You rely on m12 100-12 connectors when you need robust m12 connections in industrial automation. These connectors deliver proven reliability and withstand demanding environments where water, dust, and vibration challenge every connection. M12 100-12 connectors use a circular locking design and compact form, making them a preferred choice over M8 connector and Type B connector options. As industries move toward smart factories, you see m12 connectors supporting sensors, actuators, and field devices. The connector factory sector supplies over 120 million units annually, with m12 connections representing more than half of the industrial automation market.

| Aspect | Details |

|---|---|

| Global Market | $800 million USD |

| Key Applications | Automation, Control |

M12 100-12 Connectors: Definition and Core Features

M12 Thread and Form Factor

Circular Design and Locking Mechanism

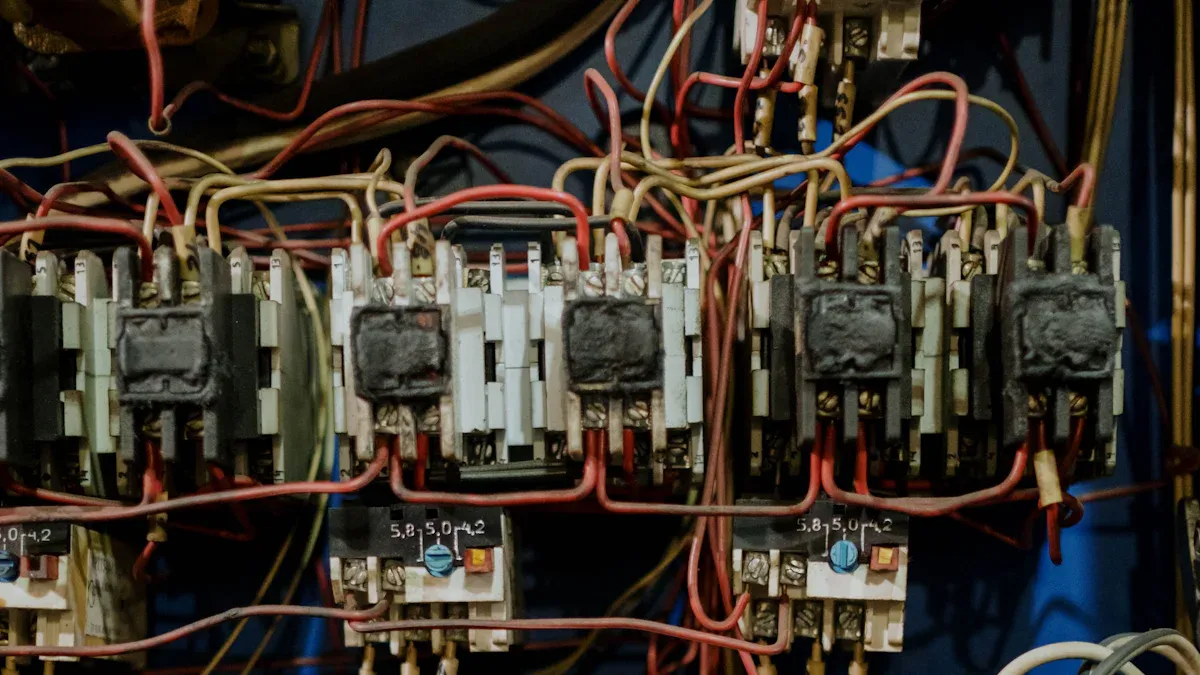

You encounter m12 connectors in environments where mechanical stability is essential. The m12 100-12 connectors use a 12 mm metric fine thread (M12x1) that creates a secure, vibration-resistant connection. The circular design ensures consistent mating interfaces, so you achieve reliable m12 connections even when machinery vibrates or moves. The threaded coupling mechanism prevents loosening under mechanical stress, maintaining a stable connection. You benefit from rugged construction materials such as nickel-plated brass or stainless steel housings, which resist temperature extremes and physical impacts. Many m12 connector types meet high ingress protection ratings like IP67, so you can trust these connectors to withstand dust, moisture, and harsh conditions.

- The circular form factor of m12 circular connectors supports mechanical stability.

- The threaded locking mechanism keeps connections secure during constant motion.

- Durable materials enhance resistance to stress and environmental hazards.

- High IP ratings protect m12 connections from dust and water.

- The compact 12 mm diameter allows you to install connectors in tight spaces without sacrificing durability.

