The B-type connector TGG metal plug is a high-end connector designed for high-reliability scenarios. It integrates a quick push-pull self-locking system and all-round shielding technology, supports high-density installation of 2-32 pins, and has both durability and space efficiency. Its plug-in life exceeds 1 million times, adapts to -45°~+125° temperature, 95% high humidity and harsh vibration and shock environments, and has a protection level of IP50. It is widely used in industrial automation, communication equipment and other fields, providing stable guarantees for signal transmission.

1. Product Features

TGG connector takes “efficient connection and stable transmission” as its core to create multiple performance advantages:

Convenient operation and reliable locking: The innovative quick push-pull self-locking system enables one-handed plugging and unplugging in seconds. The locking structure fits tightly, effectively preventing vibration and loosening, and improving the reliability of equipment operation.

Strong anti-interference ability: It adopts an all-round shielding design. The metal shielding layer tightly wraps the signal pin core wire. Combined with the grounding structure, it greatly reduces electromagnetic interference (EMI) and radio frequency interference (RFI), ensures the integrity of high-frequency signal transmission, and meets the data stability requirements of demanding electronic equipment.

High-density integrated design: It supports flexible configuration of 2-32 pin cores, and the compact structure optimizes the space layout. It realizes multi-channel signal/power integration in a limited installation area, which is especially suitable for miniaturized and highly integrated equipment. Adaptability to extreme environments: Passed multiple rigorous tests – temperature range covers -45°~+125°C, withstands 95% relative humidity at 60°C without failure; resists 15g impact at 10-20000Hz vibration frequency, 100g instantaneous impact lasts for 6ms without damage; salt spray corrosion test for more than 48 hours, protection level IP50 resists dust intrusion, and meets long-term use in complex scenes such as industry and outdoor.

Long-term durability: The number of plug-in and unplug times exceeds 1 million times (>100W times), and the contact parts adopt gold/nickel plating process to reduce contact resistance, reduce signal attenuation, and extend the life cycle of the equipment.

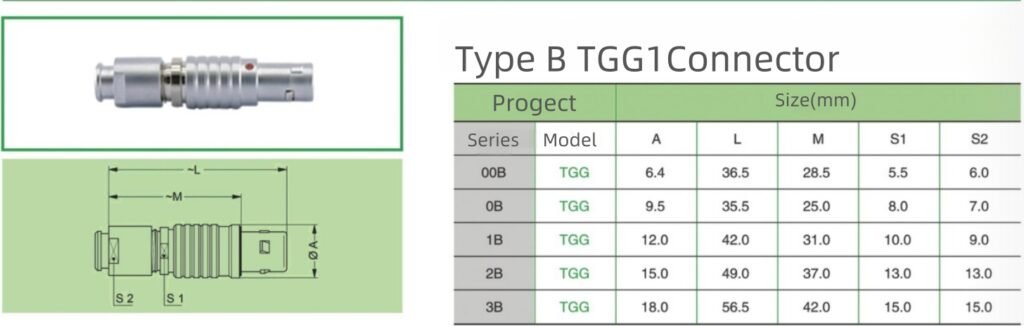

2. Product model size and characteristic parameters

3. Product overview and technical parameters

| characteristic | describe |

| Main Features | ● Quick push-pull self-locking system |

| ● Soldering pin core | |

| ●Metal straight plug | |

| ● Multiple alignment pin options to avoid mixed insertion of similar connectors | |

| ● All-round shielding effect, anti-electromagnetic interference | |

| ● Multi-core type 2-32 cores, high-density installation saves space | |

| ● Positioning pin system, G is the standard positioning pin, used for connector alignment | |

| Mechanical properties and environmental factors | ● Insertion and removal times: >5000 times |

| ● Humidity: Maximum humidity is 95% at 60°C | |

| ● Temperature range: -45°~+125° | |

| ● Vibration: 10-20000Hz, 15g | |

| ● Mechanical shock: 100g.6ms | |

| ● Salt spray service corrosion test: >48 hours | |

| ● Protection level: IP50 |

-300x300.png)

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Contact us for a custom quote within 24 hours