Selecting the right waterproof connector ensures your equipment stays protected in harsh conditions. You need to consider the environment, check compatibility, and demand reliability from every connector. For instance, the market for waterproof connectors shows strong growth, especially for circular and IP65/68 types. You can see the current and projected values below:

| Market Segment | Market Size (2022) | Projected Size (2029) | CAGR |

|---|---|---|---|

| Circular Waterproof Connector | US $1.07 Bn | US $1.39 Bn | 3.7% |

| Waterproof Wire Connector | USD 2.1 Billion | USD 3.5 Billion | 6.5% |

| IP65/68 Waterproof Connector | USD 2.5 Billion | USD 4.7 Billion | 6.8% |

You can find options like the M8 connector or Type B connector from a connector factory that match your specific waterproof needs.

What Are Waterproof Connectors?

Definition and Key Features of Waterproof Connectors

You encounter waterproof connectors in many environments where moisture poses a risk to electrical systems. These specialized components protect your connections by forming a watertight seal. Their design ensures that water cannot penetrate the connection point, which helps maintain safety and reliability.

A waterproof connector is a component meant to secure electrical flow between two devices through a tight seal. Its construction and material ensure no signs of moisture or water residues interrupt this process.

Waterproof connectors use materials such as rubber or silicone to insulate and seal the connection. You benefit from these features because they keep water out, even in high-moisture conditions. This protection is essential for outdoor, marine, and industrial applications. Waterproof electrical connectors are specifically engineered to keep water out of the connection point, which is crucial for maintaining a safe and reliable electrical connection. They achieve this through tight seals that resist moisture, ensuring that even in high-moisture conditions, the integrity of the connection is preserved.

You can compare waterproof connectors to non-waterproof connectors using the table below:

| Feature | Waterproof Connectors | Non-Waterproof Connectors |

|---|---|---|

| Definition | Designed to keep water out of the connection point | No specific design to prevent water intrusion |

| Seal | Forms tight seals to resist high-moisture conditions | Lacks effective sealing against moisture |

| Material | Often made with rubber or silicone for insulation | Typically made from standard materials |

| Applications | Essential in marine and outdoor environments | Suitable for dry, indoor applications |

| Maintenance Cost | Reduces maintenance costs due to minimized water damage | Higher maintenance costs due to potential damage |

You should look for these key features when selecting a connector for any application exposed to moisture. Waterproof connectors are designed to prevent water damage and ensure reliable connections. They form tight seals that resist moisture, often using materials like rubber or silicone. Non-waterproof connectors do not have these protective features, making them vulnerable to water exposure.

Why Waterproof Connector Selection Matters

You must choose the right waterproof connector to protect your equipment and reduce maintenance costs. Quality waterproof wire connections act as the first line of defense against moisture-related issues that can jeopardize the safety and reliability of electrical systems. By selecting and installing the right connectors, you significantly enhance the longevity and performance of your electrical projects. This choice leads to reduced maintenance costs and fewer unexpected failures.

If you select low-cost connectors, you may face performance issues. These connectors often have shorter lifespans, which results in costly replacements over time. You should always match the connector to your environment and application needs. When you prioritize quality and proper sealing, you ensure your system remains safe and reliable, even in challenging conditions.

Tip: Always check the specifications for watertight seals and material quality before making your selection. This step helps you avoid future problems and keeps your system running smoothly.

Types of Waterproof Connectors

Waterproof connectors come in several types, each designed for specific environments and technical requirements. You need to understand the differences to select the right connector for your application. The table below shows how the market categorizes these connectors:

| Category | Examples/Characteristics |

|---|---|

| By Product Type | Heat Shrink Connectors, Potted Connectors, Crimp Connectors, Screw-on Connectors, Sealed Connectors |

| By Application | Automotive, Aerospace, Marine, Industrial Equipment, Consumer Electronics |

| By Material Type | Polymer-Based Connectors, Metal-Based Connectors, Silicone Connectors, Thermoplastic Elastomers (TPE), Composite Material Connectors |

| By Voltage Rating | Low Voltage (Up to 50V), Medium Voltage (51V – 1000V), High Voltage (Above 1000V) |

| By Connection Type | Electrical Connection, Mechanical Connection, Hybrid Connection |

Circular Waterproof Connectors

Common Uses for Circular Waterproof Connectors

You will find waterproof circular connectors in many demanding environments. These connectors are standard in factory automation, sensors, and industrial equipment. M8, M12, and M23 models serve as the backbone for reliable connections in these settings. Military and aerospace applications rely on MIL-DTL-5015 and MIL-DTL-38999 series for their robust sealing and vibration resistance. Medical devices often use miniaturized waterproof circular connectors like the ODU MINI-MED® for hygiene and compactness. Audio equipment, such as XLR connectors, and consumer electronics, including GX16 connectors, also benefit from this design.

Key Advantages of Circular Waterproof Connectors

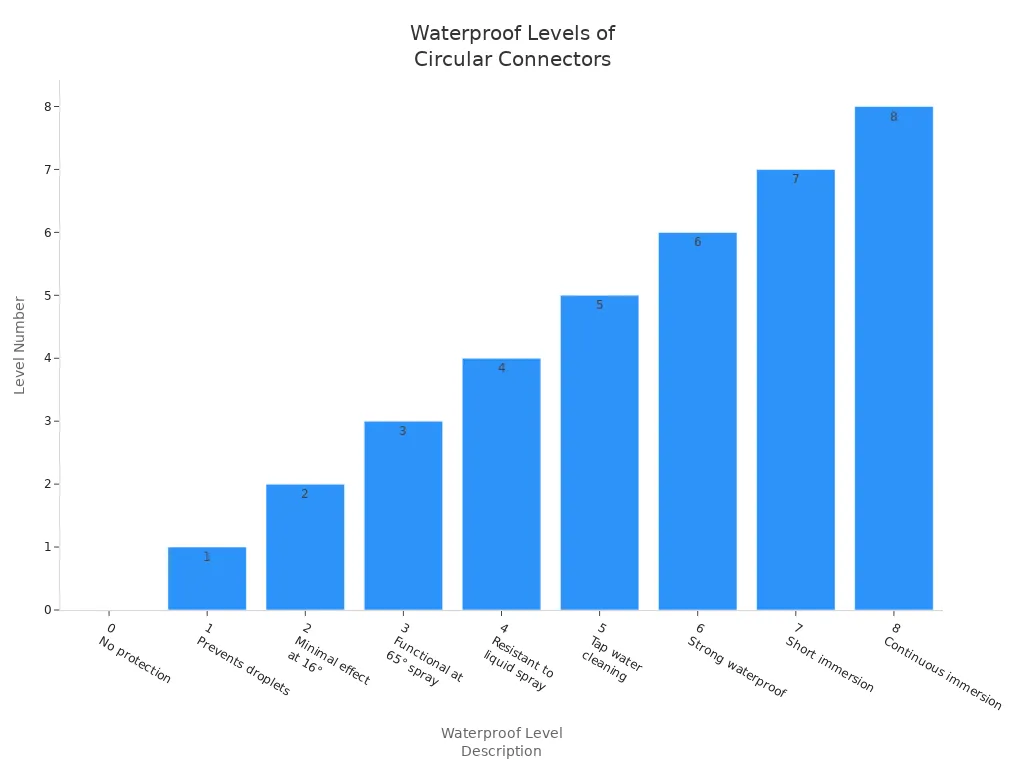

Waterproof circular connectors offer several advantages. You gain excellent environmental sealing, which protects against dust and water. These connectors resist vibration, making them ideal for mobile or industrial equipment. The round shape allows for easy mating and unmating, even in tight spaces. You can choose from a range of waterproof levels, as shown in the chart below:

Circular connectors excel in applications that require frequent connection and disconnection. You can trust them for high reliability in harsh environments.