Compact Size Advantages

You often work in control cabinets or machinery where space is limited. The compact size of m12 connectors lets you create dense arrays of connections without overcrowding. You can install multiple m12 connector types side by side, maximizing efficiency in your application. The small footprint also reduces cable clutter, making maintenance easier and improving airflow in electrical enclosures. You gain flexibility when designing systems that require many connections in a confined area.

12-Pin Configuration in M12 Connectors

Pin Layout and Signal Versatility

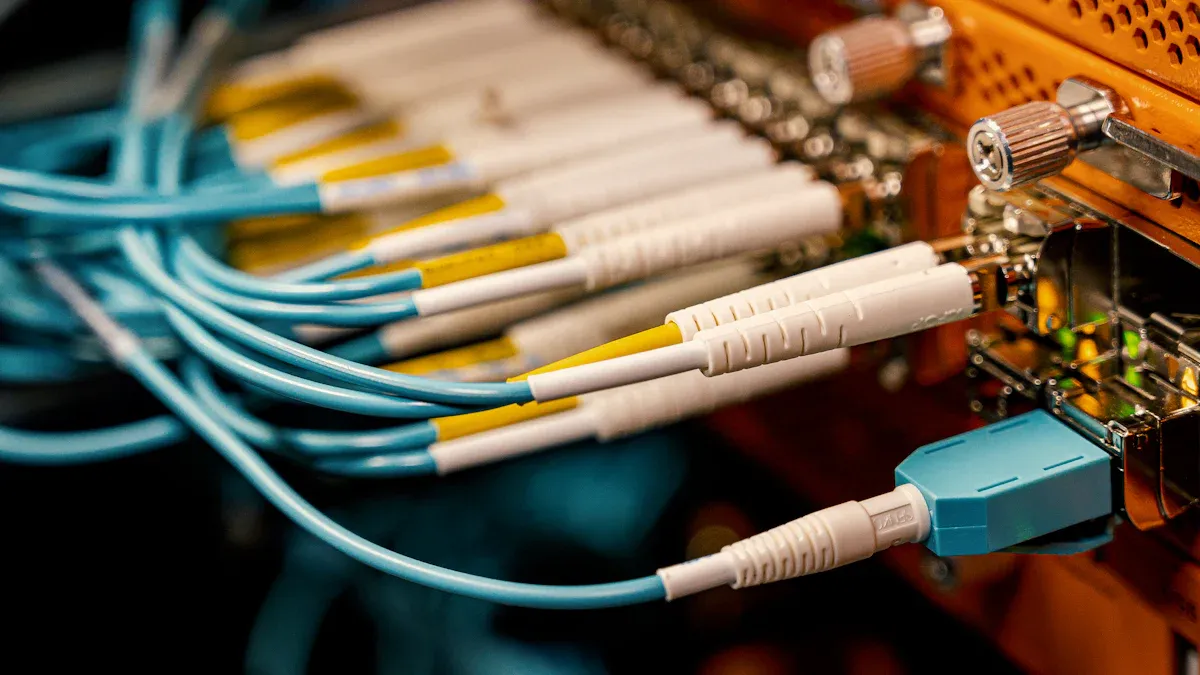

M12 100-12 connectors feature a 12-pin configuration that supports both data and power transmission. You use these m12 connectors for sensor and I/O applications, where signal integrity is critical. The compact 12 mm threaded locking mechanism enables installation in tight spaces. Robust shielding protects against electromagnetic and radio frequency interference, so you maintain reliable m12 connections. These connectors support moderate to high communication speeds, making them suitable for industrial environments. The design minimizes noise and interference, ensuring consistent performance.

| Feature | Description |

|---|---|

| Pin Configurations | Range from 2 to 17 pins; 12-pin is one of the flexible options available in A-coded m12 connector types. |

| Diameter | Compact 12 mm diameter allows multiple connectors to be installed side by side in limited spaces. |

| Construction | Robust design with shielding against EMI/RFI to ensure signal integrity and reduce interference. |

| Standards Compliance | Meets IEC standards ensuring compatibility and reliable performance in industrial environments. |

| Signal Transmission | Supports reliable signal and power transfer, maintaining signal integrity and minimizing noise. |

| Mounting Types | Cable mount options include screw joints and soldering for secure connections. |

Coding Schemes for M12 Connections

You select m12 connector types based on coding schemes that prevent mismating and ensure compatibility. Coding options such as A, B, D, and X define the pin layout and intended application. For example, A-coded m12 connectors suit sensor and actuator connections, while D-coded types support Ethernet and data transmission. Coding schemes help you avoid connection errors and maintain system integrity. You match coding to your application requirements, ensuring safe and reliable m12 connections.

