Connector definition describes a physical device that joins electrical circuits, enabling the transfer of signals or power between electronic components. Electrical connector types range from the familiar M8 connector to specialized Type B connector designs, each serving a unique function in modern electronics. The main function of an electrical connector is to create a secure, efficient path for electrical current or data, whether inside a smartphone or a complex industrial system. Electrical connectors, produced by every major connector factory, form the backbone of electronic systems by providing reliable, repeatable connections. Today, the electrical connector market has reached over USD 87 billion, fueled by the rapid growth of consumer electronics, telecommunications, and automotive industries. Electrical connectors support the function, safety, and flexibility of devices worldwide, making connector definition a foundational concept in electronics.

The diversity of connector types highlights their importance in every electronic device:

| Connector Category | Description | Examples |

|---|---|---|

| Audio connectors | Transfer audio signals, both analog and digital | Jack, RCA, XLR |

| USB connectors | Data and power transfer standard | USB-A, USB-B, USB-C |

| Data connectors | Transfer information between devices | HDMI, DisplayPort, Thunderbolt |

| Network connectors | Used in internet and LAN connections | RJ45, Optical connectors |

| Video connectors | Transfer image signals | VGA, DVI, HDMI, DisplayPort |

| Internal connectors | Connect internal components in devices | SATA, PCIe, M.2 |

| Power connectors | Supply electricity to devices | IEC-type, DC connectors |

Why Connectors Matter in Modern Electronics

Enabling Reliable Device Operation

An electrical connector serves as the critical link between components in every modern electronic device. The connector ensures a stable electrical connection, allowing current and data to flow seamlessly from the power source to each circuit. Devices such as smartphones, tablets, and industrial controllers rely on the electrical connector to maintain consistent voltage and signal integrity. The P1258 connector, for example, demonstrates how a compact and durable design can minimize signal interference and mechanical stress. Shielding within the connector protects against electromagnetic interference, which is essential for reliable operation in environments with fluctuating voltage or high electrical noise.

A secure electrical connection prevents common failures that disrupt device performance.

| Failure Type | Description | Causes/Contributors | Consequences/Effects |

|---|---|---|---|

| Short Circuits | Unintended electrical connection between pins | Moisture intrusion, terminal corrosion | Blown fuses, signal faults, electrical fires |

| Open Connections | Broken electrical path stopping current flow | Loose connections, terminal oxidation | No power or signal transfer |

| Increased Resistance | Higher resistance due to wear or corrosion | Terminal wear, corrosion | Signal loss, overheating, potential fires |

A high-quality electrical connector reduces the risk of these failures, ensuring the device receives the correct voltage and power from the power source.

Supporting Maintenance and Upgrades

Electrical connectors play a vital role in the maintenance and upgrade of electronic systems. Modular connector designs allow technicians to replace or upgrade parts without extensive rewiring or redesign. Early selection of the right electrical connector in the design process prevents mechanical interference and supports future upgrades. Modular connectors provide reliable, low-loss electrical connection between boards and modules, making it easier to swap out components as technology advances. Proper connector termination methods, such as crimping or soldering, improve mechanical strength and sealing, which enhances system reliability and simplifies future maintenance.

Tip: Choosing the correct electrical connector early in the design process ensures compatibility with voltage and power requirements, reducing costly redesigns later.

Enhancing Flexibility and Modularity

Modern electronics demand flexibility and modularity. The electrical connector enables designers to build systems that adapt to changing requirements. Modular connectors support easy expansion, allowing new modules to connect to the existing power source or data lines without major changes. This flexibility is crucial in industrial and consumer electronics, where rapid upgrades and repairs are common. By selecting connectors with the right voltage and current ratings, engineers ensure each connection delivers the necessary power and signal integrity. Environmental compatibility, such as resistance to temperature and humidity, further enhances the reliability of each electrical connector in demanding applications.

- Modular electrical connectors:

- Enable quick upgrades and repairs

- Support robust electrical connection in harsh environments

- Allow for easy adaptation to new power source or voltage requirements

A well-chosen electrical connector ensures every connection in the system remains secure, reliable, and ready for future advancements.

Main Types of Connectors and Their Applications

Modern electronics rely on a wide range of connector types to create secure and efficient interfaces. Each electrical connector serves a specific purpose, supporting reliable interconnections in diverse environments. The following sections explore the most common connector categories and their practical uses.

Circular Connectors

Common Applications

Circular connectors appear in many industries due to their robust design and versatility. Industrial automation, medical equipment, vehicle lighting, and consumer electronics all depend on this electrical connector type. Engineers often select M12 connectors for industrial automation and M8 connectors for sensor-actuator devices. These connectors also support machine tools, packaging systems, and automation equipment.

- Industrial automation

- Medical equipment

- Street and vehicle lighting

- Machine tools and packaging

- Consumer electronics

Circular connectors provide a reliable interface for both power and data signals. Their rugged construction withstands dust, water, temperature changes, and vibration. This makes them ideal for mission-critical applications in medical and military fields.

