Miniature push-release connectors play a critical role in electronic devices where space is limited and reliability is essential. These connectors, including options like the M8 connector and Type B connector, deliver secure connections that withstand vibration, shock, and harsh environments. Industry reports from Connector factory leaders highlight how compact designs with positive locking features, such as those found in modern electronics, maintain reliable performance. By supporting high-density layouts in compact spaces, miniature push-release connectors streamline assembly and extend device longevity.

What Are Miniature Push-Release Connectors?

Definition and Key Features of Miniature Push-Release Connectors

Compact Design for Space-Constrained Devices

Miniature push-release connectors address the challenges of modern electronics by offering a compact design that fits into the smallest spaces. Manufacturers like INTE-AUTO produce connectors in M7 size, which allows engineers to maximize available board area. These connectors support high-density layouts, making them ideal for devices where every millimeter counts. The lightweight and rugged construction ensures that even in a compact form, the connectors maintain durability and reliability. Miniature connectors often feature gold-plated pins, providing stable electrical performance in a small footprint.

Note: Miniature push-release connectors are suitable for applications such as audio devices, robotics, and communications equipment, where compact size and robust performance are essential.

Push-Release Mechanism Explained

The push-release mechanism sets these connectors apart from traditional options. This system uses a self-locking internal mechanism that engages automatically when the connector halves are pushed together. Inner latches retract during insertion, then slot into grooves inside the receptacle, securing the connection. Disconnection requires a deliberate action, such as pulling or squeezing the connector body, which prevents accidental disconnects. This design ensures a predictable connect and disconnect force, supporting frequent use without wear or failure.

| Feature Category | Common Key Features Across Brands |

|---|---|

| Locking Mechanism | Push-pull locking, self-locking systems, ball bearing locking, breakaway designs |

| Environmental Protection | IP50 to IP68 ratings, corrosion-resistant coatings |

| Form Factor | Miniature, compact designs for space-limited applications |

| Construction & Shielding | Metal or plastic bodies, EMI shielding, biocompatible materials |

| Mating Indicators | Auditory and tactile feedback for reliable mating |

| Durability & Reliability | High mating cycles, vibration and impact resistance, robust for harsh environments |

| User-Friendly Design | Keying systems, ergonomic operation, color coding |

| Application Suitability | Medical, industrial, aerospace, communication, and outdoor applications |

How Miniature Push-Release Connectors Work

Connection Process in Compact Electronics

Miniature push-release connectors simplify the connection process in compact electronics. The user aligns the connector and pushes it into the mating port. The internal spring clamping system expands and grips the conductor, forming a stable electrical connection. No tools are required, which reduces assembly time and minimizes the risk of installation errors. The connector provides both visual and tactile feedback, confirming a secure mating. This process supports high-density and space-sensitive applications, ensuring reliable performance even in challenging environments.

- The self-locking mechanism automatically engages during insertion.

- Inner latches slot into grooves, securing the connection.

- The connector resists vibration and movement, maintaining a stable connection.

Disconnection Process and User Benefits

Disconnection is just as straightforward. The user presses a release button or squeezes the connector body, which opens the spring clamp and allows the wire or connector half to be removed easily. This tool-free process prevents accidental disconnects and supports frequent connections and disconnections without degrading performance. The design accommodates various wire types and sizes, making it versatile for different applications. Users benefit from quick maintenance, easy upgrades, and reduced downtime in compact systems.

Tip: The push-release mechanism provides a clear acoustic click during both connection and disconnection, giving users confidence in the reliability of each operation.

How Miniature Push-Release Connectors Enhance Connection Reliability

Secure and Consistent Connections in Compact Devices

Reduced Risk of Loose Contacts and Failures

Miniature push-release connectors deliver a secure connection in compact electronics by utilizing advanced locking mechanisms. These connectors feature self-locking latches and spring clamps that maintain constant pressure on conductors, reducing the risk of loose contacts. Engineers rely on these miniature interconnects to prevent intermittent failures, which often occur in high-density layouts. The push-release design ensures that each mating cycle provides consistent electrical contact, supporting high reliability in critical applications. Devices such as medical instruments and micro miniature rf connectors benefit from this stable performance, as even minor connection faults can compromise safety and functionality.