Why M12 100-12 Connectors Matter for Engineers

Reliability in Harsh Environments

You demand reliability from every connection in your system. M12 100-12 connectors deliver consistent performance in harsh environments. The threaded locking mechanism resists vibration and mechanical stress, so you avoid unexpected disconnects. Rugged housings and high IP ratings protect m12 connections from dust, moisture, and chemicals. You trust m12 connectors to maintain signal integrity and power delivery, even in challenging industrial settings.

Flexibility Across Applications

You need connectors that adapt to various applications. M12 connector types offer flexibility for automation, robotics, transportation, and more. The compact size and multiple pin configurations let you design systems with dense m12 connections. You choose m12 connectors for sensors, actuators, field devices, and communication networks. The versatility of m12 100-12 connectors supports your engineering goals, whether you build factory automation or railway signaling systems.

Tip: When you select m12 connector types, always verify coding and pin configuration to match your application needs. This step ensures reliable m12 connections and prevents costly errors.

Key Specifications of M12 100-12 Connectors

Electrical Performance of M12 Connectors

Voltage and Current Ratings

You need to understand the electrical limits of m12 connectors before you select them for power applications. The M12 100-12 connector supports a standard voltage rating of 150 volts and a current rating of 2 amperes. These ratings match the ELC connector series 570, which specifies 12 contacts for m12 connections. You can rely on these values for most industrial automation and sensor systems. If you compare m12 connectors to other power connectors, you will notice that some bayonet HEC power connectors offer higher ratings, but those do not apply to m12 100-12 connectors. You should always check the datasheet for your specific m12 connector type to confirm the voltage and current limits.

Note: Using m12 connectors above their rated voltage or current can lead to overheating or failure. Always match your application requirements to the connector specifications.

Contact Resistance and Insulation

You want low contact resistance in your m12 connections to ensure efficient power delivery and signal transmission. M12 connectors typically feature contact resistance values below 10 milliohms, which helps minimize energy loss. The insulation resistance often exceeds 100 megaohms, providing strong protection against electrical leakage. These properties make m12 connectors suitable for both signal and power applications. You can trust m12 connections to maintain performance even when exposed to moisture or dust, thanks to robust insulation materials.

| Specification | Typical Value for M12 100-12 Connectors |

|---|---|

| Contact Resistance | < 10 mΩ |

| Insulation Resistance | > 100 MΩ |

| Voltage Rating | 150 V |

| Current Rating | 2 A |

Mechanical Properties of M12 100-12 Connectors

Mating Cycles and Durability

You expect m12 connectors to withstand frequent mating and unmating cycles. Most m12 connectors support at least 100 mating cycles, with some high-quality models reaching up to 500 cycles. The threaded locking mechanism ensures that m12 connections remain secure during repeated use. You benefit from durable housing materials such as nickel-plated brass or stainless steel, which resist wear and corrosion. These features extend the lifespan of your m12 connections in demanding environments.

- M12 connectors offer high durability for industrial use.

- You can rely on the locking thread to maintain stable connections over time.

- Robust materials protect against mechanical wear.

Vibration and Impact Resistance

You often install m12 connectors in environments with constant vibration or mechanical shocks. The circular design and secure locking thread help m12 connections resist loosening under stress. You can use m12 connectors in machinery, vehicles, and robotics without worrying about accidental disconnects. The rugged construction absorbs impacts and protects internal contacts from damage. You maintain reliable connections even when equipment operates at high speeds or in harsh conditions.

Tip: Always verify that your m12 connectors meet the mechanical requirements of your application, especially if you expect frequent movement or vibration.