Key Features

Manufacturers design circular connectors with secure locking mechanisms, such as screw locks, bayonet, push-pull, and twist locks. These features prevent accidental disconnection and maintain a stable interface. Many circular connectors comply with international standards like IP68 and Mil-spec, ensuring environmental resistance. Materials such as brass, aluminum, and composite plastics, along with gold-plated contacts, enhance durability and conductivity. Circular electrical connectors often support thousands of mating cycles, providing long-term reliability.

Note: Circular connectors combine compact size with high durability, making them a preferred electrical connector for harsh environments.

Rectangular Connectors

Typical Uses

Rectangular connectors offer modular and reliable interfaces for a variety of electronic devices. The table below highlights common applications and key features:

| Application Area | Connector Series / Type | Key Features / Use Case Description |

|---|---|---|

| Commercial Aircraft Avionics | ARINC 600 | Modular, reliable connectivity for flight-critical avionics equipment |

| In-cabin Entertainment | DMC-M Single Module | Tool-less installation, EWIS compliant connectivity for in-flight entertainment systems |

| Industrial Controls | VAL-U-LOK | Terminal Position Assurance (TPA) to prevent contact backing out under vibration, shock, or pulling forces |

| Household Appliances | POWER TRIPLE LOCK | 3-in-1 latching for improved connection reliability; ergonomic design for easier assembly in dishwashers, refrigerators |

| HVAC Systems | MATE-N-LOK | Wide range of options including seals; rated for 600VAC/VDC and 19A for power and signal transmission |

| Data Center & Networking | Sliver Internal Cabled Interconnect | Robust metal housing to withstand cable pull; active latch for connection security |

| Rugged Industrial Environments | Heavy Duty, Dynamic Series, RJ45 | Designed for durability and reliability in harsh conditions including vibration, shock, dust, temperature extremes |

Rectangular electrical connectors support both signal and power interfaces in demanding environments.

Advantages

Rectangular connectors provide several benefits. Their modular design allows for quick assembly and upgrades. Secure latching mechanisms ensure a stable interface, even under vibration or shock. Many rectangular connectors feature ergonomic designs for easy installation and maintenance. Engineers often choose this electrical connector for its ability to handle high current and voltage, as well as its flexibility in complex systems.

Board-to-Board Connectors

Applications in PCBs

Board-to-board connectors create direct electrical interfaces between printed circuit boards (PCBs). This electrical connector eliminates the need for discrete cabling, simplifying layouts and enabling modular system design. Engineers use board-to-board connectors in embedded systems, computers, and mobile devices to link internal circuits efficiently.

- Enable modularity and compact multi-board architectures

- Support high-speed data transfer between stacked or parallel boards

- Reduce wire clutter and improve thermal management

Design Considerations

Designers must consider several factors when selecting a board-to-board electrical connector. Controlled impedance and precision contact geometry maintain signal integrity, especially for high-speed data interfaces. Material selection, such as high-temperature plastics and corrosion-resistant contacts, ensures durability under vibration, electromagnetic interference, and thermal cycling. Board-to-board connectors withstand environmental stresses and support thousands of mating cycles, making them essential for reliable interconnections in modern electronics.

Tip: Choosing the right electrical connector for board-to-board interfaces improves system reliability and supports future upgrades.

Wire-to-Board and Wire-to-Wire Connectors

Use Cases

Wire-to-board and wire-to-wire connectors serve as essential interfaces in modern electronics, each designed for specific application needs. Wire-to-wire connectors directly join two or more wires, creating a flexible interface that supports quick assembly and disassembly. These connectors often appear in devices that require frequent maintenance or manual operation, such as audio equipment, video systems, data communication devices, cameras, and remote controls. Their design allows users to connect cables or coils without intermediate equipment, making them ideal for environments where flexibility and ease of use are priorities.

Wire-to-board connectors, on the other hand, link cables to printed circuit boards (PCBs) through male and female connector pairs. This interface is critical in applications that demand stable and reliable connections, including military, medical, aerospace, and industrial automation equipment. Engineers rely on wire-to-board connectors to provide a high-reliability interface between cables and PCBs, ensuring consistent signal transmission and long-term operation in precision devices.

Tip: Early planning for connector selection helps avoid costly delays and ensures the right interface for each application.

Selection Criteria

Selecting the appropriate connector involves evaluating several factors to match the application’s requirements. For wire-to-wire connectors, engineers consider the need for frequent connection and disconnection, mechanical strength, and the type of contact required. These connectors must support flexible, maintenance-heavy contexts and provide a secure interface that withstands repeated use.

Wire-to-board connectors require careful attention to ruggedization, environmental resistance, and electrical performance. Designers assess the connector’s ability to maintain a stable contact under vibration, temperature changes, and exposure to moisture or dust. Custom overmolding can enhance durability and strain relief, especially in demanding environments. The choice of connection method—such as lap-solder, wrapped wire, or intermediary PCBs—depends on movement and reliability needs. Proper planning ensures the connector delivers a robust interface and maintains optimal contact throughout the device’s lifecycle.

