M12 power connector-front lock welding type with wire connector, designed for industrial equipment connection, adopts a circular metal shell to ensure protection, and is matched with welding cables to achieve stable conductivity. It supports customized cable length and color, and is easy to install with a single nut outside the panel. The screw locking at the connection ensures reliable contact, which is suitable for the power transmission needs of various scenarios, and has both durability and flexibility

1. Product Features

The connector is made of round metal material, with excellent impact resistance and dustproof performance, suitable for harsh industrial environments. It adopts a front-locked welded wire design, and the cable is firmly connected to the terminal through the welding process to reduce contact loss; the single nut fixing structure outside the panel is convenient for installation and saves space. The screw locking design at the connection further improves the connection reliability and effectively prevents loosening. It provides S-type, T-type, L-type and other types of pin core number options (including PE/FE protection function) to meet different circuit configuration requirements. The cable length and color can be customized to facilitate engineering installation and line identification.

2. Product size and number of pins

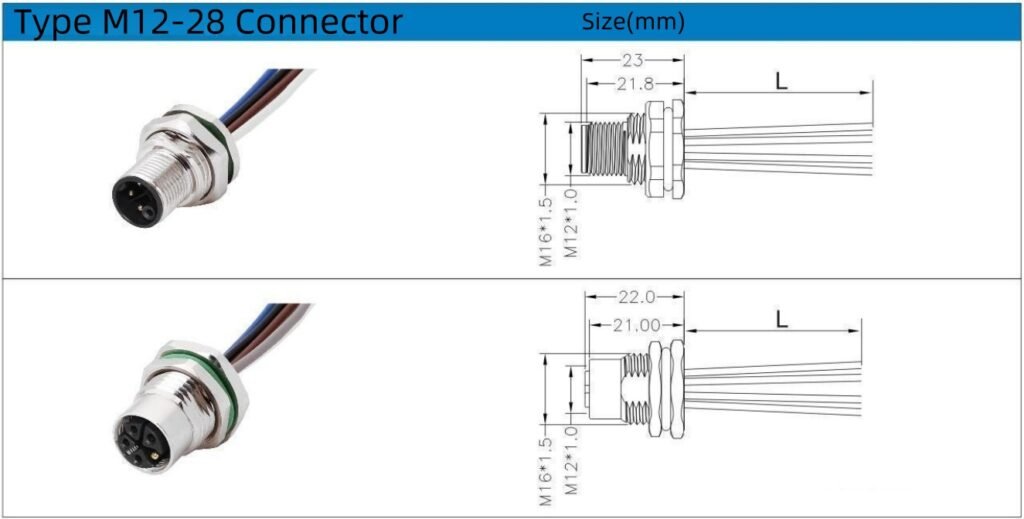

Dimensions: male head length: 23mm; female head length: 22mm; the main interface is M12 thread specification, suitable for standard industrial panels;

The thread accuracy of the fixing nut is M16×1.5, and the connection nut accuracy is M12×1.0 to ensure installation compatibility;

Number of pins configuration: 3+PE (S type), 4 pins (T type/L type/F type), 4+FE (E type), 4+PE (K type), 5+PE (M type) and other multi-pin combinations are provided. Both male and female pins adopt standardized pinhole arrangement, support fast docking, and meet the needs of multiple signal/power transmission from basic power supply to complex control system.

3. Materials and technical parameters

| Materials and parameters | |||||||

| Type | S Type | T Type | L Type | E Type | F Type | K Type | M Type |

| Number of pins | 3+PE | 4 | 4+FE | 4+FE | 4 | 4+PE | 5+PE |

| Wire gauge | max.1.5mm²(max.16 AWG) | ||||||

| Cable OD | 6~8mm | ||||||

| Operating temperature | -40℃~+85℃ | ||||||

| Mechanical operation | >100 | ||||||

| Rated voltage | 63V | ||||||

| Rated current | 12/16A | ||||||

| Protection degree | IP67/IP68 | ||||||

| Contact resistance | ≤3mΩ | ||||||

| Insulation resistance | ≥100MΩ | ||||||

| Pin contact | CuZn | ||||||

| Socket contact | CuSn | ||||||

| Contact plating | Au | ||||||

If you can provide accurate demand parameter information, we can give you a quote within 24 hours at the earliest.

These are lists of frequently asked questions by our customers. We correspond each question to a brief answer, covering aspects such as products, quality, and services. If you have other inquiries, please leave a message for consultation. Thank you.

We are a source factory with independent production capacity, with 30 years of experience in R&D and manufacturing of electric heating accessories, an annual production capacity of over 5 million sets, support OEM/ODM customization, and provide factory real-life video inspection services.

We support free sample testing, and the freight must be prepaid (collected on delivery). Conventional models are delivered in 7-10 working days, with SGS test reports and performance parameter tables.

Online response from 8:30 to 17:30 on working days. For urgent needs, you can submit a work order through the official website. We promise to provide technical replies within 2 hours and provide solutions within 48 hours.

We have two production bases in Zhongshan and Wuhu, with a monthly output of more than 3 million units, equipped with fully automatic stamping lines and automated assembly workshops. Standard product delivery time is 15 days, and customized orders are delivered within 30 days. We support batch supply.

Hold ISO9001/14001, CE (EU), ETL (North America), RoHS (environmental protection) certifications, explosion-proof products are ATEX/IECEx dual certified, and meet REACH regulations.

Serving global leading brands such as Philips,Midea,Supor,Delonghi,BSH and SEB Group, products are used in high-end projects such as coffee machines, electric irons, water dispensers, and solar heating systems., and can provide a reference list of similar customers.

Contact us for a custom quote within 24 hours