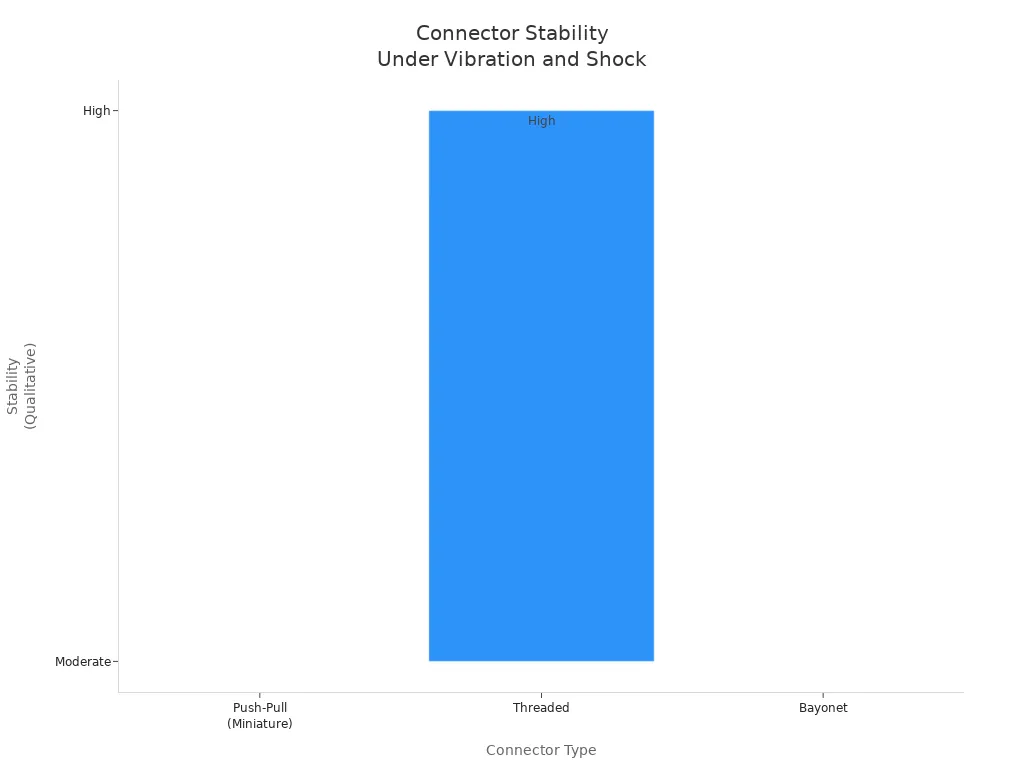

Vibration and Shock Resistance in Miniature Connectors

Miniature connectors must withstand vibration and shock, especially in portable and industrial environments. Manufacturers design micro miniature rf connectors with features like machined contacts, EMI/RFI shielding, and robust coupling systems. These enhancements allow connectors to maintain reliable components under moderate vibration and shock conditions. The following table compares connection stability across connector types:

| Connector Type | Connection Stability under Vibration and Shock | Key Advantages | Key Disadvantages |

|---|---|---|---|

| Push-Pull (Miniature) | Moderate; generally less secure than threaded connectors under high vibration and shock. Some rugged series (e.g., QUIK-LOQ™) are designed for high shock and vibration environments with features like machined contacts and EMI/RFI shielding. | Fast and easy connect/disconnect; ideal for frequent mating cycles; suitable for medical, consumer electronics, industrial automation, robotics, oil & gas. | May not provide the highest security in extreme vibration; limited robustness in some rugged environments. |

| Threaded | High; highly secure and vibration-resistant due to screw-in locking mechanism. Preferred in harsh environments like aerospace and heavy machinery. | Superior vibration resistance and connection stability; preferred for critical, harsh applications. | Slower to connect/disconnect compared to push-pull and bayonet. |

| Bayonet | Moderate; offers a balance between quick connection and moderate vibration resistance. Less secure than threaded under extreme conditions. | Quick connect/disconnect with moderate vibration resistance; suitable for automotive, industrial, and military applications. | Not as secure as threaded connectors under severe vibration and shock. |

Push-pull miniature connectors, including ruggedized micro miniature rf connectors, offer rapid latching and high mating cycles, making them suitable for environments where frequent connections and moderate vibration resistance are required. Threaded connectors provide the highest stability under severe vibration, but miniature push-release connectors balance convenience and reliability for most compact device applications.

Minimizing Human Error with Push-Release Connectors

Tool-Free Operation and Assembly

Miniature push-release connectors simplify assembly by enabling tool-free conductor connection. Users plug in the conductor directly, which streamlines the process and minimizes human error. The spring mechanism inside these connectors applies a constant clamping force, independent of user technique. This feature prevents mistakes caused by inconsistent screw tightening or improper fastening. Micro miniature rf connectors often include colored pushers, helping technicians avoid wiring errors during installation. The tool-less design allows both hands to remain free, further reducing the chance of mistakes and improving assembly efficiency.

- Quick, tool-free conductor connection

- Constant clamping force for reliable mating

- Colored pushers to prevent wiring mistakes

- Maintenance-free connection with no need for retightening

Clear Engagement Feedback for Reliable Connections

Miniature connectors provide clear tactile and visual feedback during mating. The push-release mechanism produces an audible click, confirming a secure connection. This feedback reassures users that the connector is properly engaged, reducing uncertainty and the likelihood of incomplete mating. The spring clamp ensures a gas-tight, vibration-resistant connection, which eliminates the need for periodic maintenance. Micro miniature rf connectors excel in environments where reliable components and high reliability are essential, such as medical devices and industrial automation.

Tip: Clear engagement feedback during mating helps technicians verify secure connections quickly, reducing downtime and improving overall reliability.