Specialized Connectors: FPC and IDC Connectors

Examples and Uses

Specialized connectors like FPC (Flexible Printed Circuit) and IDC (Insulation Displacement Contact) connectors address the unique challenges of compact electronic devices. FPC connectors enable flexible printed circuits to bend, fold, and conform to various shapes, supporting sleek and slim device designs. Engineers use these connectors to interface displays, cameras, and touchscreens in smartphones, tablets, and laptops. IDC connectors, with their small size and versatile form factors, fit well into limited spaces. These connectors create reliable interfaces in devices such as smartphones, tablets, and laptops, where space constraints and high-density connections are common.

Unique Characteristics

FPC connectors stand out for their flexibility, lightweight construction, and compact size. They allow designers to create interfaces that adapt to complex device geometries, enabling innovative product designs. The ability to bend and fold the circuit without compromising the contact ensures reliable performance in dynamic environments.

IDC connectors offer a unique insulation displacement connection method. This technique forms gas-tight, corrosion-resistant contacts that deliver stable and reliable electrical connections. The durability of the IDC connector makes it suitable for harsh environments and critical interfaces. Engineers value IDC connectors for their ability to maintain consistent contact quality, even after repeated use or exposure to challenging conditions.

Note: Both FPC and IDC connectors play a vital role in ensuring reliable contact and efficient interfaces in the latest compact electronic devices.

Basic Structure of Connectors: Key Components and Operation

A connector in modern electronics consists of several essential components that work together to create a reliable electrical interface. Each component plays a specific role in ensuring the connector delivers consistent performance, mechanical stability, and electrical safety.

Main Components of an Electrical Connector

Contacts (Terminals)

Contacts form the core of every electrical connector. These metal elements, often called terminals, establish the physical and electrical connection between circuits. The contact body includes male pins and female sockets, which engage during the mating process. Contact springs apply mechanical force, ensuring a tight fit at the mating interface. Contact finishes, such as gold or tin plating, protect against corrosion and maintain low resistance. The contact interface, where pins and sockets meet, must remain clean and secure to guarantee reliable signal transmission.

Housing

The housing, sometimes referred to as the shell, surrounds the contacts and provides mechanical protection. This component shields the electrical contacts from dust, moisture, and physical damage. The housing also offers electrical insulation, preventing accidental shorts between adjacent contacts. Manufacturers often use robust materials like plastic or metal to enhance environmental resistance and durability.

Insulation

Insulation separates individual contacts within the connector, maintaining electrical isolation. The insulator ensures that each contact remains in its designated position, reducing the risk of short circuits. High-quality insulation materials withstand temperature changes and mechanical stress, supporting the connector’s long-term reliability.

Locking Mechanisms

Locking mechanisms secure the connector during the mating process. These systems include threaded couplings, bayonet locks, push-pull latches, and snap-in designs. A reliable locking mechanism prevents accidental disconnection and maintains a stable mating interface, even in environments with vibration or movement.

Tip: A well-designed locking mechanism increases the connector’s lifespan by reducing wear at the mating interface.

| Component | Description |

|---|---|

| Housing (Shell) | Provides mechanical protection, electrical insulation, and environmental resistance. |

| Contact Springs | Ensure electrical connection and provide mechanical force for mating. |

| Contact Finishes | Protect against corrosion and maintain low contact resistance. |

| Contact Interface | The physical electrical connection between mated parts. |

| Insulator | Maintains contact positioning and electrical isolation. |

| Contact Body | Consists of male (pin) and female (socket) contacts that physically connect circuits. |

| Locking Mechanisms | Secure the connection; types include threaded, bayonet, push-pull, and snap-in locking systems. |

How Connector Components Work Together

Each component in an electrical connector interacts to create a secure and efficient electromechanical interface. Clean and tight contacts at the mating interface maintain reliable electrical performance. Contact springs and precise alignment prevent intermittent faults by ensuring consistent pressure between pins and sockets. The housing and insulation protect the contacts from environmental hazards, such as moisture and dust, which can cause corrosion or shorts.

Locking mechanisms hold the connector in place during the mating process, preventing accidental separation. Engineers often use non-conductive greases and plastic-safe cleaners to protect contacts and extend connector life. Metal shielding, such as D-shaped shells in some connectors, blocks electromagnetic interference and preserves signal integrity. Specialized designs, like USB Type-C’s reversible plug or ZIF technology in FFC connectors, further enhance the reliability and usability of the electrical connector.

A well-engineered connector ensures that each electromechanical component supports the others, resulting in a robust and dependable electrical connection for any application.

Key Parameters and Basic Principles of Connectors

Understanding the key parameters and basic principles of connectors is essential for anyone involved in modern electronics. These parameters determine how well a connector performs in its intended application, affecting everything from electrical safety to long-term reliability. Engineers must evaluate several factors, including electrical performance, mechanical durability, and design features, to ensure optimal operation.

Electrical Performance Factors

Electrical connectors must meet strict requirements to guarantee safe and efficient operation. The most important electrical factors include current rating, voltage rating, and contact resistance. Each plays a critical role in the overall performance of the electrical connection.

