D38999 connectors provide high-density connectivity and robust security for mission-critical military systems. Defense modernization programs in North America, Europe, and Asia Pacific consistently select d38999 for demanding applications, including avionics, ground vehicles, shipboard systems, and missile guidance. The mil-dtl-38999 connectors meet strict military standards, offering unique performance benefits such as EMI/RFI shielding, scoop-proof design, and resistance to vibration, shock, and moisture. These attributes ensure reliable operation in harsh environments. Connector factory specialists also produce compatible solutions, including M8 connector and Type B connector options, to address diverse military and demanding applications where mil-dtl-38999 and d38999 connectors excel.

High-Density Connectivity with D38999 Connectors

Maximizing Contact Density in mil-dtl-38999 connectors

Contact arrangements and pin counts for space optimization

Military systems demand compact, efficient wiring solutions. D38999 connectors deliver the highest contact density among common military circular connector types. Engineers select mil-dtl-38999 connectors for new designs because these connectors offer more electrical contacts in a smaller footprint than older standards like MIL-DTL-5015 or MIL-DTL-26482. This advantage allows system designers to maximize the number of connections in limited spaces, which is essential for advanced military electronics. The miniature, high-density circular connectors support a wide range of contact arrangements and pin counts. This flexibility enables precise matching of connector layouts to the specific requirements of each application.

Space-saving design for complex military wiring

Space constraints often challenge military platforms such as aircraft, ground vehicles, and naval systems. D38999 connectors address these challenges with a compact, lightweight design. The reduced size and weight of these connectors, compared to previous generations, allow for more efficient use of available space. Designers can route complex wiring harnesses through tight compartments without sacrificing performance or reliability. The high-density circular connectors help reduce overall system weight, which is critical for airborne and mobile applications. This space-saving approach supports the integration of more sensors, controls, and communication devices within the same platform.

Supporting Advanced Military Electronics with d38999 connectors

Integration with avionics, communications, and control systems

D38999 connectors play a vital role in integrating advanced electronics across military platforms. Their high-density contact arrangements and robust construction enable reliable connections for avionics, sensor arrays, and communication networks. The connectors’ EMI/RFI shielding protects sensitive signals from interference, which is crucial for electronic warfare and secure communications. Environmental sealing features, such as hermetic seals and gaskets, ensure durability in harsh conditions. These attributes make mil-dtl-38999 connectors the preferred choice for mission-critical systems in air, land, sea, and space environments.

Tip: Selecting the right circular connector with high-density contacts can significantly improve system performance and reliability in demanding military applications.

Modular configurations for scalable military applications

The modular design of d38999 connectors supports scalable solutions for evolving military needs. Engineers can choose from a variety of shell sizes, contact layouts, and coupling mechanisms to match each application’s requirements. This flexibility allows for easy upgrades and system expansions without major redesigns. The table below highlights key features that support advanced military electronics integration:

| Feature/Aspect | Description |

|---|---|

| Size and Weight Improvements | 30-50% smaller and lighter than previous MIL-C-5015 connectors, ideal for space-constrained platforms. |

| High-Density Contact Arrangements | Supports more connections in less space, enabling advanced avionics and sensor integration. |

| EMI/RFI Shielding | Reduces electromagnetic interference, protecting sensitive military signals. |

| Environmental Sealing | Hermetic seals and gaskets protect against moisture, dust, and contaminants. |

| Material and Durability | Corrosion-resistant materials ensure longevity in severe environments. |

D38999 connectors provide the scalability and reliability required for modern military electronics. Their modularity and robust features make them indispensable for a wide range of military applications.

Technical Specifications of D38999 and Mil-Spec Connectors

Physical Dimensions and Form Factors of mil-dtl-38999 connectors

Shell sizes, layout options, and miniature circular formats

D38999 connectors offer a wide range of physical dimensions to meet diverse military requirements. Engineers can select from multiple shell sizes, ranging from size 8 to size 24. Larger numbers indicate bigger connectors, which accommodate more contacts or higher power needs. The connectors come in several shell styles, including standard, hermetic, and bayonet types. Each style supports different operational needs, such as rapid disconnect or full environmental sealing.

The table below summarizes the standard form factors and layout options for these military specification connectors:

| Aspect | Details |

|---|---|

| Shell Sizes | Range from 8 to 24, with larger numbers indicating bigger connectors. |

| Shell Styles | Standard (common design), Hermetic (fully sealed), Bayonet (quick-disconnect) |

| Contact Arrangements | Single-row, double-row, mixed-row configurations depending on connector type and application |

| Mounting Styles | Panel Mount (secured to panel), Bulkhead Mount (through bulkhead), Cable Mount (cable clamp) |

| Series Overview | Series I: Bayonet, scoop-proof, aluminum alloy shell Series II: Bayonet, low-profile, metal shell Series III: Threaded coupling, scoop-proof, metal/composite shell Series IV: Breech-lock, rapid connect/disconnect, metal shell |

Miniature circular connector formats allow for high-density wiring in compact spaces. These circular connectors support advanced military electronics where space and weight savings are critical.

Panel mounting and mating interfaces for secure connections

Panel mounting options provide secure attachment to equipment enclosures or bulkheads. D38999 connectors support panel mount, bulkhead mount, and cable mount configurations. These mounting styles ensure stable connections even under vibration or mechanical stress. Mating interfaces use bayonet, threaded, or breech-lock mechanisms. These features prevent accidental disconnection and maintain electrical integrity during operation. The robust design of these connectors supports high-performance requirements in military and aerospace systems.