Rectangular Waterproof Connectors

Typical Applications for Rectangular Waterproof Connectors

Rectangular connectors suit applications where you need high pin counts and compact designs. You will see these connectors in electronic equipment, industrial automation, and control panels. Their shape allows you to fit more connections into a smaller space, which is valuable for complex systems.

Strengths and Limitations of Rectangular Waterproof Connectors

Rectangular connectors handle high-density connections well. You benefit from their ability to transmit multiple signals in a compact form. However, they may not match the environmental sealing or vibration resistance of waterproof circular connectors. You should use them in less demanding environments where space and pin count matter most.

Note: Circular connectors are best for harsh, wet, or vibrating environments. Rectangular connectors work well for high-density, indoor applications.

USB and Data Waterproof Connectors

Where USB and Data Waterproof Connectors Are Used

You rely on USB and data waterproof connectors in outdoor kiosks, industrial computers, and marine electronics. These connectors protect sensitive data lines from water and dust. Common models, such as the LP-24, offer IP68 or IPX9K ratings, supporting both USB 2.0 and USB 3.0 standards.

| Connector Model | IP Rating | Rated Current | Rated Voltage | Transmission Rate |

|---|---|---|---|---|

| LP-24 | IP68 / IPX9K | 1.5A / 1.8A | 5V AC | 480 Mbps / 5Gbps |

| Connector Type | IP Rating | Standard | Length Options |

|---|---|---|---|

| USB 3.0 Cable Assembly | IP67 | USB 3.0 | 0.5m, 1.0m, 1.5m |

Special Considerations for USB and Data Waterproof Connectors

You should look for features like threaded couplings and O-ring seals. These ensure a secure and watertight connection. Quick-connect designs allow you to install or replace cables easily, even in the field. Always check the IP rating to confirm the level of protection. IP67 and IP68 ratings mean the connector can withstand immersion and dust, which is essential for outdoor or industrial use.

Tip: Choose USB and data connectors with the right IP rating for your environment. This step helps you avoid data loss and equipment failure.

Power Waterproof Connectors

High-Current Applications for Power Waterproof Connectors

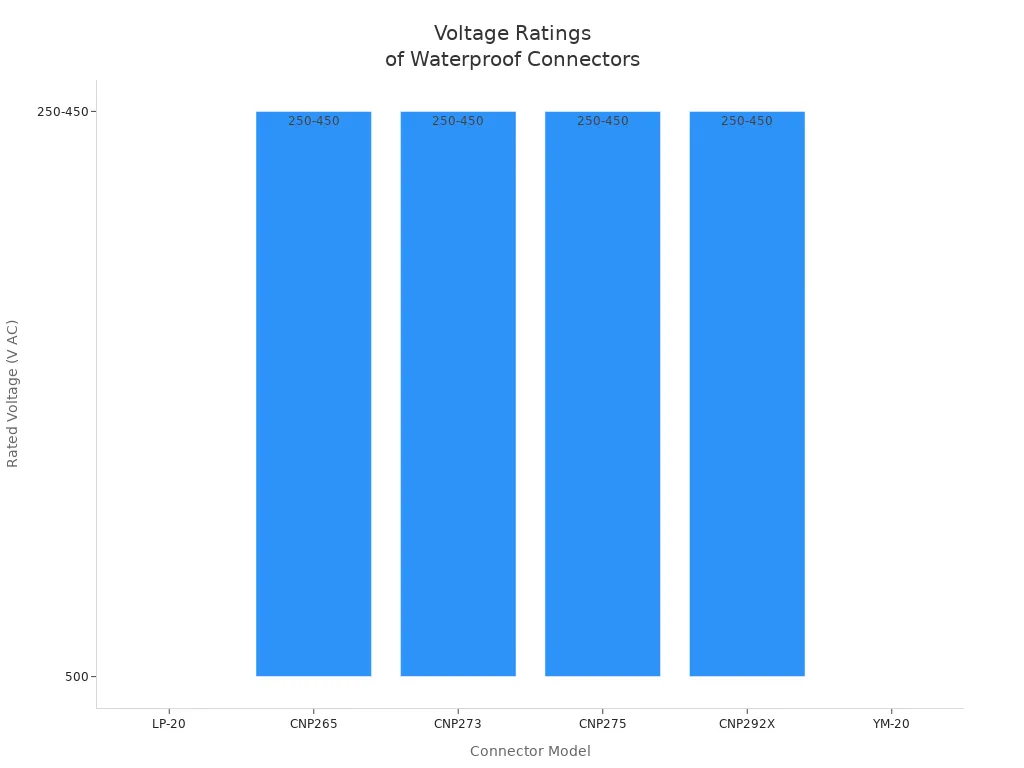

You often encounter power waterproof circular connectors in environments that demand high current and voltage. Industrial machinery, outdoor power distribution, and heavy equipment rely on these connectors for safe and stable energy transfer. You can select from a range of models designed for different current and voltage needs. The table below shows typical ratings for popular power waterproof circular connectors:

| Connector Model | Rated Current | Rated Voltage |

|---|---|---|

| ACR-16 | 11.6 A | N/A |

| SBSX-75A | Up to 135 A | N/A |

| LP-20 | 20 A | 500 V AC |

| CNP265 | 16 A | 250-450 V AC |

| CNP273 | 16 A | 250-450 V AC |

| CNP275 | 16 A | 250-450 V AC |

| CNP292X | 16 A | 250-450 V AC |

| YM-20 | 20 A | 500 V AC |

You can see that some models, such as the SBSX-75A, handle extremely high currents, making them suitable for demanding industrial applications. The LP-20 and YM-20 models support both high current and high voltage, which gives you flexibility for various power systems.

Safety Features of Power Waterproof Connectors

You gain several safety benefits when you use power waterproof circular connectors. These connectors feature robust insulation and secure locking mechanisms. You reduce the risk of accidental disconnection and electrical arcing. Many models include flame-retardant materials and built-in strain relief, which protect both the connection and the cable. You also benefit from color-coded housings and keyed designs that prevent incorrect mating. These features help you maintain a safe and reliable power system, even in harsh or wet environments.

Tip: Always check for certifications such as UL or IEC when selecting power waterproof circular connectors for critical applications.