Current Rating

Current rating defines the maximum current a connector can safely carry without overheating or failing. This parameter depends on the contact material, thermal management, and the connector’s ability to dissipate heat. For example, consumer electronics often use connectors with current ratings ranging from below 1A for audio jacks to up to 5A for USB-C power delivery. Laptop charging ports and IEC connectors can handle even higher current, supporting devices that require more power.

| Connector Type | Typical Current Rating | Notes |

|---|---|---|

| Audio Jacks | Below 1A | Suitable for low-current audio signals |

| Phone Chargers | 1A to 5A | Common range for mobile device charging |

| Laptop Charging Ports | 3A to 5A | Medium current for laptop power input |

| USB Connectors | 0.5A to 5A | USB-C supports up to 5A for power delivery |

| IEC C13/C14 | Up to 10A | Used in PCs and monitors |

Selecting a connector with the correct current rating prevents overheating and ensures the electrical connection remains stable during operation.

Voltage Rating

Voltage rating specifies the maximum voltage a connector can withstand without breakdown or arcing. This factor is crucial for both AC and DC systems. Engineers must match the voltage rating of the connector to the application’s requirements to maintain electrical safety. For instance, USB connectors typically operate at 5V, while IEC connectors can handle up to 250V. Barrel connectors in laptops and LED lights often support voltages from 5V to 24V DC.

| Connector Type | Voltage Range | Current Rating | Notes |

|---|---|---|---|

| Barrel Connectors | 5V to 24V DC | Suitable for typical device currents | Common in laptops, routers, LED lights |

| USB Connectors | 5V nominal | 0.5A to 5A | Power delivery up to 100W with USB-C PD |

| IEC C13/C14 | 250V | Up to 10A | Standardized for PCs and monitors |

A connector with an inadequate voltage rating can lead to insulation failure, electrical arcing, or even fire hazards.

Contact Resistance

Contact resistance measures the resistance to current flow at the interface between connector contacts. Even a small increase in contact resistance can cause significant voltage drops and heating, especially in high-current applications. Factors such as incomplete surface contact, oxidation, and contamination increase contact resistance. Over time, vibration, mechanical wear, and environmental exposure can further degrade the contact surface, leading to unreliable electrical connections and reduced connector lifespan.

High contact resistance often results in poor performance, unpredictable electrical behavior, and potential device failure. Regular inspection and maintenance help minimize these risks.

| Electrical Performance Factor | Description | Application Impact |

|---|---|---|

| Current Rating | Maximum current the connector can safely carry, influenced by contact material, thermal management, and contact resistance. | Ensures connector can handle power requirements without overheating or failure. |

| Rated Voltage | Maximum voltage the connector can withstand, critical for insulation and breakdown prevention. | Determines safe use in AC or DC systems, matching application voltage needs. |

| Contact Resistance | Resistance at the contact interface, affected by material, wear, and contamination. | Impacts signal quality, heating, and overall reliability. |

Mechanical Considerations for Connectors

Mechanical factors play a significant role in the durability and usability of connectors. Engineers must consider how often a connector will be mated and unmated, as well as its size and form factor.

Durability and Mating Cycles

Durability refers to how many times a connector can be connected and disconnected before failure. The number of mating cycles depends on the contact material, plating thickness, and overall design. High-quality connectors with gold-plated contacts can withstand 500 or more cycles, while specialized designs may exceed 1,000 cycles. In contrast, low-cost connectors with tin plating may only last 10 to 50 cycles.

| Connector Quality | Contact Material & Plating | Typical Mating Cycles Before Failure |

|---|---|---|

| Low-cost | Tin plating | 10 to 50 cycles |

| Mid to High-quality | Thick gold plating | Around 500 cycles |

| Specialized | Beryllium copper/brass body | 1000+ cycles |

Vibration and shock also affect connector durability, especially in industrial environments. Manufacturers test connectors under these conditions to ensure they maintain a reliable electrical connection throughout their service life.

- Key mechanical factors influencing durability:

- Vibration and shock resistance

- Quality of contact materials and plating

- Secure locking mechanisms

Size and Form Factor

Connector size and form factor determine how easily a connector fits into a device or system. Smaller connectors support compact designs but may limit current and voltage capacity. Larger connectors can handle higher power and more contacts but require more space. Engineers must balance these factors to achieve the desired electrical performance and mechanical stability.

Tip: Selecting the right size and form factor ensures the connector meets both electrical and mechanical requirements without compromising device design.

Safety and Reliability in Connector Design

Safety and reliability are fundamental to connector performance, especially in critical applications such as medical, automotive, and industrial electronics. Proper insulation, protection features, and fail-safe mechanisms help prevent accidents and ensure consistent operation.

Insulation and Protection

Insulation separates contacts within the connector, preventing short circuits and electrical arcing. High-quality insulation materials withstand temperature extremes, moisture, and mechanical stress. In medical electronics, connectors must comply with standards such as IEC 60601-1, which specifies creepage and clearance distances, leakage current limits, and device classifications based on patient contact level.

| Standard | Description |

|---|---|

| IEC 60601-1 | Core safety standard specifying patient and operator protection, creepage and clearance distances, leakage current limits, and device classifications. |

| ISO 13485 | Quality management system requirements specific to medical devices. |

| ISO 80369 | Requirements to reduce misconnections between medical devices and accessories. |

Engineers often use features like waterproof sealing (IP67 rating), EMI shielding, and thicker gold plating to enhance protection and maintain a stable electrical connection in harsh environments.