Durability in Demanding Environments

Resistance to Wear, Tear, and Environmental Factors

Miniature push-release connectors undergo rigorous durability testing to ensure reliable operation in harsh conditions. Models such as Times Locking Miniature Push-On and LEMO miniature push-pull connectors demonstrate up to 5000 mating cycles. Manufacturers use robust materials like stainless steel, aluminum, brass, and high-performance polymers such as PEEK and PTFE. These materials provide strength, corrosion resistance, and chemical resistance. Micro miniature rf connectors achieve high ingress protection ratings (IP67, IP68, IP69K), which shield internal contacts from water, dust, and contaminants. They withstand extreme temperatures from -40°C to 100°C, mechanical impacts, shock, vibration, and chemical exposure. Compliance with industrial standards validates their reliability and long-term functionality.

Miniature connectors designed for rugged outdoor sensor applications resist environmental stresses such as moisture, dust, and corrosion. Engineers select materials that maintain flexibility and sealing integrity, even when exposed to temperature extremes. High ingress protection ratings prevent dust and water ingress, while robust locking mechanisms ensure connectors remain securely mated despite vibration and shock.

Sealing and Keying Features for Enhanced Security

Manufacturers equip miniature push-release connectors with advanced sealing and keying features. O-ring seals protect against liquids and salt ingress, while EMI/EMC shielding guards against electromagnetic interference. Mechanical retention systems, such as latching mechanisms with visual lock indicators, enhance security and prevent accidental disconnects. Keying systems ensure correct mating orientation, reducing the risk of misconnection. Micro miniature rf connectors often incorporate these features to support high performance and reliability in aerospace, defense, and industrial applications.

Note: Sealing and keying features in miniature connectors help maintain a secure connection and protect reliable components, even in the most demanding environments.

Benefits of Miniature Push-Release Connectors for Compact Electronics

Space-Saving Advantages of Compact Connectors

High-Density Layouts and Flexible Mounting

Miniature push-release connectors enable engineers to design high-density layouts in compact devices. For example, EDAC’s 140 series inline PCB connectors feature a fine pitch of 2.0mm and low-profile dimensions, with widths of just 0.185 inches (4.7mm) and heights of 0.240 inches (6.1mm). These connectors support 2 to 16 positions and maintain a current rating of up to 2A per contact. Such compact dimensions allow designers to maximize PCB real estate, fitting more functionality into smaller spaces. The audible click-secure latch and low contact resistance further enhance usability in space-constrained applications like medical devices, wearables, and drones. The market for flexible flat cable connectors, which includes these space-saving solutions, reached USD 1.2 billion in 2024 and is projected to double by 2033, reflecting the growing demand for compact interconnect solutions.

Increased Functionality Without Sacrificing Reliability

Manufacturers achieve higher component density by combining multiple power and signal contacts within a small footprint. Fischer Connectors’ MiniMax™ Series demonstrates this approach by reducing size and weight while maintaining ruggedness. These connectors support up to 5,000 mating cycles and provide sealing against harsh environments. Their robust locking systems and precise manufacturing ensure that compact device designs do not compromise reliability. Plastronics H-Pin blind mate connectors further reduce component count by using a single compression-mounted connector, making devices smaller and more reliable. This approach allows engineers to add more features to compact electronics without risking connection integrity.

Simplified Assembly and Maintenance in Small Devices

Faster Installation and Reduced Connection Times

Miniature push-release connectors streamline installation and maintenance. Tool-free direct-connection technology, such as Phoenix Contact’s push-in system, enables users to insert and remove conductors quickly. The following table highlights measured time savings compared to traditional connectors:

| Aspect | Measured Time Savings / Impact |

|---|---|

| Installation workload | Over 60% reduction when using push-in insertion |

| Installation time saved | Up to 80% reduction compared to legacy screw types |

| Installation duration | 11 seconds to install and mate the connector |

| Maintenance workload | Retightening screws eliminated, reducing workload to zero |

These improvements translate to faster assembly lines and less downtime during maintenance, which is critical for compact devices that require frequent updates or repairs.

Easy Replacement and Upgrades in Compact Systems

Push-release connectors allow for easy replacement and upgrades in compact systems. The self-latching mechanism ensures secure connections while enabling quick disconnection when needed. Users can swap out modules or components without specialized tools, reducing the risk of damage to delicate electronics. This feature supports modular designs and extends the lifespan of compact devices by simplifying upgrades.

Tip: Quick-release features help technicians perform maintenance and upgrades efficiently, even in tight spaces.

Enhanced Long-Term Reliability in Compact Electronics

Consistent Performance Over Time

Miniature push-release connectors deliver consistent performance throughout their service life. High mating cycle durability, rugged metal shells, and 360° electromagnetic shielding ensure stable electrical connections. These features protect against wear, vibration, and environmental stress, which are common in compact electronics.

Lower Maintenance Requirements and Downtime

The robust design of these connectors minimizes the need for ongoing maintenance. Tool-free operation eliminates the need for retightening, and the secure locking mechanism prevents accidental disconnects. As a result, compact devices experience fewer failures and reduced downtime, supporting long-term reliability in demanding applications.

