Automation systems demand connectors that deliver both reliability and efficiency. The m8 connector, often sourced from a reputable connector factory, meets these demands with robust design and precision engineering. Recent industry findings highlight several advantages, including the prevention of mismating common to Type B connector applications. The table below outlines key benefits that set the m8 apart in modern automation:

| Advantage | Description |

|---|---|

| Prevention of Mismating and Pin Damage | Guided M8 connectors prevent incorrect connections, reducing the risk of bent or broken pins. |

| Ease of Blind Mating and Faster Installation | The design allows for quicker and error-free assembly, saving time in complex systems. |

| Extended Connector Lifespan & Maintenance Savings | These connectors last longer due to reduced wear, leading to lower maintenance costs. |

| Backward Compatibility with Standard M8 Systems | They conform to existing standards, ensuring easy integration without redesigning systems. |

Selecting the right m8 ensures optimal performance and longevity for automated operations.

What Is an M8 Connector?

Definition and Overview of the m8 connector

The m8 connector serves as a compact, circular electrical connector widely used in industrial automation. Engineers rely on this connector for transmitting both signals and low-voltage power between sensors, actuators, and control devices. The standard m8 connector features an M8X1 thread specification, which distinguishes it from larger connectors such as the M12. Most applications use the A-coded version, typically with 3 or 4 pins. Due to its small pin pitch, the m8 connector supports voltages up to 50V AC or 60V DC, making it ideal for low-voltage environments.

Key Features of m8 connectors

Compact Circular Design

Manufacturers design m8 connectors with a circular profile and an 8mm thread diameter. This compact form factor allows for dense installation in control cabinets and on machinery where space is limited. The small size also reduces the risk of accidental disconnection in environments with frequent movement or vibration.

Secure Locking Mechanism

A threaded coupling ensures a secure and reliable connection. The screw-lock design prevents accidental loosening, even in high-vibration settings. This feature helps maintain stable signal and power transmission, which is critical for automated systems that require continuous operation.

Versatile Pin Configurations

M8 connectors offer a range of pin configurations to suit different application needs. The table below summarizes common options:

| Pin Configuration | Description |

|---|---|

| 3-pin | Commonly used for basic applications |

| 4-pin | Often used for sensors and actuators |

| 5-pin | Provides additional functionality |

| 6-pin | Used in more complex systems |

| 8-pin | Suitable for advanced applications |

Engineers can select from mounting options such as panel mount, cable mount, or PCB mount. Connection types include screw, crimp, and solder, providing flexibility for various installation requirements.

M8 vs. Other Industrial Connectors

M8 connectors stand out for their small size and versatility. With an 8mm thread diameter, they fit into tight spaces where larger connectors cannot. In comparison, M12 connectors feature a 12mm thread diameter and support up to 12 pins, making them suitable for heavy-duty or complex signal applications. M8 connectors typically offer 3 to 8 pins, which covers most standard sensor and actuator needs. Their compact design makes them the preferred choice for sensor technology and installations where space is at a premium. M8 cable connectors also provide reliable performance in environments that demand both durability and ease of installation.

Technical Specifications of M8 Connectors

Understanding the technical specifications of m8 connectors helps engineers select the right component for automation systems. These specifications define the connector’s performance in electrical, mechanical, and environmental aspects.

Electrical Ratings of m8 connectors

Voltage and Current Capacity

M8 connectors support a range of voltage and current ratings, making them suitable for various automation tasks. The following table summarizes typical values based on the number of contacts:

| Number of Contacts | Rated Current | Rated Voltage |

|---|---|---|

| 3 | 1A | 60V |

| 4/5 | 1A – 3A | 60V |

| 6/8/12 | 1A – 4A | 30V – 60V |

Engineers often choose the m8 connector for low-voltage, low-current applications, such as connecting sensors and actuators. The connector’s design ensures safe and reliable power delivery within these limits.

Signal and Power Transmission

M8 connectors transmit both signals and power in automation systems. The compact design allows for efficient routing of control signals, while the robust contacts maintain stable power connections. This dual capability supports the integration of multiple devices without increasing system complexity.

Mechanical Properties of the m8 connector

Size and Thread Dimensions

The m8 connector features an 8mm thread diameter, which enables installation in tight spaces. Its compact and lightweight construction suits a wide range of industrial and commercial applications, including medical devices and ruggedized sensors.