Fail-Safe Features

Fail-safe features ensure connectors maintain reliable operation even under adverse conditions. Automotive connectors, for example, use secure locking mechanisms, multiple contact points, and audible feedback to confirm proper mating. Sealing elements such as silicone seals protect against moisture and debris, while robust designs resist vibration and thermal cycling. Compliance with industry safety standards, such as IATF 16949 for automotive applications, guarantees consistent quality and reliability.

- Common fail-safe features:

- Secure locking mechanisms to prevent accidental disconnection

- Sealing elements for moisture and dust protection

- Multiple contact points for stable electrical connection

- Audible or tactile feedback for proper mating

- Compliance with safety and quality certifications

Note: Integrating these features into connector design enhances both safety and long-term reliability, supporting the basic principles of connectors in every application.

Environmental Factors Affecting Connectors

Temperature Resistance

Connectors in modern electronics must withstand a wide range of temperatures to maintain reliable electrical performance. High temperatures, often above 150°C, can soften or melt PVC insulation. This process leads to deformation of metal contacts, which reduces the quality of the electrical contact and may cause voltage instability. When connectors operate in environments with low temperatures, such as below -40°C, materials like rubber and plastic become brittle. Brittle insulation can crack, exposing the electrical contact and increasing the risk of voltage breakdown or current leakage.

Thermal cycling, which involves repeated heating and cooling, introduces thermal stress. This stress creates micro-cracks in the insulation and metal contacts. Over time, these cracks compromise the electrical isolation between contacts and may result in voltage surges or loss of current flow. Engineers address these challenges by selecting materials that resist both high and low temperatures. For example, PTFE and silicone rubber maintain their properties at elevated temperatures, while thermoplastic elastomer and polyethylene remain flexible in cold conditions. Some connectors, such as the Amphenol 10062827-0410EDHLF FPC connector, use these advanced materials to ensure stable electrical contact and consistent voltage transmission even during extreme temperature fluctuations.

Tip: Always consider the operating temperature range when selecting a connector. The right material choice prevents electrical failures and extends the connector’s service life.

The table below summarizes how temperature extremes and thermal cycling affect connector performance and the strategies used to mitigate these effects:

| Environmental Factor | Impact on Connector Performance | Mitigation / Example |

|---|---|---|

| High Temperature (>150°C) | Softening, melting, or decomposition of insulation; deformation of metal contacts; reduced electrical contact quality | Use high-temperature-resistant materials like PTFE or silicone rubber; Amphenol FPC connector for stable voltage and current |

| Low Temperature (<-40°C) | Brittle rubber/plastic; cracks and insulation failure; exposed electrical contact | Use TPE or PE for flexibility in cold; maintain voltage and current stability |

| Thermal Cycling | Thermal stress causes micro-cracks and fatigue; reduced electrical isolation; possible voltage surges | Use thermal cycling-resistant materials; increase insulation thickness for stable electrical contact |