RF/Coaxial Waterproof Connectors

Applications for RF/Coaxial Waterproof Connectors

You use RF/coaxial waterproof circular connectors in systems that transmit radio frequency signals. These connectors play a key role in antenna installations, cellular base stations, radar systems, and satellite communications. You also find them in outdoor wireless networks and CATV systems, where signal integrity and environmental protection are essential.

Performance Factors for RF/Coaxial Waterproof Connectors

You need to consider frequency range, impedance, and environmental sealing when choosing RF/coaxial waterproof circular connectors. The table below highlights common types and their specifications:

| Connector Type | Maximum Frequency | Characteristic Impedance | Common Applications |

|---|---|---|---|

| TNC | 11-12 GHz | 50 Ohm | Antenna, cellular base station, radar |

| SMA | 18 GHz (up to 26.5 GHz) | 50 Ohm | Microwave circuitry, handheld radios, mobile telephone antennas |

| N-type | 11 GHz (up to 18 GHz) | 50 or 75 Ohm | RF equipment, satellite and radar systems, CATV systems |

You should select the connector type that matches your system’s frequency and impedance requirements. Waterproof circular connectors in this category often feature threaded couplings and O-rings to maintain signal quality in wet or dusty environments.

Fiber Optic Waterproof Connectors

Uses for Fiber Optic Waterproof Connectors

You rely on fiber optic waterproof circular connectors when you need high-speed data transmission in outdoor or industrial settings. These connectors support applications such as remote monitoring, outdoor security cameras, and telecommunications infrastructure. You also see them in marine and military systems, where both data integrity and environmental protection matter.

Key Features of Fiber Optic Waterproof Connectors

You benefit from low insertion loss and robust sealing with fiber optic waterproof circular connectors. Most general fiber connectors offer insertion loss values below 0.2 dB, which ensures minimal signal loss. Hardened types, such as OptiTap or H-type, come pre-terminated and ready for quick installation. You gain protection against water, dust, and mechanical stress, which keeps your fiber network reliable in challenging environments.

Note: Always verify the insertion loss and sealing specifications before deploying fiber optic waterproof circular connectors in mission-critical systems.

Comparison Table: Types of Waterproof Connectors at a Glance

When you select waterproof connectors, you need to compare the main types side by side. This helps you match the right connector to your application. Each type offers unique strengths for different environments and technical needs. The table below gives you a quick overview of how the most common types perform in terms of IP rating, current capacity, and where you should use them.

| Connector Type | IP Rating | Current Capacity | Application Suitability |

|---|---|---|---|

| ILME T-Type | IP69 | High | Extreme environments, food processing |

| Harting Han-Modular | IP66 | High | Complex installations, modular systems |

| Bulgin Tool-free Ethernet | IP67 | Moderate | Outdoor networking installations |

| M12 Connectors | IP68 | Low | Compact wiring needs |

You see that waterproof circular connectors, such as the M12, stand out for compact wiring. These connectors fit well in tight spaces and provide reliable sealing. You often use circular connectors when you need to protect connections in harsh or wet environments. The ILME T-Type, another example of waterproof circular connectors, offers the highest IP rating. You can trust it in extreme conditions, including food processing plants where you must wash down equipment frequently.

Tip: Always check the IP rating before you choose a connector. Higher IP ratings mean better protection against water and dust.

Harting Han-Modular connectors give you flexibility for complex systems. You can build modular solutions that handle high currents. These connectors work well in industrial automation where you need to combine power, signal, and data in one assembly. Bulgin Tool-free Ethernet connectors help you set up outdoor networks quickly. You do not need special tools, which saves you time during installation.

You should remember that waterproof circular connectors come in many sizes and pin counts. You can select from M8, M12, and larger circular connectors to match your wiring needs. These connectors often use threaded or bayonet locking to keep the seal tight. You get strong vibration resistance, which is important for mobile or industrial equipment.

When you compare types, focus on the application. If you need high current and the best waterproof protection, choose ILME T-Type or Harting Han-Modular. For compact, reliable connections, pick M12 or other waterproof circular connectors. Outdoor networking calls for Bulgin Tool-free Ethernet, which balances ease of use and moderate protection.

Note: You should always match the connector type to your environment and technical requirements. This step ensures long-term reliability and safety.

Common Applications for Waterproof Electrical Connectors

Outdoor Lighting and Signage with Waterproof Cable Connectors

You often see waterproof cable connectors in outdoor lighting and signage systems. These connectors provide reliable water protection, which is essential for outdoor electronics exposed to rain, humidity, and dust. Proper installation prevents electrical shorts and protects both property and individuals from potential hazards. Durability becomes especially important in coastal areas, where saltwater exposure can accelerate corrosion.

Key requirements for these applications include:

| Key Requirement | Description |

|---|---|

| Compatibility | Ensure connectors match the specific needs of the lighting system and environmental conditions. |

| IP Ratings | Select connectors with appropriate Ingress Protection ratings to withstand water exposure. |

| Material Types | Use robust materials that resist corrosion and degradation, especially in harsh environments. |

| Temperature Rating | Choose connectors that can handle the temperature ranges expected in outdoor applications. |

| Sealing Capability | Opt for connectors with effective sealing mechanisms to prevent moisture ingress. |

You should always select connectors with high IP ratings and robust materials to guarantee long-term outdoor protection. This approach helps maintain the performance and safety of your lighting and signage installations.

Marine and Boating Equipment Using Waterproof Connectors

Marine environments present some of the harshest conditions for electrical systems. You need waterproof connectors that can withstand saltwater, humidity, and constant vibration. Corrosion resistance stands out as a top priority. Materials like stainless steel or marine-grade plastics help prevent failures caused by saltwater exposure.

When choosing connectors for marine and boating equipment, focus on the following factors:

- Corrosion resistance to handle saltwater and humidity.

- Watertight and waterproof sealing that meets IP67 or IP68 standards.

- Vibration and shock resistance for connection integrity in turbulent conditions.

- Durability to withstand mechanical stresses common in marine settings.

- Ease of installation and compatibility with existing systems.

You benefit from selecting connectors that meet or exceed industry standards for water protection. This ensures your navigation, communication, and power systems remain reliable, even in challenging aquatic environments.

Automotive and Transportation Waterproof Connectors

Automotive and transportation sectors rely heavily on waterproof electrical connectors to ensure safety and reliability. You face challenges such as exposure to water, dust, and extreme temperatures. High reliability under vibration and mechanical stress is essential. Improper installation can lead to performance issues, while frequent disconnections may cause pin damage.

Common challenges include:

- Exposure to water, dust, and temperature extremes.

- Need for high reliability under vibration and mechanical stress.

- Risk of performance issues from improper installation techniques.

- Pin damage from frequent disconnections.

- Limitations in current capacity for certain connector types.