Mating Cycles and Durability

- M8 connectors deliver a mechanical lifetime of more than 100 mating cycles.

- The design withstands repeated connections and disconnections without performance loss.

- The connector’s durability ensures long-term reliability in demanding environments.

These mechanical properties contribute to the overall robustness of automation systems, reducing the need for frequent maintenance.

Environmental Ratings for m8 connectors

IP Protection Levels

M8 connectors offer high levels of protection against dust and water. The table below outlines common IP ratings:

| IP Rating | Description |

|---|---|

| IP68 | Protection against dust and long-term immersion in water |

| IP69K | Protection against high-temperature, high-pressure water jets |

Manufacturers test some m8 connectors to IEC 60529 standards. For example, VULCON™ m8 connectors passed submersion tests at 3 meters for 2 hours, confirming their suitability for harsh environments.

Temperature and Chemical Resistance

M8 connectors operate reliably across a wide temperature range. The materials resist exposure to oils, chemicals, and cleaning agents commonly found in industrial settings. This resilience ensures stable performance even in challenging conditions.

Tip: Always review the technical specifications for each m8 connector model to ensure compatibility with your application’s environmental requirements.

Standards and Compliance for m8 connectors

Automation systems rely on connectors that meet strict standards. These standards ensure that every m8 connector performs reliably in demanding environments. Manufacturers design m8 connectors to comply with international requirements, which helps engineers achieve consistent results across different projects.

Industry standards play a vital role in connector selection. They define mechanical dimensions, electrical properties, and environmental tolerances. When engineers choose m8 connectors, they look for products that meet recognized certifications. These certifications guarantee that the connectors will integrate smoothly with other system components.

Key Standards and Certifications for m8 connectors:

- Compliant with IEC 61076-2-104, ensuring mechanical compatibility and signal reliability.

- Built with IATF 16949 Certification, which guarantees product consistency and process traceability.

The IEC 61076-2-104 standard sets the benchmark for circular connectors in industrial automation. It specifies the dimensions, pin layouts, and performance criteria for m8 connectors. By following this standard, manufacturers produce connectors that fit seamlessly into control panels, sensors, and actuators. Engineers benefit from reduced installation errors and improved system uptime.

IATF 16949 certification focuses on quality management in manufacturing. This certification requires strict process controls and documentation. Manufacturers with IATF 16949 certification deliver m8 connectors with consistent quality. Engineers can trust these connectors to perform reliably over time, even in high-volume production environments.

| Standard / Certification | Purpose | Benefit to Automation Systems |

|---|---|---|

| IEC 61076-2-104 | Defines mechanical and electrical properties | Ensures compatibility and reliability |

| IATF 16949 | Sets quality management requirements | Guarantees consistency and traceability |

Tip: Engineers should always verify that m8 connectors meet both IEC and IATF standards before installation. This step helps prevent compatibility issues and ensures long-term system reliability.

Manufacturers often display compliance information on product datasheets. Engineers review these documents to confirm that the connectors meet project requirements. By selecting certified m8 connectors, they reduce the risk of system failures and simplify maintenance procedures.

Compliance with international standards also supports global deployment. Automation systems built with certified m8 connectors can operate in facilities worldwide. This flexibility allows companies to expand operations without redesigning their systems.

How M8 Connectors Enhance Automation Systems

Reliable Signal and Power Delivery with m8 connectors

Automation systems rely on stable signal and power transmission to function efficiently. The m8 connector plays a crucial role in this process. Engineers choose these connectors for their ability to maintain consistent electrical contact, even in challenging industrial environments.

- M8 connectors are designed for reliable signal and power delivery in automated systems.

- They are compact and versatile, suitable for various industrial applications.

- Built to withstand harsh environments, ensuring secure connections for power and signal transmission.

- Feature a waterproof design that protects against dust and moisture.

- Operate within a wide temperature range, ideal for extreme conditions.

The symmetrical contact arrangement in m8 connectors further enhances reliability. This design reduces signal loss and electrical interference by minimizing near-end crosstalk and electromagnetic interference. The cancellation of electromagnetic fields ensures stable real-time data transmission, which is essential for automation networks that demand high accuracy and uptime.

Note: The robust construction of m8 connectors allows them to deliver both power and data without compromise, making them a preferred choice for engineers who prioritize system integrity.

