You rely on connector interfaces to achieve seamless integration between devices, machines, and platforms. These interfaces ensure compatibility, whether you work with an M8 connector in industrial automation or a Type B connector in consumer electronics. When you choose the right connector factory, you guarantee efficient communication and dependable connections. Connector interfaces serve as the foundation for stable data exchange, minimizing errors and simplifying system upgrades.

Connector Interfaces and System Integration

Definition and Core Purpose of Connector Interfaces

You encounter connector interfaces whenever you need two systems or applications to exchange information, energy, or resources. In system integration, a connector interface acts as the boundary that separates and links different components. According to systems engineering principles, this interface enables reliable communication by providing a structured way for systems to interact. You can visualize connector interfaces as lines in architectural diagrams, showing how resources flow between subsystems. These interfaces support both analog and digital exchanges, including electrical signals, wireless transmissions, and even physical matter. The core purpose of connector interfaces is to facilitate seamless interaction and resource sharing, ensuring that each system or application can function together without conflict.

The Role of Connector Interfaces in Integration

Connector interfaces play a critical role in integration by bridging gaps between disparate systems. You rely on them to enable communication, manage authentication, and ensure secure data flow. When you use connector interfaces, you can:

- Bridge different systems and applications, allowing data to move smoothly.

- Handle authentication by managing credentials for secure access.

- Read and transform data into common formats, such as dictionaries or standardized objects, for interoperability.

- Support error handling, so processes do not fail entirely when issues arise.

- Write, update, or delete data in external systems, maintaining transactional integrity.

- Reduce the need for custom integrations, making maintenance easier.

- Abstract the complexity of underlying system interfaces, providing a reliable and secure way to exchange information.

Tip: By using connector interfaces, you can expose reusable business functions and accept requests in standardized formats like XML or JSON. This approach supports real-time event processing and integration with various application models, including Java and COM.

You see connector interfaces in action across many integration scenarios. The table below highlights common use cases:

| Use Case Category | Description | Example |

|---|---|---|

| Point-to-Point Integration | Simple data transfers between two systems, stable and low maintenance. | Feeding sensor data into a database; connecting an invoicing system to an ERP with one-directional flow. |

| Cloud-Based Integration (iPaaS) | Real-time data synchronization across cloud and on-premise systems using pre-built connectors. | Integration platform built on Azure for Pernod Ricard connecting Microsoft Dynamics 365 and Oracle JD Edwards. |

| Enterprise Service Bus (ESB) | Flexible, scalable integration framework used especially in regulated industries for complex needs. | Use of Mule ESB, Microsoft BizTalk, Oracle ESB in finance, banking, and industrial sectors. |

| Business Process Integration | Automating workflows between business applications to improve efficiency and reduce manual data entry. | Syncing new employees between HRIS (e.g., Namely) and ITSM tools (e.g., ServiceNow) for onboarding automation. |

How Connector Interfaces Simplify Data Integration

You simplify data integration by using connector interfaces that unify and standardize access to data from multiple sources. Middleware and management interfaces provide a universal integration layer, combining control, visualization, and synchronization. This approach reduces complexity by allowing applications to interact with a single, standardized interface instead of multiple, incompatible systems.

- Connector interfaces use standards like OPC UA to ensure compatibility across diverse equipment.

- Data virtualization and federation techniques create unified views of data, eliminating the need for physical consolidation.

- Integration tools abstract the differences between systems, letting you focus on business logic rather than technical details.

You benefit from connector interfaces in several ways:

- Automate employee onboarding by syncing HRIS and ITSM tools, triggering workflows automatically.

- Increase productivity by enabling real-time data access within familiar applications.

- Enhance experiences by eliminating redundant data entry and improving service speed.

- Improve collaboration by breaking down data silos and enabling shared access.

- Amplify application functionality by leveraging integrated data for more features.

Connector interfaces, especially APIs and application programming interfaces, serve as the backbone of modern application integration. You use APIs to connect applications, synchronize data, and support technologies like IoT and AI. By abstracting the complexities of system differences, connector interfaces ensure that your data integration projects remain efficient, secure, and scalable.