Moisture and Dust Protection

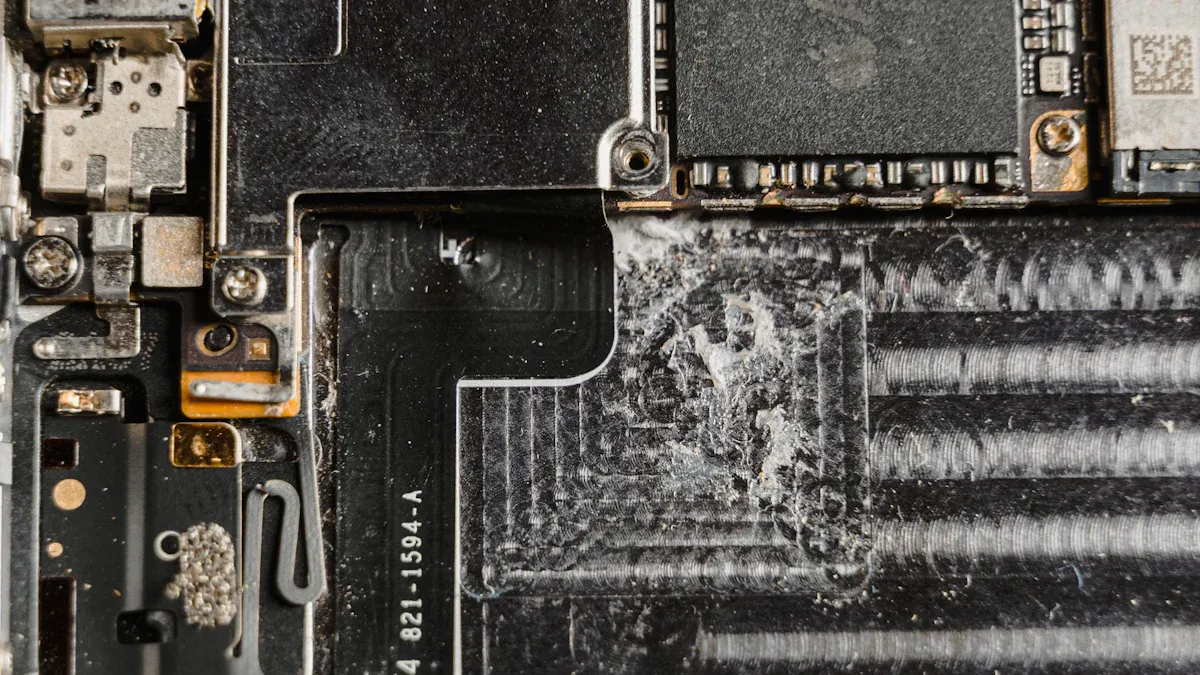

Moisture and dust present significant threats to connector reliability. When moisture enters a connector, it can corrode metal contacts. Corrosion increases contact resistance, which disrupts the flow of current and causes voltage drops. Moisture also degrades insulation, reducing dielectric strength and increasing the risk of voltage leakage or short circuits. In environments with high humidity, the electrical contact may absorb water, further compromising voltage stability and current flow.

Dust particles can accumulate on the contact surfaces, creating barriers that prevent proper electrical connection. This accumulation leads to intermittent voltage loss and unreliable current transmission. Engineers combat these issues by using corrosion-resistant plating, such as gold or silver, on the contact surfaces. High-quality sealing designs, including gaskets and O-rings, prevent moisture and dust from reaching the electrical contact. For example, TE Connectivity’s 175150-2 series connectors feature advanced sealing to maintain low contact resistance and stable voltage under harsh conditions.

Note: Proper sealing and corrosion-resistant materials are essential for connectors used in outdoor, industrial, or medical environments. These features protect the electrical contact from moisture and dust, ensuring consistent voltage and current delivery.

Key strategies for moisture and dust protection include:

- Applying gold or silver plating to the contact to prevent corrosion and maintain low resistance.

- Designing housings with high ingress protection (IP) ratings to block moisture and dust.

- Using high-quality seals and gaskets to preserve electrical isolation and voltage integrity.

The table below highlights the impact of humidity and moisture on connector performance and the solutions engineers use:

| Environmental Factor | Impact on Connector Performance | Mitigation / Example |

|---|---|---|

| Humidity / Moisture | Corrosion of metal contacts; increased contact resistance; degraded signal integrity; reduced insulation strength; voltage leakage | Use corrosion-resistant plating; high sealing designs; TE Connectivity 175150-2 series for moisture protection |

| Dust | Accumulation on contact surfaces; increased resistance; unreliable voltage and current transmission | Use sealed housings; regular maintenance; maintain clean contact surfaces |

By understanding and addressing these environmental factors, engineers ensure that connectors deliver reliable electrical contact, stable voltage, and consistent current in any application.

Common Connection Methods for Electrical Connectors

Selecting the right connection method is essential for achieving a stable electrical connection and maintaining reliable contact in modern devices. Engineers often choose between soldering, crimping, and plug-and-socket techniques based on application requirements, durability, and ease of assembly. Each connection method offers unique benefits and challenges for establishing and maintaining electrical contact.

Soldering

Soldering remains a traditional and widely used connection method in electronics. This process involves melting a filler metal, known as solder, to join the electrical contact points. Soldering creates a permanent connection that supports both signal and power transmission. Many engineers prefer soldering for its simplicity and cost-effectiveness, especially in general-duty and industrial applications.

Advantages of soldering include:

- Minimal tooling requirements, such as a low-wattage soldering iron and flux.

- Reliable electrical contact for both solid and stranded conductors.

- Tolerance for less-than-perfect technique compared to other connection methods.

- Economical materials and straightforward setup.

Disadvantages of soldering include:

- Heat from soldering can damage sensitive components or exceed temperature limits.

- Labor-intensive and more time-consuming than crimping.

- Risk of cold solder joints, which can cause unreliable electrical contact and cracks over time.

- Solder joints may develop micro-cracks and fatigue under vibration.

- Requirement for RoHS-compliant solder, which can complicate material selection.

- Filler metal degradation may eventually lead to connection failure.

Note: Proper technique and quality materials are critical for ensuring a long-lasting electrical connection when using soldering as a connection method.

Crimping

Crimping has become a preferred connection method for many electrical applications due to its reliability and efficiency. This technique uses a specialized tool to compress the connector onto the wire, forming a secure mechanical and electrical contact. Crimping creates an air-tight seal that protects the connection from moisture, dirt, and debris, which can degrade soldered joints over time.

Crimping offers several advantages:

- Stronger and more reliable electrical connection than soldering.

- Quick and easy assembly with minimal training.

- Consistent results that reduce the risk of poor contact.

- Enhanced protection against environmental factors.

Engineers value crimping for its ability to maintain a stable electrical connection, even in harsh conditions. The process eliminates the need for heat, reducing the risk of damaging the cable or connector. Crimped connections also support high-volume manufacturing, making them ideal for automotive and industrial applications.

Plug-and-Socket

Plug-and-socket connectors provide a versatile connection method for a wide range of electrical devices. This system allows users to establish or break an electrical connection by simply inserting or removing a plug from a socket. Plug-and-socket designs support repeated use without compromising the quality of the electrical contact.

