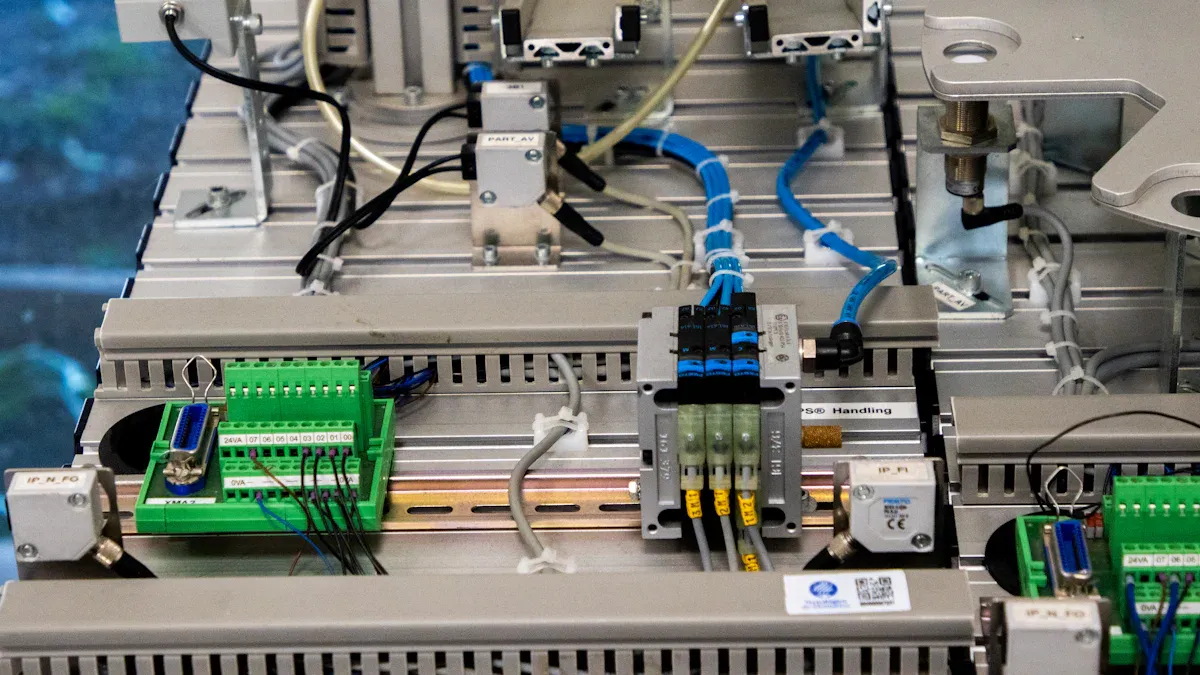

Upgrading M12 connectors gives you a distinct edge in industrial automation. You can resist dust and moisture, thanks to IP67-rated M12 designs. These connectors also withstand vibration and shock, preventing connection failures. With modular designs, you can easily scale or replace components, much like switching from a Type B connector to an M8 connector. Many connector factory experts recommend upgrading M12 connectors to improve reliability, cut downtime, and boost efficiency. When you choose advanced M12 solutions, you ensure your connectors meet the demands of today’s industrial environments.

- Upgrading M12 connectors offers:

- Enhanced protection from environmental hazards

- Reliable performance in harsh conditions

- Streamlined maintenance for lower costs

Upgrading M12 Connectors: What You Need to Know

Defining M12 Connectors

You encounter M12 connectors in almost every modern industrial automation system. These circular connectors feature a 12mm locking thread, which ensures a secure and vibration-resistant connection. M12 circular connectors come in various coding types, such as A, B, D, and X, each designed for specific signal, power, or data applications. The robust design of the M12 aviation connector allows you to use them in harsh environments, including those with dust, moisture, or high vibration. Manufacturers often choose high-quality materials like stainless steel housings and high-temperature thermoplastics to boost durability and longevity.