Environmental Ratings for M12 Connections

IP67 and Higher Protection Levels

You need m12 connectors that protect against dust and water ingress. The M12 100-12 connector commonly achieves an IP67 rating, which means it is dust-tight and can withstand immersion in water up to 1 meter. This rating is confirmed by manufacturers such as Fleconn, who specify IP67 for their m12 12 positions connectors. While some power connectors reach IP68 or IP69K, IP67 remains the standard for m12 connections in industrial automation. You can install m12 connectors outdoors or in washdown areas without concern for environmental damage.

| Protection Level | Description |

|---|---|

| IP67 | Dust-tight, protected against water immersion |

| IP68 | Extended water immersion (not standard for M12 100-12) |

| IP69K | High-pressure washdown (not standard for M12 100-12) |

Temperature and Chemical Resistance

You operate m12 connectors in environments with temperature fluctuations and exposure to chemicals. Most m12 connectors withstand temperatures from -40°C to +85°C, allowing you to use them in cold storage or near heat sources. The housing and sealing materials resist oils, solvents, and cleaning agents, so your m12 connections remain reliable in food processing, manufacturing, and outdoor installations. You should always check the chemical compatibility of your m12 connectors with your specific application.

Block Quote:

You can trust m12 connectors to deliver reliable connections in environments with dust, moisture, vibration, and chemical exposure. This versatility makes m12 connections a preferred choice for engineers in power applications and industrial automation.

Materials and Construction in M12 Connectors

Housing and Contact Materials

You need to select m12 connectors that offer both mechanical strength and electrical reliability. Manufacturers use specific materials for each component to achieve these goals. Polyamide (PA) stands out as a popular choice for housings and contact bodies. This material provides excellent resistance to impact, chemicals, and temperature changes. You often see polyamide in environments where durability is essential.

For the contacts inside m12 connectors, brass (CuZn) is the most common material. Brass delivers high conductivity and resists corrosion, which ensures stable signal transmission. Some m12 connectors use a metal shield or plastic cover for the housing shell, depending on the application. Metal shields add extra protection against electromagnetic interference, while plastic covers reduce weight and cost.

Here is a summary of typical materials used in m12 connectors:

| Component | Material Type |

|---|---|

| Housing | Polyamide (PA), Metal Shield, Plastic Cover |

| Contact Body | Polyamide (PA) |

| Contacts | Brass (CuZn) |

| Contact Plating | Gold (Au), CuSnZn (Optaloy) |

You benefit from these material choices because they extend the service life of m12 connectors and maintain performance in harsh industrial settings.

Plating and Sealing Technologies

You want m12 connectors that deliver reliable connections over thousands of cycles. Gold plating on the contacts is a proven technology that enhances durability and ensures consistent electrical contact. Gold resists oxidation and maintains low contact resistance, even after repeated mating and unmating. Some m12 connectors use alternative platings like CuSnZn (Optaloy), but gold remains the industry standard for high-performance applications.

Sealing technologies play a crucial role in protecting m12 connectors from dust, moisture, and other contaminants. Many m12 connectors achieve an IP54 or higher protection class when plugged in. This level of sealing guards against splashing water and solid particles. The use of PA66 plastic in the housing further improves the sealing capability. Some designs feature a snap-in locking system, which not only speeds up installation but also supports more than 5000 mating cycles without compromising the seal.

Tip: Always check the sealing and plating specifications of your m12 connectors before installation. These features directly impact the connector’s lifespan and reliability in your application.

Standards and Compliance for M12 100-12 Connectors

IEC and Industry Standards

You must ensure that your m12 connectors comply with recognized industry standards. The International Electrotechnical Commission (IEC) sets the primary benchmarks for these connectors. IEC 61076-2-101 defines the dimensions, pin layouts, and performance requirements for m12 connectors. Compliance with this standard guarantees that your connectors will mate correctly with other compliant products, regardless of the manufacturer.

Industry standards also address aspects such as coding, color marking, and environmental performance. You can trust m12 connectors that meet these standards to deliver consistent results in automation, transportation, and process control systems.

Certification and Regulatory Requirements

You need to verify that your m12 connectors carry the necessary certifications for your industry. Certifications such as UL (Underwriters Laboratories) and CE (Conformité Européenne) indicate that the connectors meet safety and quality requirements. Some applications may require additional certifications, such as RoHS (Restriction of Hazardous Substances) compliance, which ensures that the connectors do not contain hazardous materials.

Manufacturers often provide documentation that lists all relevant certifications for their m12 connectors. Reviewing these documents helps you avoid compliance issues during installation and operation.

Note: Always request certification details from your supplier before specifying m12 connectors for critical projects. This step helps you meet regulatory requirements and maintain system safety.

