You often see poor connections when you do not follow best practices for low-pressure waterproof wire connectors. Always remember the importance of using waterproof connectors in any electrical project, especially in wet or outdoor environments. Choosing the right types of waterproof connectors, such as an M8 connector or a Type B connector, prevents unnecessary failures. A Connector factory usually recommends strict attention to detail during installation. Your focus on safety ensures reliable and long-lasting results.

Proper installation protects your investment and keeps your system running smoothly.

Common Mistakes to Avoid with Low-Pressure Waterproof Wire Connectors

Improper Wire Stripping During Installation

Wire stripping stands as one of the most critical steps in preparing for a reliable waterproof connection. You must strip wires cleanly and keep them dry before inserting them into connectors. If you use improper techniques or rush this step, you compromise the integrity of the seal and the performance of your wire connectors.

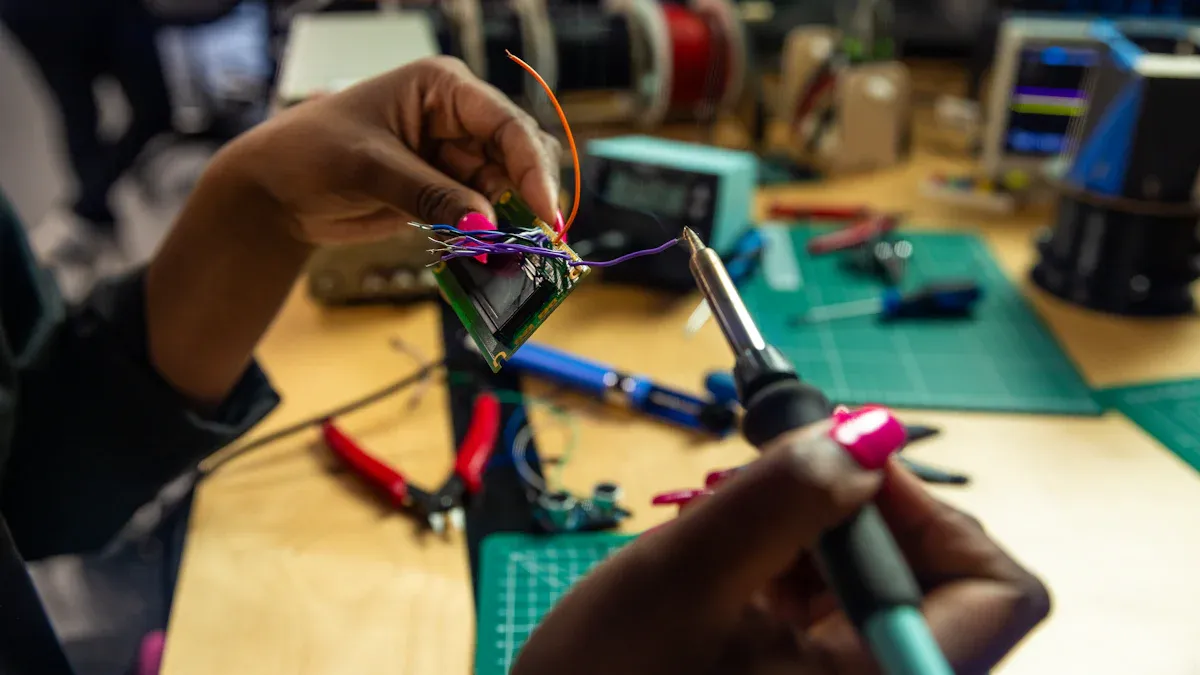

Using the Wrong Tools for Wire Connectors

You should always use tools designed for electrical work when stripping wires. Pliers, knives, or scissors can damage insulation or nick the conductor. This damage weakens the wire and makes it difficult for the connector to form a tight, waterproof seal. A proper wire stripper ensures you remove only the insulation, leaving the conductor intact and ready for a secure connection.

Damaging Wire Conductors in Preparation

When you nick or cut the wire strands during preparation, you reduce the current-carrying capacity and increase the risk of overheating. Damaged conductors also make it harder for the connector to grip the wire, which can lead to loose connections and water ingress. You must inspect each wire after stripping to confirm that the conductor remains undamaged and ready for installation.