Tip: M12 aviation connector models support plug-and-play installation, making upgrades and replacements quick and straightforward.

| Specification Aspect | Legacy M12 Connectors | Upgraded M12 Connectors |

|---|---|---|

| EMI Shielding | Basic or limited shielding | Full 360° shielding for enhanced EMI resistance |

| Compliance | May lack full IEC compliance | Compliant with IEC 61076-2-101 standards |

| Coding Options | Limited coding (mostly A, B) | Multiple coding types including A, B, D for protocol separation |

| Data Support | Limited or no Ethernet support | Supports Ethernet up to 100 Mbps (D-coded connectors) |

| Environmental Protection | Typically IP67 | Enhanced sealing up to IP69K for dust, moisture, and vibration resistance |

| Construction | Standard ruggedness | Rugged construction designed for vibration, moisture, and dust resistance |

| Installation | Standard installation | Improved ease of installation with plug-and-play capability |

| Additional Features | Basic connector functionality | Modular designs, improved thermal management, smart monitoring and diagnostics |

Why Upgrading M12 Connectors Matters

Upgrading M12 connectors gives you access to the latest advancements in connectivity. You benefit from enhanced EMI shielding, which protects sensitive signals from interference. The new generation of M12 circular connectors supports higher data rates, such as 100 Mbps with D-coded and up to 10 Gbit/s with X-coded versions. You also gain improved environmental protection, with IP69K ratings that withstand high-pressure washdowns and extreme conditions. The compact size of these connectors supports miniaturization trends in factory automation and industrial systems.

- Upgrading M12 connectors allows you to:

- Support higher-speed connections for modern industrial networks.

- Improve ruggedness and reliability in demanding environments.

- Simplify installation and maintenance with modular, plug-and-play designs.

- Prevent accidental mismating through advanced coding options.

- Enable real-time data collection and predictive maintenance with smart features.

You can easily replace outdated components with upgraded M12 aviation connector models, reducing downtime and boosting system flexibility.