Types of Connector Interfaces in Integration

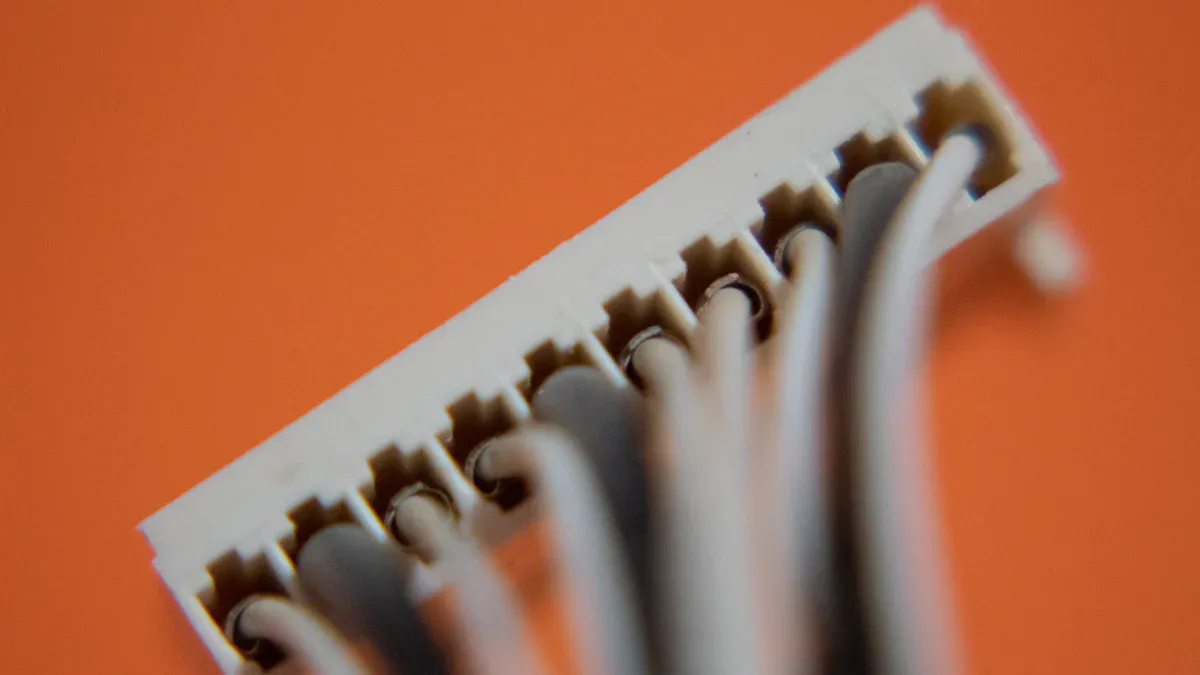

Physical Connectors for System Compatibility

Physical connectors form the backbone of hardware integration. You use these connectors to ensure that devices, machines, and systems can communicate reliably in demanding environments.

Electrical Connectors

You often rely on electrical connectors for power and signal transmission. In industrial settings, IEC 60309 connectors stand out due to their robust construction, color-coding for voltage identification, and high ingress protection. These connectors handle high amperage and provide reliable connections for heavy machinery. You also encounter pin and sleeve connectors, modular connectors, and circular connectors, which offer flexibility and durability. M8 and M12 connectors are common in automation, while Ethernet and USB connectors support data transfer in both industrial and consumer applications.

Fiber Optic Connectors

Fiber optic connectors enable high-speed data transmission with minimal signal loss. You use them in environments where electromagnetic interference poses a risk to traditional electrical connectors. These connectors support applications that demand secure, high-bandwidth communication, such as data centers and advanced manufacturing.

Mechanical Connectors

Mechanical connectors provide secure, physical attachment between components. You use panel feedthrough connectors for sealed, pluggable connections in harsh environments. These connectors ensure that your systems remain operational even under vibration, dust, or moisture.

Digital Connector Interfaces and APIs

Digital connector interfaces bridge the gap between software systems. You use APIs and application connectors to enable seamless data exchange and workflow automation.

Application Programming Interfaces (APIs)

APIs serve as the foundation for digital integration. An application programming interface defines protocols that allow different applications to communicate. You use APIs to connect software, exchange data, and automate processes. APIs require technical expertise but offer flexibility and scalability for custom integrations.