Fast and Secure Connections using m8

Speed and security in connections directly impact the efficiency of automated systems. M8 connectors feature a threaded coupling mechanism that provides a secure lock, preventing accidental disconnection during operation. This design supports quick installation and removal, which is vital for systems that require frequent maintenance or reconfiguration.

The compact size of m8 allows for dense mounting on machinery and control panels. Technicians can install these connectors in tight spaces without sacrificing accessibility. The screw-lock mechanism ensures that each connection remains stable, even in environments with constant vibration or movement.

M8 connectors also help reduce signal loss and electrical interference. The symmetrical contact arrangement minimizes electromagnetic disturbances, which supports reliable data transmission. This feature is especially important in applications where real-time communication between devices is critical.

Minimizing Downtime in Automated Operations

Downtime in automated operations can lead to significant productivity losses. The design of m8 connectors addresses this challenge by enabling fast and error-free installation. Technicians can connect and disconnect these connectors quickly, reducing the time required for maintenance or system upgrades.

- The X-Lok Micro Size Push-Lock connector offers faster installation due to its push-to-mate feature, significantly reducing downtime compared to traditional M8 connectors.

- It eliminates the need for threading, which is time-consuming and prone to errors, thus enhancing operational efficiency in automated settings.

- The design allows for blind-mating, making it easier to connect in tight spaces, further minimizing downtime during installation and maintenance.

The robust construction of m8 ensures that connections remain secure over time, reducing the likelihood of unexpected failures. This reliability translates into fewer interruptions and lower maintenance costs for automation systems.

💡 Tip: Choosing the right connectors, such as m8, can help organizations achieve higher system uptime and lower total cost of ownership.

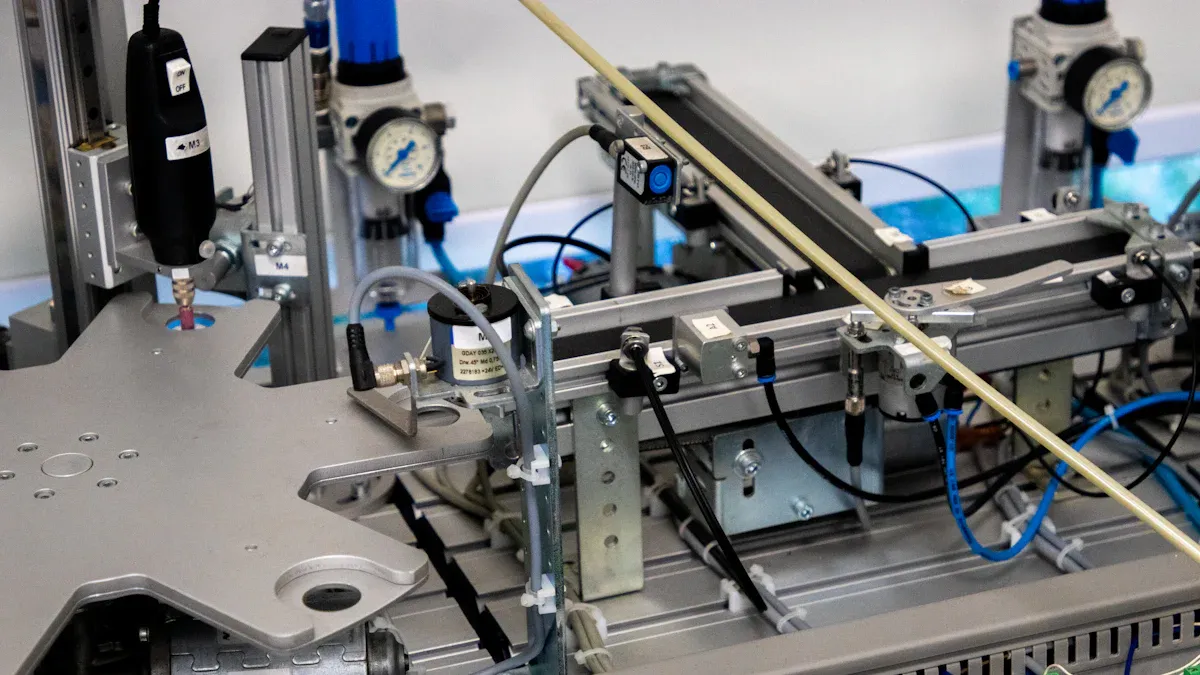

Industry Applications of M8 Connectors

Automation systems rely on versatile connectors to support a wide range of industrial tasks. The m8 connector stands out for its adaptability and robust design, making it a preferred choice in several key applications.