Tip:

Proper installation of waterproof connectors is crucial for their effectiveness. Wires must be stripped cleanly and kept dry before connecting to ensure a tight seal. Moisture entering connectors can lead to corrosion, overheating, and fire hazards.

Incorrect Wire Connector Selection

Choosing the right wire connectors for your application ensures both safety and long-term performance. You must match the connector size and type to the wires and the environment.

Mismatched Connector Size for Applications

If you select a connector that is too large or too small for your wires, you risk poor contact and unreliable sealing. Oversized connectors may not grip the wire tightly, while undersized connectors can damage the wire or fail to close properly. Always check the manufacturer’s specifications and match the wire gauge to the connector size.

Using Non-Waterproof Wire Connectors

You must use wire waterproof connectors in any environment where moisture or water exposure is possible. Non-waterproof connectors allow moisture to enter, which can cause corrosion, short circuits, and system failure. Always verify that your connectors carry the appropriate waterproof rating for your application.

Insufficient Sealing in Installation

A waterproof connection depends on a complete and secure seal. You must pay close attention to every step of the sealing process to prevent moisture ingress.

Skipping Sealant Application

Some connectors require the use of a sealant to achieve full waterproofing. If you skip this step, you leave the connection vulnerable to water intrusion. Always follow the manufacturer’s instructions regarding sealant application, especially in outdoor or wet environments.

Incomplete Connector Closure

You must close connectors fully to ensure a reliable seal. If you leave a connector partially open, water can enter and compromise the connection. Double-check each connector after installation to confirm that it is completely closed and locked in place.

Failing to seal connectors properly can result in corrosion, electrical faults, and even fire hazards. You protect your system and prevent moisture ingress by following best practices for sealing.

Over-Tightening or Under-Tightening Wire Connectors

Proper tightening of wire connectors plays a crucial role in achieving a reliable waterproof seal. You must apply the correct amount of torque to each connector. If you over-tighten or under-tighten, you risk compromising both the mechanical and waterproof integrity of the connection.

Stripping Threads During Installation

When you over-tighten wire connectors, you can strip the threads inside the connector body. Stripped threads prevent the connector from closing securely. This issue often leads to gaps that allow moisture to enter, defeating the purpose of using waterproof connectors. You should always follow the manufacturer’s torque specifications. Using a torque screwdriver or wrench helps you avoid excessive force and ensures a consistent, secure fit.

Loose Connections Affecting Waterproofing

Under-tightening creates another set of problems. Loose wire connectors do not grip the wires firmly. This lack of pressure allows water to seep into the connection, increasing the risk of corrosion and electrical faults. You must check each connector after installation. Give a gentle tug on the wires to confirm a snug fit. If you notice any movement, re-tighten the connector until you achieve a solid, waterproof seal.

Tip:

Always use tools designed for your specific connectors. Proper tightening prevents both stripped threads and loose connections, ensuring long-term waterproof performance.

Neglecting Environmental Factors in Applications

You must consider environmental factors when selecting and installing low-pressure waterproof wire connectors. Ignoring these factors can shorten the lifespan of your connectors and compromise safety.

Ignoring Temperature Ratings for Wire Connectors

Temperature extremes can affect the materials used in wire connectors. Some plastics and rubbers become brittle in cold weather. Others may soften or deform in high heat. If you install connectors without checking their temperature ratings, you risk premature failure. Always review the product specifications and choose connectors rated for the expected temperature range in your application.

Overlooking UV Resistance in Outdoor Installation

Outdoor installations expose connectors to sunlight for extended periods. UV radiation can degrade certain plastics, causing them to crack or lose flexibility. This degradation weakens the waterproof barrier and allows moisture to penetrate. You should select connectors made from UV-resistant materials, such as polyamide, for outdoor use. This choice ensures your wire waterproof connectors maintain their integrity and performance over time.

Environmental factors like temperature and UV exposure have a direct impact on the longevity of waterproof connectors. Choosing the right materials protects your electrical connections from harsh conditions and extends the life of your system.

Poor Quality Control in Waterproof Wire Connector Installation

Quality control remains essential for every installation. You must inspect and test each connection to guarantee a reliable, waterproof result.