Protocol-Based Digital Connectors

You encounter protocol-based digital connectors such as Connect SOAP, Connect REST, and Connect JMS. These connectors use established protocols like HTTP, SOAP, and messaging standards to link applications. The table below highlights common digital connector types:

| Connector Type | Description / Technology or Protocol Classification |

|---|---|

| Connect SOAP | Uses SOAP protocol over HTTP for web services integration |

| Connect REST | Uses RESTful HTTP protocol for system interactions |

| Connect JMS | Java Message Service API for messaging |

| Connect MQ | IBM WebSphere MQ messaging standard |

| Connect SAP | Connects to SAP systems via HTTP, SOAP, or IDoc |

| Connect dotNet | Connects to Microsoft .NET Framework web services |

| Connect Java | Connects to external Java applications or classes |

Middleware and Software Connectors

Middleware acts as a software layer that connects distributed systems. You use middleware to manage data, messaging, and authentication between applications. Application connectors built into middleware platforms accelerate deployment and reduce complexity, making integration accessible even if you have limited coding skills. You also use webhooks and EDI for real-time notifications and standardized business document exchange.

Note: APIs and application connectors both enhance interoperability, but APIs offer more flexibility while connectors provide faster, user-friendly integration.

Industry-Specific Connector Solutions

You face unique integration challenges in different industries. Specialized connectors and application connectors address these needs.

Industrial Automation Connectors

In automation, you use connectors like M8, M12, and IEC 60309 for reliable power and data connections. These connectors withstand harsh conditions and support real-time control.

Consumer Electronics Connectors

You rely on USB, HDMI, and D-sub connectors for connecting devices in consumer electronics. Application connectors in this sector ensure compatibility between various multimedia and smart home applications.

Automotive and Transportation Connectors

Automotive connectors must handle vibration, temperature extremes, and safety requirements. You use specialized application connectors to integrate sensors, control units, and infotainment systems, ensuring seamless operation across vehicle platforms.

How Connector Interfaces Enable Seamless Data Integration

Standardization and Protocols in Connector Interfaces

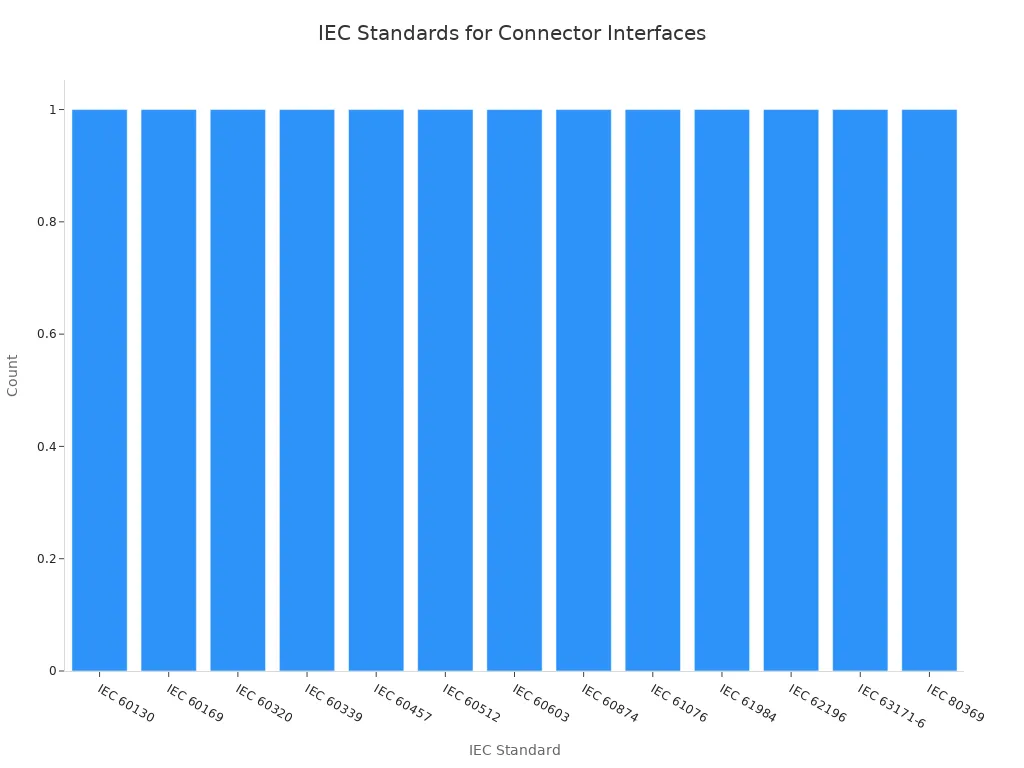

International Standards for Connectors

You achieve reliable data integration by following international standards for connectors. These standards define the physical, electrical, and safety requirements for connector interfaces across industries. When you select connectors that comply with these standards, you ensure compatibility and interoperability between devices from different manufacturers. The table below highlights some of the most important IEC and ISO standards for connector design and implementation:

| IEC Standard | Application Area / Description |

|---|---|

| IEC 60130 | Connectors for frequencies below 3 MHz |

| IEC 60169 | Radio frequency connectors |

| IEC 60320 | Appliance couplers |

| IEC 60339 | General-purpose rigid coaxial transmission lines and flange connectors |

| IEC 60457 | Rigid precision coaxial and associated precision connectors |

| IEC 60512 | Connectors for electronic equipment – Tests & Measurement |

| IEC 60603 | Connectors for frequencies below 3 MHz for use with printed boards |

| IEC 60874 | Fiber optic interconnecting devices and passive components – Connectors for optical fibers and cables |

| IEC 61076 | Connectors for electronic equipment – product requirements |

| IEC 61984 | Connectors – Safety requirements and tests |

| IEC 62196 | Plugs, socket-outlets, vehicle connectors and vehicle inlets – Conductive charging of electric vehicles |

| IEC 63171-6 | Industrial style connectors for Single Pair Ethernet (SPE) interfaces, supporting data transmission up to 600 MHz |

| IEC 80369 | Small-bore connectors for liquids and gases in healthcare applications |

You also see standards from ISO and SAE, especially in automotive and industrial applications:

| Organization | Standard | Focus Area / Description |

|---|---|---|

| ISO | ISO 6722 | Performance requirements for automotive cables, including heat and corrosion resistance |

| ISO | ISO 26262 | Functional safety of automotive electronic systems, ensuring connector reliability |

| IEC | IEC 61076 | Interface and technical requirements for various automotive connectors |

| IEC | IEC 60664 | Insulation requirements in electrical equipment, applicable to connector design |

| SAE | SAE J2030 | Performance testing requirements for car connectors, ensuring real-world reliability |

| SAE | SAE J1171 | Design and testing standards for electronic connectors used in vehicles |

IEC 63171-6 stands out as a comprehensive standard for industrial Single Pair Ethernet (SPE) connectors. This standard ensures that connectors meet strict requirements for length, bandwidth, and shielding. Developed with input from over 20 national committees and industry groups, it provides a unified framework for SPE infrastructure. You benefit from improved interoperability and reliability in industrial data integration when you use connectors that meet this standard.

Common Communication Protocols

You rely on standardized communication protocols to achieve seamless integration between systems. These protocols define how connectors exchange data, manage authentication, and handle errors. By using protocols like HTTP, HTTPS, SOAP, and REST, you ensure that data flows securely and efficiently across different platforms.

- Standardized protocols set clear rules for communication between systems.

- They ensure consistent, secure, and efficient data exchange by managing authentication, data formats, and transmission methods.

- Connectors use these protocols to extract, transform, and load data across different environments.

- Protocols support both real-time and batch processing, giving you flexibility in data integration.

- Error handling and monitoring features in connectors improve interoperability and data flow.

- By following standards such as HTTP/HTTPS, SOAP, and REST, you break down data silos and enable unified analytics.

HTTP and HTTPS form the foundation for web communication, providing stateless and secure data exchange. SOAP offers robust security and error handling, making it ideal for complex operations. REST delivers a lightweight and scalable approach, widely used for web APIs. These protocols define how data is formatted, transmitted, and secured, ensuring interoperability between diverse systems. When you use connectors that support these protocols, you guarantee reliable and consistent data integration.

Design Considerations for Compatibility

Pin Configuration and Signal Mapping

Pin configuration and signal mapping play a critical role in connector compatibility. You must ensure that each pin on a connector matches the corresponding signal or function on the device. Proper pin configuration guarantees that connectors mate physically, while correct signal mapping ensures that electrical and logical signals flow as intended.

- Pin configurations and signal mappings define how signals correspond to specific pins.

- Compatibility depends on matching these configurations to ensure correct signal routing.

- Mismatched pinouts or signal mappings can cause communication failures or even hardware damage.

- Documentation often highlights backward compatibility, such as skipping certain I/O channels to maintain support for earlier devices.

- Different network standards require specific pin and signal mappings, making precise alignment essential.

When you design or select connectors, always review pin assignments and signal maps. This step prevents costly errors and ensures seamless data integration.

Backward and Forward Compatibility

You need to consider both backward and forward compatibility when integrating new connectors into existing systems. Backward compatibility allows new connectors to work with older devices, while forward compatibility ensures that current connectors can support future upgrades.