Electrical Performance of d38999 connectors

Voltage, current ratings, and signal integrity

D38999 connectors deliver reliable electrical performance for power, signal, and data transmission. The connectors support a wide range of voltage and current ratings, depending on the contact technology and application. The table below highlights typical electrical parameters:

| Parameter | Value Range / Description |

|---|---|

| Voltage Ratings | 300 to 900 AC (RMS) volts depending on service rating (M, N, I, II) |

| 450 to 1250 DC volts depending on service rating | |

| Current Ratings | Up to 150A for size 0 crimp contacts in standard connectors |

| High Power Contacts | Up to 250A per contact using RadSok technology |

| Up to 220A per contact using Temper-Grip contacts |

Contact technologies such as RadSok and Temper-Grip enable high current handling, up to 250A per contact. Gold or silver plating options further enhance durability and conductivity. These connector specifications ensure safe operation in high-power military systems.

Signal integrity remains a top priority in military environments. D38999 connectors use advanced EMI and RFI shielding to protect sensitive signals. Series III connectors feature self-locking threaded coupling and scoop-proof design, which maintain contact integrity even under vibration. The connectors support high-frequency performance up to Ka-Band, minimizing signal loss and ensuring reliable communication.

Data transmission capabilities in military environments

D38999 connectors support complex data transmission needs in modern military platforms. High contact density allows for simultaneous transmission of multiple signal types, including power, analog, and digital data. The connectors maintain low insertion loss, stable impedance, and minimal attenuation, which are essential for high-speed data links. EMI/RFI shielding provides up to 65dB protection at 10GHz, ensuring data security and signal clarity.

Key features supporting data transmission include:

- High-frequency performance for advanced communication systems

- Multi-signal management for mixed power and data applications

- Mechanical locking to prevent accidental disconnection

- Customizable contact arrangements for specific system requirements

These features make d38999 connectors ideal for avionics, robotics, and other high-performance military applications.

Environmental Resistance in mil-spec connectors

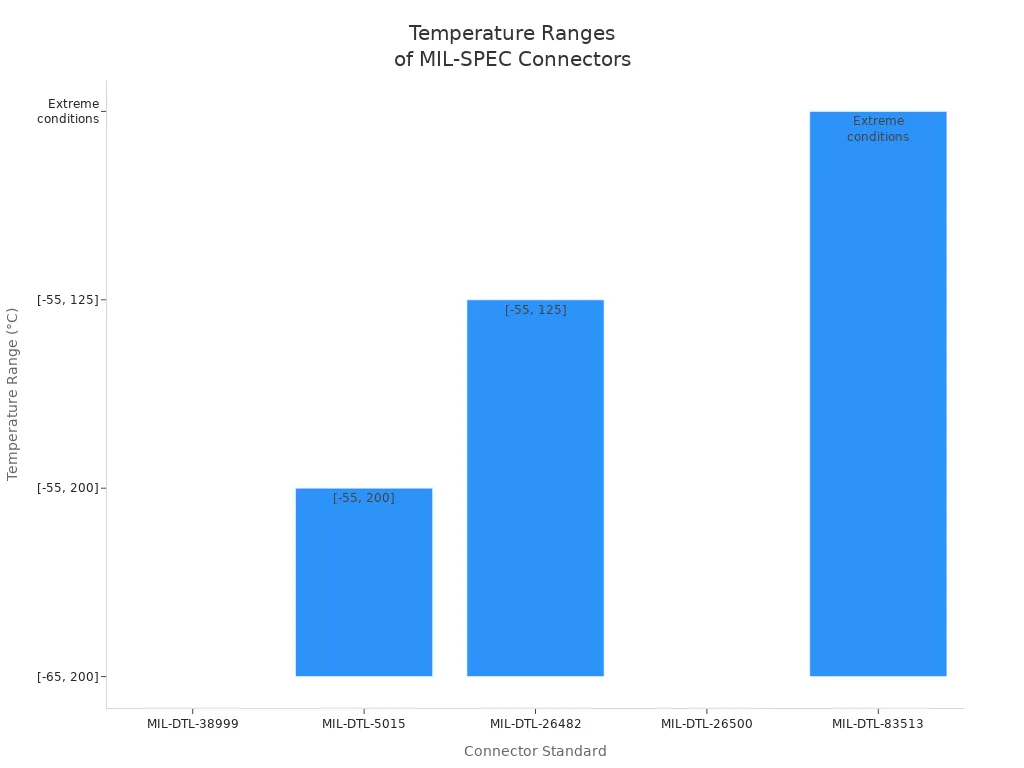

Temperature range, thermal stability, and vibration resistance

Mil-spec connectors must withstand extreme environmental conditions. D38999 connectors operate reliably across a wide temperature range, from -65°C to +200°C. This broad range supports deployment in arctic, desert, and high-altitude environments. Thermally stable contact materials and high-performance insulators maintain connector performance under rapid temperature changes.