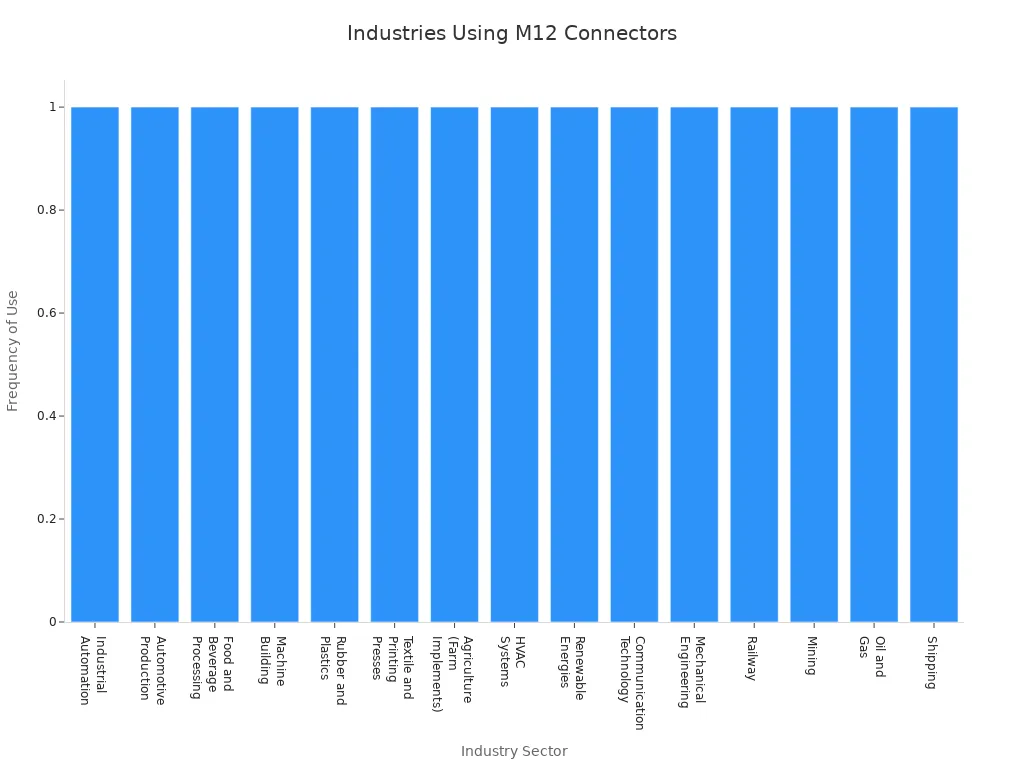

Industrial Applications of M12

You find M12 connectors across a wide range of industrial sectors. These connectors play a vital role in sensor and actuator connections, power supply, and data transmission. In industrial automation, you use M12 for connecting sensors, actuators, and industrial bus systems like CANbus, Profibus, and RS-485. The food and beverage industry relies on M12 for rugged, sealed connections that withstand washdowns. Automotive production, machine building, and renewable energy sectors also depend on M12 for reliable performance.

| Industry Sector | Primary Applications and Notes |

|---|---|

| Industrial Automation | Sensor and actuator connections, industrial bus systems (CANbus, Profibus, RS-485), Ethernet communication |

| Automotive Production | Specific cables for reliability, sensor and actuator connections |

| Food and Beverage Processing | Rugged sealed connectors for harsh environments |

| Machine Building | Sensor and actuator connections, industrial control systems |

| Renewable Energies | Industrial automation, communication technology |

| Communication Technology | Ethernet communication, data transmission |

| Railway, Mining, Oil & Gas | Rugged connectors for harsh environments, high temperature resistance |

You can select from a variety of coding types and pin counts to match your application needs. This flexibility makes M12 connectors a top choice for both legacy and next-generation industrial systems.

Key Benefits of Upgrading M12 Connectors

Enhanced Protection and Durability

IP67 Ratings and Environmental Resistance

You need connectors that can withstand the toughest industrial environments. Upgraded M12 connectors deliver IP67 protection, which means they block dust and resist water ingress. This level of sealing is essential for maintaining reliable sensor connections in factory automation and other demanding settings. Manufacturers design these circular connectors with high-quality materials and advanced sealing techniques, so you can trust them to perform even when exposed to moisture, dust, or cleaning chemicals.

Note: M12 A coded connectors are IP67 rated, ensuring full protection against dust and water ingress. This feature is critical for maintaining proven reliability in sensor and actuator connections.

The table below compares protection ratings and durability features of different connector types:

| Connector Type | Generation/Use Case | Protection Rating | Durability Features | Additional Notes |

|---|---|---|---|---|

| M12 | Latest, used on new SPYDR 2, VYPR 3, RAZRm fixtures | IP65 | Threaded design, good environmental protection | Compatible with newer equipment, improved ease of use |

| M16 Push Lock | Predecessor to M12, used on earlier SPYDR 2, VYPR 2 | IP67/IP68 | Rugged metal shell, 360° EMI shielding, high vibration and shock resistance | Higher ingress protection, suitable for harsher environments |

| M16 Twist Lock | Used on SPYDRx, VYPRx, RAZRx, RAY fixtures | IP67/IP68 | Rugged metal shell, EMI shielding, vibration and shock resistance | High durability, used in earlier models |

You gain robust durability and protection with upgraded M12 connectors, making them ideal for modern industrial applications.

Vibration and Shock Tolerance

In industrial automation, vibration and shock can cause connection failures. Upgraded M12 connectors use vibration-proof locking mechanisms to prevent accidental disconnects. This design reduces unplanned downtime and ensures stable connections, even in high-vibration environments like robotics or transportation systems.

- Vibration-proof locking prevents accidental disconnects.

- Rugged construction reduces failures caused by environmental factors.

- Compliance with IEC standards guarantees global compatibility and safety.

You benefit from rugged performance and fewer maintenance disruptions, which keeps your systems running smoothly.

High-Speed Data and Signal Performance

Industrial Ethernet and Fieldbus Support

Modern industrial systems demand high-speed data transmission. Upgraded M12 connectors support industrial Ethernet data rates up to 10 Gbit/s. This capability meets the requirements of advanced automation, real-time monitoring, and high-precision machine control. D-coded M12 connectors handle up to 100 Mbit/s, while X-coded versions reach 10 Gbit/s, making them suitable for both standard and high-demand applications.

You can use these connectors for Ethernet/IP networks, fieldbus systems, and other data-intensive tasks. Their design ensures stable and fast communication, which is essential for Industry 4.0 and IIoT environments.