Applications of M12 100-12 Connectors

Typical Industrial Uses for M12 Connectors

Automation and Control Systems

You often see m12 connectors as the backbone of automation and control systems. These connectors provide secure connections for programmable logic controllers (PLCs), distributed I/O modules, and industrial sensors. You can rely on m12 connectors to maintain signal integrity in noisy environments. In factory automation applications, you use m12 connectors to link control panels with field devices. The compact size allows you to fit multiple connections in tight control cabinets. You benefit from fast installation and easy maintenance, which keeps your production lines running smoothly.

Sensors, Actuators, and Field Devices

You deploy m12 connectors in a wide range of sensor and actuator networks. These connectors support both power applications and data applications, making them ideal for transmitting signals from proximity sensors, photoelectric sensors, and limit switches. You also use m12 connectors to connect actuators such as pneumatic valves and motor drives. The robust design ensures reliable connections in harsh industrial automation environments. You can quickly replace faulty devices without rewiring the entire system, which reduces downtime in factory automation.

Advanced Applications of M12 Connections

Robotics and Motion Control

You use m12 connectors in robotics for both signal and power transmission. These connectors handle the rapid movements and vibrations found in robotic arms and automated guided vehicles. You can trust m12 connections to deliver consistent performance in dynamic environments. The secure locking mechanism prevents accidental disconnects during high-speed operations. In motion control systems, you rely on m12 connectors to transmit encoder signals and feedback data with minimal interference.

Transportation and Railway Systems

You find m12 connectors in transportation and railway systems where reliability is critical. These connectors withstand vibration, shock, and extreme temperatures. You use m12 connections for signaling equipment, passenger information systems, and surveillance cameras. The IP67 rating protects connections from dust and water, which is essential for outdoor and onboard applications. You can install m12 connectors in control cabinets, junction boxes, and trackside equipment with confidence.

Food, Beverage, and Harsh Environments

You select m12 connectors for food and beverage processing lines because they resist chemicals and frequent washdowns. The sealed design prevents contamination and ensures safe connections in hygienic environments. You also use m12 connectors in harsh environments such as mining, oil and gas, and wastewater treatment. The durable construction and high ingress protection keep your connections secure, even when exposed to aggressive cleaning agents or corrosive substances.

Real-World Case Studies Using M12 100-12 Connectors

Factory Automation Example

You implement m12 connectors in a packaging plant to connect sensors, actuators, and conveyor controls. The connectors support both power applications and data applications, allowing you to monitor and control every stage of production. You achieve rapid installation and easy troubleshooting, which increases uptime in factory automation applications. The robust m12 connections withstand vibration from heavy machinery and exposure to cleaning fluids.

Railway Signaling Example

You use m12 connectors in railway signaling systems to link trackside sensors and control units. The connectors maintain reliable connections despite constant vibration and temperature changes. You benefit from the IP67 sealing, which protects the connections from rain, dust, and debris. This ensures safe and uninterrupted operation of signaling equipment in demanding railway environments.

Tip: When you plan m12 connector applications, always match the connector type and coding to your specific requirements. This step ensures safe, reliable, and efficient connections in every application.

Installation Best Practices for M12 100-12 Connectors

Selecting the Right M12 Connector for Your Application

Application-Specific Selection Criteria

When you choose m12 connectors for your project, you must evaluate several factors to ensure reliable performance. Start by identifying the connector coding system. This step helps you avoid mismating and ensures the correct pin count and keying for your application. Next, match the connector type to your needs—signal, data, or power. Always check the environmental protection rating, such as IP67, to confirm the connector can withstand dust and water in industrial automation settings. Review the voltage and current ratings to make sure they meet your electrical requirements. For safety, never plug or unplug m12 connectors under load, and secure threaded connections with adhesive if you work with dangerous voltages. Only trained personnel should handle installation, following all relevant standards. Prevent accidental disconnection by using locking mechanisms. If you install m12 connectors outdoors, protect them from corrosion. Consider the pollution degree and overvoltage category for your environment. Finally, always tighten the threaded ring to the recommended torque of 1 Nm to lock the connector securely.

Compatibility and Coding Considerations

You must verify that your m12 connectors are compatible with your devices and systems. Coding schemes, such as A, B, D, or X, prevent mismating and ensure proper function. Always match the coding to your application, especially in industrial automation, where incorrect connections can cause downtime. Check the pin layout and ensure the connector fits your equipment. This attention to detail helps you avoid costly errors and supports safe, efficient operation.