Real-World Applications of Miniature Push-Release Connectors

Consumer Electronics and Wearables

Miniature push-release connectors play a vital role in consumer electronics and wearable devices. Manufacturers design these connectors to meet the demands of compact, high-performance products. Engineers select them for their secure locking mechanisms, high mating cycles, and resistance to environmental factors.

Smartphones, Tablets, and Portable Audio Devices

Smartphones, tablets, and portable audio devices require reliable connectors to maintain signal integrity and power delivery. The following table highlights popular connector series and their features in these applications:

| Connector/Product Series | Key Features | Real-World Applications in Consumer Electronics and Wearables |

|---|---|---|

| Fischer LP360 (Freedom Series) | Rugged, low-profile, push-to-connect/pull-to-release, IP67/IP68 sealed, 5,000-10,000 mating cycles, 360° mating | Smart PPE vests, biometric sensors, communication systems, GPS, lighting, bodycams, IoT/IoH wearables |

| Amphenol 103 Series Board-to-Board | 0.35 mm pitch, low-profile (0.6 mm stack height), high current (up to 5A), USB 3.1 Gen 2 compatible | Smart watches, VR headsets, smart glasses, e-wallets, hearing aids, wireless EEG headsets |

| Hirose Electric BK13C Series | Hybrid FPC-to-board, 0.35 mm pitch, 0.6 mm height, 5A power contacts, rugged metal shell | Earbuds, smart watches, smart glasses, audio players, cameras, laptops, gaming consoles |

These connectors support high-density layouts and flexible mounting, which are essential for modern electronics.

Fitness Trackers and Smartwatches

Fitness trackers and smartwatches rely on miniature push-release connectors for battery connections and data transfer. Manufacturers use miniaturized, flat-stacking connectors with high current resistance to ensure long-term reliability. Engineers favor these connectors for their lightweight design and secure mating, which withstands daily wear and movement.

Medical Devices Using Compact Connectors

Miniature push-release connectors have transformed the design of wearable medical devices and diagnostic equipment. Engineers value their compact size, rugged construction, and user-friendly interfaces.

Diagnostic Equipment and Patient Monitoring

Diagnostic monitors and patient monitoring systems require stable, secure connections. Miniaturized connectors provide reliable electrical and mechanical contact, supporting high mating cycles and environmental resistance. Spring-loaded probes and sealed designs prevent fluid ingress during cleaning and sterilization, which is critical for medical applications.

- Miniaturized connectors enable rugged, IP-sealed interfaces for wearable medical devices.

- Spring-loaded probes support battery charging in hearing aids and docking stations.

- Magnetic connectors simplify charging and protect users and devices.

- Non-magnetic, blind-mate connectors offer 360° mating freedom and quick-release features.

Implantable and Wearable Health Technologies

Implantable and wearable health technologies benefit from connectors with EMI shielding and modular designs. Engineers select series such as LEMO B and SOURIAU JBX for their high density, IP68 sealing, and tactile indicators. These connectors enhance device effectiveness and patient safety by ensuring stable, secure connections.

Industrial and Automotive Electronics

Industrial and automotive electronics demand connectors that perform reliably in harsh environments. Manufacturers design ruggedized systems with miniature push-release connectors to withstand vibration, shock, and extreme temperatures.

Sensors, Control Units, and In-Vehicle Infotainment

Amphenol’s 2M Micro Miniature circular connectors offer push-pull quick disconnect features for industrial sensors and control units. These connectors maintain high electrical and mechanical performance, supporting reliable operation in ruggedized automotive electronics.

Ruggedized Compact Systems for Harsh Environments

ITT Cannon’s MIKQ Push-Pull Microminiature Circular Connector and LEMO’s OPTIMA F series provide lightweight, compact solutions for transportation and aerospace systems. These connectors feature robust locking mechanisms, wide temperature tolerance, and high contact density. Engineers use them in commercial TV cameras, portable radios, military gun sights, and airborne landing systems. The connectors operate reliably within a broad temperature range and resist vibration, ensuring secure signal transmission in demanding applications.

Note: Miniature push-release connectors support a wide range of applications, from consumer electronics to industrial and medical devices, by delivering secure, reliable connections in compact systems.

Emerging Applications: IoT Devices, Robotics, and Drones

IoT Sensors and Smart Home Devices

Miniature push-release connectors have become essential in the rapid expansion of IoT. The internet of things relies on compact, reliable interconnects to support a vast network of sensors and smart home devices. Engineers select these connectors for their ability to deliver secure, high-density connections in limited spaces. Many IoT sensors operate in environments exposed to dust, moisture, and temperature fluctuations. Miniature push-release connectors, especially those with circular designs like the M5 to M12 series, offer robust environmental resistance and secure latching. These features ensure stable power and data transmission, even in challenging conditions.