Signal Integrity and Reduced Downtime

You need reliable signal transmission to avoid costly downtime. Shielded M12 connectors provide 360° EMI protection, reducing electromagnetic interference and ensuring consistent performance. The separation of signal types through different coding options minimizes errors and improves system integrity.

Tip: Shielded M12 connectors reduce signal loss and connection failures, supporting reliable operation in harsh industrial environments.

With these features, you experience fewer disruptions and maintain high system uptime.

Modularity and System Flexibility

Fast System Expansion

Upgraded M12 connectors offer modular features that make system expansion and reconfiguration simple. You can use plug-and-play standardized connection systems to handle power, signal, and data. This approach enables quick assembly, disassembly, and customization without specialized wiring.

- Plug-and-play systems enable fast assembly and customization.

- Advanced coding systems prevent mismatches and reduce errors.

- Standardization across brands supports flexible sourcing and compatibility.

You can scale your systems quickly to meet changing production needs.

Easy Maintenance and Replacement

Maintenance and replacement become much easier with upgraded M12 connectors. Patented locking mechanisms prevent accidental disconnections, even in high-vibration environments. You can assemble cables quickly and replace components without special tools, minimizing downtime.

- Clear coding reduces accidental mating errors.

- Multiple coupling systems (push-pull, threaded, bayonet) enhance ease and security.

- Hot-swappable design allows you to connect or disconnect while equipment is running.

These features simplify maintenance and maximize productivity in industrial settings.

Compliance and Compatibility

International Standards for M12

You rely on M12 connectors to meet strict international standards in industrial environments. The IEC 61076-2-101 standard defines the physical and coding characteristics of M12 connectors, including the 12mm locking thread and keying notches that prevent mismating. Manufacturers design upgraded M12 models with multiple coding types—A, B, D, L, and X—to ensure correct application and prevent cross-connection. You benefit from 360-degree EMI shielding, which protects sensitive signals from electromagnetic interference. Certified materials, such as those compliant with RoHS, REACH, and UL, guarantee safety and reliability.

- M12 connectors feature threaded coupling for vibration resistance.

- You find field-installable designs and flame-retardant materials for demanding environments.

- Leading manufacturers produce M12 connectors in IATF 16949 certified facilities, ensuring rigorous process control and traceability.

You can trust upgraded M12 connectors to deliver consistent performance and meet global safety requirements.

Backwards Compatibility with Legacy Systems

You often need to upgrade equipment without replacing entire systems. Upgraded M12 connectors maintain backwards compatibility with legacy systems by supporting standardized coding and pin layouts. You can integrate new connectors with older devices, reducing downtime and avoiding costly overhauls. The standardized design allows you to swap connectors without extensive rewiring or modification.

Tip: When you upgrade to new M12 models, you preserve existing infrastructure and ensure seamless integration with legacy equipment.

You achieve reliable connections and future-proof your operations while maintaining compatibility with previous generations.

Space-Saving and Compact Design

Optimizing Layouts in Tight Spaces

You face challenges when working in environments with limited panel space. M12 connectors have a compact footprint of about 12 millimeters in diameter, making them ideal for tight enclosures. Their small size allows you to install multiple connectors side by side without overcrowding. This space-saving design improves organization and flexibility in industrial layouts.

- You simplify installation and reduce the risk of tangled wires.

- Compact connectors enable efficient use of available space.

You optimize your layouts and enhance system performance by choosing M12 connectors for space-constrained applications.

Supporting Miniaturization

You see ongoing miniaturization efforts in M12 connector technology. Ultra-compact versions maintain robustness and performance while reducing physical dimensions. This enables you to design more compact and lightweight automation systems. Real-world examples show that push-pull M12 connectors reduce installation time by 74% compared to traditional threaded models. The IX Industrial connector, which is 75% smaller than the RJ45 form factor, supports high data rates up to 10 Gbps and is robust enough for industrial use. Integrating functionalities like magnetics within M12 connectors reduces board space and component count.

You benefit from these advancements by achieving more compact configurations, easier installation in constrained spaces, and enhanced system flexibility.