Failing to Inspect Connections

Skipping inspection after installation can lead to undetected issues. You might miss incomplete closures, damaged wires, or improper sealing. Always perform a visual check on every connector. Look for signs of misalignment, gaps, or exposed conductors. A thorough inspection helps you catch mistakes before they cause problems.

Not Testing for Waterproofing

Testing ensures your connectors deliver the waterproof protection you expect. If you skip this step, you risk hidden leaks that can lead to corrosion or system failure. Use manufacturer-recommended test procedures, such as submersion or spray tests, to verify the waterproof seal. Regular testing gives you confidence in the reliability of your wire connectors.

- Checklist for Quality Control:

- Inspect all connections visually.

- Confirm complete closure of each connector.

- Test for waterproofing as specified by the manufacturer.

- Document your inspection and test results for future reference.

Consistent quality control prevents costly repairs and ensures your waterproof connectors perform as intended in any environment.

Applications of Low-Pressure Waterproof Wire Connectors

Low-pressure waterproof wire connectors serve as essential components in many electrical systems. You rely on these connectors to maintain safe and reliable connections in environments where water or moisture may cause damage. The most common applications of waterproof connectors include:

- Wiring systems exposed to moisture, such as outdoor lighting and irrigation systems in residential areas.

- Outdoor lighting and signage in commercial settings.

- Machinery and equipment in industrial environments that operate in wet conditions.

Outdoor Lighting Installation Best Practices

You often use wire connectors in outdoor lighting because these systems face constant exposure to rain, humidity, and temperature changes. Proper installation ensures your lighting remains functional and safe.

Landscape Lighting Applications

Outdoor landscape lighting requires connectors that can withstand both moisture and soil contact. You should select types of waterproof connectors designed for burial or direct ground contact. These connectors protect your wiring from corrosion and electrical shorts. When you install landscape lighting, always check that each connector forms a tight, waterproof seal. This step prevents water from entering and damaging your system.

Garden and Pathway Lights Installation

Garden and pathway lights create beautiful and safe walkways. You need waterproof wire connectors to keep these lights operating in all weather conditions. Use connectors rated for outdoor use and verify that each connection is fully sealed. This practice helps prevent failures caused by water ingress. For underwater lighting or fixtures near water features, choose connectors specifically rated for submersion.

Tip: Always inspect connectors after installation. A quick check ensures you have a complete seal and reduces the risk of future electrical issues.

Irrigation System Wire Connectors

Irrigation systems present unique challenges because water is always present. You must use waterproof connectors to avoid corrosion and electrical faults.

Sprinkler Control Wiring Applications

Sprinkler control wiring often runs underground or inside valve boxes. You should use low-pressure waterproof wire connectors to protect these connections from constant moisture. Select connectors that match your wire gauge and confirm they are rated for wet locations. This approach keeps your sprinkler system reliable and safe.

Valve Box Connections Installation

Valve boxes house critical wiring for irrigation systems. You need connectors that resist both water and soil contaminants. Always use wire waterproof connectors with proven sealing capabilities. Secure each connection and apply any recommended sealant to ensure long-term protection.

Marine and Boating Applications

Marine environments demand the highest level of waterproof protection. Saltwater, humidity, and constant movement can quickly degrade poor-quality connectors.

Dock Lighting Installation

Dock lighting installations require connectors that can handle splashes, rain, and even brief submersion. Choose connectors with high waterproof ratings and UV resistance. Install each connector according to manufacturer guidelines to maintain a secure, watertight connection.

Bilge Pump Wiring Applications

Bilge pumps play a vital role in keeping boats safe and dry. You must use waterproof connectors that can withstand continuous exposure to water. Select connectors designed for marine use and test each connection for leaks before completing the installation.

Note: In all these common applications of waterproof connectors, you protect your investment and ensure safety by following best practices for installation and inspection.

Automotive and RV Wire Connector Installation

Automotive and RV systems demand reliable waterproof connections. You often encounter harsh conditions, including vibration, dust, and moisture. Using the right connectors ensures your vehicle’s electrical systems remain safe and functional.

