The B-type connector ZEG single nut fixed socket is a high-performance fixed socket (female) designed for industrial scenarios. It adopts rear panel installation and single nut chassis external fixing structure. It uses bronze substrate with nickel coating process, has excellent conductivity and corrosion resistance, and supports millions of installation and plug-in life. The product provides multiple models and specifications to adapt to different interface requirements and is suitable for precision equipment fields with strict connection reliability requirements.

1. Product Features

ZEG connector takes “stable connection, durable and reliable” as its core design concept and has three significant advantages: Scientific structural design: The fixed socket female head is matched with a single nut chassis external fixing solution, and precise alignment is achieved through positioning pins (G type/A&M type/R type). There is no need to disassemble the internal components of the chassis during installation, which greatly improves the efficiency of on-site maintenance; the rear panel installation method saves the front space of the equipment and adapts to the compact chassis layout.

Excellent material performance: The main body adopts a bronze alloy matrix, which has both high strength and good elasticity to ensure stable contact pressure during long-term plugging and unplugging; the surface is covered with a dense nickel coating, which effectively resists erosion from harsh environments such as moisture and salt spray, prolongs the service life of the connector, and reduces contact resistance to ensure signal transmission stability.

Extremely long mechanical life: After rigorous testing, the number of plugging and unplugging can reach more than one million times, meeting the needs of long-term high-frequency use of industrial equipment, reducing maintenance costs and downtime risks.

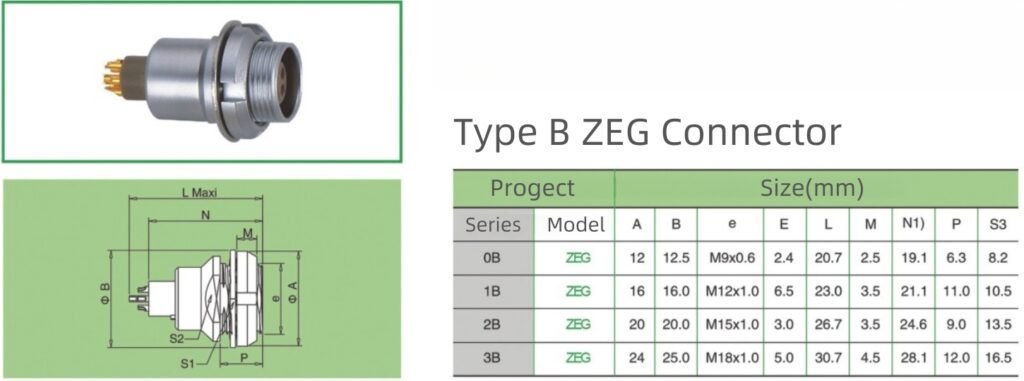

2. Product model size and characteristic parameters

3. Product overview and technical parameters

| characteristic | describe |

| Main Features | ● Quick push-pull self-locking system |

| ● Soldering pin core | |

| ●single nut fixed socket | |

| ● Multiple alignment pin options to avoid mixed insertion of similar connectors | |

| ● All-round shielding effect, anti-electromagnetic interference | |

| ● Multi-core type 2-32 cores | |

| ● Positioning pin system, G is the standard positioning pin, used for connector alignment | |

| Mechanical properties and environmental factors | ● Insertion and removal times: >5000 times |

| ● Humidity: Maximum humidity is 95% at 60°C | |

| ● Temperature range: -45°~+125° | |

| ● Vibration: 10-20000Hz, 15g | |

| ● Mechanical shock: 100g.6ms | |

| ● Salt spray service corrosion test: >48 hours | |

| ● Protection level: IP50 |

-300x300.png)

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Contact us for a custom quote within 24 hours