Safety and Reliability Improvements

Secure Locking Mechanisms

You need secure connections to prevent accidental disconnects in industrial environments. Upgraded M12 connectors use patented locking mechanisms, such as threaded couplings and push-pull systems, to provide reliable mating. These features ensure connectors stay in place, even under vibration or mechanical stress.

| Reliability Metric | Description / Importance |

|---|---|

| Mechanical Locking Mechanism | Prevents accidental disconnections, especially under vibration. |

| Ingress Protection (IP67/68) | Protects against dust and water ingress. |

| Shielding (EMI/EMC) | Blocks electromagnetic interference for stable data transmission. |

You maintain stable connections and reduce the risk of unexpected failures.

Reducing Connection Failures

You want to minimize downtime and avoid costly repairs. Upgraded M12 connectors incorporate 360° shielding to block electromagnetic interference, flame-resistant materials rated UL 94V-0, and compliance with IEC standards. These features improve reliability and safety in harsh industrial environments. Standardized coding types restrict mating to the correct orientation and application, reducing the risk of mismating.

Note: M12 connectors operate reliably over a wide temperature range and withstand repeated connections and disconnections, ensuring long-term durability.

You achieve higher system uptime and lower maintenance costs by choosing reliable M12 connector solutions.

Implementing Upgrading M12 Connectors in Industrial Environments

Assessing System Requirements

Identifying Upgrade Opportunities

You start by evaluating your current systems to pinpoint where an upgrade will deliver the most value. Begin with a thorough inspection of your existing connectors. Look for visible damage, contamination, or signs of wear. Confirm that the connector coding matches your intended applications to prevent mismating. Verify the pin configuration aligns with your device requirements. Review voltage and current ratings from datasheets to ensure compatibility. Clean all mating surfaces to avoid dust or debris interfering with connection integrity. Plan your installation layout to allow easy access for future maintenance and troubleshooting.

Recommended steps for assessing system requirements:

- Confirm connector coding matches your application.

- Verify pin configuration with device needs.

- Inspect connectors for damage or contamination.

- Check environmental protection rating (e.g., IP67).

- Select cables with proper shielding and temperature resistance.

- Prepare necessary tools, including torque wrenches.

- Review voltage and current ratings.

- Clean mating surfaces before installation.

- Plan layout for easy maintenance.

Evaluating Environmental and Performance Needs

You must consider the environment where your m12 aviation connector will operate. Assess exposure to dust, moisture, chemicals, vibration, and temperature extremes. Select connectors with suitable IP ratings, such as IP67, for reliable performance in harsh conditions. Choose cable materials like PUR for abrasion resistance or TPE for chemical resistance. Match connector type and coding to your specific application to ensure safe and efficient connections. Always follow manufacturer guidelines and industry standards to maintain compliance and reliability.

Selecting the Right M12 Connector Codes

Understanding Coding Types (A, B, D, X, etc.)

You encounter several coding types when selecting an m12 aviation connector. Each code supports different functions and prevents mismating. A-coded connectors work well for sensors and actuators. B-coded connectors suit industrial networks like Profibus. D-coded connectors support Ethernet up to 100 Mbit/s, while X-coded versions handle high-speed Ethernet up to 10 Gbit/s. S-coded and T-coded connectors serve power applications, and L-coded models distribute DC power for LED lighting.

| M12 Coding | Typical Use Case | Key Considerations |

|---|---|---|

| A-coded | Sensors, actuators, IO-Link devices | Prevents mismating; supports 3-12 pins |

| B-coded | Profibus, Interbus | Signal/data communication in legacy systems |

| C-coded | AC power devices, motors | AC power transmission with PE pins |

| D-coded | Industrial Ethernet (100 Mbit) | Reliable factory automation networks |

| X-coded | High-speed Ethernet (up to 10 Gbit/s) | High data rate, reduced crosstalk |

| S-coded | High-load AC power equipment | Rugged upgrade to C-coded |

| T-coded | DC power up to 12A/63V | Motors, drives, power controls |

| K-coded | 3-phase AC power up to 630V/12A | Compact high-load equipment |

| L-coded | DC power for LED lighting | Compact, up to 16A/63V |

| P-coded | Hybrid signal/power | Quick-change equipment |

Matching Codes to Application Needs

You define your application requirements before choosing a connector code. Consider the number of poles or pins needed for signal, data, or power. Select straight or angled connectors based on installation space and cable routing. Pick the correct gender to ensure proper mating. Evaluate environmental conditions and choose connectors with suitable IP ratings. Prefer reputable manufacturers for quality and reliability. Always match connector coding to your application to prevent mismating and ensure efficient operation in industrial systems.