Exterior Lighting Applications

Exterior lighting on vehicles faces constant exposure to rain, road spray, and temperature changes. You must select waterproof connectors designed for these environments. Proper installation prevents water from entering and causing corrosion. Always use heat-shrink tubing to seal connections. This step adds an extra layer of protection against moisture. When you install low-pressure waterproof wire connectors, you improve the durability of your lighting applications and reduce the risk of electrical faults.

Trailer Wiring Installation

Trailer wiring presents unique challenges. You connect and disconnect trailers frequently, which increases the risk of loose or damaged connections. To maintain a secure and waterproof seal, follow these best practices:

- Use waterproof connectors for all exposed wiring.

- Apply proper crimping techniques to avoid corrosion and equipment failure.

- Select high-quality materials and tools for enhanced durability.

- Seal connections with heat-shrink tubing to block out moisture and dust.

These steps help you achieve long-lasting performance in your trailer wiring installations.

Residential and Commercial Electrical Applications

You rely on waterproof connectors in many residential and commercial settings. These connectors protect critical systems from water damage and ensure reliable operation.

Outdoor Outlets Installation

Outdoor outlets require special attention. You must use wire connectors rated for outdoor use. Install each connector according to manufacturer instructions to guarantee a waterproof seal. This practice keeps your electrical systems safe during storms and heavy rain. Outdoor lighting also benefits from these connectors, as they prevent short circuits and maintain consistent power delivery.

Security System Wiring Applications

Security systems often include cameras and sensors placed outside. You need waterproof wire connectors to protect these sensitive devices from moisture. Secure each connection and check for a complete seal. This approach prevents false alarms and system failures caused by water ingress.

Specialized Uses for Low-Pressure Waterproof Wire Connectors

Some applications require advanced protection and reliability. You can trust these connectors to perform in demanding environments.

Solar Panel Installations

Solar panel systems operate outdoors year-round. You must use waterproof connectors to protect wiring from rain, snow, and UV exposure. Select connectors with proven sealing capabilities. This choice ensures your solar panels deliver consistent power and remain safe over time.

Temporary Event Wiring Applications

Temporary events, such as outdoor concerts or festivals, often require quick and reliable electrical setups. You should use wire waterproof connectors for all exposed wiring. These connectors provide fast installation and effective waterproofing. After the event, you can disconnect and reuse them for future applications.

Tip: Always inspect connectors before and after use. A quick check helps you catch potential issues and maintain system reliability. 🛠️

Step-by-Step Installation Guide for Low-Pressure Waterproof Wire Connectors

Preparing the Wires for Installation

Measuring and Cutting Wires

You start every successful installation by measuring your wires accurately. Use a tape measure to determine the exact length needed for your application. Cut the wires cleanly with a sharp wire cutter. This step prevents frayed ends and ensures a neat fit inside the connectors. Always double-check your measurements before cutting. A precise cut helps you avoid waste and guarantees a secure connection.

Stripping Insulation Properly

After cutting, you must strip the insulation from each wire. Select a wire stripper that matches your wire gauge. Place the wire in the correct notch and squeeze gently. Remove only enough insulation to expose the conductor for the connector. Avoid nicking or damaging the wire strands. Damaged conductors can weaken the waterproof seal and reduce electrical performance. Inspect each stripped wire to confirm a clean, undamaged surface.

Tip: Keep the exposed conductor as short as possible. This practice reduces the risk of moisture entering the connector.

Selecting the Right Wire Connectors for Applications

Matching Wire Gauge to Connector

Choosing the right waterproof connector for your wire gauge is essential. Check the manufacturer’s specifications for both the wire and the connector. Insert the wire into the connector to verify a snug fit. A mismatch can lead to loose connections or difficulty achieving a waterproof seal. Always use connectors designed for your specific wire size.

Verifying Waterproof Rating for Installation

You must confirm that your connectors have the correct waterproof rating for your installation. Look for ratings such as IP67 or IP68, which indicate strong protection against water and moisture. Never use standard connectors in wet environments. Only select wire waterproof connectors that meet or exceed the requirements for your application. This step ensures long-term reliability and safety.

Assembling the Wire Connector Installation

Inserting Wires Correctly

Insert each wire straight into the connector until it reaches the stop point. Make sure no bare conductor is exposed outside the connector. If your connector uses a screw or clamp, tighten it according to the manufacturer’s instructions. Proper insertion prevents gaps that could allow moisture to enter.