Robotics and Motion Control with m8 connectors

Robotics and motion control systems demand reliable connectivity for precise operation. The m8 provides secure and compact connections, supporting both signal and power transmission in dynamic environments.

Servo Motors and Actuators

Engineers use m8 to connect servo motors and actuators in robotic arms and automated machinery. These connectors deliver stable electrical contact, ensuring accurate movement and positioning. The guided key design eliminates mismating, which helps prevent installation errors and equipment failure.

End-of-Arm Tooling

End-of-arm tooling, such as grippers and suction cups, relies on m8 for quick and secure integration. The compact size fits tight spaces on robotic arms, while the rugged construction withstands repeated motion and vibration. This reliability supports continuous operation in high-speed automation lines.

M8 connectors are ideal for miniature robotics and small-scale automation lines, where lightweight wiring and space-saving designs are essential.

| Application Area | Description |

|---|---|

| Factory Automation Machinery | Connects sensors, switches, actuators, PLCs, and I/O boxes in machinery. |

| Miniature Robotics | Fits tight spaces and supports lightweight wiring needs. |

| Automotive Industry | Used in lighting, sensors, and onboard electronics. |

| RFID Readers | Enables identification and tracking in rail and industrial markets. |

Factory Equipment and Machinery using m8 connectors

Modern factories require connectors that perform reliably under harsh conditions. The m8 excels in these environments due to its durable construction and high IP-rated sealing.

Conveyors and Assembly Lines

Conveyors and assembly lines depend on m8 for connecting sensors, switches, and control devices. The robust design resists dust and moisture, reducing downtime and maintenance costs. M8 withstands high vibration, ensuring consistent performance throughout production cycles.

Packaging Machines

Packaging machines utilize m8 to link sensors and actuators for precise control. The connectors support data rates up to 1 Gbps, meeting the demands of advanced automation. Their compact form allows for flexible installation in crowded control panels.

- M8 connectors eliminate mismating with guided keys.

- They endure high vibration and protect against dust and water.

- The design supports secure connections, minimizing equipment failure.