Installation Best Practices

Cable Selection and Routing

You select cables based on movement and environmental demands. For stationary installations, PVC jackets offer cost-effective protection. For dynamic or robotic applications, PUR jackets provide high flex and chemical resistance. Use cables with 20 gauge conductors and proper stranding to improve flexibility and longevity. Avoid over-bending cables and maintain the recommended bend radius. Plan cable routing to minimize strain and support connector reliability.

Proper Termination Techniques

You prepare cables by stripping 6-8mm of insulation with the right tools, keeping the jacket up to the seal area. Apply a thin layer of dielectric grease to contacts to prevent corrosion. Align connectors carefully and insert straight to engage seals and locking mechanisms. Use a torque wrench to secure threaded connections, applying 0.4-0.6 Nm for critical applications. Clean connectors regularly and use protective caps when not in use. Test electrical continuity before finalizing installation. Perform routine inspections to detect wear or loose fittings early.

Tip: Keep spare connectors available to minimize downtime and support long-term reliability.

Ensuring Seamless Integration

Compatibility with Existing Equipment

You want your upgraded m12 connectors to work smoothly with your current equipment. Compatibility remains a top priority during integration. You often face challenges such as electromagnetic interference, distance limitations, and mismatched components. Upgraded m12 connectors address these issues with 360° shielding, robust construction, and compliance with IEC standards. These features help block interference and ensure reliable connections. You should inspect connectors after maintenance or relocation and engage patented locking mechanisms to prevent accidental disconnections. Using standardized components simplifies expansion and reduces compatibility problems.

| Integration Challenge | Solution/Feature |

|---|---|

| Electromagnetic interference | Shielded m12 cables and 360° connector shielding |

| Accidental disconnects | Patented locking mechanisms, secure reconnection |

| Compatibility issues | IEC standard compliance, standardized coding |

| Environmental conditions | Flame-resistant materials, robust construction |

You can optimize your network design to minimize data transmission issues and use flexible connector options for easier upgrades and replacements. Certifications like IATF 16949 ensure quality and reliability in critical applications.

Testing and Validation

Testing and validation play a crucial role in seamless integration. You should conduct regular electrical tests to monitor network speed and signal quality. After installation, perform continuity checks to confirm proper connections. Visual inspections help you spot damage or improper termination. You need to replace worn-out cables and inspect shielding to prevent intermittent data loss. Integrated monitoring tools allow you to predict failures and schedule preventive maintenance. These steps help you maintain signal integrity and reduce downtime in your industrial systems.

Tip: Always test new connections before powering up equipment to avoid costly errors.

Maintenance and Troubleshooting

Routine Inspection Guidelines

Routine inspections keep your m12 connectors performing at their best. You should visually check for cuts, improper termination, or crimping errors. Look for signs of wear, corrosion, or loose fittings. Use continuity testing to verify electrical integrity. Allow enough cable length and avoid sharp bends near connectors to reduce mechanical stress. Keep spare cables available for quick replacement. Regular inspections help you detect problems early and maintain reliable operation.

- Inspect connectors for physical damage.

- Test electrical continuity.

- Check for proper shielding and grounding.

- Replace cables showing signs of wear.

- Use protective caps when connectors are not in use.

Addressing Common Issues

You may encounter issues such as intermittent connections, noise, or grounding problems. Visual inspections and continuity tests help you identify faults. If you cannot pinpoint the cause, replace the entire cable to restore reliability. Avoid using self-made cables; choose premade industrial-grade shielded cables for correct pin assignments and wire gauge. Ensure proper shielding and grounding to reduce noise. Motor feedback cables require precise assembly to avoid connection problems. Systematic testing and replacement often resolve the hardest-to-diagnose faults.

