or imperial standards.

Rank these needs from most to least important. This step helps you focus on the features that will impact your project’s success.

Match Fastener Features

Now, compare the features of available fasteners to your prioritized needs. Use a table to visualize the match:

| Feature | 4-40 Screw | M5 Push Pin |

|---|---|---|

| Strength | High | Moderate |

| Installation | Tool required | Tool-free |

| Reusability | Excellent | Good |

| Speed | Slower | Faster |

| Cost | Low | Low to Moderate |

| Compatibility | Imperial | Metric |

Check which fastener aligns best with your top priorities. For example, if you value strength and reusability, a 4-40 screw may be the better choice. If you need fast, tool-free assembly, consider an M5 push pin.

Make Your Choice

After you compare features, select the fastener that best fits your application and priorities. Double-check that your choice meets all technical requirements, such as size, material, and compatibility with other components. If you feel uncertain, consult technical datasheets or industry standards for additional guidance. Remember, choosing the right fastener ensures your project performs reliably and efficiently.

Callout: A careful, step-by-step approach to choosing the right fastener saves time, reduces errors, and improves the quality of your finished work.

You often find 4-40 screws as the top choice in computer hardware, especially for:

- Fastening connectors on VGA, serial, and DVI ports

- Securing cables and adapters with hexagonal standoffs

Selecting the right fastener for your project increases efficiency and reduces costly repairs. Industry experts agree that matching fastener type to your application leads to safer, more reliable results. Use the checklist above to make confident decisions and achieve the best outcome for your work.

FAQ

What is the main difference between a 4-40 screw and an M5 push pin?

You see a 4-40 screw uses threads for secure fastening, while an M5 push pin relies on a push-fit design. The screw offers higher strength. The push pin provides faster, tool-free assembly.

Can you reuse both 4-40 screws and M5 push pins?

You can reuse both fasteners. Screws maintain their grip over many cycles. Push pins may lose holding power after repeated use, especially in soft materials.

Which fastener works best for electronics projects?

You should choose 4-40 screws for electronics. They provide reliable strength and fit standard mounting holes. M5 push pins suit modular panels but may not offer enough security for sensitive components.

Do you need special tools for installing these fasteners?

You need a screwdriver or nut driver for 4-40 screws. M5 push pins require no tools. You simply press them into place by hand.

How do you decide which fastener to use for rapid prototyping?

You should use M5 push pins for quick changes and temporary fixtures. They speed up assembly. For prototypes needing repeated adjustments and strong connections, select screws.

Are metric fasteners compatible with imperial designs?

You cannot mix metric and imperial fasteners without risking poor fit or damage. Always match the fastener type to your design’s measurement system.

What materials work best with each fastener type?

You see screws perform well in metal, wood, and plastic. Push pins suit lightweight panels and modular assemblies. Always check material compatibility before installation.

Does vibration affect the performance of push pins and screws?

You notice screws resist vibration better due to their threads. Push pins may loosen in high-vibration environments. For secure connections, choose screws in areas exposed to movement.