Smart home devices, such as security cameras, thermostats, and lighting controls, benefit from the tool-free operation of push-release connectors. Users can install or replace components quickly, reducing installation time and minimizing the risk of wiring errors. The connectors’ magnetic self-mating options provide additional convenience, guiding connections automatically and locking securely. This design supports frequent connect and disconnect cycles, which is common in modular IoT applications. The break-away safety function allows automatic disconnection under excessive force, protecting both the device and the user.

Tip: Magnetic self-mating connectors simplify maintenance for smart home electronics, making upgrades and repairs safer and faster.

Robotics, Drones, and Autonomous Systems

Robotics and drones demand connectors that combine ruggedness with ease of use. These applications often involve exposure to shock, vibration, extreme temperatures, and even saltwater. Military-grade miniature push-release connectors, adapted from micro-D or nano-D designs, provide the necessary durability. Engineers favor these connectors for their secure latching mechanisms, which prevent accidental disconnects during operation.

Mobile robots and drones require frequent battery charging and component swaps. Magnetic self-mating connectors with break-away functions enable quick, safe connections. When a robot or drone experiences a sudden pull or impact, the connector disconnects automatically, preventing damage or injury. This feature proves vital in field robotics and aerial drone operations, where reliability and safety are paramount.

Circular miniature connectors support power levels up to 40 A and 60 V, making them suitable for both power and data transmission in robotics and industrial IoT. The wide range of coding options allows engineers to customize connections for specific applications, ensuring compatibility and reducing the risk of misconnection. These connectors support the evolving needs of autonomous systems, where fast, reliable, and safe interconnects are critical for mission success.

- Miniature push-release connectors support:

- Rugged, sealed connections for outdoor and industrial robotics

- Quick battery swaps and modular upgrades in drones

- Reliable signal and power transmission in autonomous vehicles

The adoption of these connectors in emerging fields highlights their versatility and importance in modern electronics.

Comparing Miniature Push-Release Connectors to Traditional Connectors

Traditional Connector Types in Compact Electronics

Soldered Connections and Their Limitations

Soldered connections have served as a foundation in compact electronics for decades. Engineers use them to create permanent bonds between wires and printed circuit boards. While these interconnects provide strong electrical contact, they present several challenges. Soldered joints require skilled labor and specialized tools for assembly and repair. The process can be time-consuming, especially when frequent changes or repairs are necessary. Soldered connections also lack flexibility, making upgrades or replacements difficult in modern devices that demand modularity.

Screw-Terminal and Standard Plug Connectors

Screw-terminal connectors and standard plug types, such as pin headers, USB, and D-sub connectors, remain common in many compact devices. These connectors often require tools for installation and removal. Their bulkier size and need for precise alignment can slow down assembly. Frequent use may lead to wear, reducing durability over time. The table below summarizes the main types and their limitations:

| Connector Type | Description | Limitations |

|---|---|---|

| Pin Headers and Sockets | Common on PCBs for board-to-board or wire-to-board connections. | Require precise alignment; bulkier than newer connectors; less durable for frequent mating. |

| USB Connectors | Widely used for data transfer and power in consumer electronics. | Bulkier than newer types; limited mating cycle durability. |

| D-sub Connectors | Older, robust connectors used in industrial and legacy equipment. | Larger size; less suitable for compact modern devices; lower mating cycle durability. |

| FPC/FFC Connectors | Connect flexible circuits or flat cables to PCBs in compact devices. | Not designed for very high mating cycles; delicate alignment needed. |

Traditional connectors often struggle with environmental resistance and require more maintenance, especially in high-vibration or harsh settings.

Performance and Reliability Differences

Connection Security and Stability

Miniature push-release connectors, including micro miniature rf connectors, offer significant improvements in connection security. Their internal locking mechanisms automatically engage during mating, providing a stable and reliable connection. Unlike traditional connectors, which may loosen under vibration or repeated use, push-release designs maintain consistent pressure and resist shock. Micro miniature rf connectors use spring-loaded contacts that ensure reliable electrical performance, even in demanding environments. Blind mating connectors further enhance reliability by allowing secure connections without precise alignment, reducing the risk of misconnection.

- Pogo pins in micro miniature rf connectors deliver consistent contact force.

- Spring action reduces damage risk and increases durability.

- Blind mating connectors support secure connections in tight or hard-to-reach spaces.