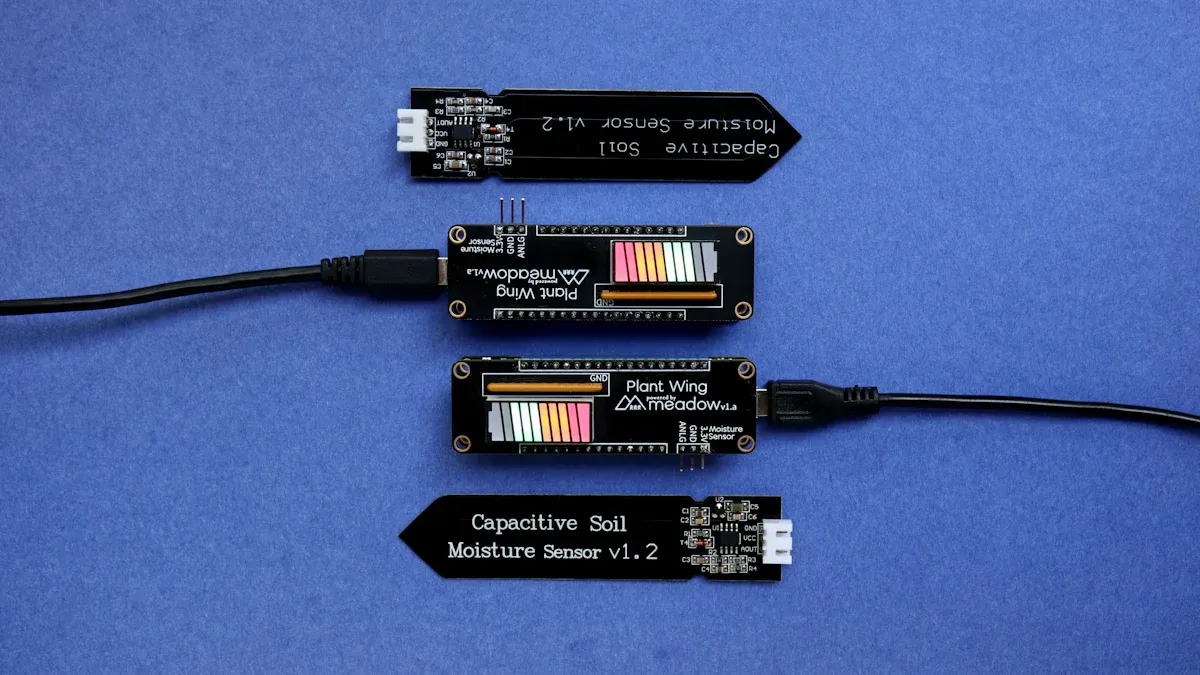

Sensor and Device Integration with m8 connectors

Industrial automation relies on accurate sensor data for efficient operation. The m8 connector enables seamless integration of various sensors and devices.

Proximity and Photoelectric Sensors

Proximity and photoelectric sensors use m8 for reliable signal transmission. The connectors maintain stable contact, even in environments exposed to chemicals and temperature fluctuations. Engineers select m8 for its compatibility with temperature, pressure, and position sensors.

Industrial Cameras and Vision Systems

Industrial cameras and vision systems require high-speed data transfer and robust connections. M8 supports these needs with secure locking mechanisms and flexible mounting options. The connector’s versatility allows integration with robotic actuators and end effectors.

- M8 connectors are commonly used for connecting temperature, pressure, position, and proximity sensors.

- They also link sensors to actuators and end effectors in robotic applications.

Tip: Selecting the right m8 connector ensures reliable performance across diverse industrial applications.

Automated Test and Measurement Systems with m8 connectors

Automated test and measurement systems require connectors that deliver consistent performance in demanding environments. M8 connectors play a vital role in these systems by providing reliable connections for sensors, actuators, and data acquisition devices. Manufacturers design m8 connectors with a compact size and high contact density, which allows engineers to maximize space within control panels and testing equipment.

Test and measurement equipment often operates in harsh industrial settings. M8 connectors withstand exposure to acids, alkalis, and chemical cleaning agents. Their robust construction resists damage from welding sparks, ensuring long-term reliability. Engineers benefit from reduced wiring needs, which streamlines equipment assembly and maintenance.

Industrial laboratories and manufacturing facilities rely on m8 connectors for precise measurement tasks. Leading manufacturers use these connectors in length measurement systems, where accuracy and durability are essential. Laboratory automation systems for environmental analytics also integrate m8 connectors to support continuous monitoring and data collection. Industrial cameras from well-known brands feature m8 connectors, enabling high-speed image capture and analysis in automated inspection lines.

The waterproofing and oil resistance of m8 connectors protect sensitive electronics from moisture and contaminants. This feature proves critical in environments where frequent cleaning or exposure to fluids occurs. The connectors maintain stable electrical contact, even when subjected to vibration or temperature fluctuations.

Engineers select m8 connectors for their versatility across a wide range of test and measurement applications. The compact design fits into tight spaces, while the secure locking mechanism prevents accidental disconnection during equipment operation. Technicians can quickly install or replace connectors, minimizing downtime and ensuring continuous system performance.

Key benefits of m8 connectors in automated test and measurement systems include:

- High resistance to chemicals and cleaning agents

- Durability against welding sparks and mechanical stress

- Efficient wiring for streamlined equipment assembly

- Compact size and high contact density for space-saving installations

- Reliable waterproofing and oil resistance for harsh environments

Tip: When designing automated test and measurement systems, engineers should consider m8 connectors for their proven reliability and adaptability in industrial settings.

M8 connectors support the integration of advanced sensors, cameras, and measurement devices. Their robust design and environmental protection features make them a preferred choice for engineers seeking dependable solutions in automated test and measurement systems.

Advantages of Using M8 Connectors in Automation

Durability and Longevity of m8 connectors

Engineers value durability in automation components. The m8 connector features robust construction that withstands repeated use and exposure to harsh industrial environments. Manufacturers design these connectors with materials that resist corrosion, vibration, and mechanical stress. This resilience ensures stable performance over time, even in facilities with frequent equipment movement. The locking mechanism prevents accidental disconnections, which helps maintain uninterrupted operation. Regular inspections and maintenance further extend the lifespan of m8, supporting consistent system reliability.