Weather Pack connectors, for example, provide moisture sealing but are not suitable for submersion. You must ensure proper crimping and installation to prevent ingress of contaminants. Selecting the right connector helps you maintain system integrity and supports the increasing demands of electric vehicles and advanced safety systems.

| Application Sector | Description |

|---|---|

| Industrial | Largest segment driven by automation, robotics, and process control systems. |

| Automotive | Growth fueled by electric vehicles, connected cars, and advanced safety systems. |

| Aerospace & Defense | Critical for avionics and communication systems, requiring ruggedized performance. |

| Marine | Essential for navigation and communication in challenging aquatic environments. |

| Healthcare | Demand driven by portable diagnostic devices and medical imaging equipment. |

| Consumer Electronics | Rising popularity of wearables and outdoor gadgets boosts demand for waterproof connectors. |

You see that waterproof connectors play a vital role across many sectors. Each application demands specific features to ensure reliable operation and long-term durability.

Industrial Machinery and Waterproof Electrical Connectors

You face demanding conditions in industrial environments. Dust, moisture, and vibration can threaten the reliability of your equipment. Choosing the right waterproof electrical connectors helps you maintain safe and efficient operations. In industrial machinery, connectors with proper IP ratings protect against environmental hazards. For example, IP67-rated connectors withstand dust and brief water immersion. You can use these on factory floors or outdoor equipment. If your machinery operates in harsher environments, IP68 connectors offer protection against long-term immersion in water.

- IP ratings follow the IEC 60529 standard.

- IP67 provides dust protection and brief immersion.

- IP68 allows for long-term immersion, ideal for harsh settings.

You should always match the connector’s IP rating to your application. This step ensures your equipment stays operational, even in wet or dusty conditions. Proper selection reduces downtime and extends the lifespan of your machinery.

Tip: Always check the IP rating before installation. This simple step prevents costly failures and keeps your production line running smoothly.

Consumer Electronics and Waterproof Cable Connectors

You expect your devices to work in all kinds of environments. Waterproof cable connectors play a key role in protecting consumer electronics from water, dust, and temperature changes. When you select connectors for these devices, consider several important criteria:

- Match the connector to your device’s needs and the environment.

- Check voltage, current capacity, and resistance to environmental stress.

- For outdoor devices, choose connectors that resist rain, snow, and temperature swings.

| Criteria | Description |

|---|---|

| IP Rating | Defines the connector’s ability to resist dust and water penetration. |

| Temperature Range | Ensures materials withstand operating temperatures (e.g., -40°C to 125°C). |

| Mating Cycles | Indicates durability; consumer devices need 500+ cycles. |

| Certifications | Look for UL, CSA, or ATEX for hazardous environments. |

You can choose between plastic and metal housings. Plastic connectors are lightweight and cost-effective. Metal connectors offer more durability and corrosion resistance. Before you buy, check for certifications like UL or CE. These marks show the connector has passed strict testing.

Note: Reliable connectors help your devices last longer and perform better, even in tough conditions.

Renewable Energy Systems and Waterproof Connectors

You need robust connectors in renewable energy systems such as solar and wind installations. These systems face constant exposure to rain, dust, and temperature extremes. Waterproof connectors prevent water from entering electrical connections, which could cause short circuits or system failures. Manufacturers design these connectors with seals and gaskets to block moisture and dust.

| Connector Type | Waterproof Rating | Features |

|---|---|---|

| USB Connectors | IP67 | Bayonet-style or threaded, vibration resistant |

| D-Sub Connectors | IP67 | Epoxy sealed, silicone O-ring for waterproofing |

| Electrical Pin Connectors | IP67, IP68, IP69K | Multi-layered gaskets for dust and water resistance |

- IP67 protects against immersion up to 1 meter for 30 minutes.

- IP68 allows for continuous immersion under manufacturer-specified conditions.

- IP69K resists high-pressure, high-temperature water jets.

You should always select connectors with the right waterproof rating for your installation. This choice ensures your renewable energy system remains safe and reliable, even in severe weather.

Callout: Waterproof connectors are essential for the long-term success of solar and wind power projects.

Medical Devices Using Waterproof Electrical Connectors

You play a critical role in ensuring patient safety when you select connectors for medical devices. Waterproof electrical connectors protect sensitive equipment from moisture, dust, and cleaning agents. In medical environments, you often face strict hygiene requirements and frequent sterilization. You need connectors that maintain performance even after repeated exposure to harsh cleaning chemicals or autoclave cycles.

Medical device applications demand connectors that deliver both reliability and compliance. You see waterproof cable connectors used in patient monitors, diagnostic imaging systems, infusion pumps, and surgical instruments. These connectors help prevent fluid ingress, which can cause malfunctions or safety hazards. You also benefit from their ability to withstand accidental spills and routine disinfection.

When you choose connectors for medical devices, you must consider several regulatory requirements:

- CE marking shows that the connector meets European health, safety, and environmental standards.

- The Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive apply to many medical connectors.

- Compliance with IEC 60601-1 ensures the connector meets international safety standards for medical electrical equipment.

- The FDA must clear medical devices before they reach the market. Connectors undergo the same scrutiny as the devices themselves.

- Adequate shielding is necessary to prevent electromagnetic interference (EMI), which can disrupt device operation.

You can use the table below to review key selection criteria for medical waterproof connectors:

| Selection Criteria | Why It Matters |

|---|---|

| IP Rating | Protects against fluid ingress during cleaning or use |

| Chemical Resistance | Withstands disinfectants and sterilization agents |

| EMI Shielding | Prevents interference with sensitive medical electronics |

| Regulatory Compliance | Meets CE, FDA, and IEC 60601-1 standards |

| Durability | Handles frequent connection cycles and harsh environments |

Tip: Always verify that your connector supplier provides documentation for regulatory compliance. This step helps you avoid delays in device approval and ensures patient safety.

You should also consider ease of use. Medical staff often need to connect and disconnect devices quickly, sometimes while wearing gloves. Choose connectors with ergonomic designs and clear mating indicators. This approach reduces the risk of connection errors and supports efficient workflows.

Waterproof cable connectors give you peace of mind in medical device applications. They help you maintain high standards of safety, reliability, and compliance in every healthcare setting.

Key Selection Criteria for Waterproof Connectors

Choosing the right waterproof connectors for your project requires a careful look at several technical factors. You need to ensure that your selection delivers reliable connections, withstands harsh environments, and meets your application’s safety standards. This section guides you through the most important criteria, helping you make informed decisions for long-term reliability and watertight performance.