The chart below compares temperature ranges for several MIL-spec connector standards:

Vibration resistance is another critical requirement. D38999 connectors use secure coupling mechanisms, such as threaded or bayonet couplings, anti-rotation keying, and vibration-dampening materials. These features prevent loosening and maintain electrical contact during continuous vibration or shock. The connectors meet or exceed MIL-STD-810G for shock and vibration resistance, making them suitable for aircraft, ground vehicles, and naval systems.

Corrosion protection and moisture sealing

Corrosion resistance ensures long-term reliability in harsh environments. D38999 connectors use materials such as stainless steel, nickel-plated aluminum, and cadmium plating. Sealing gaskets and O-rings protect internal contacts from moisture, dust, and chemical exposure. The connectors achieve waterproof ratings up to IP67 or IP68, supporting operation in wet or submerged conditions.

The table below summarizes environmental resistance features for key MIL-spec connectors:

| MIL-SPEC Connector Standard | Temperature Range | Coupling Mechanism | Vibration Resistance Features | Additional Environmental Resistances |

|---|---|---|---|---|

| MIL-DTL-38999 | -65°C to +200°C | Bayonet, Threaded, Breech Lok | Excellent vibration resistance; anti-rotation keying; vibration-dampening materials | Waterproof (IP67/IP68), corrosion resistant, shock resistant |

| MIL-DTL-5015 | -55°C to +200°C | Threaded or Bayonet | Threaded coupling prevents loosening under vibration | Waterproof, shock resistant, corrosion resistant |

| MIL-DTL-26482 | -55°C to +125°C | 3-lug Bayonet | Quick-disconnect with hermetic sealing options | Waterproof, corrosion resistant |

| MIL-DTL-26500 | -65°C to +200°C | Bayonet or Threaded | Designed for fluid resistance and vibration | Waterproof, corrosion resistant |

| MIL-DTL-83513 | Extreme conditions | Crimp/Solder, Polarized rectangular | Shock and vibration resistant; high-density inserts | Lightweight, corrosion resistant |

These environment-resistant electrical connectors provide robust protection against salt fog, chemicals, and mechanical impacts. Their resistance to harsh environments ensures reliable operation in the most demanding military applications.

Note: Selecting connectors with proper environmental resistance and electrical performance is essential for mission success in military systems.

Materials and Plating in mil-dtl-38999 connectors

Shell materials: aluminum, stainless steel, composite

Engineers select shell materials for mil-dtl-38999 connectors based on the need for strength, weight savings, and environmental resistance. High-strength aluminum alloys remain the most common choice for military applications. Aluminum shells offer a balance of lightweight construction and mechanical strength, making them ideal for airborne and mobile platforms. Stainless steel shells provide enhanced resistance to corrosion and mechanical wear. These shells perform well in marine or chemical-rich environments where exposure to salt spray or harsh substances is likely. Composite materials have gained popularity in recent years. They deliver significant weight reduction while maintaining high performance. Composite shells also resist corrosion and do not conduct electricity, which can help prevent galvanic corrosion in mixed-material assemblies.

The table below summarizes the main shell materials and their typical applications in mil-spec connectors:

| Shell Material | Key Properties | Typical Use Cases |

|---|---|---|

| Aluminum Alloy | Lightweight, strong, corrosion-resistant | Aircraft, ground vehicles, general military |

| Stainless Steel | High corrosion resistance, strong | Naval, marine, chemical environments |

| Composite | Lightweight, non-conductive, corrosion-resistant | Weight-sensitive and high-performance systems |

Note: The choice of shell material directly affects the connector’s weight, corrosion resistance, and suitability for specific military environments.

Plating options for enhanced durability and longevity

Plating plays a critical role in extending the service life of mil-dtl-38999 connectors. Manufacturers apply specialized platings to both shells and contacts to protect against corrosion, wear, and electrical degradation. Traditional cadmium plating provided excellent corrosion resistance but raised environmental and safety concerns. Modern mil-spec connectors now use RoHS compliant, hexavalent chromium-free, alternate-to-cadmium plating options. These platings meet strict environmental standards while maintaining high performance.

Contact surfaces use copper alloys plated with gold or silver. Gold plating ensures low contact resistance and high conductivity, which is essential for reliable signal transmission. Silver plating offers a cost-effective alternative with good electrical properties. Insulators within the connector use high-quality plastics or ceramics, providing electrical isolation and environmental protection.

The following table outlines the materials and plating options found in mil-dtl-38999 connectors:

| Component | Materials Used | Plating Options and Purpose |

|---|---|---|

| Shell | Aluminum, stainless steel, composite | Corrosion-resistant platings, RoHS compliant, alternate-to-cadmium |

| Contacts | Copper alloys | Gold or silver plating for conductivity and low resistance |

| Insulators | Plastics, ceramics | Provide electrical isolation and protection |

These material and plating choices help mil-spec connectors resist temperature extremes, vibration, shock, humidity, salt spray, and fungus. The result is a rugged and durable connector that meets the demanding specifications of military environments. Engineers rely on these features to ensure long-term reliability and performance in mission-critical systems.

Tip: Always review connector specifications to confirm the plating type and shell material match the intended application. This step helps maximize durability and operational life.