Space-Saving Design of the m8 connector

Automation panels often require dense wiring and compact layouts. The m8 connector addresses these needs with a space-saving design. Its small size allows engineers to maximize available panel space, integrating more devices without overcrowding. Compared to larger alternatives, m8 offers higher contact density, which supports efficient signal, power, and data transmission. The following table highlights the space efficiency of m8 compared to M12 connectors:

| Feature | M8 Connectors | M12 Connectors |

|---|---|---|

| Size | 30% smaller | Larger |

| Ideal for tight spaces | Yes | No |

| Contact density | High | Moderate |

| Application suitability | Miniaturized devices | Standard devices |

Engineers often select m8 for miniaturized devices and installations where every millimeter counts. The compact design proves essential in modern automation panels, enabling flexible layouts and reducing the risk of wiring errors.

Tip: M8 connectors are 30% smaller than M12 connectors, making them perfect for integration in tight spaces and supporting high contact density.

Ease of Installation and Maintenance with m8 connectors

Technicians appreciate components that simplify installation and maintenance. The m8 connector excels in this area. Its compact form fits easily into constrained environments, streamlining the assembly process. The locking mechanism ensures secure connections, reducing the likelihood of accidental disconnections during operation. This reliability minimizes maintenance interruptions and supports continuous system performance. Engineers find that regular inspections and maintenance help preserve the connector’s integrity, extending its service life.

- M8 connectors facilitate easier installation in tight spaces.

- The robust design reduces maintenance needs in harsh conditions.

- The locking mechanism enhances reliability and minimizes maintenance interruptions.

- Routine maintenance ensures consistent performance and longevity.

Automation systems benefit from the straightforward installation and dependable operation provided by m8. These features contribute to lower total cost of ownership and improved productivity in industrial settings.

Flexibility for Modular Systems using m8

Automation systems often require frequent reconfiguration to meet evolving production demands. M8 connectors provide engineers with the flexibility needed for modular system design. Their compact form factor and standardized interface allow technicians to swap components or expand systems without extensive rewiring. This adaptability supports rapid changes in manufacturing lines and laboratory setups.

Manufacturers offer m8 connectors in a range of configurations. Options include male and female connectors, as well as 3-pin and 4-pin variants. These choices enable engineers to match connector types with specific device requirements. The robust design ensures reliable connectivity, even when systems undergo repeated assembly and disassembly. Technicians can install or replace modules quickly, minimizing downtime and supporting continuous operation.

Modular automation relies on connectors that maintain performance during frequent changes. M8 connectors deliver consistent signal and power transmission, which is essential for reconfigurable setups.

Engineers value the ease of installation provided by m8 connectors. The threaded locking mechanism secures connections, reducing the risk of accidental disconnection. This feature proves critical in environments where equipment moves or vibrates. The compact size allows for dense mounting on control panels, supporting high contact density in limited spaces.

M8 connectors support a wide variety of industrial applications. Their versatility makes them suitable for sensor integration, actuator control, and data acquisition. The ability to choose from multiple pin configurations and mounting styles enables engineers to design systems that meet specific operational needs. Modular systems benefit from this flexibility, as technicians can add or remove devices without disrupting the overall architecture.

A modular approach to automation enhances scalability. Facilities can expand production capacity by adding new modules or upgrading existing ones. M8 connectors simplify this process, allowing engineers to maintain system integrity while adapting to changing requirements. The standardized interface ensures compatibility across different devices and manufacturers.

- Engineers select m8 connectors for modular systems due to:

- Multiple configuration options

- Reliable locking mechanisms

- Compact design for space efficiency

- Compatibility with diverse devices

Tip: When designing reconfigurable automation systems, engineers should consider m8 connectors for their proven adaptability and ease of integration.

M8 connectors play a vital role in supporting modularity and flexibility. Their design enables automation systems to evolve with minimal disruption, ensuring reliable performance across a broad range of industrial environments.

Challenges and Considerations for M8 Connectors

Compatibility with Existing Systems

Engineers often encounter compatibility challenges when integrating m8 connectors into legacy automation systems. Many older platforms rely on relational databases, while newer systems may use NoSQL databases. This difference can create data model compatibility issues. Legacy environments typically process data in batches, but modern systems favor real-time or event-driven processing. Synchronizing these approaches can prove difficult. Some legacy systems lack support for modern API protocols such as REST or GraphQL. Engineers must develop custom adapters or connectors to bridge this gap. Outdated security mechanisms, including weak encryption and authentication, may introduce vulnerabilities during integration. Addressing these issues requires careful planning and a thorough understanding of both old and new system architectures.