IP Ratings Explained for Waterproof Connectors

What IP Ratings Mean for Waterproof Connectors

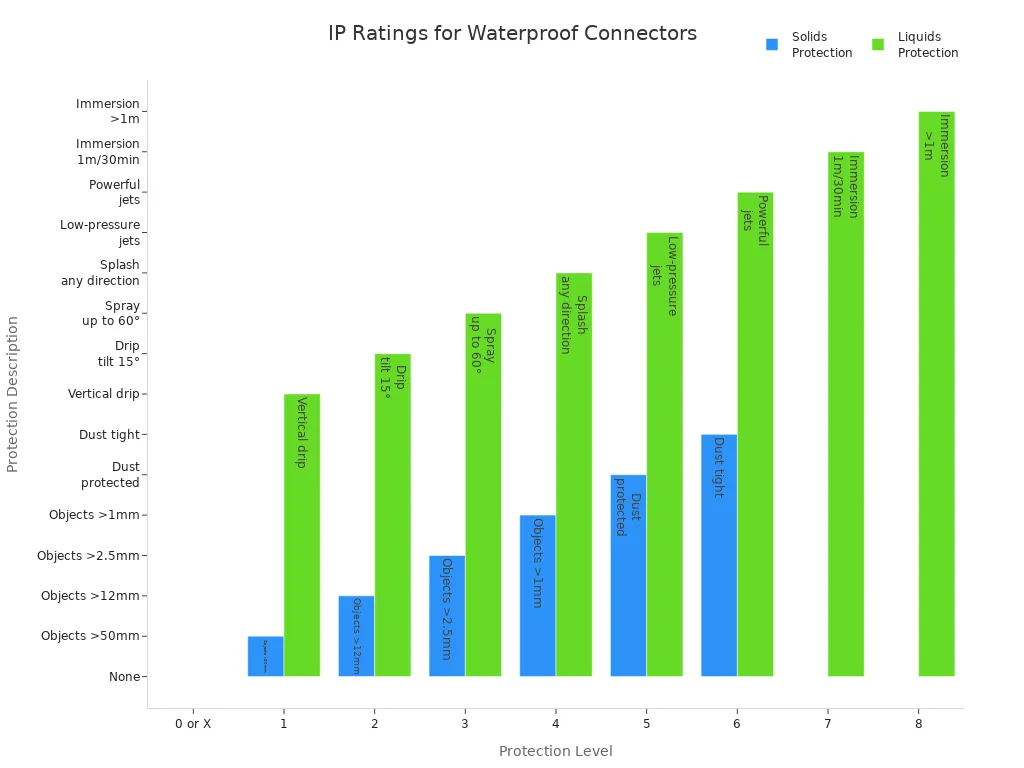

IP ratings serve as a universal standard for measuring the level of protection that a waterproof connector offers against solids and liquids. Each rating consists of two digits. The first digit shows how well the connector resists solid objects like dust. The second digit indicates the level of protection against water ingress. For example, an IP67 rating means the connector is dust-tight and can handle immersion in water up to 1 meter for 30 minutes.

| Protection Level | Solids Rating | Liquids Rating |

|---|---|---|

| 0 or X | Not rated for protection against contact or ingress. | Not rated for protection against ingress. |

| 1 | Protection against solid objects larger than 50 mm. | Protection against vertically dripping water. |

| 2 | Protection against solid objects larger than 12 mm. | Protection against vertically dripping water when tilted up to 15°. |

| 3 | Protection against solid objects larger than 2.5 mm. | Protection against water sprayed at any angle up to 60° off vertical. |

| 4 | Protection against solid objects larger than 1 mm. | Protection against splashing water from any direction. |

| 5 | Dust protected: partial protection against dust. | Protection against low-pressure jets from any direction. |

| 6 | Dust tight: full protection against dust. | Protection against powerful water jets. |

| 7 | N/A | Protection against full immersion at up to 1 meter depth for up to 30 minutes. |

| 8 | N/A | Protection against immersion beyond 1 meter. |

You can see how each level provides a different degree of environmental protection. The higher the numbers, the better the defense against dust and water.

Choosing the Right IP Level for Waterproof Connectors

You should always match the IP rating to your application’s environment. For outdoor or marine use, select connectors with at least IP67 or IP68 ratings. These ratings ensure the connector remains watertight even during immersion. In less demanding indoor settings, a lower IP rating may suffice. Testing for these ratings involves projecting pressurized water jets, submerging the enclosure, and simulating various water flows. This process guarantees that watertight electrical connectors meet strict standards for water and dust resistance.

Tip: Always check the IP rating before installation. This step helps you avoid water ingress and ensures long-term reliability.

Material and Build Quality of Waterproof Connectors

Plastic vs. Metal Waterproof Connector Housings

You face a choice between plastic and metal housings when selecting waterproof connectors. Each material offers unique advantages. Plastic housings, such as those made from nylon or thermoplastic elastomers (TPE), provide strength, impact resistance, and flexibility. These materials also handle fluctuating temperatures well. Metal housings, like titanium or 316L stainless steel, deliver superior durability and resist crevice corrosion. They work best in environments where mechanical stress and harsh chemicals are common.

| Material | Advantages |

|---|---|

| Nylon | Strong, impact-resistant, handles temperature changes |

| Thermoplastic Elastomers (TPE) | Durable, resists impacts and temperature swings |

| Titanium or 316L Stainless Steel | Excellent corrosion resistance, high durability |

| Glass-Reinforced Polyamide | Withstands compression forces |

| PVC | Cost-effective, suitable for light-duty applications |

You should choose the housing material based on your application’s exposure to physical stress, chemicals, and temperature extremes.

Corrosion Resistance in Waterproof Connectors

Corrosion resistance plays a critical role in the longevity of waterproof electrical connectors. In humid or marine environments, stainless steel or titanium alloy housings prevent rust and degradation. High-density rubber sealing rings block moisture, ensuring poor electrical contact does not occur. Hydrogenated nitrile rubber (HNBR) maintains its properties under pressure, making it ideal for high-performance connectors.

| Material | Advantages |

|---|---|

| Corrosion-Resistant Stainless Steel/Titanium | Prevents rust and corrosion in humid environments |

| High-Density Rubber Sealing Rings | Blocks moisture, maintains electrical integrity |

| Hydrogenated Nitrile Rubber (HNBR) | Maintains sealing under pressure |

Note: Always select high-quality connectors with proven corrosion resistance for marine, industrial, or outdoor use.

Durability and Environmental Resistance of Waterproof Connectors

Temperature Tolerance in Waterproof Connectors

You need connectors that perform reliably across a wide temperature range. Silicone rubber excels in this area, offering flexibility and insulation from extreme cold or heat. Many waterproof connectors use materials that withstand temperatures from -40°C to 125°C. This capability ensures that your electrical systems remain operational in both freezing and scorching conditions.

Waterproof electrical connectors are engineered to maintain electrical flow and performance during severe weather, heavy rain, or high humidity. Tight seals and robust materials shield internal components from water exposure, supporting reliability in extreme environments.

UV and Chemical Resistance of Waterproof Connectors

Outdoor and industrial applications often expose connectors to ultraviolet (UV) rays and harsh chemicals. You should select watertight connectors with UV-resistant materials, such as silicone rubber or glass-reinforced polyamide. These materials prevent degradation from sunlight and chemical exposure. In washdown areas or medical settings, chemical resistance ensures connectors withstand frequent cleaning and sterilization without losing their watertight properties.

- Waterproof connectors are crucial in:

- Automotive engine compartments and underbody sensors

- Marine electronics and navigation systems

- Industrial machinery in washdown zones

- Outdoor lighting and infrastructure

- Medical devices requiring sterilization

Callout: Choosing connectors with strong UV and chemical resistance protects your investment and guarantees long-term reliability.