Mounting and Assembly of M12 Connectors

Panel Mount vs. Field-Attachable Options

You can select between panel mount and field-attachable m12 connectors based on your installation requirements. Panel mount connectors provide a fixed interface on equipment or control panels. They offer a secure, permanent connection point. Field-attachable connectors give you flexibility for on-site assembly and repairs. You can quickly replace cables or connectors in the field, which reduces downtime in industrial automation environments.

Proper Torque and Sealing Methods

You must apply the correct torque when tightening m12 connectors. Use a torque wrench to achieve the recommended 1 Nm. This practice ensures a secure connection and maintains the IP67 seal. Over-tightening can damage the threads or seals, while under-tightening may allow dust or water to enter. Always inspect the sealing surfaces before assembly. Clean and dry them to prevent contamination. Proper sealing protects your m12 connectors from harsh conditions and extends their service life.

Wiring and Termination for M12 Connections

Cable Selection and Preparation

Select cables that match the electrical and environmental demands of your application. Use shielded cables for data transmission to reduce electromagnetic interference. Choose cables with appropriate temperature and chemical resistance for industrial automation. Cut cables cleanly and strip insulation carefully to avoid damaging conductors. Prepare the cable ends according to the connector manufacturer’s instructions.

Soldering vs. Crimping Techniques

You can terminate m12 connectors using soldering or crimping. Soldering provides a strong, conductive bond but requires skill and proper tools. Crimping offers a fast, reliable method for field assembly. Use the correct crimping tool and die for your connector type. Always inspect the finished connection for secure contact and proper insulation. Both methods support robust, long-lasting m12 connections when performed correctly.

Tip: Always follow the manufacturer’s guidelines for wiring and assembly. Proper technique ensures safe, reliable operation in every industrial automation application.

Ensuring Reliable M12 Connections

Avoiding Common Installation Errors

You can prevent many issues with m12 connectors by following best practices during installation. Always check the orientation of the m12 connector before mating. If you force the connection, you risk damaging the pins or the housing. Use the correct coding to match the m12 connectors with your devices. This step helps you avoid mismating, which can cause system failures.

You should tighten the threaded coupling to the recommended torque. Under-tightening can lead to loose connections, while over-tightening may damage the threads. Use a torque wrench for accuracy. Inspect the sealing surfaces for dirt or debris before assembly. Clean surfaces help maintain the integrity of the m12 connection.

Tip: Never connect or disconnect m12 connectors under load. This practice protects both your equipment and your personal safety.

Environmental Protection and Sealing

You need to ensure that m12 connectors maintain their environmental protection. Always verify that the O-rings and seals are in place and undamaged. These components keep dust and moisture out of the m12 connection. If you work in wet or dusty environments, double-check the IP rating of your m12 connectors. IP67-rated m12 connectors provide reliable sealing against water and dust.

Apply the correct torque to maintain the seal. If you notice any cracks or wear on the seals, replace them immediately. You can use protective caps on unused m12 connectors to prevent contamination. This simple step extends the life of your m12 connectors and keeps your system running smoothly.

Troubleshooting and Maintenance of M12 100-12 Connectors

Diagnosing Connection Issues

You may encounter problems with m12 connectors during operation. If a device fails to communicate or loses power, start by checking the physical connection. Look for loose or disconnected m12 connectors. Inspect the pins for signs of bending or corrosion. Use a multimeter to test continuity across the m12 connection. This tool helps you identify open circuits or high resistance.

If you find intermittent faults, vibration may have loosened the m12 connectors. Tighten the coupling and retest the connection. Replace any damaged m12 connectors to restore reliable operation.

Cleaning and Inspection Procedures

You should schedule regular inspections for all m12 connectors in your system. Disconnect power before handling any m12 connectors to ensure safety. Use a soft brush or compressed air to remove dust and debris from the connector surfaces. For stubborn dirt, use a lint-free cloth dampened with isopropyl alcohol. Avoid using harsh chemicals that may damage the m12 connector materials.

Inspect the contacts for signs of oxidation or wear. If you see discoloration or pitting, replace the m12 connectors. Check the seals and housings for cracks or other damage. Proper maintenance keeps your m12 connectors performing reliably in demanding environments.

Note: Consistent inspection and cleaning routines help you avoid unexpected downtime and extend the service life of your m12 connectors.