Comparing the Four Series of D38999 Connectors

The D38999 connector series offers tailored solutions for military and aerospace applications. Each series features unique coupling mechanisms and design attributes that address specific operational challenges. Understanding the distinctions among these connector series helps engineers select the optimal solution for their mission requirements.

| Series | Coupling Mechanism | Shell Size Range | Key Performance Features |

|---|---|---|---|

| Series I | Bayonet | #9 to 25 | High-density, high performance for military/aerospace; widely used in harsh environments |

| Series II | Bayonet (miniature) | #8 to 24 | Low-profile shells; EMI shielding; excellent shock, vibration, and fluid ingress resistance |

| Series III | Threaded | #9 to 25 | High reliability; withstands high vibration (44g), high temperature (up to 200°C); 500 mating cycles |

| Series IV | Breech-lock | N/A | Designed for rapid mating; specialized coupling for quick connect/disconnect |

This table highlights the fundamental differences in coupling types and performance attributes across the connector series.

Series I D38999: Bayonet Coupling Mechanism

Quick connect/disconnect and vibration resistance

Series I connectors use a bayonet coupling mechanism that delivers high vibration resistance. The bayonet system prevents rotation, ensuring secure connections even in harsh conditions. Engineers value the scoop-proof design, which protects contacts during mating. The bayonet coupling supports blind mating and enables fast disconnection, critical for rapid deployment and maintenance in military operations.

- High vibration resistance ensures stable connections.

- Scoop-proof design prevents contact damage.

- Fast disconnect supports efficient field operations.

- Bayonet coupling allows secure, blind mating in confined areas.

Field-deployable military system applications

Series I connectors excel in environments with heavy wind and moisture. Their robust construction and reliable coupling make them ideal for field-deployable military systems. Solder contacts maintain electrical integrity under demanding conditions, supporting mission-critical equipment in land, air, and sea platforms.

Series II D38999: Solder and Crimp Contacts

Low-profile design for tight military spaces

Series II connectors feature a miniature bayonet coupling and a low-profile shell. This design achieves up to 20% reduction in mated pair length and up to 39% reduction in outside diameter compared to Series I. Weight decreases by up to 40% for a 128-pin mated pair. Thinner shell walls and length restrictions enable these reductions, meeting military requirements for space-constrained installations.

- Lightweight, space-saving design fits confined spaces.

- High-density contact arrangements with smaller dimensions.

- Quick positive coupling system streamlines installation.

- Hermetic sealing ensures reliable performance in harsh environments.

Use in airborne and naval platforms

The compact size and reduced weight of Series II connectors make them suitable for airborne and naval platforms. Engineers integrate these connectors into tight compartments without sacrificing functionality. The design supports efficient wiring and reliable operation in environments exposed to vibration, shock, and fluid ingress.

Series III D38999: Triple-Start Thread Coupling

High vibration resistance and scoop-proof design

Series III connectors utilize a triple-start threaded coupling mechanism. This design enables fast mating and secure connections, providing robust mechanical engagement that resists loosening under vibration. The scoop-proof feature enhances reliability, protecting contacts during harsh conditions.

- Triple-start thread coupling resists vibration-induced loosening.

- Fast mating supports efficient maintenance.

- Scoop-proof design ensures contact safety.

- Meets stringent aerospace specifications for reliability.

Enhanced safety for severe environments

Series III connectors withstand high vibration (up to 44g) and high temperatures (up to 200°C). The design supports up to 500 mating cycles, making it suitable for severe military environments. Engineers rely on this connector series for applications demanding maximum reliability and safety.

Series IV D38999: Push-Pull Coupling

Fast mating/unmating for rapid deployment

Series IV D38999 connectors feature a Breech-Lok push-pull coupling mechanism designed for speed and reliability. The mechanism secures the connection with a simple one-fourth turn, allowing personnel to achieve rapid mating and unmating in the field. This design supports blind mating, which means users can connect components without precise visual alignment. The push-pull system proves especially valuable during urgent deployments, where every second counts.

- Breech-Lok coupling requires only a quarter turn for secure engagement.

- Lightweight construction reduces fatigue during installation.

- Non-slip grip ensures safe handling in wet or windy conditions.

- High vibration resistance maintains connection integrity in mobile platforms.

- Blind mating capability streamlines assembly in low-visibility environments.

The connector series also provides 360° EMI/RFI shielding, a wide operating temperature range from -65°C to 200°C, and robust shell finishes. These features enable Series IV connectors to perform reliably in harsh climates and demanding operational scenarios.

Note: Fast and secure connections are essential for military teams working under pressure. The push-pull coupling mechanism in Series IV D38999 connectors supports rapid deployment and minimizes downtime.

Specialized military use cases

Series IV D38999 connectors serve specialized roles in military operations. Their rapid connect/disconnect capability suits applications where equipment must be deployed or reconfigured quickly. Personnel use these connectors in mobile command centers, field communication systems, and emergency power distribution units. The high vibration resistance and environmental sealing make them ideal for platforms exposed to shock, moisture, and dust.

Military engineers select Series IV connectors for systems that require frequent maintenance or rapid replacement. The lightweight and compact design supports integration into portable devices and tactical gear. The connector series meets stringent requirements for reliability, ensuring mission-critical systems remain operational in unpredictable conditions.

