The F-type connector TLG short straight plug is a short straight plug connector designed for military scenarios. It adopts a multi-petal positioning structure and a semicircular metal anti-misinsertion device, combined with phosphor copper material and IP68 protection level, to achieve waterproof and dustproof, anti-seismic and anti-interference and rapid deployment functions, suitable for high-reliability electrical connections in harsh environments such as battlefield communications and individual equipment.

1. Product Features

The straight plug uses multi-petal positioning technology as its core, and achieves precise alignment between the plug and the socket through a mechanical snap-on structure, avoiding misaligned plugging and unplugging caused by vibration or manual operation, and significantly improving the connection stability. The semicircular metal anti-misplugging device adopts an asymmetric groove design, which only allows the plug of the matching model to be inserted in one direction, effectively preventing the risk of interface damage or short circuit caused by mistouch. The phosphor copper material is nickel-plated, with high conductivity and corrosion resistance, and can adapt to military environments such as salt spray and humidity; the plastic shell adopts flame-retardant engineering plastics, which has a lightweight design and impact resistance, reducing the load pressure of vehicles or individual equipment. The IP68 protection level ensures that the connector can still maintain airtightness under extreme conditions such as deep water immersion and sand and dust intrusion, and is suitable for special combat scenarios such as plateaus and deep seas.

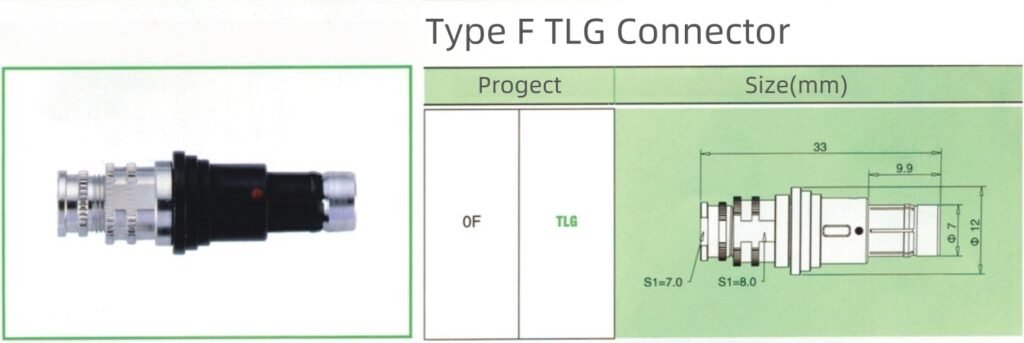

2. Product model size and characteristic parameters

| of F-type connector | |

| Main Features | Positioning straight plug |

| Phosphor copper material, high strength, good toughness | |

| Safe split-flap push-pull self-locking system; | |

| 2-40 cores; | |

| High-density installation, saving space | |

| Internal semicircular positioning to prevent mis-insertion | |

| 360-degree shielding provides all-round EMC protection | |

| Plug-in times: >100W times | |

| Protection level: IP68 or above | |

3. Application scenarios

Individual combat system: integrated into tactical vests or handheld terminals, short design saves space, multi-petal positioning ensures stable connection during intense exercise, and semi-circular metal anti-misinsertion mechanism prevents equipment failure caused by misoperation.

In-vehicle electronic equipment: in the high vibration environment inside vehicles such as armored vehicles and missile transporters, phosphor copper contacts and anti-misinsertion structures ensure the continuity of power and signal transmission, and the lightweight design of the plastic shell optimizes the vehicle weight.

Field communication base station: unmanned site exposed to dust and rain for a long time, IP68 protection and corrosion-resistant materials ensure that the equipment continues to operate in harsh climates, and the quick plug-in function supports emergency repairs.

Shipborne electronic system: adapted to the marine environment of high salt fog and high humidity, multi-petal positioning technology reduces poor contact caused by sea turbulence, and the metal shielding layer resists electromagnetic interference to ensure accurate transmission of communication instructions.

This series of products has passed the National Military Standard (GJB) certification and provides high-reliability connection solutions for national defense equipment.

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Contact us for a custom quote within 24 hours