Key benefits of plug-and-socket connectors include:

- Durability, withstanding frequent connection and disconnection cycles.

- Convenience, enabling users to connect or disconnect devices easily.

- Safety, preventing accidental disconnections and protecting sensitive components.

- Modularity, supporting quick replacement and maintenance of system parts.

Plug-and-socket connectors have become standard in consumer electronics, where reliable electrical contact and user-friendly operation are essential. Their design ensures a secure connection while allowing for flexibility in system upgrades and repairs.

Tip: Choosing the appropriate connection method ensures optimal electrical performance and long-term reliability for any application.

Insulation Displacement Connection (IDC)

Insulation Displacement Connection (IDC) stands out as a modern connection method that streamlines the process of joining wires to connectors. Engineers often select IDC for its speed, reliability, and suitability for high-volume manufacturing. This connection method eliminates the need to strip insulation from wires before making a connection, which reduces assembly time and minimizes the risk of damaging the conductor.

The principle behind IDC technology relies on a unique mechanical process. During assembly, the installer forces an unstripped conductor into a V-shaped metal tube within the connector. The tube is intentionally smaller than the conductor’s diameter. As the wire enters, sharp metal blades inside the connector spread open and pierce the insulation. This action exposes the bare copper beneath the insulation and forms a direct contact between the conductor and the metal blade. The blades exert a spring-like inward force, which maintains a secure and vibration-resistant connection over time.

Key features of IDC technology include:

- The connection forms without stripping the insulation from the wire.

- Metal blades penetrate any oxide or film on the conductor, ensuring a gas-tight and corrosion-resistant contact.

- The spring force of the blades keeps the contact stable, even in environments with vibration.

- The connection method supports mass termination, especially for flat ribbon cables, allowing multiple wires to connect simultaneously.

- The design of the metal contacts ensures the insulation is only displaced at the piercing zone, preserving the integrity of the wire.

Tip: IDC connectors provide a reliable connection in applications where speed and consistency are critical, such as telecommunications, automotive wiring, and consumer electronics.

A table below summarizes the advantages of IDC as a connection method:

| Feature | Benefit |

|---|---|

| No insulation stripping needed | Faster assembly, reduced risk of wire damage |

| Gas-tight contact | Corrosion resistance, long-term reliability |

| Vibration resistance | Stable connection in dynamic environments |

| Mass termination capability | Efficient for ribbon cables and harnesses |

IDC technology creates a gas-tight contact that resists corrosion and maintains low electrical resistance. This ensures the connection remains reliable throughout the device’s lifespan. The connection method also reduces the chance of human error during assembly, as the process is straightforward and repeatable.

Manufacturers often use IDC connectors in devices that require many connections in a compact space. The technology supports high-density wiring and delivers consistent contact quality. IDC remains a preferred connection method for engineers who value efficiency, reliability, and robust electrical performance.

Trends and Innovations in Connector Design

Miniaturization of Connectors

Miniaturization has become a defining trend in connector technology. Engineers now create connectors with higher contact densities and smaller pitches to fit the compact spaces of modern devices. Portable electronics, wearables, medical devices, and autonomous vehicles all demand smaller connectors that do not compromise performance. This trend addresses space constraints and enables functional integration in advanced systems.

- Mechanical durability faces new challenges from vibration, misalignment, and repeated mating cycles in smaller connectors.

- Signal integrity risks increase due to electromagnetic interference and signal degradation in compact interfaces.

- Assembly precision requires tighter manufacturing tolerances and robust strain relief.

- Manufacturers respond with high-precision locking mechanisms, shielded contact structures, and connectors rated for high mating cycles.

Innovations such as ultra-fine pitch terminals, staggered contact layouts, and hybrid signal-power interfaces support applications in ADAS vehicle systems, smart wearables, and industrial IoT nodes. Rigorous industrial testing ensures these miniaturized connectors deliver long-term reliability in space-constrained environments.

Note: Miniaturization in connector technology enables new possibilities for device design but requires advanced engineering to maintain reliability and performance.

High-Speed Data Transmission

Modern technology relies on rapid and reliable data transfer. Connector technology has evolved to support high-speed data transmission for applications like HD video streaming, real-time analytics, and advanced communications. Engineers design connectors with high bandwidth capacity and low latency, which are essential for industries such as finance, telecommunications, and entertainment.

- Advanced signal conditioning and robust construction maintain signal integrity, even in environments with significant electromagnetic interference.

- Rigorous testing ensures connectors withstand extreme temperatures, vibration, and mechanical stress.

- Specialized connector types include:

- Rectangular connectors with high-density packaging for space-limited applications.

- Circular connectors for ruggedness in aerospace and transportation.

- RF connectors for high-frequency wireless communication.

- Board-to-board connectors for direct high-speed data transfer within devices.

Emerging technologies like 5G, IoT, AR, and VR drive the need for connectors that support multi-functionality and ultra-fast data rates. Product lines now feature matched impedance differential pairs, multi-point contact engagement, and robust EMI shielding, supporting data rates up to 50 Gbps.