Tip: Engineers should assess the existing infrastructure before selecting connectors to avoid costly integration problems.

Cost Factors and Budgeting for m8 connectors

Cost plays a significant role in connector selection for automation projects. M8 connectors typically range in price from $12.45 to $99.85. This price point makes them more affordable than larger alternatives like M12 connectors. Their compact size suits applications with limited space, which can help reduce overall system costs. Project managers must consider not only the initial purchase price but also long-term expenses such as installation, maintenance, and potential replacement. Choosing the right connectors can optimize budget allocation and prevent unnecessary spending.

| Connector Type | Typical Cost Range | Suitability for Tight Spaces |

|---|---|---|

| M8 | $12.45 – $99.85 | Excellent |

| M12 | Higher | Moderate |

Note: Factoring in both upfront and ongoing costs ensures a more accurate project budget.

Selection Criteria for Specific Applications

Selecting the appropriate m8 connectors for specific automation applications requires a systematic approach. Engineers should follow these criteria:

- Identify the type of connector needed, such as pre-wired, field-wireable, or panel-mount.

- Assess the electrical parameters, including current-carrying capacity, to match application requirements.

- Consider the installation environment and choose between straight or angled connectors based on available space.

- Check for environmental features like waterproofing and shock resistance, especially for harsh conditions.

- Evaluate the connector’s durability and design lifespan to ensure long-term reliability.

Engineers who apply these criteria can select connectors that meet both technical and operational needs. This approach supports efficient system performance and reduces the risk of premature failure.

Engineers should always match connector specifications to the demands of their intended applications for optimal results.

Maintenance and Replacement Concerns

Proper maintenance of M8 connectors ensures reliable operation in industrial automation systems. Engineers recognize that regular inspection and timely replacement prevent unexpected failures and costly downtime. M8 connectors, though robust, face environmental stressors such as vibration, moisture, and chemical exposure. These factors can accelerate wear and compromise performance.

Routine maintenance schedules help technicians identify issues before they escalate. The following table outlines recommended inspection tasks, frequencies, and methods for M8 connectors in industrial settings:

| Inspection Task | Frequency | Recommended Method |

|---|---|---|

| Tightness Check | Quarterly | Visual marker, hand check |

| Loop Resistance Test | Annually | Multimeter |

| Corrosion Inspection | Semi-annual | Visual, tactile |

| Cable Jacket Review | Quarterly | Visual, physical |

Technicians perform tightness checks every quarter using visual markers and manual verification. This step confirms that threaded couplings remain secure, reducing the risk of accidental disconnection. Loop resistance tests, conducted annually with a multimeter, detect electrical degradation. Increased resistance may signal contact wear or contamination. Semi-annual corrosion inspections involve both visual and tactile assessment. Engineers look for discoloration, pitting, or rough surfaces that indicate chemical damage. Cable jacket reviews, performed quarterly, help identify cracks, abrasions, or other physical damage that could expose conductors.

Replacement decisions rely on clear criteria. Persistent looseness, visible damage, or corrosion that cannot be cleaned signal the need for connector replacement. Technicians also replace any connector showing signs of electrical degradation, such as increased loop resistance or intermittent signal loss. These symptoms often precede complete failure and can disrupt automation processes.

Tip: Engineers should document all inspection results and replacement actions. Accurate records support predictive maintenance and help optimize replacement intervals.

Selecting high-quality replacement connectors maintains system integrity. Engineers match new connectors to existing specifications, ensuring compatibility and minimizing installation errors. Proper handling during replacement prevents damage to contacts and seals. Technicians use clean tools and avoid excessive force when disconnecting or installing connectors.

Environmental factors influence maintenance frequency. Facilities with high humidity, chemical exposure, or frequent washdowns may require more frequent inspections. Engineers adjust schedules based on observed wear patterns and operational demands.

Regular maintenance and timely replacement of M8 connectors protect automation systems from unexpected failures. These practices extend equipment lifespan, reduce downtime, and support consistent performance in demanding industrial environments.