- Define compatibility requirements early in the design process.

- Use standardized interfaces and modular designs to support both backward and forward compatibility.

- Employ simulation and emulation tools to test compatibility before deployment.

- Conduct thorough validation, including design reviews and functional testing.

- Monitor industry standards and update compatibility requirements as needed.

By following these steps, you maintain interoperability and protect your investment in data integration infrastructure.

Achieving Interoperability with Connectors

Cross-Platform Integration

You often face the challenge of integrating systems that run on different platforms or use different connector interfaces. Achieving cross-platform integration requires a combination of technical strategies and industry best practices. The table below summarizes common methods:

| Method | Description | Benefits/Notes |

|---|---|---|

| Messaging Adapters | Use message queuing systems like IBM WebSphere MQ to handle message delivery and logic exchange. | Reliable connections, guaranteed delivery, operation acknowledgements. |

| Batch Interfaces | Process multiple transactions in bulk, often scheduled and non-interactive. | Efficient bulk data movement and processing. |

| Interface Tables | Use point-to-point data import/export with working files formatted for the target system. | Defined data structure, customizable fields. |

| Electronic Data Interchange (EDI) | Standardized computer-to-computer exchange of business transactions. | Shorter fulfillment cycles, increased data integrity, reduced manual work. |

| Table Conversion | High-speed data manipulation and transfer between tables, including non-native tables. | Enables data gathering, formatting, import/export, and direct business function calls. |

You also use product testing, engineering with common standards, and industry partnerships to ensure that connectors work across platforms. Hospitals, for example, use standardized APIs like HL7 FHIR and policy frameworks such as TEFCA to simplify cross-network data exchange. These approaches help you overcome technical and organizational barriers to interoperability.

Vendor-Neutral Connector Solutions

Vendor-neutral connector solutions give you flexibility and reduce the risk of vendor lock-in. When you choose connectors that follow open standards, you can integrate systems from different suppliers without compatibility issues.

- Use common technology and intellectual property to reduce complexity.

- Implement standards through industrial, national, or international agreements.

- Participate in industry and community partnerships to refine and adopt common standards.

- Continuously monitor and update your integration strategies to align with evolving standards.

Vendor-neutral connectors support seamless integration, allowing you to adapt quickly to new technologies and business requirements. You maintain control over your data integration architecture and avoid costly migrations in the future.

Best Practices for Selecting and Implementing Connector Interfaces

Assessing Integration and System Requirements

Performance and Scalability Needs

You should start by defining clear objectives for your integration project. This step helps you focus on the most impactful opportunities and guides your selection of connectors and application connectors. Evaluate the expected data volume and transaction speed. Consider how your system will handle increased loads as your organization grows. Always assess whether your chosen connectors can scale without causing bottlenecks or requiring frequent upgrades. Prioritize security by implementing encryption and OAuth 2.0 to protect sensitive data during integration.

Environmental and Operational Factors

You must examine the physical and operational environment where connectors and application connectors will operate. Factors such as temperature, humidity, vibration, and electromagnetic interference can affect connector performance. Choose connectors that meet the necessary ingress protection ratings and comply with industry standards. Document your integration process to track goals and challenges, and conduct thorough testing to verify that connectors function reliably under real-world conditions.

Tip: Cleanse your data before integration to ensure accuracy and reliability. Use a phased rollout approach to minimize risk and catch errors early.

Ensuring Compatibility and Future-Proofing

Supporting Multiple Standards

You ensure long-term compatibility by selecting connectors and application connectors that adhere to established industry standards like IEEE 802.3 or MSA specifications. This approach guarantees interoperability between devices from different manufacturers. Modular connector systems, such as those used in industrial automation, allow you to upgrade or reconfigure your infrastructure without replacing the entire system. For example, modular MPO adapters support easy installation and reconfiguration, enabling you to adapt to new technologies and higher data rates as your needs evolve.

Planning for System Growth

You should always plan for future expansion when implementing connectors and application connectors. Verify compatibility with existing hardware before installation and follow proper procedures to avoid damage. Regularly update firmware to maintain compatibility with new modules. Modular designs let you scale your network or system without major infrastructure changes. Features like adjustable keyways and support for advanced network speeds help you maintain flexibility and reliability as your organization grows.