Securing the Connector for Waterproofing

Once you insert the wires, secure the connector tightly. Follow the recommended torque settings to avoid over-tightening or under-tightening. A secure closure creates a reliable waterproof barrier. Double-check that the connector is fully closed and locked. This step is critical for keeping water and contaminants out of your electrical system.

Note: Always follow the manufacturer’s guidelines for installation. Proper assembly protects your system from moisture and extends the life of your low-pressure waterproof wire connectors.

Sealing the Connection for Reliable Installation

Applying Sealant as Needed

You achieve a reliable waterproof seal by applying the correct sealant during installation. Many connectors require a silicone-based or gel sealant to block out moisture. Always check the manufacturer’s instructions before you begin. Apply the sealant evenly around the wire entry points. This step fills any small gaps and prevents water from reaching the conductors. Some connectors come pre-filled with sealant, while others need you to add it manually. Never skip this step if your connectors require it. Proper sealant application increases the lifespan of your electrical connections and reduces the risk of corrosion.

Ensuring Complete Connector Closure

You must close each connector fully to guarantee a waterproof barrier. Incomplete closure leaves gaps that allow water to enter. After inserting the wires, press or twist the connector until you hear or feel a click. Some connectors use a locking mechanism for extra security. Double-check that no part of the conductor is exposed. For added protection, consider using heat shrink tubing over the connector. When heated, this tubing shrinks tightly and forms a second layer of waterproofing. The table below shows common sealing techniques and their advantages:

| Connector Type | Description | Advantages |

|---|---|---|

| Crimp Connectors | Require a crimping tool to secure the connection, often with a waterproof seal. | Easy to use, fast installation, suitable for various wire types, and customizable sizes. |

| Twist-On Wire Connectors | Operate by twisting wire ends together, often with waterproof seals. | Quick installation, accommodates multiple wire sizes, compact design for tight spaces. |

| Heat Shrink Tubing | Used over connections to create a tight seal when heated. | Provides additional waterproofing and protection against environmental factors. |

Tip: Always inspect the connector after closure. A secure fit keeps your system safe from moisture and environmental hazards.

Testing the Waterproof Wire Connector Installation

Visual Inspection of Connections

You should always perform a visual inspection after installation. Look for any exposed conductors or gaps in the connectors. Check that the sealant covers all entry points. Make sure the connector is fully closed and locked. A careful inspection helps you catch mistakes before they cause problems. Use a flashlight to see inside tight spaces.

Waterproofing Test Procedures

After visual checks, you need to test the waterproof integrity of your connectors. Many professionals use a simple spray test. Lightly spray water over the connectors and watch for leaks. For critical installations, submerge the connectors briefly and check for bubbles. If you see any sign of water entry, redo the installation. Testing ensures your connectors provide the protection your system needs.

Note: Regular testing and inspection help you maintain reliable waterproof performance over time.

Finalizing Wire Connector Installation

Organizing Wires for Safety

You improve safety and reliability by organizing wires after installation. Bundle wires neatly using cable ties or clips. Keep connectors off the ground and away from standing water. Arrange wires so they do not pull on the connectors. Good organization prevents accidental damage and makes future maintenance easier.

Documenting Work for Future Maintenance

You should document every installation for future reference. Record the type of connectors used, the date of installation, and any special steps taken. Take photos of the finished work if possible. Store this information in a safe place. Good documentation helps you or other technicians troubleshoot issues and plan maintenance.

Keeping records of your installations saves time and ensures consistent quality in your electrical projects. 📝

Installation Best Practices for Reliable Waterproof Wire Connectors

Use High-Quality Wire Connectors for Applications

Choosing Reputable Brands

You set the foundation for a reliable waterproof connection when you choose reputable brands. Trusted manufacturers design connectors to meet strict industry standards. These brands often test their products for durability and performance in demanding applications. You reduce the risk of premature failure by selecting connectors from established companies. This choice becomes especially important in outdoor lighting and other environments where moisture and weather can threaten your electrical system.