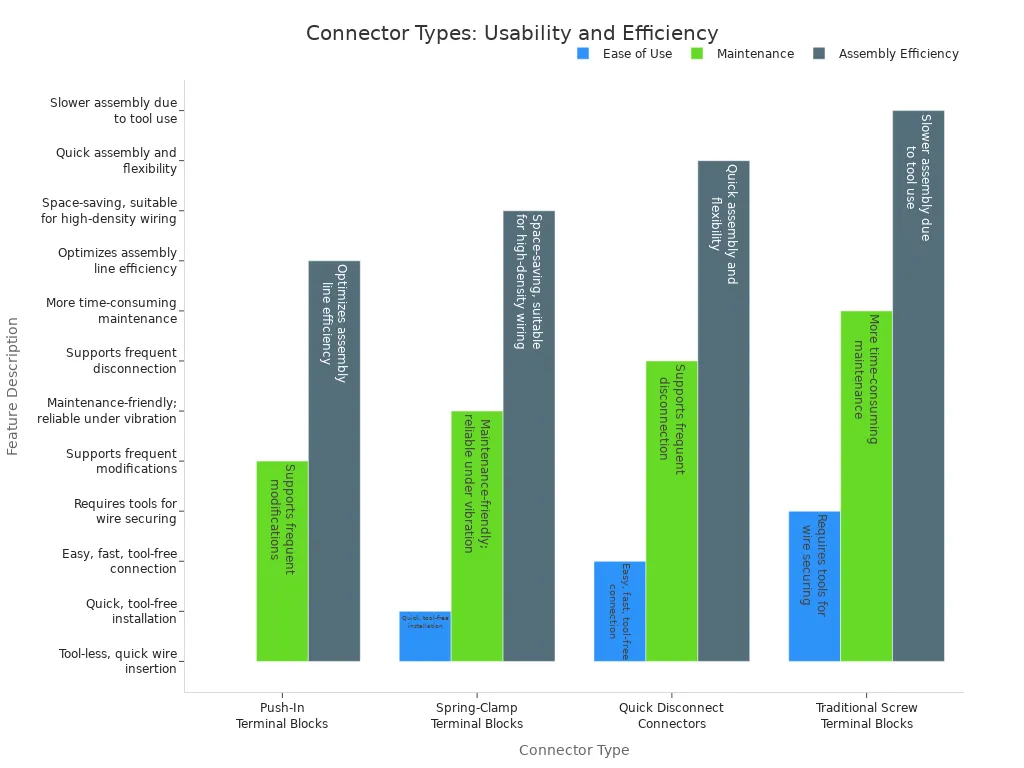

Ease of Use, Maintenance, and Assembly Efficiency

Push-release connectors simplify assembly and maintenance. Users can connect or disconnect them quickly without tools, saving time during installation and repairs. The following table compares ease of use and efficiency:

| Connector Type | Ease of Use | Maintenance | Assembly Efficiency |

|---|---|---|---|

| Quick Disconnect Connectors (Push-Pull) | Easy, fast, tool-free connection and disconnection | Supports frequent disconnection/reconnection; facilitates maintenance | Enables quick assembly and flexibility in system changes |

| Traditional Screw Terminal Blocks | Requires tools for wire securing | More time-consuming maintenance due to screws | Slower assembly due to tool use and manual tightening |

Micro miniature rf connectors and blind mating connectors support frequent assembly and disassembly, making them ideal for applications that require flexibility and rapid maintenance.

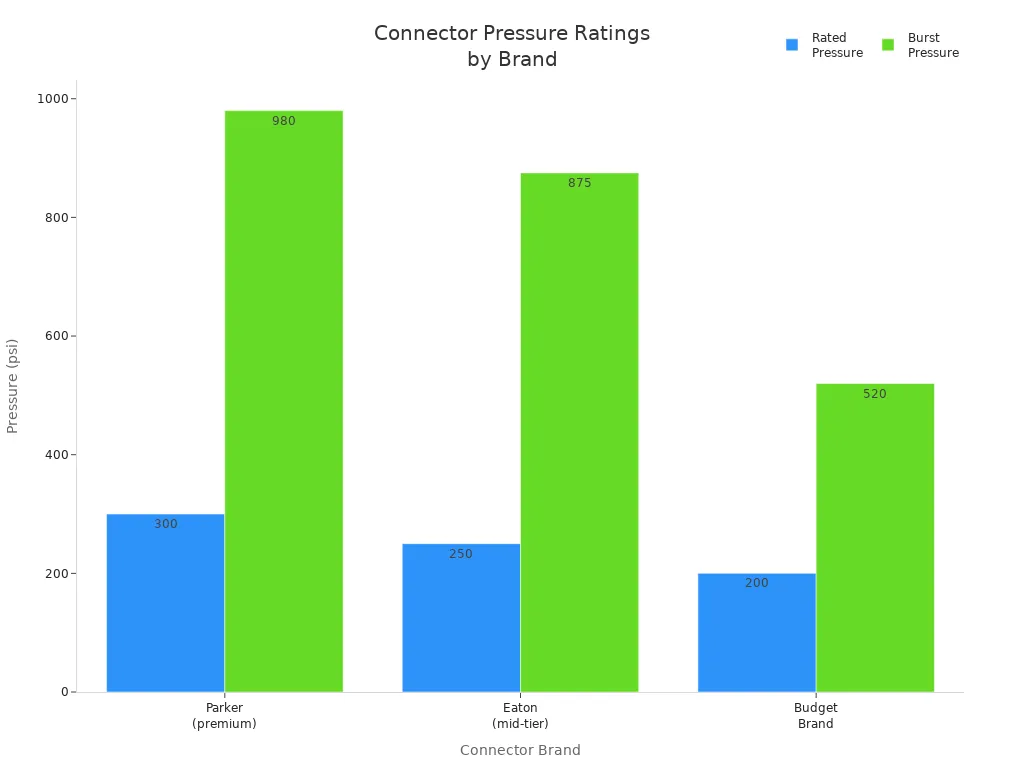

Cost and Lifecycle Considerations for Connectors

Initial Investment vs. Long-Term Savings

Miniature push-release connectors may require a higher initial investment compared to some traditional types. However, their durability and ease of use often result in lower long-term costs. Premium brands of micro miniature rf connectors demonstrate superior resistance to vibration and environmental stress, reducing the likelihood of failure and costly downtime. Proper installation and material selection play a crucial role in maximizing these savings.