Implementation Strategies for Connector Interfaces

Testing and Validation Processes

You achieve reliable integration by conducting comprehensive testing. This includes unit, integration, and user acceptance testing for all connectors and application connectors. Test each connector in its intended environment to identify potential issues before full deployment. Use analytical and simulation tools, such as digital twins or system dynamics modeling, to predict performance and optimize your integration strategy.

Documentation and Ongoing Support

You should document every step of your integration process, including connector specifications, pin configurations, and signal mappings. Maintain clear records to simplify troubleshooting and future upgrades. Establish ongoing support protocols, such as regular audits and monitoring, to ensure that your connectors and application connectors continue to perform as expected. Encourage cross-team collaboration to address challenges and share best practices for the effective use of application connectors.

Note: Pre-built connectors can accelerate deployment and reduce complexity, but you must still validate their compatibility with your unique environment.

Common Challenges in Connector Interface Integration

Compatibility and Legacy System Issues

Integrating with Older Systems

You often face significant obstacles when integrating connectors with legacy systems. These older platforms may rely on outdated technologies that do not align with modern integration requirements. Common issues include:

- Legacy systems often use relational databases, while modern platforms may use NoSQL databases. This difference creates challenges in data model compatibility and normalization.

- Batch processing in legacy environments contrasts with real-time or event-driven processing in new systems, complicating synchronization.

- Many legacy systems lack native support for modern API protocols such as REST or GraphQL, which means you must develop custom connectors or adapters.

- Outdated security mechanisms, including weak encryption and authentication, introduce vulnerabilities during integration.

These compatibility gaps can lead to integration failures, data loss, or even system crashes. You can reduce these risks by adopting standardized protocols and upgrading legacy hardware or software components.

Proprietary Connector Interfaces

Proprietary connectors present both benefits and challenges during integration. You may benefit from pre-built connectors that reduce development time and preserve valuable legacy data. Vendors often maintain these connectors, which can increase agility and adaptability. However, you must also consider several drawbacks:

- Scarcity of expertise in outdated technologies can complicate integration.

- Lack of documentation and low-quality data formats increase complexity.

- Security concerns rise when integrating legacy systems with new technologies.

- Vendor lock-in can limit flexibility and future upgrades.

To address these issues, you should conduct thorough audits, use middleware to translate data formats, and prefer standardized communication protocols when possible. Phased implementation and pilot programs help identify problems early and ensure operational continuity.

Technical and Physical Limitations

Bandwidth and Speed Constraints

You must ensure that connectors maintain high data transfer rates and signal integrity, especially in demanding environments. In harsh conditions, connectors face humidity, temperature extremes, vibration, and electromagnetic interference. Modern high-density connectors, such as those meeting the MIL-DTL-38999 standard, now support up to 10 Gb/s, reflecting the growing demand for bandwidth. You see similar trends in data centers and 5G infrastructure, where rapid data transmission is essential. Innovations in miniaturization, EMI shielding, and durability help connectors meet these requirements. High-speed connectors like SFF-8470 support multi-lane data transmission, maintaining performance even under environmental stress.

Space and Form Factor Challenges

Space constraints often limit your connector choices. Compact, lightweight connectors are necessary for applications in aerospace, telecom, and industrial automation. Mechanical design elements, such as locking systems and abrasion-resistant cable assemblies, ensure durability without sacrificing speed or data throughput. Enhanced thermal management and sustainable materials also play a role in supporting high-speed operation in limited spaces.

Security and Data Integrity in Connectors

Ensuring Secure Data Transmission

Security remains a top priority when you integrate connectors into your systems. You must protect data during transmission and at rest. Encryption, such as SSL/TLS, safeguards sensitive data from unauthorized access. Role-based access controls and multi-factor authentication prevent breaches. Regular updates and patches close vulnerabilities in your network infrastructure. Firewalls and intrusion detection systems monitor and block threats, while network segmentation further protects data flows.

Maintaining Data Integrity

You need to maintain data integrity throughout the integration process. Change Data Capture (CDC) techniques help avoid duplicates and inconsistencies. Data transformations clean and enrich data, eliminating discrepancies. Checkpointing allows you to resume data syncs after failures, increasing reliability. Audit trails and logging provide oversight and support compliance with standards like HIPAA and GDPR. Error handling mechanisms detect and correct inconsistencies promptly, ensuring that your connectors deliver accurate and reliable data.

Tip: Always validate input data on both client and server sides, and implement strong access controls to maintain security and data integrity.