Series Selection Guide for mil-dtl-38999 connectors

Comparing coupling mechanisms and density

Selecting the right connector series involves evaluating coupling mechanisms and contact density. Engineers compare bayonet, threaded, and push-pull couplings to determine which best suits the operational environment. Bayonet and threaded couplings offer high vibration resistance and secure locking, while push-pull mechanisms provide unmatched speed for rapid deployment.

| Coupling Mechanism | Speed of Mating | Vibration Resistance | Suitable Applications |

|---|---|---|---|

| Bayonet | Moderate | High | Aircraft, ground vehicles |

| Threaded | Slow | Very High | Aerospace, severe vibration |

| Push-Pull (Breech-Lok) | Fast | High | Rapid deployment, field use |

Contact density also influences selection. High-density arrangements allow more signals in a compact footprint, which is critical for advanced electronics and space-constrained platforms.

Environmental suitability for military scenarios

Environmental factors play a key role in connector series selection. Engineers assess temperature extremes, humidity, vibration, and exposure to chemicals. Connectors with robust construction and corrosion-resistant materials, such as aluminum or stainless steel shells, perform well in harsh environments. Sealing methods like grommet seals and O-rings protect against moisture and dust.

Military standards, including MIL-DTL-38999, ensure connectors meet stringent requirements for reliability and interoperability. Engineers verify certifications such as ISO 9001 and AS9100 to confirm quality control. Application-specific needs, such as high pin count, modularity, and data transmission speed, guide the final choice.

Tip: Always match the connector series to the operational demands and environmental conditions of the intended military application. This approach maximizes reliability and system performance.

Security and Reliability Features of D38999 Connectors

Scoop-Proof Design in mil-spec connectors

Preventing contact damage during mating

Military operations often require fast, reliable connections in challenging conditions. The scoop-proof design in mil-spec connectors addresses this need by using a long shell that physically shields the pins during the mating process. This feature prevents accidental bending or damage to the contacts, even when users connect components by touch without visual guidance. Alignment keys and scoop-proof pins minimize workmanship errors, allowing personnel to mate connectors quickly and confidently. In MIL-DTL-38999 Series III connectors, the 100% scoop-proof design not only protects the pins but also enhances interfacial sealing. This improvement maintains connector integrity in severe environments, supporting high reliability in mission-critical systems.

Safe handling in field operations

Field operations demand connectors that withstand rough handling and unpredictable conditions. The scoop-proof construction ensures that grounding between the plug and receptacle occurs before the pins and sockets engage. This sequence increases both durability and safety, reducing the risk of electrical faults. Soldiers and technicians can handle mil-spec connectors with confidence, knowing that the design protects sensitive contacts from damage during rapid deployment or maintenance.

EMI/RFI Shielding in d38999 connectors

Protecting sensitive military signals from interference

Modern military systems rely on secure, interference-free communication. D38999 connectors incorporate advanced EMI/RFI shielding mechanisms to protect sensitive signals from electromagnetic and radio frequency interference. These connectors integrate capacitive and ferrite filtering elements, which suppress high-frequency noise and maintain signal integrity. By preventing EMI/RFI issues caused by poorly routed cables or non-filtered connectors, mil-dtl-38999 connectors help ensure consistent system performance in demanding environments.

Shielding materials and construction details

Manufacturers use several techniques to enhance EMI/RFI protection in mil-spec connectors:

- Filtered connectors with individual pin filtering and built-in ground plane barriers suppress high-frequency noise and surge spikes.

- Chip-on-Flex technology integrates flexible circuits with chip capacitors, providing high-frequency filtering and transient voltage surge protection.

- Shielding materials such as copper, silver, and nickel coatings, along with plating options like black zinc nickel, improve EMI/RFI protection and corrosion resistance.

- 360° shielding features, EMI springs, and conductive O-rings further boost shielding effectiveness.

These construction details set MIL-DTL-38999 connectors as a benchmark for high-performance military applications, offering unparalleled protection for critical data and control signals.

Environmental Sealing in mil-dtl-38999 connectors

IP ratings, sealing gaskets, and moisture resistance

Environmental sealing remains a core requirement for mil-spec connectors in military and aerospace settings. MIL-DTL-38999 connectors deliver superior sealing, including hermetic options for the most demanding applications. While explicit IP ratings like IP65 are not always specified, certain hermetically sealed versions meet or exceed these standards. Sealing gaskets and O-rings provide resistance to moisture, fuels, hydraulic fluids, and contaminants. Some variants withstand prolonged immersion without loss of integrity, ensuring reliable operation in wet or submerged conditions.

Protection against dust, chemicals, and humidity

The robust sealing features of mil-dtl-38999 connectors protect against dust, chemicals, and humidity. These connectors outperform older standards, such as MIL-DTL-5015, by offering advanced sealing suited for harsh environments. The combination of durable materials and effective sealing accessories ensures long-term reliability and performance, even when exposed to extreme weather or corrosive substances.

Note: Selecting connectors with proven environmental sealing and EMI/RFI protection is essential for maintaining system reliability in military operations.

Mechanical Integrity of mil-spec connectors

Locking mechanisms and retention features

Mechanical integrity stands as a defining characteristic of mil-spec connectors. Engineers design these connectors with secure locking mechanisms to ensure stable connections in the most demanding military environments. Threaded, bayonet, and breech-lock couplings each provide unique advantages. Threaded couplings deliver maximum resistance to vibration, while bayonet systems allow for quick and reliable engagement. Breech-lock mechanisms enable rapid connect and disconnect, supporting field operations where speed is essential.