Failure Rates, Downtime, and Total Cost of Ownership

Failure rates and total cost of ownership depend on connector quality and application. Premium micro miniature rf connectors show lower failure rates and better performance in endurance tests. In contrast, budget or improperly installed connectors can lead to expensive repairs and downtime. The chart below illustrates differences in rated and burst pressure among connector brands, highlighting the importance of quality in reducing total cost of ownership.

Selecting high-quality connectors and ensuring proper installation can significantly reduce maintenance costs and improve device reliability over time.

Design Considerations for Integrating Miniature Push-Release Connectors

Selecting the Right Miniature Connector for Compact Devices

Size, Form Factor, and Application Requirements

Engineers evaluate several factors when choosing a miniature push-release connector for compact devices. The available board space and profile height determine the connector’s size suitability. Application requirements influence the switch function type, such as momentary or maintained action. Mechanical robustness and durability affect material selection and cost. Designers consider mounting options, including panel mount or PCB mount, to ensure proper integration. Additional features, like illumination for user feedback, enhance usability. Ruggedized designs support harsh environments, providing reliable performance in demanding conditions.

- Size constraints and available board space

- Switch function type: momentary vs maintained

- Mechanical robustness and durability

- Mounting options: panel or PCB mount

- Illumination and user feedback features

- Ruggedized designs for harsh environments

Injection molding plays a vital role in manufacturing miniature connectors, especially for medical devices. This process uses medical-grade plastics, heated and injected into molds, to create connectors with tight tolerances. Precision molding improves product quality, reduces costs, and shortens production cycles, making it ideal for compact devices that require reliable miniature push-release connectors.

Electrical, Mechanical, and Environmental Needs

Engineers assess electrical ratings to match voltage and current requirements. Contact resistance impacts signal integrity, especially in small-signal circuits. Insulation resistance and withstand voltage ensure safety, preventing breakdown under rated voltages. Shielding properties protect against electromagnetic interference, often achieved with metal shells. Flame retardancy and self-extinguishing materials reduce fire risk. Environmental resistance addresses long-term effects of operating conditions, such as temperature extremes and exposure to moisture or chemicals.

Tip: Selecting connectors with high insulation resistance and effective shielding helps maintain device safety and signal integrity.

Best Practices for Compact Connector Implementation

PCB Layout Tips for Miniature Connectors

Designers optimize PCB layouts by placing connectors close to signal sources, minimizing trace lengths and reducing signal loss. They avoid routing traces under connectors to prevent interference. Proper pad sizing and spacing ensure reliable solder joints. Engineers use ground planes to enhance EMI shielding and maintain signal quality. Clear labeling and color coding simplify assembly and reduce wiring errors.

Assembly Guidelines for Reliable Integration

Reliable integration starts with following manufacturer guidelines for connector placement and orientation. Technicians verify mating alignment and use recommended insertion forces. Tool-free designs speed up assembly and reduce human error. Regular inspection of contact surfaces prevents contamination and ensures consistent performance. Modular designs allow easy upgrades and replacements, supporting long-term device reliability.

Compliance and Safety Standards for Connectors

Industry Certifications and Regulatory Factors

Connectors must meet industry standards to ensure safety and reliability. Devices often comply with IEC 60950-1 and IEC 62368-1, covering electrical safety, thermal limits, grounding, and mechanical hazards. Early integration of compliance testing, including schematic reviews and thermal simulations, prevents hazards such as burns or fire. The following table summarizes key standards for miniature connectors:

| Standard | Description |

|---|---|

| MIL-C-27599 | Intermateable miniature connectors with series I and II compatibility. |

| MIL-C-81703 | Environment resisting circular miniature connectors with removable crimp or solder contacts. |

| MIL-DTL-5015 | Reliable rear release connectors for aerospace and ground support, combining solder and crimp. |

| MIL-DTL-32139 | Covers plastic and metal nanominiature connectors. |

| MIL-DTL-38999 | Miniature, high-density, environment resistant connectors operating from -65°C to +200°C. |

| MIL-DTL-83513 | Performance-driven plastic and metal shell Micro-D connectors. |

| MIL-DTL-83723 | General requirements for environment resisting circular electrical connectors with crimp/solder contacts. |

Environmental and Safety Considerations

Manufacturers design connectors to support sterilization methods, such as EtO and gamma sterilization, ensuring safe reusability. IP67 sealing protects against dust and water ingress. EMI/RFI shielding maintains signal integrity and device safety. High-density miniaturization fits more contacts into smaller footprints without compromising reliability. Connectors support multiple mating cycles and operate within specified temperature ranges. Supply chain availability and regulatory approval help avoid delays in device market release.

