HR10 series connector-welding socket is a miniature high-reliability connector launched by Hirose. It adopts a single nut internal fixing structure and brass nickel plating process. It is designed for industrial automation, instrumentation and precision electronic equipment. It supports welding cables at the pin core end and can be flexibly used in various scenarios. It has compact size, anti-vibration interference and long-term stable connection characteristics, suitable for electrical signal transmission in harsh environments.

1. Product Features

Miniaturized precision design: The shell is made of zinc alloy, supports high-density wiring, and is suitable for circuit boards or internal structures of equipment with limited space.

High reliability welding process: The welding barrel contacts are made of beryllium copper and gold-plated to ensure low-loss signal transmission; the welding process is compatible with automated production lines to improve assembly efficiency.

Single nut internal fixing structure: The built-in nut locking system provides a stable axial fixing force to prevent accidental loosening during plugging and unplugging, and is suitable for industrial scenes under vibration environments.

Wide temperature and voltage adaptability: The operating temperature covers -40°C to +85°C, the rated voltage reaches 100VAC/140VDC, and the withstand voltage performance passes the 500V/min high-voltage test to meet the complex working conditions of industrial equipment.

Environmental protection optimization: The halogen-free flame-retardant shell is RoHS certified, with a protection level of IP54 (dust and splash proof), and can withstand industrial environmental erosion such as salt spray and oil pollution, extending the service life.

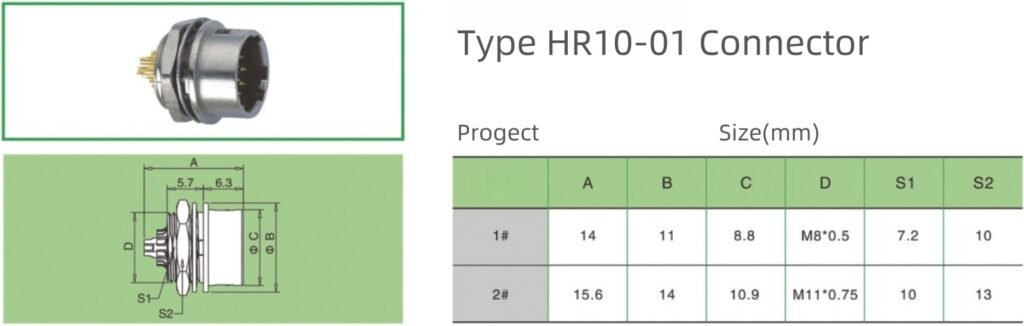

2. Product model size and characteristic parameters

3. Application scenarios

The HR10 series has become the core connection solution for industrial vision, semiconductor, medical, consumer electronics and other fields through its miniaturized structure, environmental tolerance (-40℃~+125℃ operating temperature) and diversified interface configuration (4-12 pins optional), taking into account high reliability and space efficiency.

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Contact us for a custom quote within 24 hours