Retention features further enhance connector performance. Precision-machined cylindrical shells, often made from aluminum alloy, stainless steel, or advanced composites, provide structural strength and 360-degree environmental sealing. Protective finishes such as olive drab chromate over cadmium or electroless nickel resist corrosion and extend service life. Dielectric inserts, crafted from robust materials, insulate contacts and withstand chemical and temperature extremes. Gold-plated contacts maintain low resistance and prevent corrosion, ensuring consistent electrical performance.

Tip: Secure coupling mechanisms and retention features help prevent accidental disconnects, even during intense vibration or shock.

Endurance under repeated military use

Mil-spec connectors must endure thousands of mating and unmating cycles without loss of performance. Manufacturers rate these connectors for 500 to 5,000 cycles, depending on the series and application. High-grade metals such as aluminum, stainless steel, and composites provide superior structural integrity, allowing connectors to withstand repeated use in harsh conditions.

A typical mil-spec connector includes the following endurance features:

- Rugged construction using high-strength materials for long-term durability.

- Advanced sealing technologies that protect against dust, moisture, and chemicals.

- Corrosion-resistant coatings, including cadmium plating and anodized finishes, to extend lifespan.

- Temperature ratings from -55°C to +200°C, supporting reliable operation in extreme climates.

- Gold-plated contacts that preserve signal integrity and prevent electrical degradation.

- EMI/RFI shielding to maintain performance in environments with electromagnetic interference.

These features ensure that mil-spec connectors deliver consistent reliability throughout their operational life. Military systems depend on this endurance to maintain mission readiness and reduce maintenance needs.

Selecting the Right D38999 Connector for Military Applications

Application-Specific Requirements for mil-dtl-38999 connectors

Matching connector series to system needs

Selecting the correct mil-dtl-38999 connector for military systems requires a careful evaluation of the application’s unique demands. Engineers must consider several factors to ensure optimal performance and reliability. The following ordered list outlines the most important requirements:

- Mechanical and Environmental Performance: Evaluate vibration resistance, shock tolerance, ingress protection, and operating temperature range. Material selection, such as aluminum, stainless steel, or composite, ensures durability in harsh environment use.

- Shell Size and Insert Arrangement: Choose the appropriate shell size, typically ranging from Size 9 to 25, and select an insert layout that matches the electrical contact requirements and mechanical fit of the system.

- Electrical Performance and Protocol Compatibility: Confirm support for high-speed digital protocols, including USB 3.x, PCIe, SATA, Ethernet, and HDMI. Impedance-matched differential pairs and low skew/jitter are essential for signal integrity.

- EMI Shielding and Grounding: Opt for connectors with 360-degree EMI shielding, such as Series III shells, and consider additional internal shielding to maintain signal integrity in environments with high electromagnetic noise.

- Mating Cycles and Maintenance Durability: Select connectors rated for a high number of mating cycles. Durable contact plating and robust coupling mechanisms help withstand frequent maintenance.

- Customization and Hybrid Layouts: For complex applications, consider hybrid configurations that combine power, signal, RF coax, or fiber optics within a single connector.

By aligning these requirements with the intended application, engineers can ensure that the chosen d38999 connector meets both operational and mil-spec requirements.

Contact arrangements for power, signal, and data

Military systems often require connectors that handle multiple types of circuits. D38999 connectors offer a wide range of contact arrangements, supporting power, signal, and data transmission within a single interface. Engineers can select layouts that optimize the number of contacts for each function, ensuring efficient use of space and reliable performance. Hybrid layouts allow for the integration of power and high-speed data lines, which is critical for modern military electronics. This flexibility supports diverse applications, from avionics to ground vehicles, where compact and efficient wiring is essential.

Tip: Matching the contact arrangement to the system’s power, signal, and data needs improves reliability and simplifies maintenance.

Environmental and Operational Considerations for d38999 connectors

Assessing exposure to harsh military conditions

Military deployments expose connectors to extreme environments. D38999 connectors must operate reliably in conditions that include wide temperature swings, high humidity, and exposure to chemicals. The following table summarizes key environmental and operational factors that impact connector performance:

| Factor Type | Specific Factors / Tests | Description / Impact on Connectors |

|---|---|---|

| Environmental Factors | Temperature extremes | Connectors must operate reliably across extreme temperature ranges. |

| Environmental sealing | Prevents ingress of moisture, dust, and contaminants. | |

| Vibration | Ensures resistance to mechanical vibrations. | |

| Shock | Ensures ability to withstand mechanical shocks. | |

| Rain | Tests resistance to liquid exposure. | |

| Blowing sand and dust | Assesses durability in dusty/sandy environments. | |

| High altitude | Evaluates performance at altitude. | |

| Fungus | Tests susceptibility to fungal growth. | |

| Salt fog | Assesses resistance to salt fog corrosion. | |

| Explosive atmosphere | Examines performance in explosive atmospheres. | |

| Operational Factors | Insert retention | Specifies force needed to insert/remove contacts, ensuring secure connection. |

| Mating and unmating forces | Defines forces for connector coupling and decoupling, balancing reliability and ease of use. | |

| EMI/RFI interference resistance | Connectors must shield against electromagnetic and radio-frequency interference. | |

| Corrosion and chemical exposure resistance | Use of corrosion-resistant materials and coatings is critical. | |

| Maintenance practices | Regular inspection, cleaning, and seal integrity checks are essential for sustained performance. |

D38999 connectors use advanced materials and coatings to resist corrosion, dust, and moisture. Engineers must assess the specific environmental threats present in each application and select connectors that meet or exceed the required protection levels.