Note: Early consideration of compliance and safety standards ensures that connectors meet regulatory requirements and deliver reliable performance in compact devices.

Future Trends and Innovations in Miniature Push-Release and Micro Miniature RF Connectors

Advances in Miniaturization and Connector Technology

Smaller, More Robust Designs for Compact Devices

Manufacturers continue to push the boundaries of miniaturization. They design micro miniature rf connectors that meet the strictest size constraints in modern electronics. These connectors now feature advanced materials and precision engineering. Engineers achieve smaller footprints while increasing durability. The latest miniature push-release connectors withstand thousands of mating cycles and resist harsh environments. This progress supports the miniaturization demands of next-generation devices. As a result, designers can pack more functionality into smaller spaces without sacrificing reliability.

Note: The trend toward miniaturization drives the need for connectors that deliver both compactness and ruggedness.

Integration with Smart and Connected Technologies

Micro miniature rf connectors now play a central role in smart and connected technologies. Engineers integrate these connectors into devices that require fast data transfer and secure signal integrity. Many miniature connectors support wireless charging, sensor integration, and real-time monitoring. These features enable seamless communication between devices in connected environments. The rise of IoT has increased the demand for connectors that offer high performance in compact formats. Manufacturers respond by developing connectors with enhanced shielding and low-loss signal paths.

Expanding Application Areas for Micro Miniature RF Connectors

Next-Generation Consumer and Medical Devices

Micro miniature rf connectors have become essential in next-generation consumer electronics and medical devices. Designers use these connectors in wearables, hearing aids, and portable diagnostic tools. The miniature size allows for discreet integration into slim product profiles. Medical device engineers rely on micro miniature rf connectors for their reliability and biocompatibility. These connectors support high performance in devices that require frequent sterilization and long-term use. The ability to maintain stable connections in small, mobile products sets a new standard for the industry.

Growth in Industrial, IoT, and Automotive Sectors

Industrial, IoT, and automotive sectors now adopt micro miniature rf connectors for a wide range of applications. Factories use these connectors in sensors and control systems that operate in challenging environments. Automotive engineers select micro miniature rf connectors for in-vehicle infotainment, safety systems, and advanced driver-assistance features. The IoT sector benefits from connectors that support dense sensor networks and reliable data transmission. As industries demand more compact and robust solutions, micro miniature rf connectors continue to evolve to meet these needs.

- Micro miniature rf connectors enable:

- Reliable connections in high-vibration industrial settings

- Secure data transfer in automotive electronics

- Scalable sensor networks in IoT applications

Tip: Selecting the right micro miniature rf connectors ensures long-term reliability and supports the rapid evolution of connected technologies.

Miniature push-release connectors play a vital role in reliable electronics. Their innovative design supports miniaturization and streamlines assembly. Engineers and designers choose these connectors to enhance device performance in compact systems. Key benefits include:

- Secure, stable connections in small spaces

- Reduced failure rates and simplified maintenance

These connectors help teams build dependable, high-performing devices for modern applications.

FAQ

What makes miniature push-release connectors reliable in small devices?

Engineers design these connectors with self-locking mechanisms and robust materials. These features ensure stable electrical contact and prevent accidental disconnects. Devices benefit from consistent performance, even in environments with vibration or movement.

Can users install miniature push-release connectors without special tools?

Yes. Most miniature push-release connectors support tool-free installation. Users simply push the connector into place. This design reduces assembly time and minimizes the risk of installation errors.

Where do manufacturers commonly use miniature push-release connectors?

Manufacturers use these connectors in consumer electronics, medical devices, industrial sensors, automotive systems, and IoT devices. Their compact size and secure locking make them ideal for space-constrained applications.

How do these connectors handle harsh environments?

Manufacturers use corrosion-resistant metals and high-performance polymers. Many models feature IP-rated sealing and EMI shielding. These features protect the connectors from dust, moisture, and electromagnetic interference.

Are miniature push-release connectors suitable for frequent connections and disconnections?

Yes. Engineers design these connectors for high mating cycles. The push-release mechanism maintains performance over thousands of connections, making them ideal for devices that require regular maintenance or upgrades.

What safety standards apply to miniature push-release connectors?

Manufacturers follow industry standards such as IEC 60950-1, MIL-DTL-38999, and IP67/IP68 ratings. These standards ensure electrical safety, environmental protection, and reliable operation in demanding applications.

Do miniature push-release connectors support both power and data transmission?

Yes. Many models offer hybrid designs that carry both power and signal lines. This capability allows engineers to reduce component count and save space in compact devices.

Tip: Always check the connector’s datasheet for specific ratings and compatibility before selecting it for your application.