Enhanced Durability and Longevity

Durability and longevity remain critical in connector technology, especially for harsh environments. Engineers use ruggedized designs with advanced sealing technologies to protect against moisture, temperature extremes, vibration, and contaminants. These features prevent corrosion and electrical faults, ensuring reliable operation over time.

Innovations include the use of high-performance polymers such as Polyether ether ketone (PEEK) for mechanical strength and low friction. Composite materials like carbon fiber-reinforced polymer provide a high strength-to-weight ratio and resist corrosion. Advanced metal alloys, including copper-nickel-silicon, enhance conductivity and resist oxidation. Coatings such as diamond-like carbon improve wear resistance and extend connector lifespan.

Companies also focus on ease of installation and maintenance, which facilitates diagnostics and repairs. Precision manufacturing and safety-engineered designs further extend operational life and reduce downtime in demanding sectors like automotive, mining, and marine operations.

Tip: The latest connector technology combines material science and engineering innovation to deliver reliable, efficient, and long-lasting connections in the most challenging environments.

Smart and Modular Connectors

Smart and modular connectors represent the next evolution in connector technology. These connectors combine traditional electrical functions with advanced features that support intelligent monitoring, diagnostics, and flexible system design. Engineers now use smart connectors to improve device performance, simplify maintenance, and enable new levels of automation.

Smart connectors integrate sensors and microchips directly into the connector housing. These components monitor parameters such as temperature, current, voltage, and connection status. The connector can send real-time data to a control system or maintenance team. This capability helps engineers detect problems early, such as overheating or loose connections, before they cause system failures.

Smart connectors help prevent downtime by providing early warnings about potential issues.

Key features of smart connectors include:

- Embedded sensors for real-time monitoring

- Data transmission capabilities for diagnostics

- Self-identification to support plug-and-play operation

- Compatibility with industrial communication protocols

Modular connectors offer a flexible approach to system design. Engineers can customize these connectors by selecting different modules for power, signal, or data transmission. This modularity allows for quick changes or upgrades without redesigning the entire system. For example, a modular connector in a factory automation system might include separate modules for Ethernet, power, and control signals. If the system requirements change, the engineer can swap out a module instead of replacing the whole connector.

| Feature | Smart Connectors | Modular Connectors |

|---|---|---|

| Monitoring | Yes (sensors, diagnostics) | No |

| Customization | Limited | High (mix-and-match modules) |

| Plug-and-play support | Yes | Yes |

| Application flexibility | Medium | High |

Smart and modular connectors support Industry 4.0 and the Industrial Internet of Things (IIoT). These connectors enable machines to communicate their status and needs automatically. Maintenance teams can use the data from smart connectors to schedule repairs or replacements, reducing unplanned downtime.

Engineers also value modular connectors for their ability to simplify complex wiring. Modular designs reduce installation time and errors. They also make it easier to expand or reconfigure systems as technology advances.

Note: The combination of smart features and modularity gives engineers powerful tools to build reliable, future-ready electronic systems.

Smart and modular connectors continue to shape the future of electronics. Their advanced features and flexibility support the growing demand for intelligent, adaptable devices in every industry.

A connector forms the backbone of every modern electronic system. Engineers rely on the right connector to ensure stable electrical performance. Each connector type supports specific electrical needs, from power delivery to data transfer. Understanding the connector definition helps users select the best connector for any application. The basic structure of a connector includes contacts, housing, and locking mechanisms. Electrical safety depends on the connector’s design and material. Innovations in connector technology drive progress in electronics. A connector must withstand harsh environments and maintain electrical reliability. The future of electronics will depend on smarter, more adaptable connector solutions.

Selecting the correct connector improves electrical safety and device performance.

- Engineers should review connector options for each electrical system.

- Ongoing research continues to advance connector capabilities.

FAQ

What is the main purpose of an electrical connector?

An electrical connector joins circuits to allow current or signals to pass between components. Engineers use connectors to create secure, reliable, and repeatable connections in electronic devices.

How do engineers select the right connector for a project?

Engineers consider current and voltage ratings, size, environmental resistance, and application requirements. They also review durability, mating cycles, and safety standards before making a selection.

Why do some connectors have gold-plated contacts?

Gold plating resists corrosion and maintains low contact resistance. This feature ensures stable signal transmission and extends the connector’s lifespan, especially in harsh environments.

What does “mating cycle” mean in connector specifications?

A mating cycle counts one complete connection and disconnection of a connector pair. Manufacturers rate connectors for a specific number of cycles to indicate expected durability.

Can connectors handle both power and data signals?

Many connectors support both power and data. For example, USB connectors deliver power and transfer data. Engineers must verify that the connector meets the requirements for both functions.

How do environmental factors affect connector performance?

Temperature, moisture, and dust can degrade connectors. High temperatures may soften insulation. Moisture causes corrosion. Dust increases contact resistance. Engineers use protective materials and sealing to maintain performance.

What is the difference between crimping and soldering?

Crimping compresses a connector onto a wire for a strong mechanical and electrical bond. Soldering uses melted metal to join wires. Crimping is faster and more reliable for mass production.