Compliance with mil-dtl-38999 standards

Compliance with mil-dtl-38999 standards ensures that connectors meet strict military performance criteria. These standards cover temperature cycling, thermal shock, vibration, and chemical resistance. Testing protocols validate that connectors can withstand peak loads up to 300g, temperature ranges from -65°C to +175°C, and exposure to salt fog or fungus. Engineers should verify that the selected connector series and materials align with the operational environment and mission profile. Regular maintenance, including inspection of seals and cleaning with approved agents, helps maintain compliance and prolongs connector life.

Note: Adhering to mil-dtl-38999 standards is essential for mission-critical reliability in military applications.

Procurement and Lifecycle Support for mil-spec connectors

Sourcing from qualified manufacturers

Reliable performance in military systems depends on sourcing mil-spec connectors from qualified manufacturers. The best practice is to work with suppliers listed on the Qualified Products List (QPL), which ensures compliance with military standards and traceability. Manufacturers such as PEI-Genesis offer both standard and customized mil-dtl-38999 connector solutions, assembled to precise project specifications. Engineers should prioritize suppliers who provide:

- 100% testing of connectors, including RF parameters like VSWR and insertion loss.

- Lot traceability and documentation for quality assurance.

- Rapid delivery options, including in-stock availability and same-day shipping.

- Value-added services, such as custom assembly and technical support.

Using commercial off-the-shelf (COTS) components can also help balance military requirements with cost and availability, especially for rapid prototyping or urgent deployments.

Maintenance and replacement strategies

Long-term reliability of mil-spec connectors depends on effective maintenance and replacement strategies. Regular inspection of seals, cleaning with mild agents, and timely replacement of damaged components prevent moisture ingress and corrosion. Engineers should establish maintenance schedules based on the connector’s rated mating cycles and environmental exposure. Using connectors with high mating cycle ratings and robust materials reduces the frequency of replacements. Proper documentation and inventory management ensure that replacement parts are available when needed, minimizing system downtime.

Tip: Proactive maintenance and sourcing from QPL-approved manufacturers help ensure mission readiness and reduce lifecycle costs for military systems.

Key Military Applications of D38999 and Mil-Spec Connectors

Avionics and Aircraft Systems with d38999 connectors

Flight control, navigation, and communication integration

D38999 connectors play a vital role in modern military aircraft. Engineers rely on these connectors for flight control systems, including mechanical, hydraulic, and fly-by-wire controls. These systems require reliable, high-speed data transmission and strong resistance to electromagnetic interference. D38999 connectors support seamless communication between sensors, actuators, and control units. They also protect critical circuits in landing gear and targeting systems. In avionics, these connectors enable navigation and control subsystems to function under harsh conditions. Their EMI shielding ensures signal integrity, which is essential for mission success. Military communications systems, such as tactical radios and satellite links, also depend on D38999 connectors for secure, interference-free operation.

D38999 connectors help maintain flawless operation in mission-critical flight control and communication systems, even when exposed to vibration, moisture, and extreme temperatures.

High-density wiring in limited aircraft spaces

Aircraft designers face strict space and weight constraints. D38999 connectors offer high-density contact arrangements, allowing more circuits in a smaller footprint. This feature supports the integration of advanced avionics and communication devices without adding unnecessary bulk. The compact design enables efficient routing of wiring harnesses through tight compartments. As a result, military aircraft can accommodate more sensors and electronic systems, improving situational awareness and operational capability.

Ground Vehicles and Tactical Equipment using mil-dtl-38999 connectors

Ruggedized connections for mobile military platforms

Ground vehicles and tactical equipment operate in some of the harshest environments. D38999 connectors meet MIL-DTL-38999 Series III standards, providing rugged and durable connections that withstand vibration, dust, water, and temperature extremes. Their triple-start threaded coupling and anti-decoupling devices ensure secure mating, even during intense movement. Engineers use these connectors with various shell materials and plating options, such as marine bronze or nickel-plated aluminum, to resist corrosion. The connectors’ environmental sealing achieves IP68 protection, keeping out dust and fluids in both mated and unmated states.

Secure data and power transmission in tactical scenarios

Modern tactical systems demand reliable data and power transmission. D38999 connectors support high-speed data rates, including up to 10 Gb/s Ethernet, which is essential for live situational awareness and command systems. Their EMI shielding reduces interference, maintaining clear communication channels. Customization options allow integration of power, signal, and fiber optics within a single connector, increasing versatility for different applications. High mating cycle durability ensures these connectors perform reliably throughout extended missions.

Naval and Marine Platforms with mil-spec connectors

Corrosion-resistant solutions for marine environments

Naval and marine platforms present unique challenges due to constant exposure to saltwater and corrosive elements. Mil-spec connectors address these challenges by using noncorrosive, conductive metals such as gold-plated beryllium copper for contacts and corrosion-resistant aluminum shells. Some designs use marine bronze, which provides extreme corrosion resistance without additional plating. Rigorous salt spray testing ensures these connectors maintain performance in maritime conditions.

Integration with shipboard electronics and systems

Engineers integrate mil-spec connectors into shipboard electronics, propulsion controls, and communication networks. These connectors feature EMI/RFI shielding and scoop-proof shells, protecting sensitive circuits from interference and environmental hazards. Their versatility allows for reliable connections in navigation, weapons control, and power distribution systems. The combination of corrosion resistance and robust construction ensures long-term reliability in demanding marine environments.