Future Trends in M8 Connector Technology

Miniaturization and Higher Density in m8 connectors

Manufacturers continue to push the boundaries of miniaturization in m8 connectors. They use lightweight metal alloys and high-temperature polymers to create compact designs that fit into increasingly smaller devices. This trend supports the demand for space-saving solutions in modern automation systems. Engineers now see board-to-board and wire-to-board interconnect solutions that offer higher integration and contact density. These advancements allow for more connections within limited spaces, which increases the functionality of control panels and sensor arrays.

| Advancement Type | Description |

|---|---|

| Miniaturization | Use of lightweight metal alloys and high-temperature polymers for compact designs. |

| Connector Density | Board-to-board and wire-to-board interconnect solutions that support higher integration. |

| Customization | Tailored designs and materials for specific industry needs, enhancing functionality and durability. |

Customization also plays a key role. Manufacturers tailor designs and materials to meet specific industry requirements. This approach enhances both functionality and durability, making m8 suitable for specialized applications in harsh environments.

Enhanced Data Transmission Capabilities of m8

Automation systems require fast and reliable data transmission. The m8 connector supports these needs by enabling stable signal integrity, even in environments with high electromagnetic interference. Engineers design m8 to handle higher data rates, which supports the integration of advanced sensors and real-time monitoring devices. As industries adopt more sophisticated automation technologies, connectors must transmit both power and data efficiently. The compact design of m8 allows for dense installations without sacrificing performance.

The ability to maintain signal quality and support higher bandwidths positions m8 as a critical component in next-generation automation networks.

Integration with Smart Automation Solutions

Industry 4.0 and smart manufacturing rely on seamless connectivity between devices. M8 connectors play a vital role in this transformation. Their compact size and robust design make them ideal for sensors and small drive equipment. As industrial systems move toward modularization, m8 connectors enhance system reliability and performance. They enable real-time data exchange, which supports predictive maintenance and efficient resource management.

M8 connectors facilitate communication between devices in smart factories and automated warehouses. Their versatility allows engineers to deploy them across a wide range of Industry 4.0 applications. By supporting real-time analytics and IoT integration, m8 connectors help industries improve productivity and scalability. This capability drives innovation and supports future growth in automation.

Tip: Engineers should consider m8 connectors when designing systems for smart automation and Industry 4.0 to ensure reliable connectivity and data integrity.

Automation systems achieve higher reliability and performance with the m8 connector. Recent case studies show several advantages:

- M8 circular connectors endure harsh conditions, such as vibration and humidity, supporting stable signal and power transmission.

- Quick field repairs and compatibility with standard pin layouts simplify integration.

- Robust construction and high-grade seals maintain insulation integrity over time.

Engineers should review technical specifications and match connector types to application needs. Careful selection of m8 ensures long-term system reliability and efficient operation.

FAQ

What is the main advantage of using M8 connectors in automation systems?

M8 connectors offer a compact design and secure locking mechanism. Engineers choose them for reliable signal and power transmission in tight spaces. These features help maintain system uptime and reduce maintenance needs.

Can M8 connectors withstand harsh industrial environments?

Manufacturers design M8 connectors with high IP ratings, such as IP68 and IP69K. These ratings ensure protection against dust, water, and chemicals. The robust construction supports long-term use in demanding conditions.

How do engineers select the right M8 connector for an application?

Engineers review electrical ratings, pin configurations, and environmental requirements. They match connector specifications to device needs. Selection depends on installation type, durability, and compatibility with existing systems.

Tip: Always check datasheets for compliance with IEC and IATF standards.

Are M8 connectors compatible with older automation equipment?

M8 connectors follow international standards for mechanical and electrical properties. This compatibility allows integration with many legacy systems. Engineers may need adapters for specific older devices.

What maintenance tasks help extend the lifespan of M8 connectors?

Technicians perform regular inspections, including tightness checks and corrosion reviews. They test loop resistance and examine cable jackets for damage. Scheduled maintenance prevents unexpected failures and supports reliable operation.

| Task | Frequency |

|---|---|

| Tightness Check | Quarterly |

| Corrosion Inspection | Semi-annual |

Can M8 connectors support both signal and power transmission?

M8 connectors transmit signals and low-voltage power. Engineers use them for sensors, actuators, and control devices. The design maintains stable electrical contact, supporting efficient data and power delivery.

What trends are shaping the future of M8 connector technology?

Manufacturers focus on miniaturization, higher contact density, and enhanced data transmission. M8 connectors now support smart automation and real-time analytics. These advancements improve system flexibility and reliability.

Engineers should consider future-proof designs for evolving automation needs.