By focusing on these key selection criteria—IP ratings, material and build quality, and environmental resistance—you ensure that your waterproof connector delivers the performance and protection your application demands.

Electrical Specifications for Waterproof Electrical Connectors

Voltage and Current Ratings of Waterproof Connectors

You must always check the voltage and current ratings before selecting a waterproof connector. These ratings define the maximum electrical load the connector can safely handle. If you exceed these limits, you risk overheating, arcing, or even equipment failure. Manufacturers test connectors under strict conditions to determine these values. You should match the connector’s ratings to your application’s requirements. For example, outdoor lighting may need connectors rated for 250V and 10A, while industrial machinery could demand much higher values.

You will find that most datasheets list both continuous and peak ratings. Always use the continuous rating for regular operation. Peak ratings only apply to short bursts. If you operate near the maximum, consider a connector with a higher rating for added safety. This approach helps you avoid costly downtime and ensures long-term reliability.

Signal Integrity in Waterproof Cable Connectors

Signal integrity matters when you transmit data or sensitive signals through waterproof cable connectors. You want to minimize signal loss, interference, and crosstalk. High-quality connectors use shielding, gold-plated contacts, and precise pin alignment to maintain clean signals. You should also consider the connector’s impedance, especially for RF or high-speed data applications.

Poor signal integrity can cause data errors, slow communication, or even system failures. You can prevent these issues by choosing connectors designed for your signal type and by following best installation practices. Always keep connector surfaces clean and free from debris. Use dielectric grease if recommended by the manufacturer. This step helps maintain a strong, reliable connection in any environment.

Compatibility and Fit of Waterproof Connectors

Connector Size and Pin Count for Waterproof Connectors

You need to select the right size and pin count for your application. Connector size affects how easily you can install it in tight spaces. Pin count determines how many circuits you can connect at once. If you choose a connector that is too large, it may not fit your device. If you select too few pins, you may not support all your electrical needs.

Manufacturers offer a wide range of sizes and configurations. You should review your system’s requirements before making a choice. Always check the datasheet for dimensions and pin layouts. This step ensures a proper fit and reduces the risk of installation errors.

Cable and Device Matching with Waterproof Connectors

Matching your cables and devices with the correct connector is essential for reliable performance. You should always verify that the connector’s contacts align with your cable’s conductors. Mismatched connectors can cause poor connections, signal loss, or even damage to your equipment.

To avoid common compatibility issues, follow these best practices:

- Keep connectors in a clean, dry environment to avoid contamination.

- Store connectors in their original packaging until use.

- Regularly inspect connectors for signs of wear or degradation.

- Ensure surfaces are clean before installation.

- Use compatible dielectric grease for sealing.

- Follow torque specifications to avoid damage.

By following these steps, you help ensure a secure and lasting connection.

Ease of Installation for Waterproof Connectors

Tool-Free vs. Soldered Waterproof Connector Connections

You have two main installation options: tool-free and soldered connections. Tool-free connectors use push-fit, screw, or clamp mechanisms. These designs let you install or replace connectors quickly, even in the field. You do not need special tools or advanced skills. This option works well for temporary setups or when you need to make frequent changes.

Soldered connectors require more time and skill. You must use a soldering iron to attach wires to the contacts. This method creates a strong, permanent bond. Soldered connections offer better vibration resistance and lower electrical resistance. You should choose this option for critical or high-vibration applications.

Field Serviceability of Waterproof Connectors

Field serviceability refers to how easily you can install, maintain, or replace connectors on-site. Several factors affect this process. The table below summarizes the main considerations:

| Factor | Description |

|---|---|

| Connector Size | Ensures proper fit and integration into existing equipment. |

| Interface Type | Affects compatibility and ease of connection with other devices. |

| Installation Methods | Different methods (e.g., panel mount, soldering) influence installation ease. |

You should select connectors that match your field requirements. Smaller connectors fit better in compact spaces. Simple interface types reduce installation errors. Choose installation methods that suit your team’s skills and available tools. By considering these factors, you improve efficiency and reduce downtime during maintenance or upgrades.

Step-by-Step Selection Guide for Waterproof Connectors

Assess Your Application Environment for Waterproof Connectors

You start the selection process by evaluating the environment where your connector will operate. This step ensures you choose a solution that withstands real-world conditions and delivers reliable performance.

-

Identify Your Specific Needs

Begin by listing the electrical load, environmental conditions, and the intended application. Consider temperature extremes, exposure to chemicals, and the presence of dust or moisture. For example, connectors used outdoors may face rain, UV rays, and fluctuating temperatures, while those in industrial settings might encounter oils or solvents. -

Evaluate Different Connector Brands

Research available brands and compare their reputations for quality and durability. Look for certifications such as UL or IEC, and review warranty options. Reliable brands often provide detailed datasheets and support, which helps you make informed decisions. -

Make the Final Decision

Weigh the pros and cons of each option based on your needs. Focus on durability and performance rather than just cost. A higher upfront investment in a robust connector can save you from costly failures and maintenance down the line.

Tip: Always document your environmental requirements before moving to the next step. This habit streamlines your selection process and reduces the risk of overlooking critical factors.

Define Electrical and Mechanical Needs for Waterproof Connectors

You must clearly define the electrical and mechanical requirements before choosing a connector. This step prevents compatibility issues and ensures safe operation.

-

Identify Environmental Conditions

Assess the specific challenges your connectors will face, such as submersion, extreme temperatures, or physical impacts. For example, connectors in marine environments need to resist saltwater and vibration. -

Check Compatibility

Ensure the connector matches your existing electrical equipment. Verify voltage, current capacity, and size to avoid mismatches that could cause failures. -

Look for Quality Materials

Select connectors made from durable materials that withstand environmental stressors. Materials like stainless steel or high-grade plastics offer resistance to corrosion and mechanical wear. -

Evaluate the IP Rating

Choose connectors with appropriate IP ratings. For demanding conditions involving moisture or submersion, opt for IP67 or IP68 ratings. These ratings indicate strong protection against dust and water ingress. -

Consider Installation Tools

Confirm you have the necessary tools for secure installation. Some connectors require specialized equipment, while others offer tool-free assembly for faster deployment.

Note: Defining these requirements early helps you avoid costly redesigns and ensures your system operates safely and efficiently.

Match Waterproof Connector Type to Use Case

You need to match the connector type to your specific application to achieve optimal performance and reliability.