Checking Certification and Ratings

You should always check for certifications and ratings before purchasing connectors. Look for products that meet recognized standards, such as UL or CE. These certifications indicate that the connectors have passed rigorous safety and performance tests. Pay close attention to waterproof ratings like ip65 connectors, ip67 connectors, and ip68 connectors. Each rating offers a different level of protection against water and dust. For example, ip65 connectors resist water jets, ip67 connectors withstand temporary immersion, and ip68 connectors offer continuous submersion protection. Matching the rating to your specific applications ensures your installation can handle the expected conditions.

Tip: Always verify that the connectors you select carry the appropriate waterproof rating for your installation. This step provides peace of mind and long-term protection.

Follow Manufacturer Instructions for Installation

Reading Product Manuals Thoroughly

You gain a clear understanding of the installation process when you read the product manual thoroughly. Manufacturers include detailed steps and important warnings in their manuals. Skipping this information can lead to mistakes that compromise the waterproof seal. Take time to review all instructions before you begin. This habit helps you avoid common errors and ensures you follow installation best practices.

Adhering to Torque Specifications

You achieve a secure and waterproof connection by adhering to the recommended torque specifications. Over-tightening can damage the connector body or strip threads, while under-tightening may leave gaps for moisture to enter. Use a torque screwdriver or wrench if the manufacturer specifies a torque value. This approach guarantees a consistent and reliable seal, especially in outdoor lighting and other critical applications.

Installation tips for waterproof connectors: Always use the correct tools and follow the manufacturer’s torque guidelines. This practice prevents leaks and extends the life of your connectors.

Regular Maintenance and Inspection of Wire Connectors

Scheduled Checks for Waterproofing

You maintain the integrity of your waterproof connectors by performing regular inspections. Routine checks help you identify any wear, damage, or signs of moisture intrusion early. Create a maintenance schedule based on the environment and the critical nature of your applications. For outdoor lighting or irrigation systems, inspect connectors at least once per season. Look for cracks, discoloration, or degraded sealing materials. Replace any damaged components immediately to maintain reliable protection.

- Conduct routine inspections to identify any wear or damage.

- Regularly check sealing materials for signs of degradation.

- Replace any damaged components to maintain reliability.

Addressing Wear and Tear in Applications

You extend the lifespan of your connectors by addressing wear and tear promptly. Environmental factors such as UV exposure, temperature changes, and vibration can degrade waterproof seals over time. When you notice any issues, act quickly to repair or replace affected connectors. This proactive approach prevents small problems from turning into major failures. You keep your electrical systems safe and functional by staying vigilant.

Note: Consistent maintenance and inspection routines ensure your waterproof connectors continue to provide effective protection in all applications.

Troubleshooting Common Issues in Waterproof Wire Connector Installation

Identifying Leaks in Connections

You may encounter leaks in waterproof connectors during installation or routine maintenance. Leaks often occur when you do not seal the connector properly or when the connector body sustains damage. You should inspect each connection visually. Look for signs of moisture, corrosion, or discoloration around the connector. If you see bubbles during a spray or submersion test, you have a leak.

To identify leaks quickly, follow these steps:

- Examine the connector for gaps or cracks.

- Check the sealant coverage at all entry points.

- Perform a waterproof test using a spray bottle or by briefly submerging the connector.

- Watch for water ingress or bubbles.

Tip: You can use a flashlight to inspect connectors in tight spaces. Early detection of leaks helps you prevent electrical faults and maintain protection in high-moisture environments.

Fixing Loose Wire Connectors

Loose wire connectors compromise both waterproof integrity and electrical performance. You may notice movement in the wires or gaps in the connector closure. Loose connections allow moisture to enter, which can lead to corrosion and system failure.

To fix loose connectors:

- Remove the connector and inspect the wire ends for damage.

- Strip the insulation again if needed, ensuring you do not nick the conductor.

- Reinsert the wires into the connector, making sure they fit snugly.

- Tighten the connector according to installation best practices and manufacturer specifications.

- Test the connection for waterproof sealing.

You should always use connectors that match your wire gauge and application requirements. If you continue to experience loose connections, consider switching to ip68 connectors for superior waterproof protection.

Note: Addressing loose connectors promptly ensures safety and reliable operation in all applications.