Missile and Weapon Systems utilizing d38999 connectors

Reliability under extreme military conditions

Missile and weapon systems operate in some of the most demanding environments found in military applications. D38999 connectors deliver exceptional reliability under these extreme conditions. Their robust construction withstands intense shock, vibration, and electromagnetic interference. Engineers select these connectors for critical roles in ballistic missiles, armored vehicles, and advanced weapon platforms.

- High resistance to shock and vibration ensures stable connections during launch and flight.

- Hermetic style connectors provide sealed protection against air and gas, preventing contamination of sensitive electronics.

- A variety of shell materials, including composite, aluminum, and stainless steel, offer durability and corrosion resistance.

- Secure locking mechanisms with tactile feedback prevent accidental disengagement, even under rapid movement or impact.

- Extensive use in aerospace and defense demonstrates proven performance in real-world scenarios.

The table below highlights key features that support reliability in missile and weapon system environments:

| Feature/Aspect | Description |

|---|---|

| Rugged Design | Withstands shock, vibration, extreme temperatures, moisture, and corrosion |

| Secure Locking Mechanism | Bayonet or threaded coupling ensures secure and quick connection/disconnection |

| Military Standards | Compliance ensures interoperability and reliability across systems |

| Hermetic Sealing | Options available for air and gas resistance, protecting internal contacts |

| Contact Arrangements | Multiple configurations for power, signal, and hybrid use |

| Corrosion Resistance | Materials and construction prevent degradation in harsh environments |

Centaur high-density connectors, a type of D38999, provide high-speed data links essential for missile guidance, targeting, and telemetry. Their rugged design ensures durability under harsh environmental conditions, enabling accurate and timely communication between missile components during flight. This high-bandwidth capability supports rapid and secure data transmission, which is critical for real-time situational awareness and mission success.

Fast deployment and secure operation

Weapon systems require connectors that support both fast deployment and secure operation. D38999 connectors meet these needs through advanced engineering and user-focused design. The locking mechanisms provide a clear tactile “click,” confirming a secure connection. This feature allows personnel to assemble or disassemble systems quickly, even in low-visibility or high-stress situations.

Missile crews and maintenance teams benefit from the following advantages:

- Quick connect and disconnect features reduce setup and maintenance time.

- Secure engagement prevents accidental separation during transport or operation.

- Modular contact arrangements allow integration of power, signal, and data lines within a single connector, streamlining system architecture.

- Hermetic sealing and corrosion-resistant materials extend operational life, reducing the need for frequent replacements.

Note: Reliable connectors like D38999 play a vital role in the success of military missions. Their ability to maintain secure connections under extreme conditions ensures that weapon systems perform as intended, every time.

These qualities make D38999 connectors a trusted choice for a wide range of missile and weapon system applications. Their proven reliability and rapid deployment capabilities help military teams achieve mission objectives with confidence.

D38999 connectors deliver unmatched reliability and high-density performance for military-grade connectivity. Their robust construction, advanced locking mechanisms, and environmental sealing support mission-critical operations in extreme conditions. The table below summarizes key specifications and reliability features:

| Feature | Details |

|---|---|

| Construction | Aluminum, stainless steel, composites; multiple conductive coatings |

| Pin Density | Up to 128 pins; sizes 4 to 22D |

| Environmental Protection | EMI shielding, hermetic sealing, dust, water, and corrosion resistance |

| Temperature Range | -65°C to +200°C |

| Durability | Shock, vibration, and moisture resistant; shovel-proof designs |

Selecting the right d38999 for each mission ensures optimal performance and advances military connectivity.

FAQ

What makes D38999 connectors suitable for military environments?

D38999 connectors use rugged materials, advanced sealing, and EMI/RFI shielding. These features ensure reliable performance in extreme temperatures, vibration, and moisture. Engineers trust these connectors for mission-critical military applications.

How do D38999 connectors prevent accidental contact damage?

The scoop-proof design protects pins during mating. The shell shields contacts, reducing the risk of bending or breaking. This feature supports safe handling in field operations.

Can D38999 connectors support both power and data transmission?

Yes. D38999 connectors offer hybrid layouts. Engineers can combine power, signal, and high-speed data contacts within a single connector. This flexibility supports complex military systems.

What are the main differences between the D38999 series?

| Series | Coupling Mechanism | Key Feature |

|---|---|---|

| Series I | Bayonet | Quick connect |

| Series II | Bayonet (mini) | Low profile |

| Series III | Threaded | High vibration resist |

| Series IV | Push-pull | Rapid deployment |

How do engineers select the right D38999 connector?

Engineers assess application needs, environmental exposure, and required contact arrangements. They match connector series, shell material, and plating to system requirements. Qualified suppliers provide guidance and technical support.

Are D38999 connectors compatible with other mil-spec connectors?

D38999 connectors follow MIL-DTL-38999 standards. They offer compatibility with other connectors built to the same specification. Always verify pin arrangement and shell size before mating different brands.

What maintenance do D38999 connectors require?

Regular inspection, cleaning, and seal checks help maintain performance. Engineers replace damaged contacts or seals as needed. Following manufacturer guidelines extends connector service life.