-

Determine the Requirements

Define your project’s needs, including application, environment, voltage, current ratings, and any relevant standards. -

Research Connector Types

Familiarize yourself with the different types of waterproof connectors and their unique features. For example, circular connectors often provide better sealing for harsh environments, while rectangular connectors suit high-density applications. -

Consult Manufacturer Datasheets

Review datasheets for specifications such as IP rating, material compatibility, and mechanical properties. This information helps you verify that the connector meets your technical requirements. -

Consider Connector Size and Configuration

Ensure the physical dimensions and pin configurations align with your application. A mismatch can lead to installation challenges or unreliable connections. -

Evaluate Environmental Compatibility

Assess the connector’s ability to withstand moisture, temperature extremes, and other environmental factors. Select a connector that matches the demands of your use case. -

Seek Expert Advice

Consult manufacturers or distributors for guidance on technical requirements. Their expertise can help you navigate complex specifications and avoid common pitfalls. -

Test and Validate

Obtain samples for testing in your actual environment. This step confirms that the connector performs as expected before full-scale deployment. -

Ensure Compliance

Verify that the connector meets industry standards and certifications. Compliance ensures safety and reliability in regulated industries. -

Work with a Reputable Supplier

Partner with trusted suppliers who offer technical support and a range of product options. A reputable supplier can provide valuable insights and help you source the best solution.

Callout: Matching the right connector type to your use case guarantees long-term reliability and reduces the risk of unexpected failures.

Check IP Rating and Material of Waterproof Connectors

You need to evaluate both the IP rating and the material before you select any waterproof connector. The IP rating tells you how well the connector resists dust and water. You should look for ratings like IP67 or IP68 if your application faces rain, splashes, or immersion. These ratings guarantee that the connector will perform in harsh environments.

Material selection matters just as much. You must choose a housing that matches your environment. For outdoor use, stainless steel or reinforced plastic provides strong resistance to corrosion and impact. In marine settings, you benefit from connectors made with marine-grade metals or high-density rubber seals. These materials prevent rust and maintain a tight seal.

Tip: Always check both the IP rating and the material specification on the datasheet. This step helps you avoid failures caused by water ingress or material breakdown.

You can use the table below to compare common materials and their strengths:

| Material Type | Strengths | Typical Use Cases |

|---|---|---|

| Stainless Steel | Corrosion resistance, durability | Marine, industrial |

| Reinforced Plastic | Lightweight, impact resistant | Outdoor electronics |

| High-Density Rubber | Flexible, watertight seal | Medical, marine |

You should match the IP rating and material to your specific environment for the best results.

Confirm Compatibility and Fit of Waterproof Connectors

You must confirm that the connector fits your cable and device before installation. Size and pin count play a key role. If you select a connector that is too large, it may not fit your equipment. If you choose too few pins, you cannot connect all your circuits.

You should always check the datasheet for dimensions and pin layout. This step ensures that the connector matches your cable and device. You need to verify that the contacts align with your conductors. Mismatched connectors can cause poor connections or damage.

- Measure the available space for the connector.

- Count the number of circuits you need to connect.

- Review the pin configuration and layout.

- Confirm that the connector matches your cable type.

Note: Proper fit and compatibility prevent installation errors and ensure reliable performance.

You should test the connector with your actual cable and device before full deployment.

Review Installation Requirements for Waterproof Connectors

You need to review the installation requirements before you begin. Some connectors offer tool-free installation, while others require soldering or crimping. Tool-free connectors save you time and allow quick changes in the field. Soldered connections provide a strong bond and work well in high-vibration environments.

You should check if you need special tools or training. You must follow the manufacturer’s instructions for torque and sealing. This step ensures that the waterproof seal remains intact.

| Installation Method | Advantages | Considerations |

|---|---|---|

| Tool-Free | Fast, easy, no tools | May not suit all uses |

| Soldered | Strong, vibration-proof | Needs skill and tools |

| Crimped | Reliable, quick | Requires crimping tool |

Callout: Always follow the recommended installation method to maintain the waterproof integrity of the connector.

You should plan for field serviceability and future maintenance when you select your installation method.

Evaluate Cost vs. Performance of Waterproof Connectors

You face a critical decision when balancing cost and performance for waterproof connectors. Price often draws your attention first, but you should look deeper. The lowest-cost option may not deliver the reliability or lifespan your application demands. You need to weigh the initial investment against long-term value.

Start by identifying the essential features for your project. Ask yourself these questions:

- Does your application require a high IP rating for complete waterproof protection?

- Will the connector face frequent connection cycles or harsh environments?

- Do you need advanced materials for chemical or UV resistance?

Once you define your requirements, compare available options. Use a table to organize your findings:

| Feature | Basic Connector | Mid-Range Connector | Premium Connector |

|---|---|---|---|

| IP Rating | IP65 | IP67 | IP68/IP69K |

| Material | Standard Plastic | Reinforced Plastic | Stainless Steel |

| Lifespan (cycles) | 200 | 500 | 1000+ |

| Price (per unit) | $2 | $5 | $12 |

| Warranty | 6 months | 1 year | 2+ years |

You see that higher-priced connectors often provide better protection, longer service life, and stronger warranties. These benefits can reduce maintenance costs and downtime over the product’s lifetime.

Tip: Consider the total cost of ownership, not just the purchase price. A premium waterproof connector may save you money by preventing failures and reducing replacement frequency.

You should also factor in installation and maintenance. Some connectors require special tools or training, which adds to your project cost. Tool-free designs may cost more upfront but save you time and labor.

When you evaluate performance, test connectors in real-world conditions if possible. Look for certifications and compliance with industry standards. Reliable performance in your environment justifies a higher investment.

You make the best choice by balancing your budget with the level of protection and durability you need. Always match the connector’s capabilities to your application’s demands. This approach ensures you get the most value from your investment in waterproof technology.

Installation and Maintenance Tips for Waterproof Connectors

Preparing for Waterproof Connector Installation

You set the stage for a reliable connection by preparing carefully before installation. Start by gathering all necessary tools and materials. Use only undamaged connectors and check each one for cracks or imperfections. Measure and strip wires to the correct length, following the manufacturer’s guidelines. Align wires precisely within the connector sleeve to prevent poor contact. Take your time and avoid rushing, as a careful approach reduces the risk of mistakes.

Many installers make common errors during this process. The table below highlights frequent mistakes and how you can prevent them:

| Mistake | Prevention Strategy |

|---|---|

| Failing to Use the Right Tools | Invest in the right tools for the job to ensure reliable connections. |

| Overlooking Wire Alignment | Ensure wires are well aligned within the connector sleeve before crimping. |

| Ignoring Weatherproofing | Use waterproof heat shrink or silicone gel to protect connectors from moisture. |

| Not Double-Checking the Connection | Always test the connection with an appropriate device after installation. |

| Using Damaged Connectors | Inspect connectors for any damage or imperfections before use. |

| Rushing Through the Process | Take your time to follow each step carefully and avoid last-minute scrambles. |

| Ignoring Wire Exposure Length | Measure and adjust exposure lengths to meet electrical standards. |

| Disregarding Connector Type | Choose the correct type of connector for the specific application and environment. |

By following these strategies, you improve the reliability and longevity of your waterproof connector installation.

Proper Sealing Techniques for Waterproof Connectors

You achieve a watertight seal by using the right techniques and materials. Always use the sealing components provided with your connector, such as O-rings or gaskets. Position these seals correctly before tightening the connector. For added protection, apply waterproof heat shrink tubing or silicone gel around the joint. This step blocks moisture and dust from entering the connection.