Solutions for Overcoming Integration Challenges with Connectors

Adapter and Converter Technologies for Integration

Hardware Adapters for Compatibility

You often encounter situations where hardware from different generations or manufacturers must work together. Hardware adapters bridge these gaps by converting signals, voltages, or connector types. For example, you might use a USB-to-serial adapter to connect legacy equipment to modern systems. These adapters ensure that connectors with different pinouts or physical formats can communicate reliably. In industrial environments, hardware adapters help you maintain compatibility without replacing entire systems.

Software Bridges and Middleware

Software bridges and middleware play a vital role in connecting disparate systems. You use these tools to translate data formats, protocols, and authentication methods between application connectors. Middleware platforms provide a unified interface, allowing you to manage data flows and automate processes across multiple applications. By leveraging software bridges, you can implement custom integrations that support both legacy and cloud-based systems. This approach reduces complexity and accelerates deployment, especially when you need to synchronize data between platforms that do not natively communicate.

Custom Connector Interface Development

Tailored Solutions for Unique Integration Needs

You may face integration requirements that off-the-shelf connectors or application connectors cannot address. Custom connector interface development allows you to design solutions for proprietary or industry-specific data sources. The process involves several steps:

1. Identify the need for integration with unique data sources or APIs. 2. Use SDKs or development services to build connectors tailored to your requirements. 3. Develop and test the connector locally, ensuring it meets your business needs. 4. Deploy and validate the connector through user acceptance testing. 5. Unlock critical data sources, automate specialized workflows, and control data filtering and synchronization.

Custom integrations offer full customization, scalability, and enhanced security. You gain compatibility with legacy systems and can automate workflows unique to your industry. However, you should consider the higher development costs and the need for skilled developers.

Collaboration with Vendors and Partners

Collaboration with vendors and partners strengthens your integration strategy. You can work with connector manufacturers or software providers to develop application connectors that meet your specific requirements. Joint development ensures that your custom integrations align with industry standards and benefit from managed infrastructure features like retries and failure recovery. This partnership approach helps you maintain control over your data and ensures long-term support for your connectors.

Maintenance and Updates for Connector Interfaces

Monitoring and Troubleshooting Integration

Ongoing monitoring is essential for reliable integration. You should implement robust error handling, detailed logging, and automated alerts to detect and resolve issues quickly. Regularly review the performance of your connectors and application connectors to identify bottlenecks or failures. By maintaining clear documentation and conducting thorough testing, you ensure that your custom integrations remain stable and efficient.

Adapting to Evolving Standards

APIs and protocols evolve over time. You must track changes and update your connectors and application connectors proactively. Support for API versioning, modular design, and abstraction layers allows you to adapt without extensive rewrites. Strong security measures, such as encryption and authentication, protect your data as standards change. By staying current, you maintain compatibility and ensure that your integration architecture continues to support your business needs.

The Future of Connector Interfaces and Integration

Emerging Trends in Connector Technologies

Wireless and Contactless Connector Interfaces

You see a rapid shift toward wireless and contactless connector interfaces. The rise of IoT devices drives this trend, enabling seamless wireless communication among sensors and controllers. You no longer face the limitations of physical connections. In smart homes, contactless connectors allow devices like thermostats, cameras, and voice assistants to connect wirelessly, improving user experience and system flexibility.

Recent advances focus on increasing data transfer speed, reliability, and efficiency. For example, companies now use inductive coupling technology to support wireless charging in electric vehicles. This technology improves convenience and encourages adoption. You also benefit from wireless charging connectors, which dominate the market as more smart devices require cable-free charging.

Manufacturers like Molex have acquired wireless chip-to-chip technology to meet the demand for high data rate transmissions. Their solutions support data rates up to 6 Gbps on the 60 GHz band, avoiding interference from WiFi or Bluetooth. These contactless connectors eliminate cables, improve design flexibility, and offer dust- and water-proof packaging. However, you must address security concerns, such as unauthorized access and data interception, by implementing robust encryption and cybersecurity measures.

Smart and Adaptive Connectors

You notice that smart connectors with IoT capabilities are transforming how you monitor and manage systems. These connectors enable real-time insights into operational status, which enhances efficiency and reliability. In renewable energy and electric vehicle charging, smart connectors support predictive maintenance and remote diagnostics.