Safety Precautions During Installation

Power Off Before Installing Wire Connectors

You must always turn off power before you begin installation of waterproof connectors. Working with live electrical systems exposes you to serious risks, including shock and fire. You should verify that the circuit is de-energized using a voltage tester. Lock out and tag out the power source if you work in commercial or industrial applications.

⚡ Always prioritize safety. Turning off power before installation protects you and meets safety standards for electrical work.

Using Personal Protective Equipment

You need to wear personal protective equipment (PPE) during installation. PPE includes insulated gloves, safety glasses, and protective clothing. These items shield you from electrical hazards and accidental contact with sharp tools or exposed wires. You should select PPE that meets industry safety standards for electrical applications.

A simple PPE checklist for waterproof connector installation:

| PPE Item | Purpose | When to Use |

|---|---|---|

| Insulated Gloves | Protects against electric shock | During all installations |

| Safety Glasses | Shields eyes from debris | When stripping or cutting wires |

| Protective Clothing | Prevents skin contact | In high-moisture environments |

Safety considerations are essential for every installation. Proper PPE reduces the risk of injury and ensures compliance with safety standards.

Environmental Considerations for Wire Connector Applications

Protecting Against UV Exposure

You must protect waterproof connectors from UV exposure in outdoor applications. Sunlight can degrade connector materials, causing cracks and loss of flexibility. You should select connectors made from UV-resistant materials for installations exposed to direct sunlight. Polyamide and other engineered plastics offer excellent UV protection.

You can also use protective covers or install connectors in shaded areas. Regularly inspect connectors for signs of UV damage, such as discoloration or brittleness. Replacing damaged connectors maintains waterproof integrity and electrical safety.

Tip: UV-resistant connectors extend the lifespan of your system and reduce maintenance costs in outdoor applications.

Managing Temperature Extremes

Temperature extremes affect the performance of waterproof connectors. High heat can soften connector bodies, while cold temperatures may cause materials to become brittle. You should choose connectors rated for the temperature range of your application. Review manufacturer specifications to confirm suitability for both hot and cold environments.

In high-moisture environments, temperature fluctuations can increase the risk of condensation inside connectors. You should install connectors in locations that minimize exposure to direct heat or freezing conditions. For critical applications, use connectors with enhanced temperature ratings and waterproof seals.

Note: Managing temperature extremes ensures reliable operation and long-term protection for your electrical systems.

You avoid costly errors when you focus on the most common mistakes, such as improper sealing, incorrect connector selection, and poor quality control. Following installation best practices improves safety and reliability. You should always check that seals and gaskets remain undamaged, align connectors carefully, and use waterproof connectors with corrosion-resistant housings and secure locking mechanisms. Regular maintenance and post-installation checks help you achieve long-term performance. Prioritize the importance of using waterproof connectors to protect your electrical systems in every environment.

FAQ

What tools do you need for installing waterproof wire connectors?

You need a wire stripper, a sharp cutter, and a torque screwdriver. Always use tools designed for electrical work. Proper tools help you avoid damaging wires and ensure a secure, waterproof connection.

How do you know if a wire connector is truly waterproof?

Check the IP rating on the connector. Look for ratings like IP67 or IP68. These ratings show the connector can resist water and dust. Always verify this information on the product label or datasheet.

Can you reuse waterproof wire connectors?

Most waterproof wire connectors are not designed for reuse. Once you seal and close them, you should replace them if you disconnect the wires. Reusing connectors can compromise the waterproof seal.

What should you do if water gets inside a connector?

Disconnect power immediately. Remove the connector and inspect the wires for corrosion. Dry all parts completely. Replace the connector if you see any damage. Never reuse a connector that has failed to keep water out.

Are all waterproof connectors suitable for underground use?

No, not all waterproof connectors work underground. You must choose connectors rated for direct burial. Check the manufacturer’s specifications before installation. Using the wrong type can lead to failure and safety hazards.

How often should you inspect waterproof wire connectors?

Inspect connectors at least once per season in outdoor or wet environments. Look for cracks, discoloration, or loose fittings. Regular checks help you catch problems early and maintain reliable performance.

Do you need to use sealant with every waterproof connector?

Not every connector requires extra sealant. Some come pre-filled or have built-in seals. Always follow the manufacturer’s instructions. If sealant is recommended, apply it as directed to ensure full waterproof protection.