Quick-Reference Checklist for Engineers Using M12 100-12 Connectors

Pre-Installation Checklist for M12 Connectors

Before you begin any installation, you need to prepare your M12 100-12 connectors for reliable performance in all applications. Use this checklist to avoid common mistakes:

- Confirm the connector coding matches your intended applications.

- Verify the pin configuration aligns with your device requirements.

- Inspect each connector for visible damage or contamination.

- Check that the IP rating meets the environmental demands of your applications.

- Select cables with the correct shielding and temperature resistance for your applications.

- Ensure all tools and torque wrenches are ready for proper assembly.

- Review the datasheet for voltage and current ratings to match your applications.

- Clean all mating surfaces to prevent dust or debris from affecting connections.

- Plan the installation layout to allow easy access for future maintenance in your applications.

Tip: Careful preparation reduces the risk of downtime and supports safe, efficient applications.

Post-Installation Verification of M12 Connections

After you complete the installation, you must verify that every connection supports your applications as intended. Follow these steps:

- Tighten each connector to the recommended torque (1 Nm) to maintain environmental sealing.

- Inspect the O-rings and seals to confirm they are seated correctly for all applications.

- Test electrical continuity using a multimeter to ensure proper signal flow in your applications.

- Check for secure locking by gently pulling on each connector.

- Confirm that all connectors are coded and mated correctly for your specific applications.

- Document the installation, noting connector types and locations for future reference in your applications.

Note: Post-installation checks help you catch issues early and guarantee reliable performance in all applications.

Ongoing Maintenance Reminders

You need to maintain your M12 100-12 connectors to ensure long-term reliability in demanding applications. Keep these reminders in mind:

- Schedule regular inspections for all connectors used in your applications.

- Clean connectors with a soft brush or compressed air to remove dust and debris.

- Replace any damaged seals or connectors immediately to protect your applications.

- Monitor for signs of corrosion or wear, especially in harsh environments.

- Keep spare connectors and seals available for quick replacement in critical applications.

- Update your maintenance records after each inspection to track connector performance in your applications.

- Train your team on proper handling and troubleshooting procedures for all applications.

- Use protective caps on unused connectors to prevent contamination in your applications.

- Review manufacturer updates or advisories that may affect your applications.

Remember: Consistent maintenance extends the service life of your connectors and supports uninterrupted applications.

You rely on m12 100-12 connectors to deliver robust performance in every industrial setting. These m12 connectors support your automation, control, and sensor networks with proven reliability. When you specify m12 connectors, always match coding, pin configuration, and environmental ratings to your application. Install m12 connectors using proper torque and sealing methods. Maintain your m12 connections with regular inspections and cleaning.

Remember: Careful selection, correct installation, and ongoing maintenance keep your m12 connectors safe and dependable.

FAQ

What does the “100-12” mean in M12 100-12 connectors?

You see “100-12” indicating the series and the number of contacts. “M12” refers to the metric thread size. “12” means the connector has 12 pins, supporting complex signal or power requirements.

How do you ensure proper sealing for M12 connectors?

You must tighten the threaded coupling to the recommended torque. Always check that O-rings and seals are undamaged and seated correctly. This practice maintains the IP67 rating and protects against dust and moisture.

Can you use M12 100-12 connectors for outdoor installations?

You can use these connectors outdoors. The IP67 rating protects against dust and water immersion. For extreme conditions, verify chemical resistance and consider protective caps for unused connectors.

What coding options exist for M12 connectors?

You select from coding schemes such as A, B, D, and X. Each coding prevents mismating and supports specific applications. Always match the coding to your device requirements.

Tip: Coding ensures safe and reliable connections.

How often should you inspect and maintain M12 connectors?

You should inspect connectors every six months in industrial environments. Clean contacts, check seals, and replace damaged parts. Regular maintenance extends connector life and prevents unexpected failures.

What tools do you need for installing M12 connectors?

You need a torque wrench for tightening, wire strippers for cable preparation, and a multimeter for testing continuity. Use manufacturer-recommended tools for crimping or soldering terminations.

| Tool | Purpose |

|---|---|

| Torque Wrench | Secure connection |

| Wire Stripper | Prepare cables |

| Multimeter | Test electrical paths |

Are M12 100-12 connectors compatible with all M12 devices?

You must check pin configuration and coding before connecting. Not all M12 connectors are interchangeable. Always review datasheets to confirm compatibility with your devices.