Connectors now use advanced materials and designs to withstand harsh environments. You see miniaturization, making connectors smaller and lighter for compact electronic assemblies. Ruggedness and reliability remain top priorities, especially in aerospace and industrial automation. The table below highlights key trends shaping connector technology:

| Emerging Trend | Description | Supporting Impact |

|---|---|---|

| Miniaturization | Smaller, lighter connectors for compact assemblies. | Enables integration in aerospace, automotive, and telecom. |

| Ruggedness and Reliability | Designed for harsh environments with extreme conditions. | 61% of engineers prioritize high-reliability connectors. |

| Increased Current Density | Higher current in smaller footprints. | Supports efficient power delivery in advanced applications. |

| Advanced Materials | New alloys and coatings for better conductivity and durability. | Meets ecological standards and operates in challenging environments. |

| Digital Transformation | Use of AI, online configurators, and 3D printing in design. | Over half of specifiers use digital tools, improving speed and accuracy. |

You benefit from these trends as they support smarter, more sustainable, and resilient infrastructures.

Impact of Connector Interfaces on Data Integration

Automation and Workflow Efficiency

You gain significant advantages in automation and workflow efficiency through modern connector interfaces. Application connectors now support real-time monitoring, control, and predictive maintenance. These features reduce manual intervention and streamline operations. You can automate data flows between applications, which improves accuracy and reduces errors. In cloud application integration, you use application connectors to synchronize data across platforms, ensuring that your workflows remain efficient and scalable.

Digital transformation accelerates as you adopt connectors that support advanced communication protocols. You can leverage AI-driven insights to optimize processes and respond quickly to changing business needs. This approach allows you to focus on higher-value tasks while connectors handle routine data integration.

Enhanced User Experience and System Interoperability

You experience a better user interface and improved system interoperability with the latest connector technologies. Application connectors bridge gaps between diverse applications, making it easier to share data and insights. You no longer need to worry about compatibility issues, as vendor-neutral and adaptive connectors support a wide range of devices and platforms.

Digital transformation continues to drive the development of connectors that enhance user experience. You receive real-time insights, which help you make informed decisions and improve service delivery. As connectors become smarter and more adaptive, you benefit from seamless integration and a unified experience across all your applications.

Tip: Stay updated on connector innovations to maximize your system’s interoperability and gain actionable insights from your data.

Connector interfaces give you a standardized way to connect systems, making integration seamless and efficient. You benefit from connectors that handle data transformation, mapping, and secure communication, which reduces complexity and manual work.

- Choose and implement connectors carefully to ensure long-term compatibility and security.

- Manage and update your connectors regularly to adapt to new business needs.

- Prioritize connector compatibility in every integration project to support scalability and operational efficiency.

By focusing on robust connector strategies, you set your systems up for reliable growth and success.

FAQ

What is a connector interface?

A connector interface provides a defined point where two systems or devices connect. You use it to enable communication, data transfer, or power delivery between different components. This interface ensures compatibility and reliable operation across various platforms.

How do connector interfaces improve system compatibility?

Connector interfaces standardize connections. You benefit from easier integration, reduced errors, and faster deployment. By following industry standards, you ensure that devices from different manufacturers work together without custom modifications.

What types of connector interfaces exist?

You encounter physical connectors (electrical, fiber optic, mechanical) and digital interfaces (APIs, protocol-based connectors, middleware). Each type serves specific integration needs. The table below summarizes common types:

| Type | Example |

|---|---|

| Electrical | USB, IEC 60309 |

| Fiber Optic | LC, SC |

| Digital | REST API, SOAP |

Why is standardization important in connector interfaces?

Standardization ensures that you can connect devices from different vendors. It reduces compatibility issues and simplifies maintenance. You also gain flexibility to upgrade or expand your systems without major redesigns.

How do you select the right connector interface for your project?

You should assess your system’s requirements, including performance, environment, and scalability. Review industry standards and future-proofing needs. Always test connectors in real-world conditions before full deployment.

Can you integrate legacy systems with modern connectors?

Yes, you can use adapters, middleware, or custom connectors to bridge legacy and modern systems. This approach allows you to extend the life of older equipment while benefiting from new technologies.

What security measures should you consider for connector interfaces?

You must use encryption, authentication, and access controls to protect data. Regularly update firmware and monitor for vulnerabilities. Secure connector interfaces help you maintain data integrity and prevent unauthorized access.

How do wireless connector interfaces differ from traditional connectors?

Wireless connectors eliminate physical cables. You gain flexibility and easier installation. However, you must address potential security risks and ensure reliable wireless communication through proper protocols and encryption.

Tip: Always document your connector choices and integration process. This practice helps you troubleshoot issues and supports future upgrades.