Note: Cabling faults related to connectors can be difficult to diagnose. Thorough inspection and use of quality components reduce troubleshooting time.

You improve system reliability and minimize downtime by following these maintenance and troubleshooting practices.

Overcoming Challenges in Upgrading M12 Connectors

Minimizing Downtime During Upgrades

You face pressure to keep your systems running during connector upgrades. Minimizing downtime requires a strategic approach and the right tools. You can use several proven methods to streamline the process:

- Choose compact M8 connectors to increase sensor deployment density and save valuable installation space.

- Integrate SPE Hybrid cables to combine data and power transmission, which simplifies wiring and shortens installation time.

- Rely on threaded locking designs for reliable connections in high-vibration environments, reducing the risk of failures.

- Standardize connector specifications to make parts management easier and cut maintenance time and costs.

- Centralize production to improve supply chain coordination and reduce complexity.

- Implement modern ERP systems, such as SAP, to enhance order processing, inventory transparency, and data reliability.

- Maintain safety stocks for high-demand parts to ensure availability during transitions.

- Streamline customer order channels to reduce lead times and improve service levels.

- Use advanced connector designs like the SpeedTec quick-locking system for faster installation and maintenance.

- Monitor processes with performance indicators to maintain flexibility and service levels.

Tip: High automation and strict quality controls in connector assembly help you ensure reliability and reduce failures during upgrades.

These strategies enable you to complete upgrades quickly, reduce wiring errors, and maintain connection reliability.

Training for New M12 Systems

You need proper training to adapt to new M12 connector systems. Industry leaders offer specialized programs and resources to help you build the necessary skills. Cisco provides the ‘Cisco Optical Technology Intermediate (OPT200)’ course, which includes hands-on training with Cisco ONS 15454 M6 and M12 shelves. You learn installation, configuration, maintenance, and troubleshooting for optical networking systems that use M12 connector technology. The course combines lectures and practical experience, teaching you how to deploy and maintain networks using Cisco Transport Controller software with M12 hardware.

Fluke Networks supports your learning with Certified Cabling Technician Training, online videos, webinars, and workshops. You gain access to specialized testing adapters, such as DSX M12D or M12X, which are essential for testing and certifying cabling systems with M12 connectors. These resources help you understand industrial Ethernet cabling and connector standards, ensuring you work confidently with upgraded M12 systems.

Note: Investing in training programs improves your team’s ability to install, maintain, and troubleshoot new connector systems, reducing errors and downtime.

Budgeting and Cost Management

You must manage costs carefully when upgrading M12 connectors. Start by evaluating your current inventory and identifying which connectors need replacement. Create a detailed budget that includes connector costs, labor, training, and potential downtime. Standardize connector types to reduce inventory complexity and take advantage of bulk purchasing discounts. Use ERP systems to track expenses and optimize order processing. Maintain safety stocks for critical parts to avoid delays and unexpected costs.

| Cost Management Strategy | Benefit |

|---|---|

| Standardize connector types | Simplifies inventory, reduces costs |

| Bulk purchasing | Lowers unit price, improves supply |

| ERP system integration | Tracks expenses, streamlines orders |

| Safety stock management | Prevents delays, controls costs |

Tip: Careful planning and process monitoring help you stay within budget and maximize the value of your connector upgrades.

You achieve a smooth upgrade process by balancing investment in quality components, training, and efficient supply chain management.

Future-Proofing with M12 Connector Upgrades

Supporting Industry 4.0 Initiatives

You play a key role in shaping the future of industrial automation when you upgrade to advanced M12 connectors. These connectors support Industry 4.0 by enabling seamless integration of smart technologies and real-time data exchange. You benefit from modular expansion capabilities that allow you to connect sensors, power sources, RJ45, and fiber optic interfaces. This flexibility meets the composite data and power needs of industrial IoT systems.

- You use M12 connectors as standard interfaces in robot joints and servo drives, which enables precise motion control for collaborative robots.

- You build high-speed Ethernet links in 5G and TSN factory networks, supporting low-latency data exchange for digital twins and edge computing.