After assembly, test the seal by gently tugging on the wires and inspecting for gaps. If your connector includes a locking mechanism, engage it fully to maintain the seal under vibration or movement. Never substitute makeshift materials for the manufacturer’s recommended seals. Proper sealing ensures your connection remains waterproof, even in harsh environments.

Tip: Double-check every seal before completing the installation. A small oversight can lead to water ingress and equipment failure.

Routine Inspection and Cleaning of Waterproof Connectors

You extend the life of your connectors by performing regular inspections and cleaning. Schedule routine checks, especially in outdoor or industrial settings. Look for signs of wear, corrosion, or damage to the housing and seals. If you notice any issues, replace the connector immediately to prevent system failures.

Clean the exterior of each connector with a soft brush or cloth. Avoid harsh chemicals that could degrade the seals. For stubborn dirt, use a mild soap solution and rinse with clean water. Dry the connector thoroughly before reconnecting. During inspection, verify that all seals remain intact and that locking mechanisms function properly.

Note: Consistent maintenance helps you catch problems early and keeps your waterproof connectors performing at their best.

Troubleshooting Common Issues with Waterproof Connectors

You may encounter problems with waterproof connectors even after careful installation. Recognizing and addressing these issues quickly helps you maintain system reliability and prevent costly downtime. Here are some of the most common problems and practical steps you can take to resolve them:

1. Moisture Ingress

If you notice corrosion or intermittent signals, moisture may have entered the connector. Check the seals and gaskets for damage or improper seating. Replace any worn or cracked seals. Always ensure you tighten the connector fully to maintain the waterproof barrier.

2. Poor Electrical Contact

Loose or misaligned pins can cause signal loss or power failure. Inspect the connector for bent or damaged pins. Use a small tool to realign pins if possible. If you see significant wear, replace the connector to restore reliable performance.

3. Contamination by Dirt or Debris

Dirt, dust, or sand can compromise the waterproof seal. Clean the connector with a soft brush or compressed air. Avoid using harsh chemicals that might degrade the sealing materials. After cleaning, check that the seals remain intact.

4. Mechanical Damage

Physical impacts or repeated bending can crack housings or break locking mechanisms. Examine the connector body for visible cracks or deformation. If you find damage, replace the connector immediately to prevent further issues.

5. Overheating

Excessive current or poor connections can generate heat. If you feel warmth or see discoloration, disconnect power and inspect the connector. Verify that you use the correct current rating for your application. Replace any damaged parts before restoring power.

Tip: Schedule regular inspections for all connectors in your system. Early detection of wear or damage helps you avoid unexpected failures.

Common Troubleshooting Steps Table

| Issue | Likely Cause | Recommended Action |

|---|---|---|

| Moisture ingress | Damaged or loose seal | Replace seal, retighten connector |

| Signal loss | Bent or corroded pins | Clean or replace pins |

| Dirt/debris inside | Improper sealing, exposure | Clean and reseal |

| Physical damage | Impact, stress, vibration | Replace connector |

| Overheating | Overcurrent, poor contact | Check ratings, replace as needed |

You can prevent most issues by following manufacturer guidelines and performing routine maintenance. Always use the correct installation tools and avoid forcing connectors into place. If you encounter persistent problems, consult technical support for further guidance.

Quick-Reference Checklist for Waterproof Connector Selection

Essential Questions to Ask When Choosing Waterproof Connectors

When you select waterproof connectors, you need to ask the right questions. This approach helps you avoid costly mistakes and ensures your system works reliably. Use the following checklist to guide your decision:

-

What is the operating environment?

You must identify if the connector will face rain, dust, chemicals, or vibration. -

What IP rating does your application require?

You should check if the connector needs to withstand immersion or only splashes. -

What voltage and current ratings do you need?

You must confirm that the connector matches your system’s electrical demands. -

How many pins or circuits must you connect?

You need to count the required connections for your device. -

What material offers the best durability?

You should decide between plastic, metal, or rubber based on exposure and stress. -

Is the connector compatible with your cables and devices?

You must verify fit and alignment before installation. -

How easy is installation and maintenance?

You should consider if you need tool-free, soldered, or crimped options.

Tip: Always document your answers to these questions before you purchase any waterproof connector. This habit helps you compare products and make informed choices.

Must-Have Features for Your Waterproof Connector Application

You need to focus on essential features when you select a waterproof connector for your application. The following table summarizes the must-have attributes you should look for:

| Feature | Why It Matters |

|---|---|

| High IP Rating | Protects against water and dust ingress |

| Robust Material | Ensures long-term durability and corrosion resistance |

| Secure Sealing | Maintains waterproof integrity in harsh conditions |

| Proper Pin Count | Supports all required electrical connections |

| Easy Installation | Reduces setup time and risk of errors |

| Field Serviceability | Allows quick repairs or replacements |

| Compliance Certifications | Meets industry safety and quality standards |

You should always check for these features in the product datasheet. Reliable waterproof connectors keep your equipment safe and operational in challenging environments.

Note: Choosing connectors with these features helps you avoid downtime and protects your investment.

You now have a clear process for selecting waterproof connectors that fit your application. Review your environment, define your requirements, and match each waterproof connector to real-world conditions. Use the quick-reference checklist to guide your decision and ensure you choose the right connector every time. For complex projects, consult a supplier or expert to confirm your waterproof solution meets all technical demands.

FAQ

What does the IP rating mean on a connector?

You see the IP rating as a measure of how well a connector resists dust and water. Higher numbers mean better protection. For example, IP68 means the connector can handle dust and long-term water immersion.

Can you use waterproof connectors for underground wiring?

You can use waterproof connectors for underground wiring if they have a high IP rating and strong sealing. Always check the manufacturer’s guidelines to ensure the connector suits direct burial or underground use.

How do you know if a connector is truly waterproof?

You should look for third-party certifications and test results. Manufacturers often provide IP ratings and compliance documents. Always verify these details before installation to ensure the connector meets your needs.

Are waterproof connectors reusable after disconnection?

You can reuse many waterproof connectors, especially those with screw or bayonet locking. Inspect the seals and contacts before reuse. Replace any damaged parts to maintain a watertight connection.

What is the best way to maintain waterproof connectors?

You should inspect connectors regularly for signs of wear, corrosion, or damage. Clean them with a soft brush and mild soap. Always check seals and locking mechanisms to ensure continued protection.

Do waterproof connectors affect signal quality?

You may notice minimal impact on signal quality if you use high-quality connectors. Proper installation and correct matching to your cable type help maintain strong signal integrity.

Can you install waterproof connectors without special tools?

You can install many waterproof connectors without special tools. Tool-free designs use push-fit or screw mechanisms. Always follow the manufacturer’s instructions for best results.

Where are waterproof connectors most commonly used?

You find waterproof connectors in outdoor lighting, marine equipment, industrial machinery, and renewable energy systems. These connectors protect electrical connections in harsh or wet environments.