- You adapt M12 connectors for flexible production systems, such as AGV charging stations and sensor networks, improving dynamic response and production efficiency.

- You select customizable protection levels and cable materials to enhance reliability in harsh environments, supporting intelligent manufacturing ecosystems.

Tip: User-friendly assembly designs, like HARTING’s preLink concept, simplify installation and future upgrades. You do not need special skills to maintain or expand your network.

You ensure your facility remains competitive and ready for the next wave of smart manufacturing.

Scalability for Evolving Demands

You need scalable solutions to keep pace with changing production requirements. Upgraded M12 connectors provide compact, robust, and modular connectivity for power, signal, and data. You integrate these connectors into existing automation systems and cabling infrastructures with ease. Fast Ethernet communication, including Gigabit and 10 Gigabit speeds, supports smart factory applications and future expansion.

- You extend cabling quickly using pre-terminated patch leads, reducing installation time and complexity.

- You expand sensor networks and add new devices without major rewiring.

- You maintain flexibility in your production line, adapting to new technologies and processes as they emerge.

| Feature | Benefit for Scalability |

|---|---|

| Modular design | Easy system expansion |

| Pre-terminated leads | Faster installation |

| Multiple interface types | Supports diverse applications |

| Compact footprint | Fits space-constrained layouts |

You future-proof your operations by choosing connectors that grow with your business.

Innovations in M12 Technology

You see rapid advancements in M12 connector technology that shape the future of industrial connectivity. Manufacturers design X-coded connectors for high-speed Ethernet, supporting Industry 4.0 applications. Waterproof models with IP67 ratings ensure reliable performance in moisture-prone environments. Push-pull locking mechanisms simplify installation and removal, saving you valuable time.

- You use high-density pin configurations, such as 12-pin connectors, for complex data and power transmission.

- Shielded connectors maintain signal integrity in environments with electromagnetic interference.

- Compact and robust designs fit into tight industrial spaces, supporting miniaturization trends.

- Integrated LED indicators provide enhanced diagnostics and status visibility.

You also benefit from environmentally friendly and energy-saving designs that meet global sustainability standards. Continuous improvements in integration, size reduction, and material optimization increase the intelligence and reliability of connectors. You handle higher currents and frequencies, improving data transmission speed and bandwidth. Enhanced anti-interference and protection features adapt to harsh industrial environments.

Note: Future M12 connectors will become even more compact, lightweight, and intelligent, meeting the demands of advanced automation equipment.

You stay ahead of industry trends by adopting the latest innovations in M12 connector technology.

You gain measurable improvements in reliability, flexibility, and performance by upgrading m12 connectors in your industrial systems. Careful selection and proper implementation help you achieve long-term benefits and meet global standards. Evaluate your current setup and plan upgrades to stay competitive and ready for future demands.

Take action now to ensure your operations remain efficient and compliant as technology evolves.

FAQ

What is the main advantage of upgrading to M12 connectors?

You gain improved reliability, faster data transmission, and better protection against harsh environments. Upgraded M12 connectors help you reduce downtime and support modern industrial automation needs.

Can you use M12 connectors in wet or dusty environments?

Yes. You can use M12 connectors with IP67 or higher ratings in wet or dusty environments. These connectors resist water and dust, making them ideal for demanding industrial settings.

How do you choose the right M12 coding type?

You select the coding type based on your application. For example, use A-coded for sensors, D-coded for Ethernet, and X-coded for high-speed data. Always match the code to your device requirements.

Are upgraded M12 connectors compatible with older equipment?

Yes. Most upgraded M12 connectors maintain backward compatibility. You can integrate them with legacy systems if you match the coding and pin configuration.

What maintenance do M12 connectors require?

You should inspect connectors regularly for damage, corrosion, or loose fittings. Clean contacts and replace worn cables as needed. Routine checks help you maintain reliable performance.

How do you ensure proper installation of M12 connectors?

You use the correct tools, follow manufacturer guidelines, and check torque specifications. Always test connections before powering up your equipment to prevent errors.

Can M12 connectors support high-speed Ethernet?

Yes. X-coded M12 connectors support Ethernet speeds up to 10 Gbit/s. You can use them for high-speed data transmission in advanced automation systems.